Conductive composite material and preparation method thereof

A technology of conductive composite materials and conductive fillers, applied in the field of composite materials, can solve the problems of poor mechanical properties, low electrical stability and high resistance, and achieve the effects of improving mechanical properties, low cost and low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

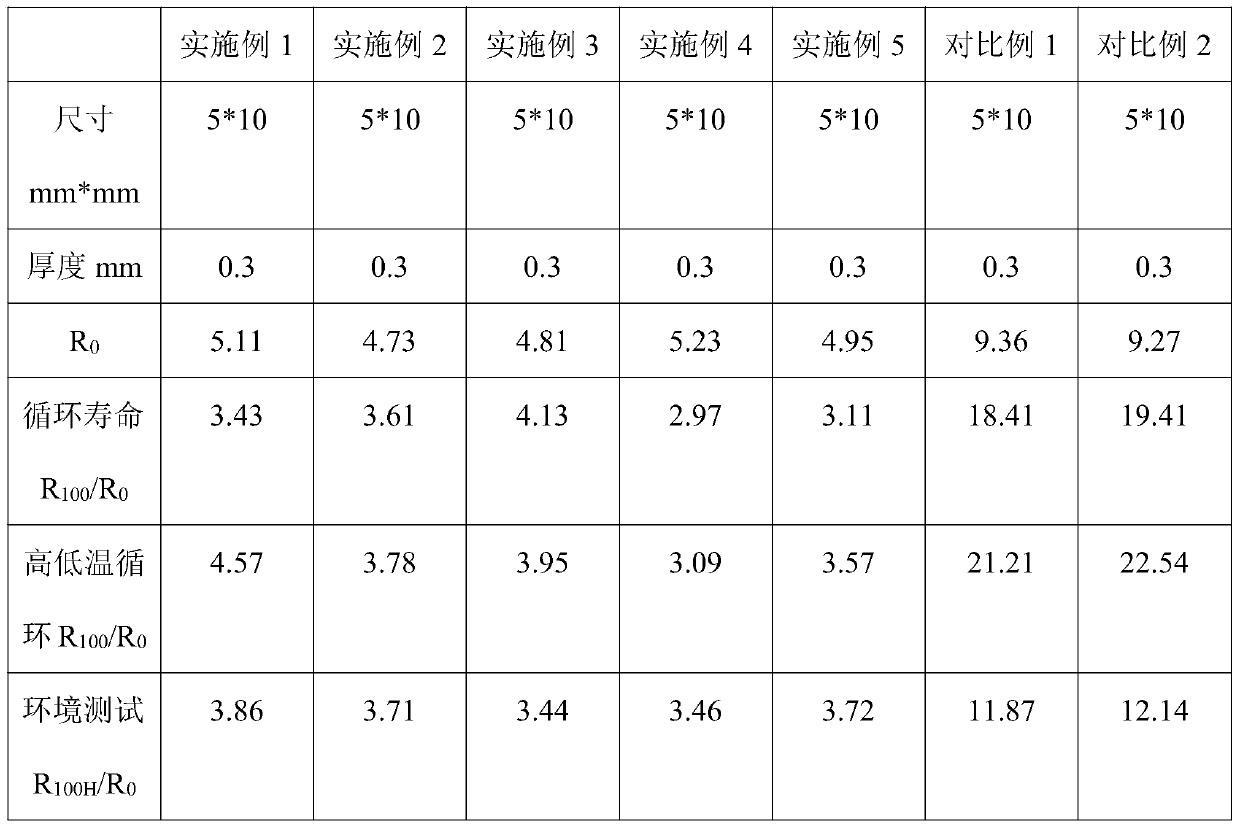

Examples

Embodiment 1

[0026] A conductive composite material, consisting of the following raw materials in parts by weight: 60 parts of crystalline polymer substrate, 15 parts of conductive filler, 0.02 part of metal passivator, 0.1 part of photoinitiator, 0.1 part of anti-dripping agent, radiation exchange 3 parts of joint agent, 4 parts of stabilizer, 10 parts of toughening agent, 4 parts of flame retardant.

[0027] The preparation method of the conductive composite material, the specific steps are as follows:

[0028] (1) take each raw material according to parts by weight;

[0029] (2) adding the conductive filler to nitric acid with a concentration of 0.5wt% for 30 minutes, and the reaction temperature is 60° C.;

[0030] (3) Set the temperature of the torque rheometer at 180°C and the rotating speed at 30r / min, first add the crystalline polymer substrate, metal passivator, photoinitiator, anti-dripping agent, radiation crosslinking agent, Stabilizer, toughener and flame retardant banburyin...

Embodiment 2

[0034] A conductive composite material, consisting of the following raw materials in parts by weight: 65 parts of crystalline polymer substrates, 18 parts of conductive fillers, 0.03 parts of metal passivators, 0.2 parts of photoinitiators, 0.2 parts of anti-dripping agents, radiation exchange 3.5 parts of joint agent, 5 parts of stabilizer, 11 parts of toughening agent, 4.5 parts of flame retardant.

[0035] The preparation method of the conductive composite material, the specific steps are as follows:

[0036] (1) take each raw material according to parts by weight;

[0037] (2) adding the conductive filler to hydrofluoric acid with a concentration of 0.75wt% for 40 minutes, and the reaction temperature is 80°C;

[0038] (3) Set the temperature of the torque rheometer at 180°C and the rotating speed at 30r / min, first add the crystalline polymer substrate, metal passivator, photoinitiator, anti-dripping agent, radiation crosslinking agent, Stabilizer, toughener and flame re...

Embodiment 3

[0042] A conductive composite material, consisting of the following raw materials in parts by weight: 70 parts of crystalline polymer substrates, 20 parts of conductive fillers, 0.04 parts of metal passivators, 0.3 parts of photoinitiators, 0.3 parts of anti-dripping agents, radiation exchange 4 parts of joint agent, 6 parts of stabilizer, 12 parts of toughening agent, 5 parts of flame retardant.

[0043] The preparation method of the conductive composite material, the specific steps are as follows:

[0044] (1) take each raw material according to parts by weight;

[0045] (2) adding the conductive filler to nitric acid with a concentration of 0.9wt% for 50 minutes, and the reaction temperature is 100°C;

[0046] (3) Set the temperature of the torque rheometer at 180°C and the rotating speed at 30r / min, first add the crystalline polymer substrate, metal passivator, photoinitiator, anti-dripping agent, radiation crosslinking agent, Stabilizer, toughener and flame retardant ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com