Patents

Literature

50results about How to "Fast baking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for forming an absorber layer of a thin film solar cell

InactiveUS20100248420A1Increase surface areaLow costFinal product manufactureSemiconductor/solid-state device manufacturingLiquid mediumControl banding

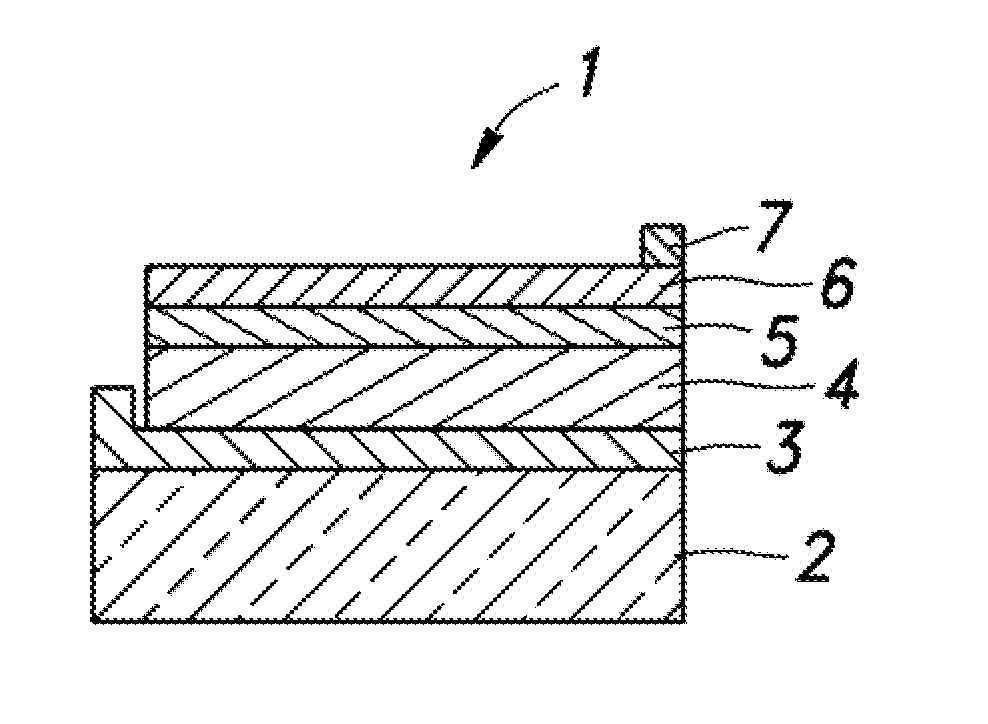

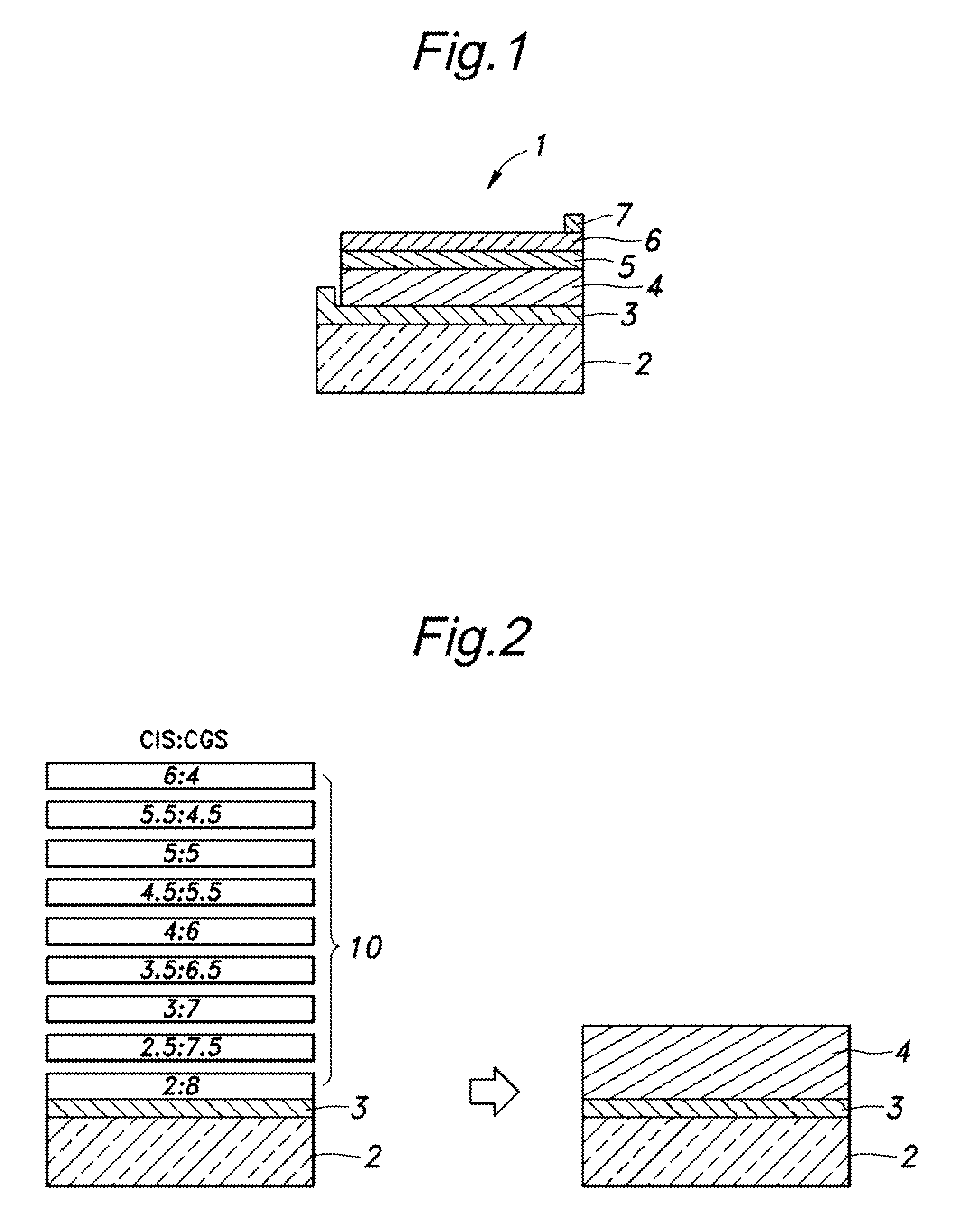

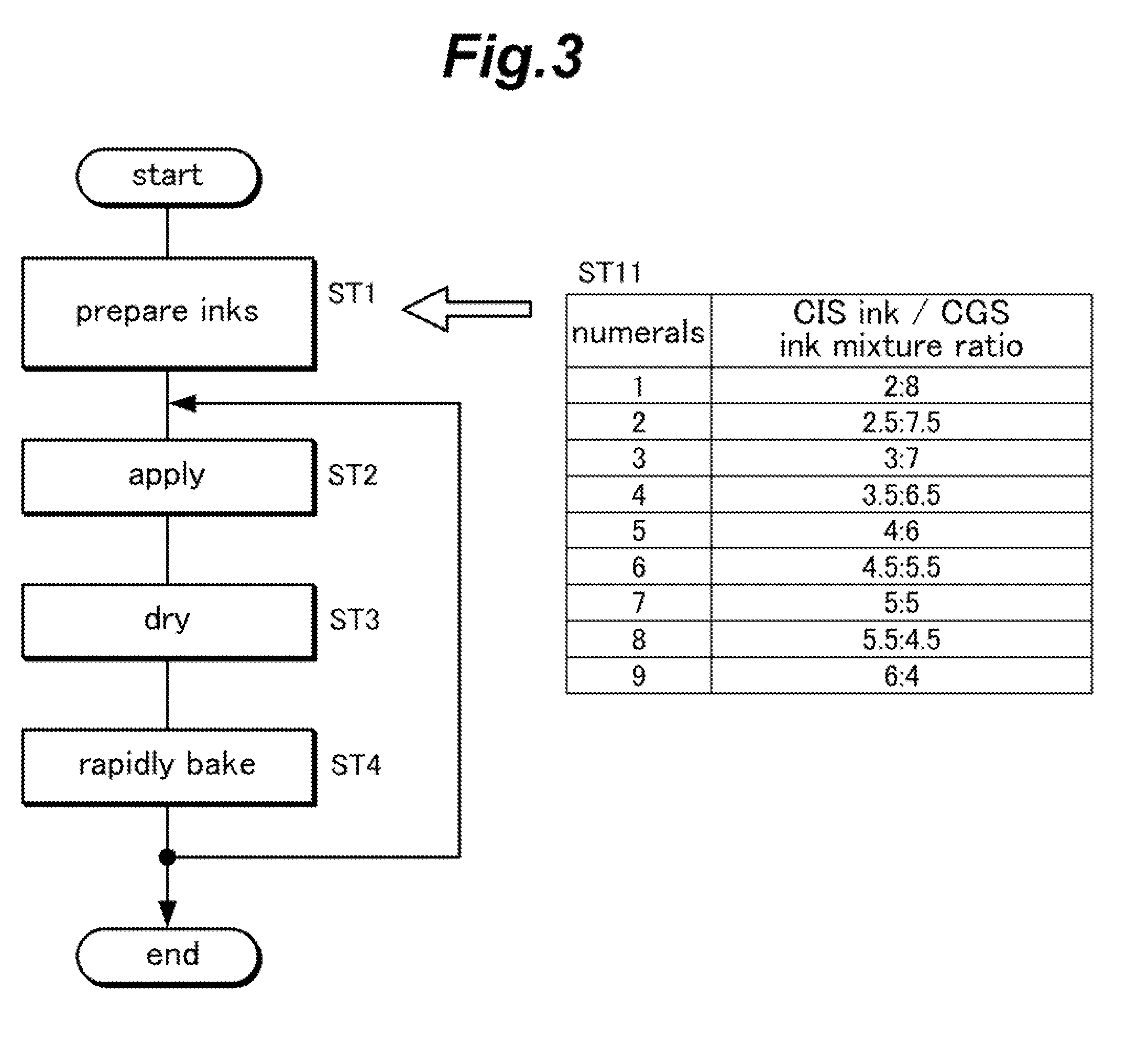

In a method for forming a light absorber layer (4) of a thin film solar cell, the absorber layer is formed from a plurality of sub-layers each of which is formed by preparing a plurality of mixtures containing Cu, Se, In and Ga in a liquid medium, a composition ratio of In to Ga being progressively increased from one mixture to another, the mixtures optionally including a mixture containing no In or Ga; applying a layer of one of the mixtures onto a back electrode layer (3) formed on a substrate (2); drying the applied layer of the mixture; and rapidly baking the dried layer of the mixture. By forming the absorber layer with a plurality of thin absorber sub-layers each having a controlled band gap, a solar cell having a large surface area can be fabricated at low cost and the efficiency of the solar cell can be improved by forming a favorable band gap gradient structure. As these sub-layers can be applied simply by any known processes, the method of the present invention is highly suited to be used for mass producing solar cells.

Owner:HONDA MOTOR CO LTD

Spicy bean curd snack food

