High-performance thick-film resistor paste composition

A technology of thick-film resistors and compositions, which is applied in the field of resistor paste compositions for high-performance thick-film circuits. Resistance accuracy and reliability, and the effect of excellent withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] Preparation and evaluation method of lead borosilicate glass powder:

[0050] Weigh each raw material according to the mass ratio, fully mix the weighed raw materials, put the mixed mixture into a crucible, and then put it into an electric furnace at 1200 ° C ~ 1400 ° C for melting, keep it warm for 30 min ~ 60 min, and wait for the compound It is completely melted and no bubbles are eliminated. The molten glass is poured into cold water and quenched. The granular glass is ball-milled to the target particle size. The ball-milled glass powder is dried, crushed, sieved, tested, and packaged.

[0051] The glass powder is first die-cast into a cylinder with a film pressing machine, and pre-sintered at 600°C to 900°C, and then the softening point and expansion coefficient are tested with DTA.

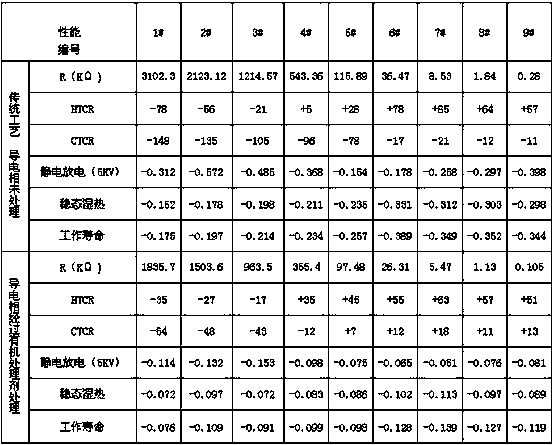

[0052] Evaluation method of resistance paste:

[0053] Conductive powder, lead-borosilicate glass powder, inorganic additives, and organic carrier are formulated according to Table 2...

Embodiment 1

[0057] A high-performance thick film resistor paste composition, comprising the following materials by mass, specifically:

[0058] Conductive powder: 2 parts of ruthenium dioxide, 10 parts of lead ruthenate;

[0059] Lead borosilicate glass powder: 60 parts;

[0060] Inorganic additives: 5 parts;

[0061] Organic vehicle: 23 parts;

[0062] Lead-borosilicate glass powder is two kinds of glass, and the ratio of glass powder A is: Pb 3 o 4 55%, CaO 18%, SiO 2 23%, B 2 o 3 4%, the component in the slurry is 39 parts, the ratio of glass powder B is: Pb 3 o 4 70%, SiO 2 19%, B 2 o 3 11%, the component in the slurry is 21 parts.

[0063] Inorganic additives consist of Ta 2 o 5 3%, Nb 2 o 5 1%, CuO 0.5%, ZrO 2 0.5%.

[0064] The organic carrier is composed of resin ethyl cellulose 15%, soybean lecithin 1%, terpineol 84%.

Embodiment 2

[0066] A high-performance thick film resistor paste composition, comprising the following materials by mass, specifically:

[0067] Conductive powder: 4 parts of ruthenium dioxide, 10 parts of lead ruthenate;

[0068] Lead borosilicate glass powder: 55 parts;

[0069] Inorganic additives: 4.5 parts;

[0070] Organic vehicle: 24.5 parts;

[0071] Lead-borosilicate glass powder is two kinds of glass, and the ratio of glass powder A is: Pb 3 o 4 55%, CaO 18%, SiO 2 23%, B 2 o 3 4%, the component in the slurry is 33 parts, the ratio of glass powder B is: Pb 3 o 4 70%, SiO 2 19%, B 2 o 3 11%, the component in the slurry is 22 parts.

[0072] Inorganic additives consist of Ta 2 o 5 2.5%, Nb 2 o 5 1%, CuO 0.5%, ZrO 2 0.5%.

[0073] The organic carrier is composed of resin ethyl cellulose 15%, soybean lecithin 5%, terpineol 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com