A kind of modified PTC conductive composite material and its preparation and application

A technology of conductive composite materials and conductive fillers, applied in circuits, resistors, electrical components, etc., can solve the problems of poor adhesion, poor resistance reproducibility, and inability to effectively reduce the overall resistance value, etc., to achieve increased surface area, low resistivity, The effect of excellent resistance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The raw material components of the modified PTC conductive composite material are:

[0043] Based on the total volume of the modified PTC conductive composite material, the volume percentage of the crystalline polyolefin polymer substrate and the conductive filler is:

[0044] Crystalline polyolefin polymer substrate 30%;

[0045] Conductive filler 70%;

[0046] In addition, the raw material component of the modified PTC conductive composite material also contains 0.5% peroxide crosslinking agent whose volume fraction is the volume fraction of the conductive filler.

[0047] The crystalline polyolefin polymer substrate is a high-density polyethylene with a melting temperature of 132° C. and a density of 0.936 g / cm 3 .

[0048] The conductive filler is acid-treated titanium carbide. The particle size of the titanium carbide is less than 5um, and the volume resistivity is 35uΩ.cm. The acid treatment process of titanium carbide is as follows: titanium carbide is added...

Embodiment 2

[0055] The concentration of acid used in this embodiment is 0.5wt%, and other steps and parameters are the same as in Example 1.

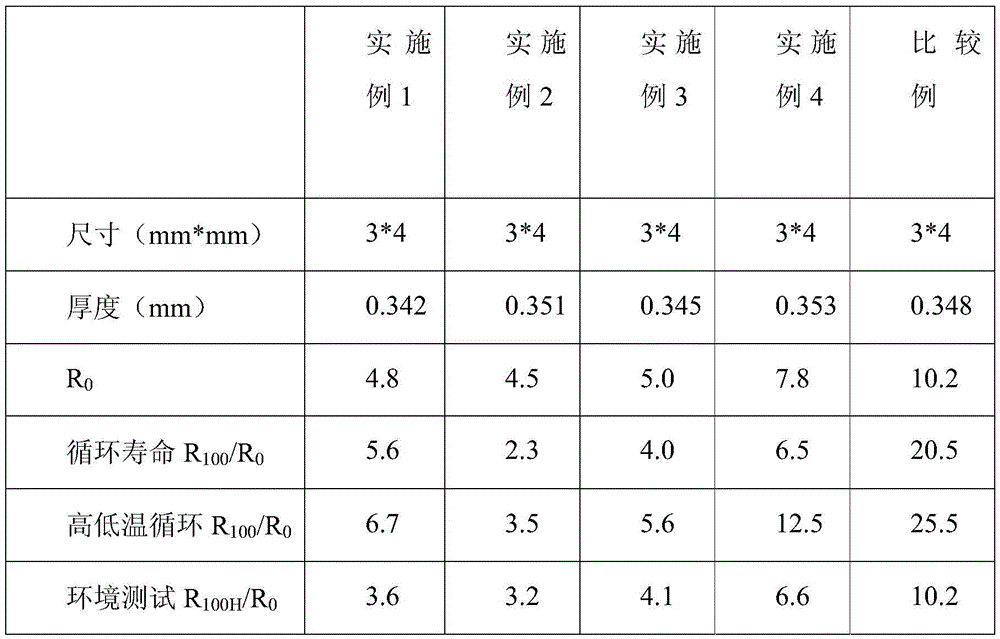

[0056] The electrical characteristics of the PTC over-current and over-temperature protection element of this embodiment are shown in Table 1.

Embodiment 3

[0058] The concentration of acid used in this embodiment is 1 wt%, and other steps and parameters are the same as in embodiment 1.

[0059] The electrical characteristics of the PTC over-current and over-temperature protection element of this embodiment are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com