InactiveCN104642559AGreat tasteUniform tasteCheese manufactureFood scienceNutritive valuesSnack food

The invention discloses a spicy bean curd snack food, which is prepared from the following raw materials in parts by weight: 30,000 parts of bean curd, and spicy accessories including 500-700 parts of red oil, 80-120 parts of chilli powder, 30 parts of beef essential oil, 80-120 parts of cumin powder, 100 parts of thirteen spices, 30 parts of sesame oil essence and 30,000 parts of brine. The preparation method comprises the following steps: selecting the raw materials; pulping; boiling; curdling; shaping; baking; marinating; stirring; packaging; sterilizing; cleaning; airing; and warehousing. The invention aims at providing the spicy bean curd snack food which is spicy, good in taste, high in nutritive value and long in storage time.

Owner:XINHUANG XIAOFEINIU FOOD

Novel main iron runner casting material

The invention discloses a novel main iron runner casting material which is prepared from alumina, corundum, SiC, SiO2 micropowder, alpha-Al2O3 micropowder, modified nano carbon powder, explosion-proof fiber, metallic silicon powder, calcium aluminate cement and sodium tripolyphosphate. According to the invention, since the modified nano carbon powder, of which the activity is much higher than that of asphalt carbon residues, is substituted for the asphalt, so the oxidation resistance effect is better. In addition, the modified nano carbon powder used as a substitute for asphalt can improve the bursting resistance of the product in the baking process.

