An environment-friendly exhaust gas purification treatment device for a spray roasting machine

A waste gas purification and treatment device technology, which is applied in the direction of drying gas arrangement, dryer, local agitation dryer, etc., can solve the problems of poor adaptability of baked goods, and achieve the effect of speeding up and speeding up baking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

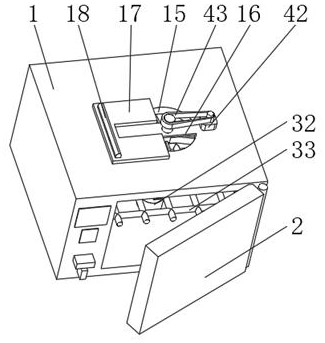

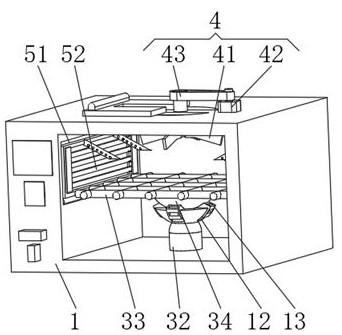

[0035] see Figure 1-4 , the present invention provides a technical solution: an environment-friendly waste gas purification treatment device for a spray roasting machine, comprising a baking box 1, one side of the baking box 1 is rotatably connected with a box door 2, and the inside of the baking box 1 is provided with:

[0036] Blowing device 4, this blowing device 4 has fan blade plate 41, and fan blade plate 41 is installed on the inside top of oven 1, and described fan blade plate 41 is to push forward air fan blade plate, and the rotation of fan blade plate 41 The shaft runs through the oven 1 and extends to the outside of the oven 1. The top of the oven 1 is fixedly connected with a blower motor 42, and the outside of the output end of the blower motor 42 is driven by a belt 43 and the rotating shaft of the blade plate 41. connect;

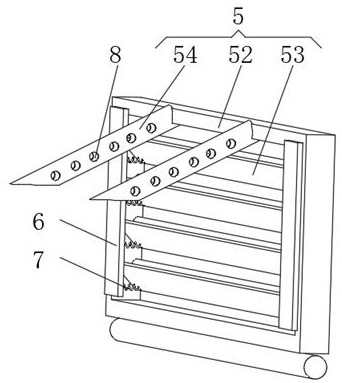

[0037] Guide device 5, the guide device 5 has a storage groove 51, the storage groove 51 is symmetrically opened on both sides of the inner...

Embodiment 2

[0048] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, a placement device 3 is provided inside the oven 1, and the placement device 3 has a fixed column 31, and the fixed column 31 is installed on the side of the oven 1. Inner bottom, the outer cover of fixed column 31 is provided with limit frame 32, and the top of limit frame 32 is equipped with put frame 33, and the bottom of put frame 33 is fixedly connected with half disc 34, and half disc 34 and limit frame 32 sliding connections.

[0049] The top of the limiting frame 32 is symmetrically provided with a limiting groove 12, and the outer side of the half disk 34 is slidably connected with the limiting block 13, and one side of the limiting block 13 is provided with an embedding groove 14, and the embedding groove 14 runs through the limiting block 13.

[0050] During use, the limit frame 32 is placed on the fixed column 31, then the half disc 34 at the bottom of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com