Manufacturing method for circuit board with embedded magnetic core

A technology of printed circuit board and manufacturing method, which is applied in the direction of printed circuit, printed circuit, assembling printed circuit with electrical components, etc., can solve the problems of magnetic core cracking, magnetic core not shaking, etc., so as to reduce the overall cost and reduce the number of solder joints. number, the effect of improving limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] This embodiment provides a method for manufacturing a printed circuit board with a buried magnetic core, which includes the following steps:

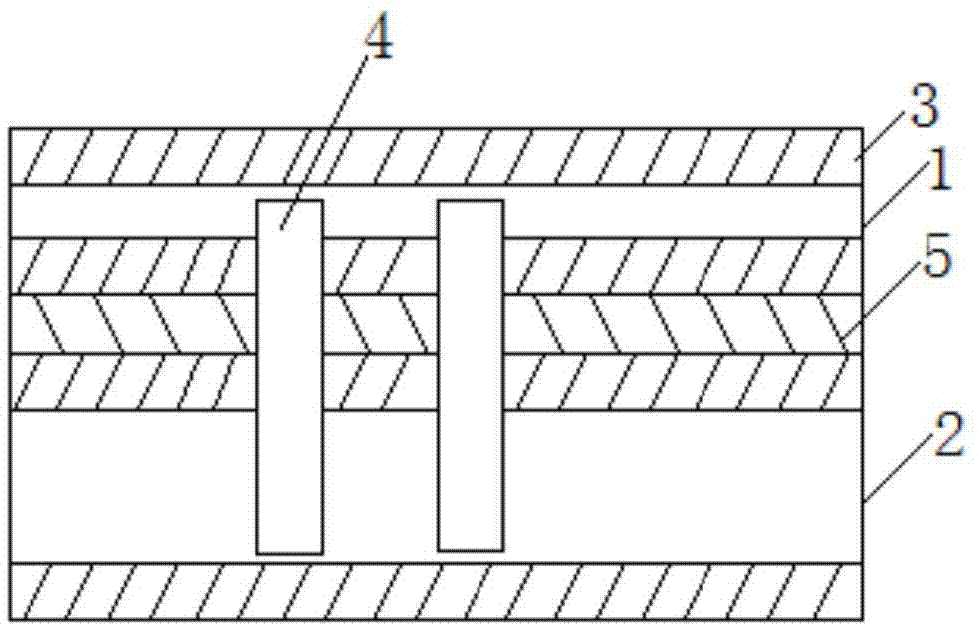

[0026] S1, the previous process, provide the magnetic core, copper-clad core board, and prepreg 3, and cut the copper-clad core board and prepreg, and cut out the required size, such as figure 1 As shown, in this embodiment, the copper-clad core board and the prepreg 5 are made of FR4 material, including two copper-clad core boards, that is, the first copper-clad core board 1 and the second copper-clad core board 2, and a prepreg 5;

[0027] S2. Etching the copper foil, etching away the copper foil on the inside of the copper clad core board layer where the magnetic core is located close to the circuit board. In this embodiment, the lower layer copper foil 3 and the second clad The upper copper foil 3 of the copper core board 2;

[0028] S3. Controlled deep milling of the copper clad core board to form the magnetic core groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com