Owner:长兴云峰炉料有限公司

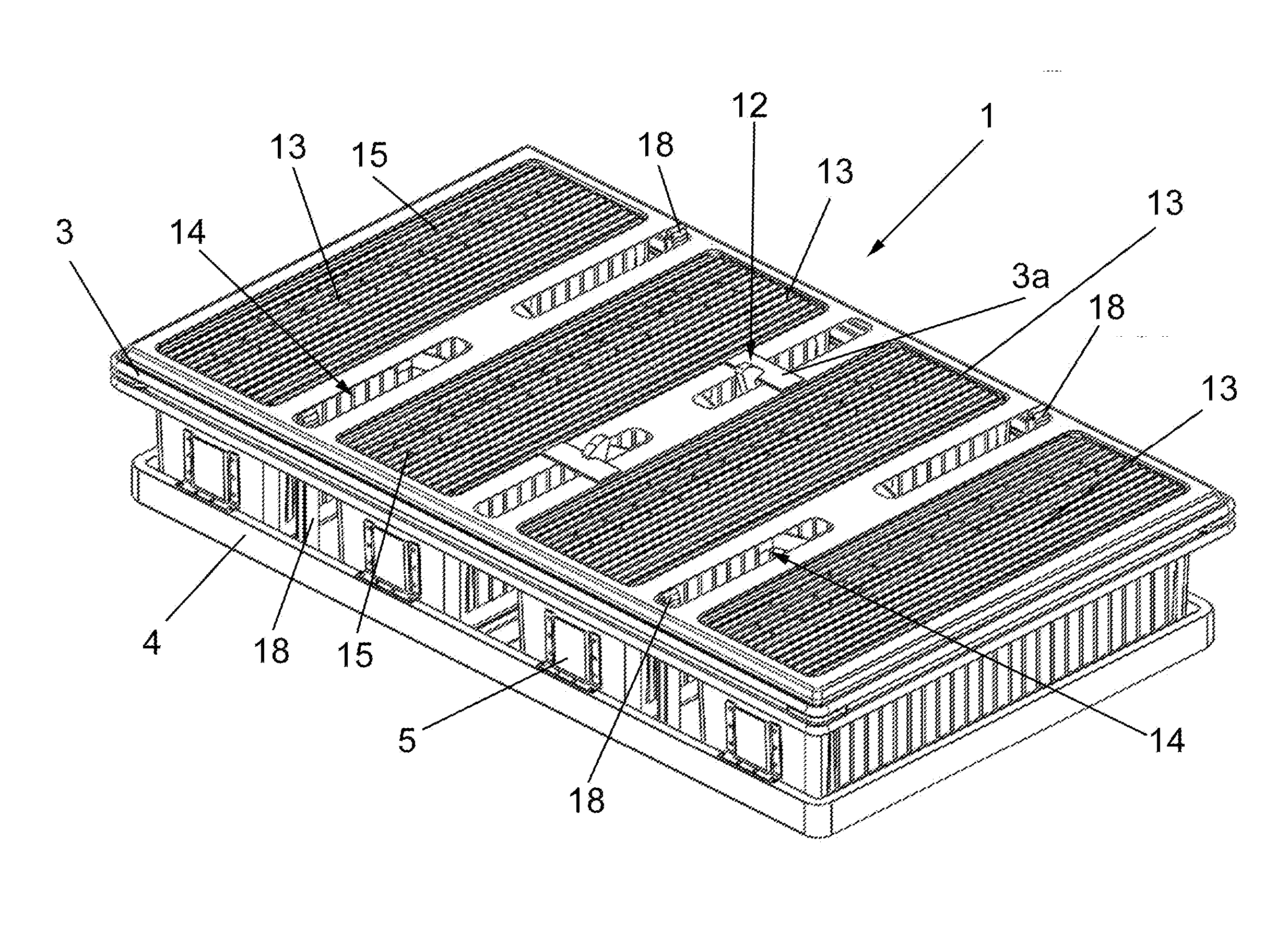

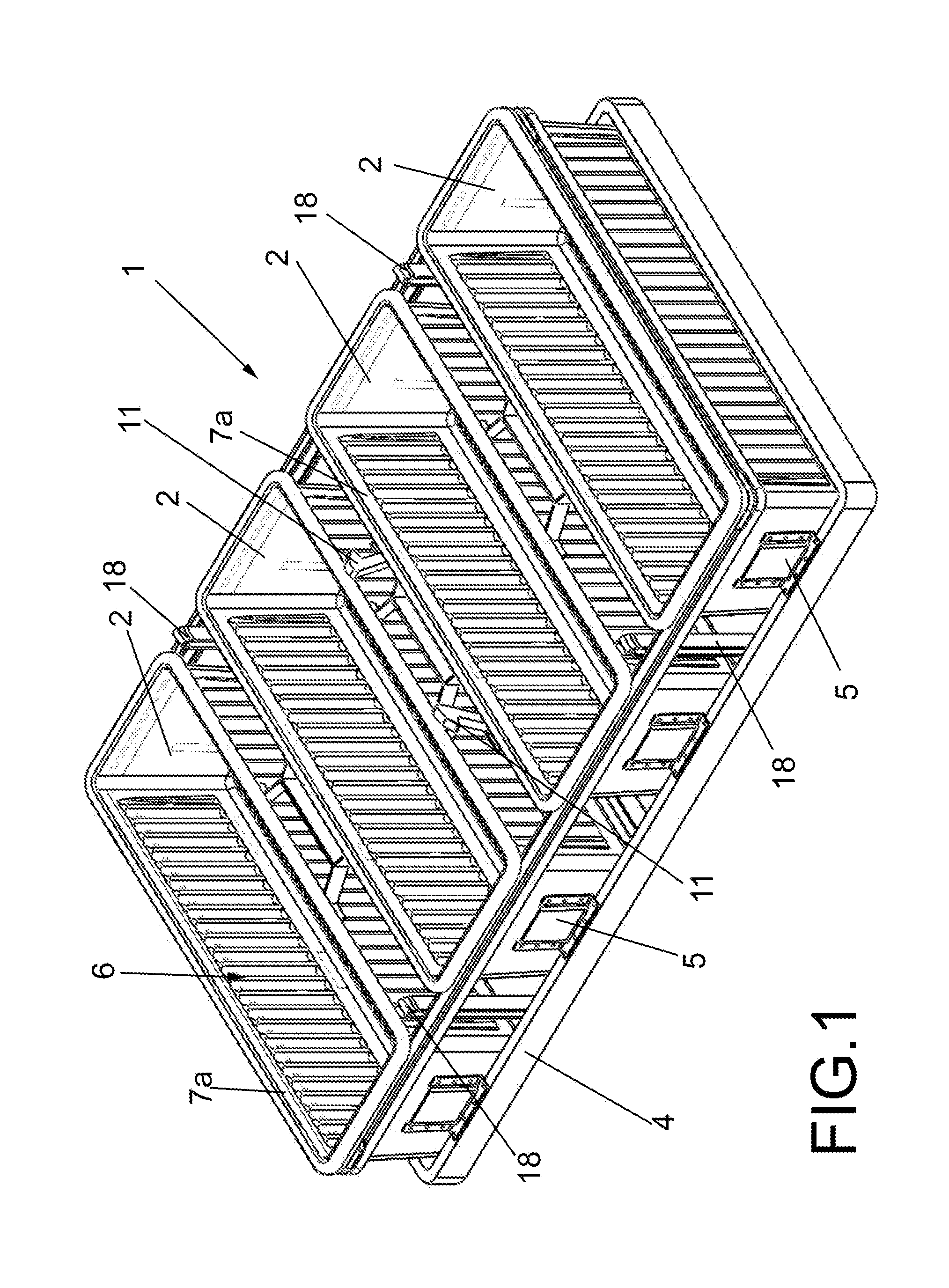

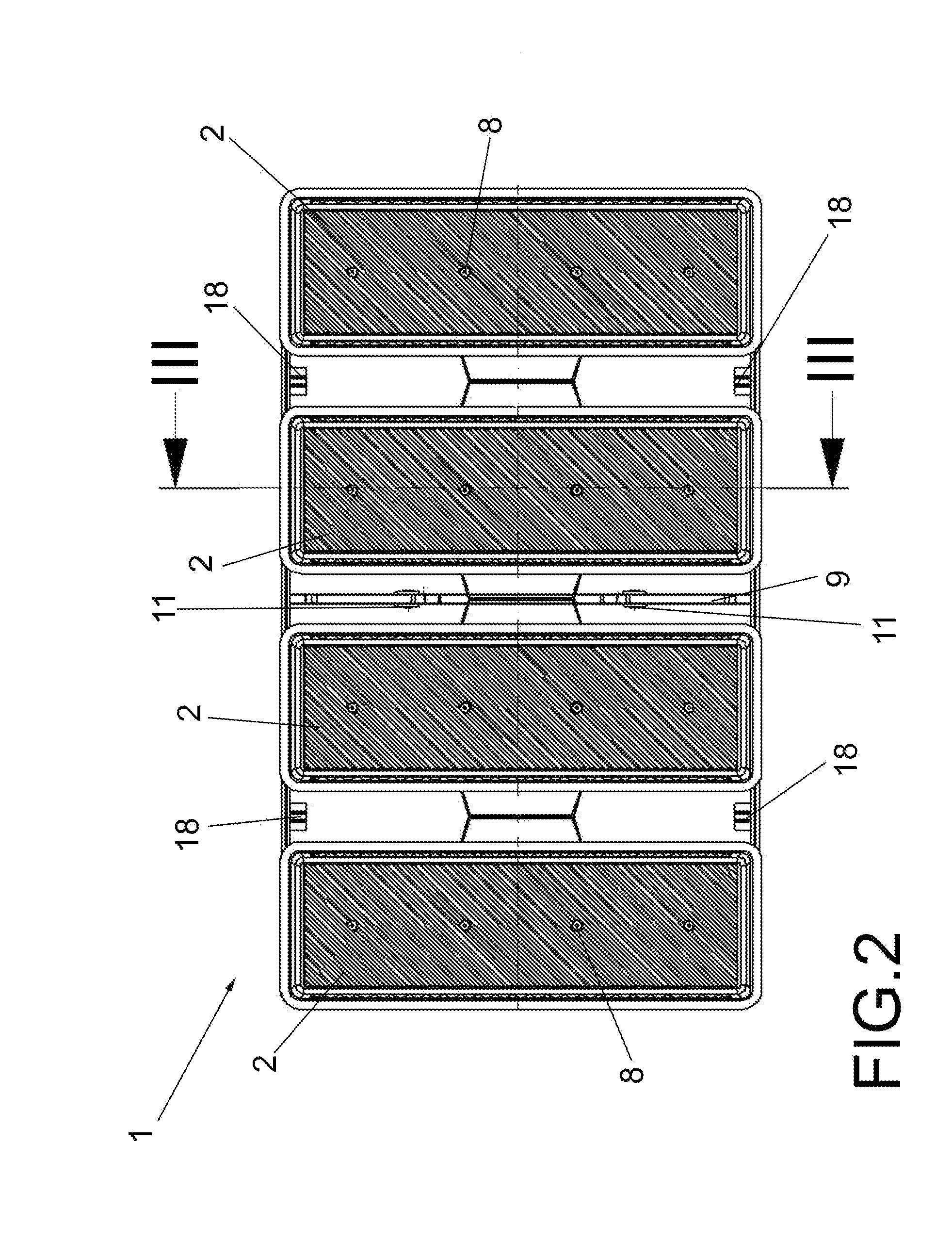

Pan for baking bread

ActiveUS20150250189A1Effectively and safely prevents raising coverReduce weightMeat processingTable equipmentsCooking & bakingEngineering

Owner:COATRESA S L U +1

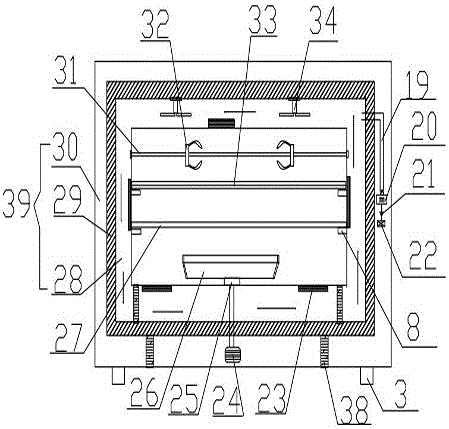

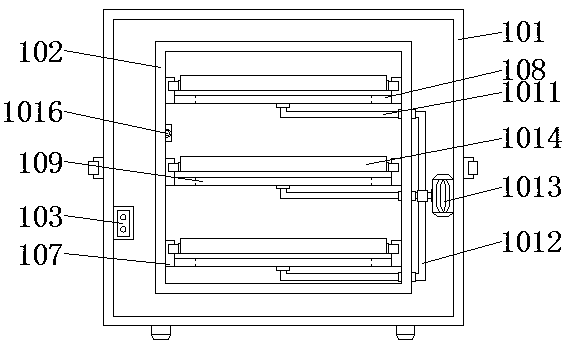

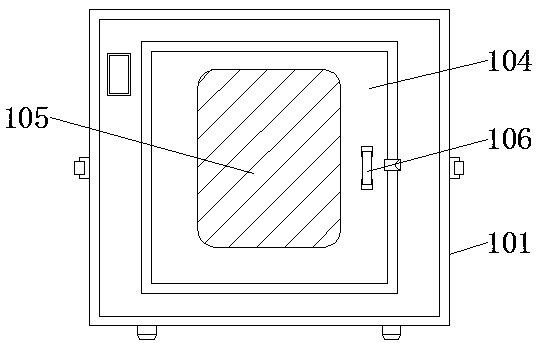

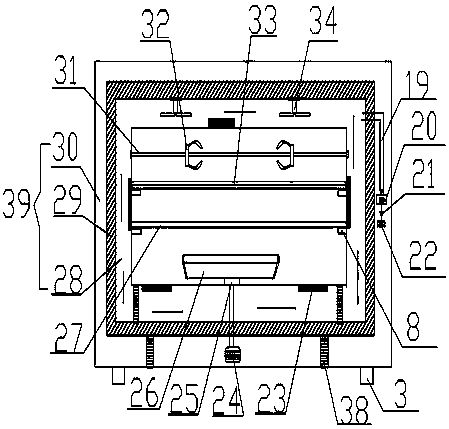

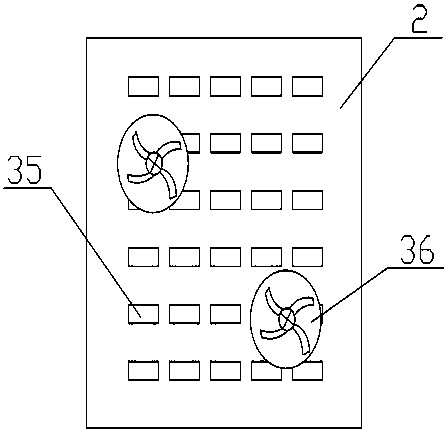

Novel oven

InactiveCN105996799AAvoid manual switchingShorten the timeRoasters/grillsThermal insulationEngineering

The invention discloses a novel oven. The novel oven comprises an oven body, a casing, an inner container, an oven door and an outer wall, wherein second ventilation holes are formed in the rear side of the casing; first ventilation holes and clamping grooves are formed in two side surfaces of the inner container, a lamp is arranged at the top of the inner container, and a rotary support is arranged at the bottom of the inner container; supporting legs are arranged at the bottom of the oven body, a plug is arranged on the rear side of the oven body, and the oven door and a control panel are arranged on the front of the oven body; a glass panel and a handle are arranged on the oven door; the outer wall comprises an air exchange layer, a thermal insulation layer and a cooling layer, heaters are arranged on the air exchange layer, and a filtering guide tube, a magnetic control tube, a high-voltage rectifier tube and a transformer are arranged on the cooling layer; supporting columns are arranged between the air exchange layer and the thermal insulation layer and between the thermal insulation layer and the cooling layer. When food is baked, instant heating is performed through microwaves firstly, so that the inside of baked food expands quickly, then far infrared heating is adopted, time is saved, uniform heating is realized, the quality is improved, and the cost is reduced.

Owner:XUCHANG UNIV

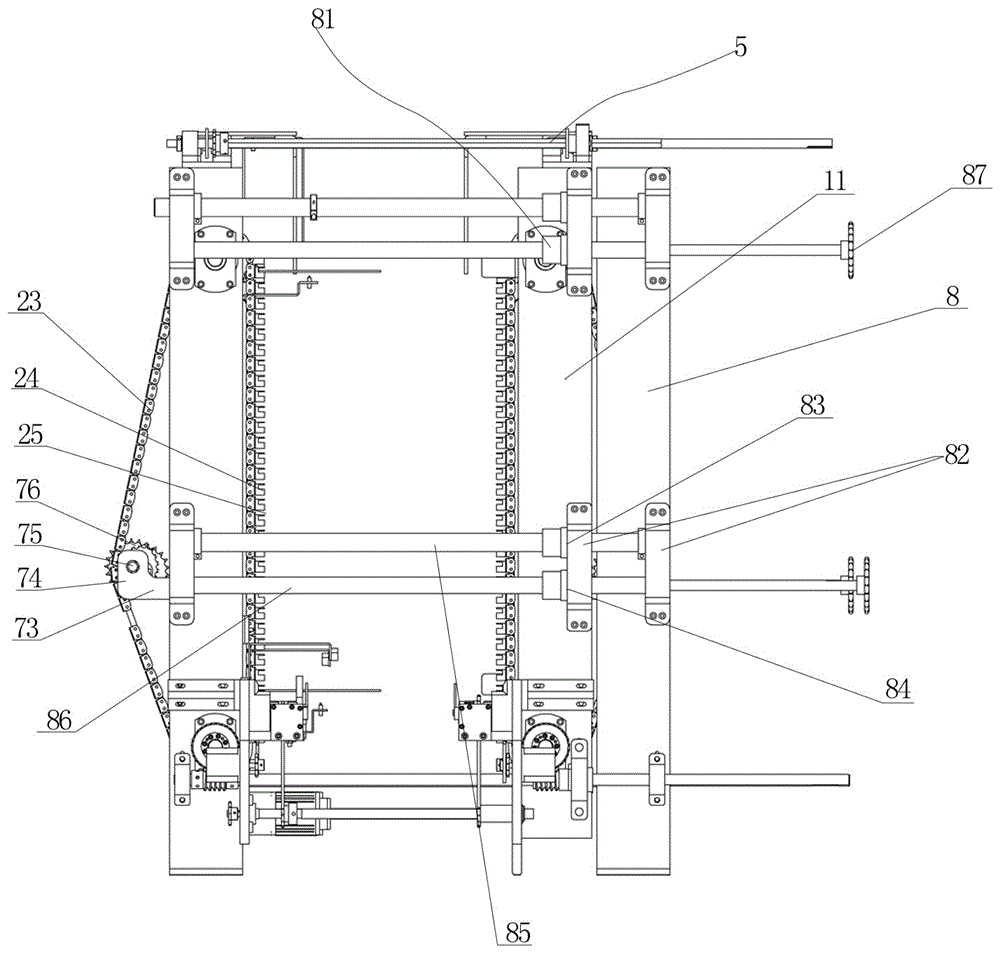

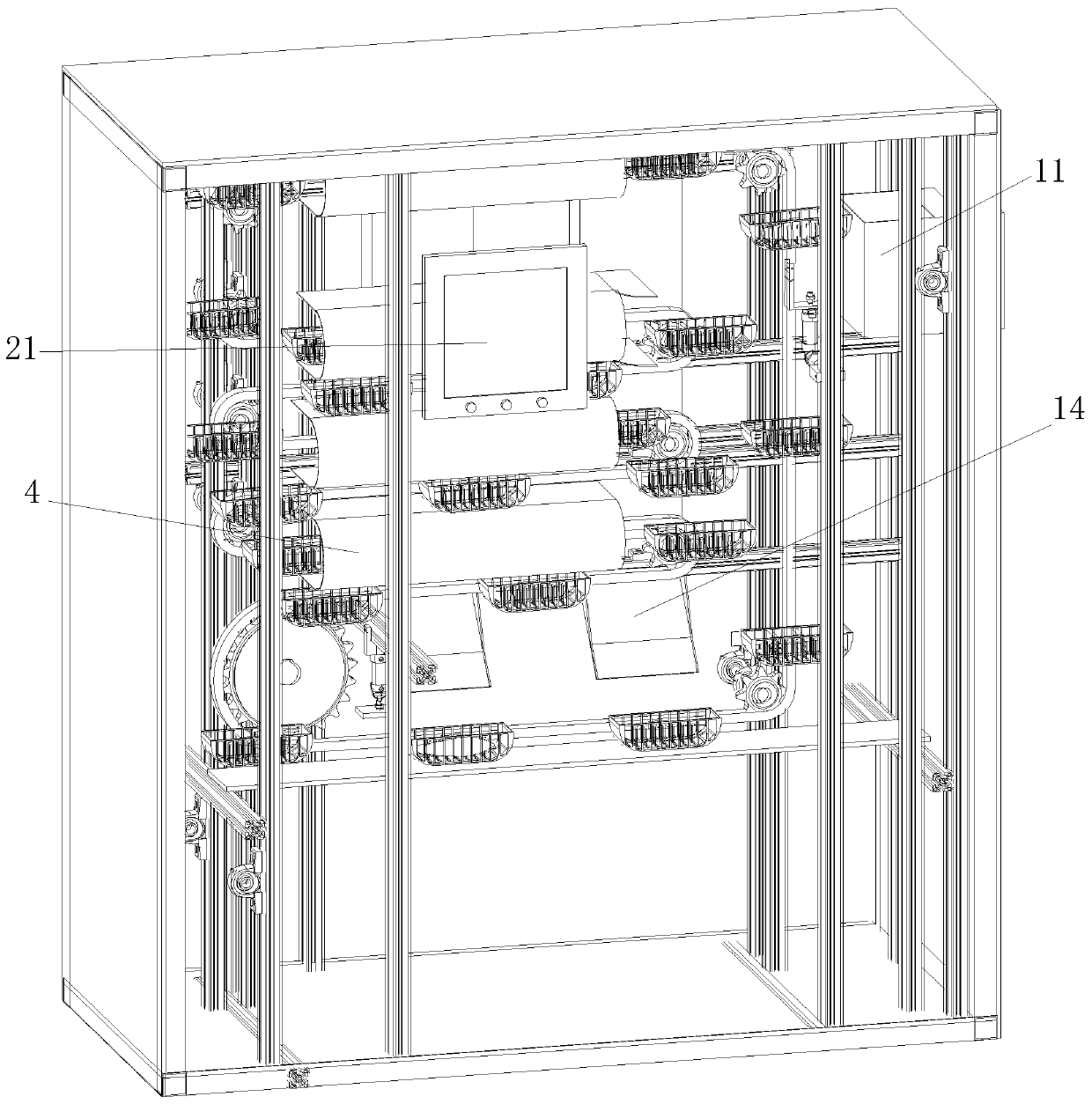

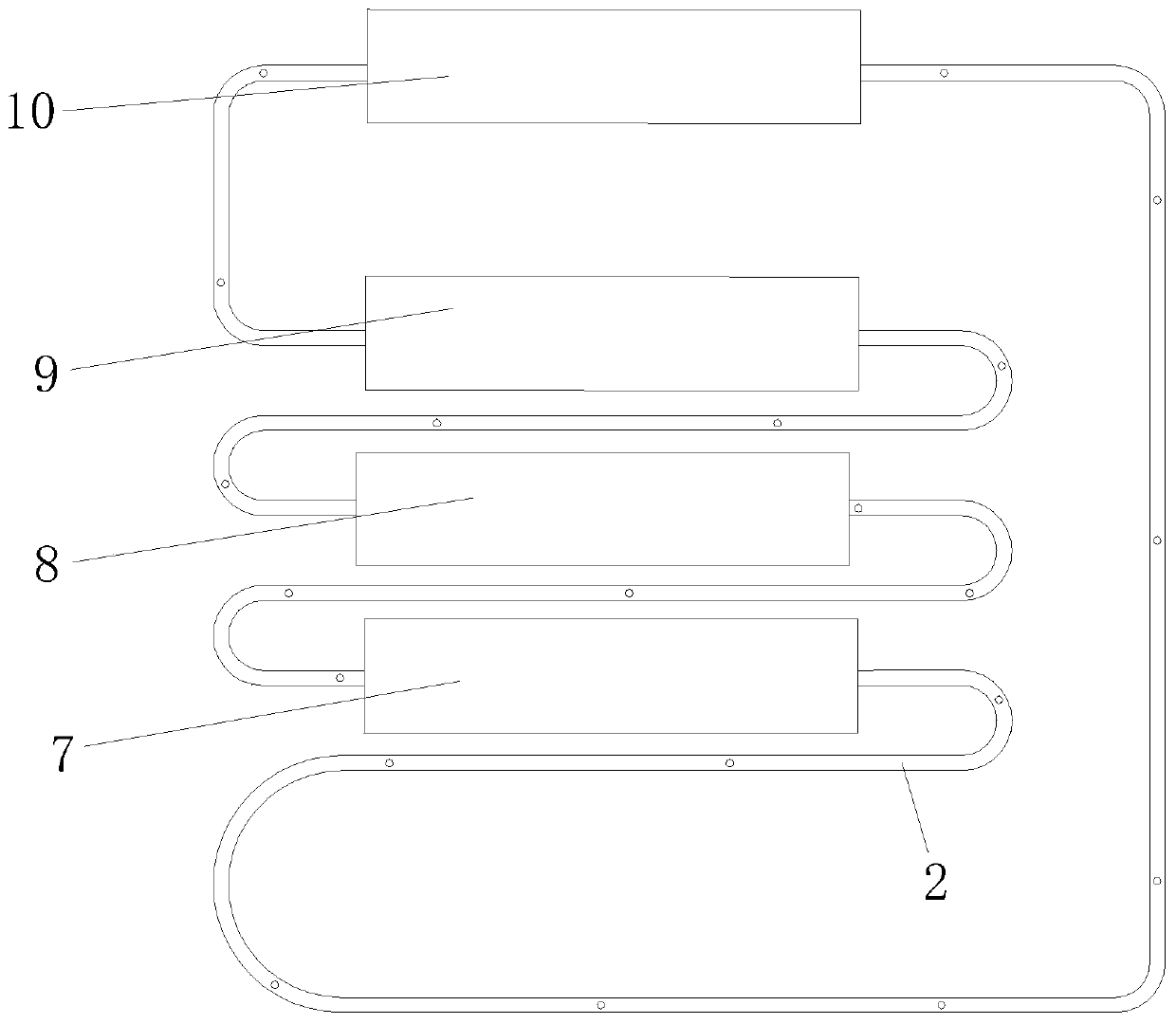

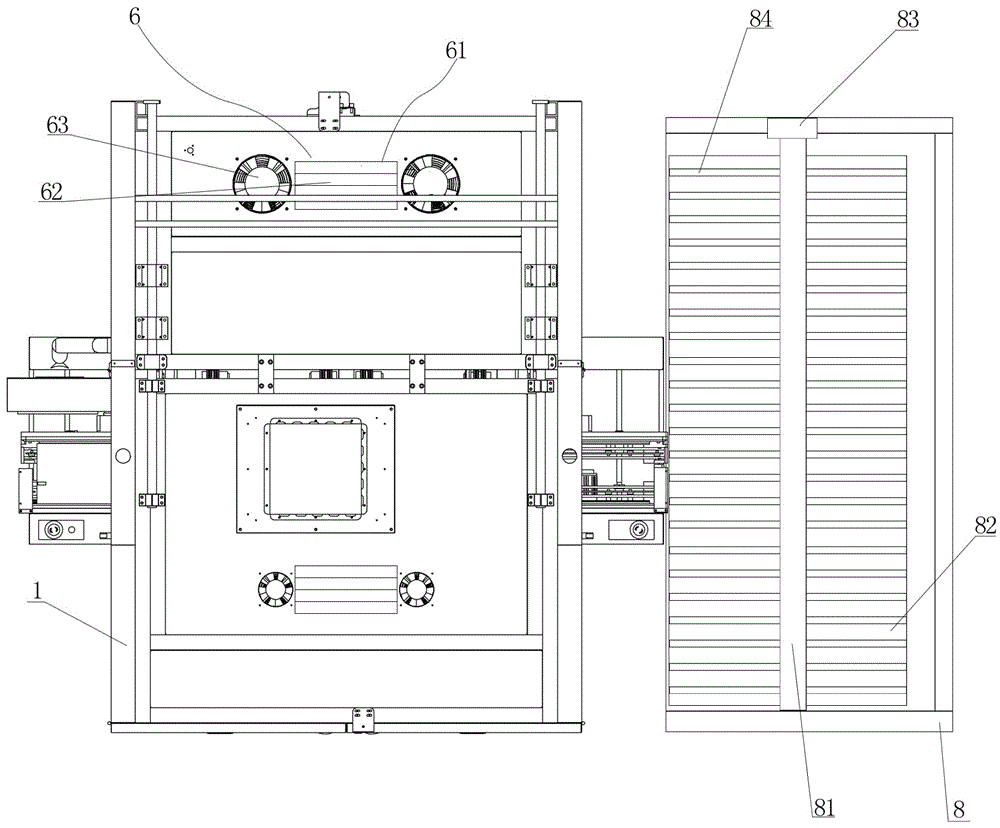

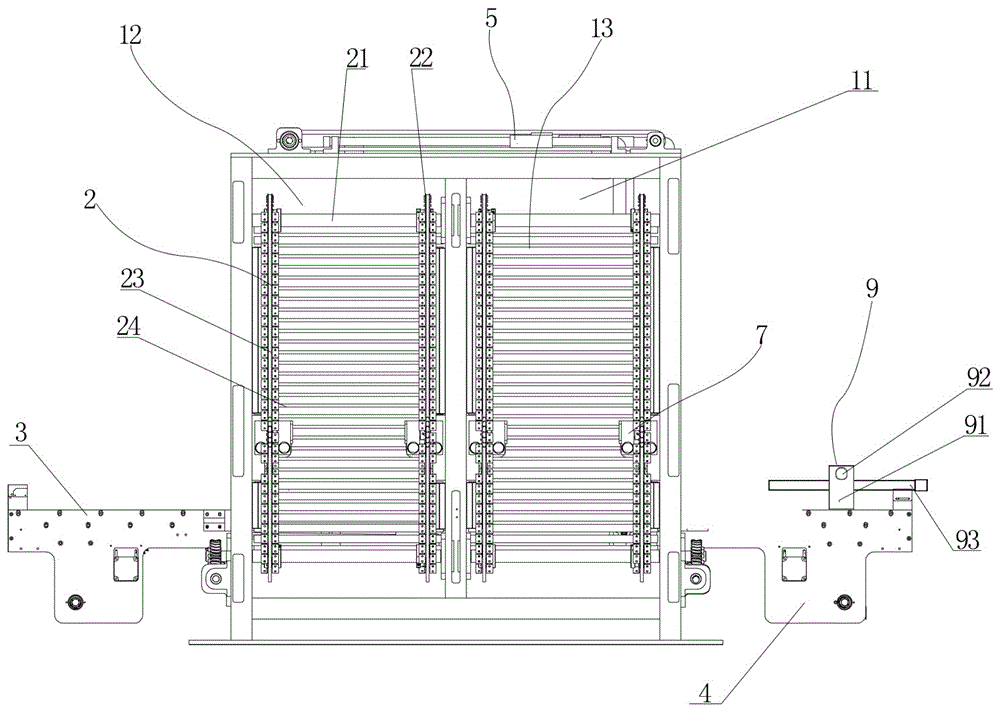

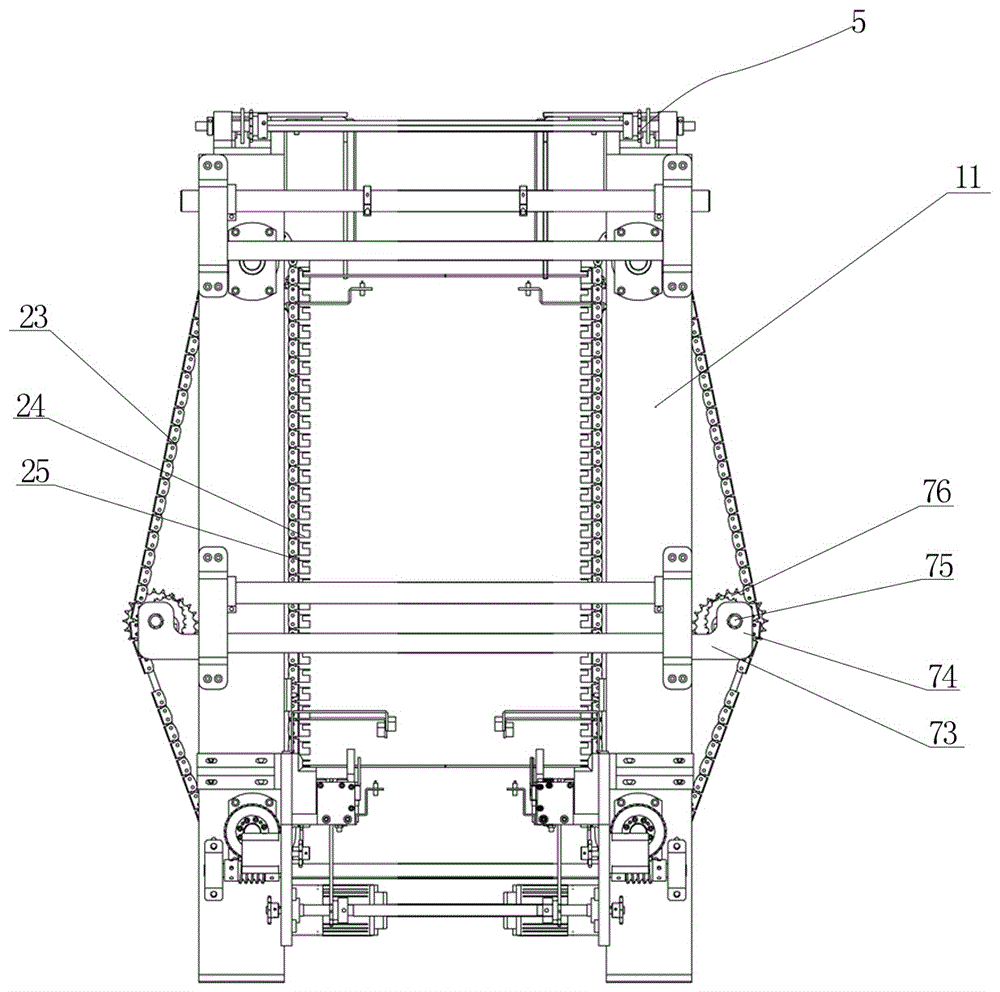

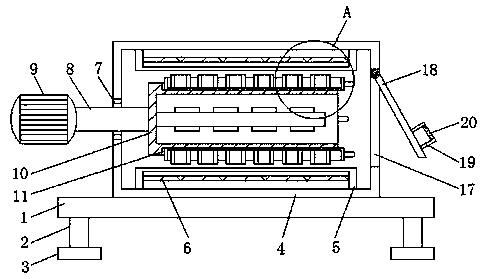

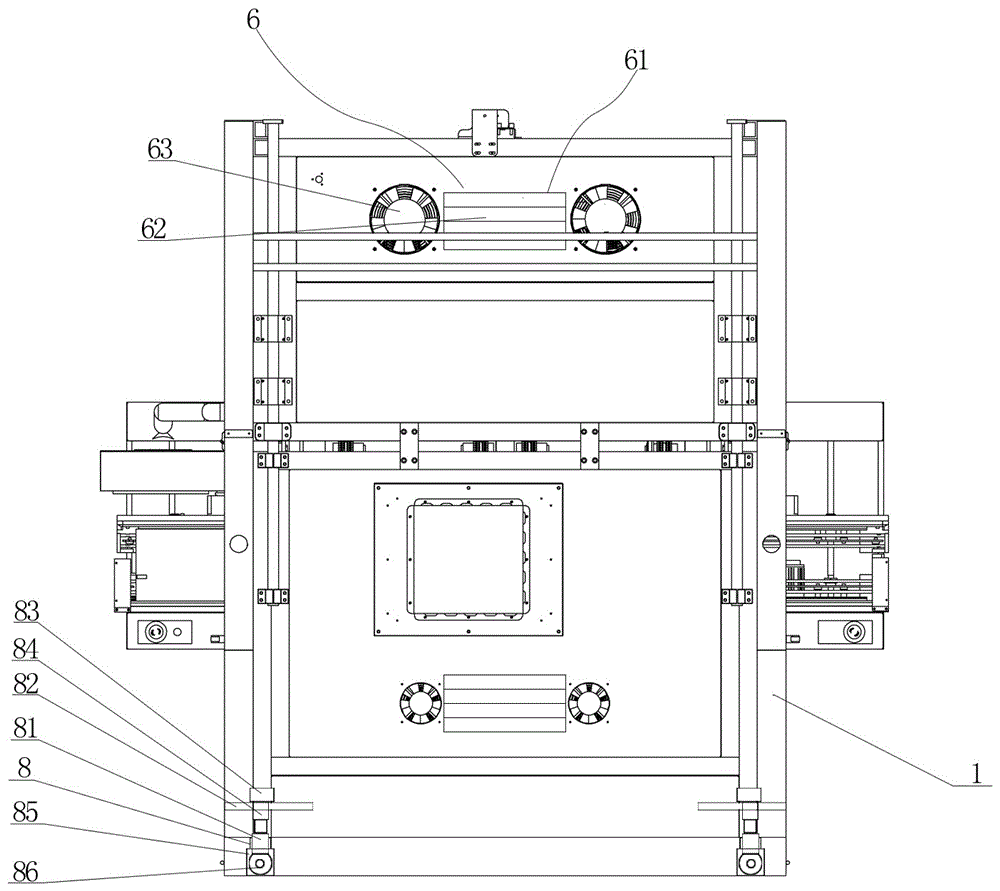

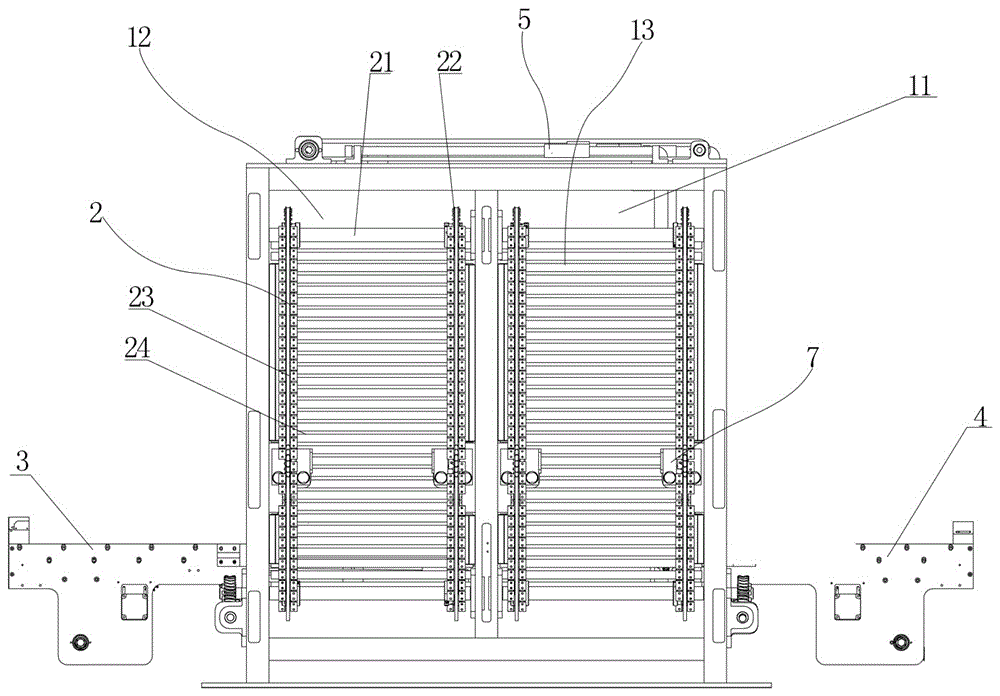

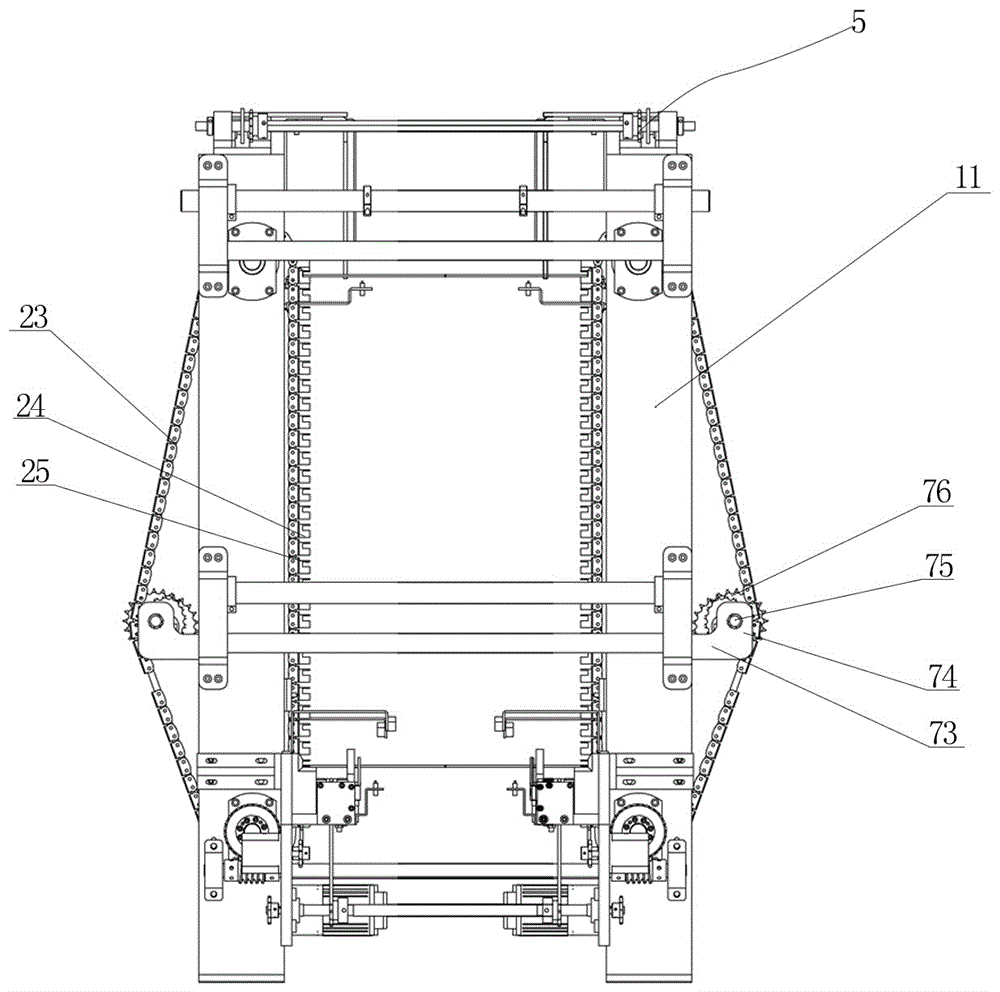

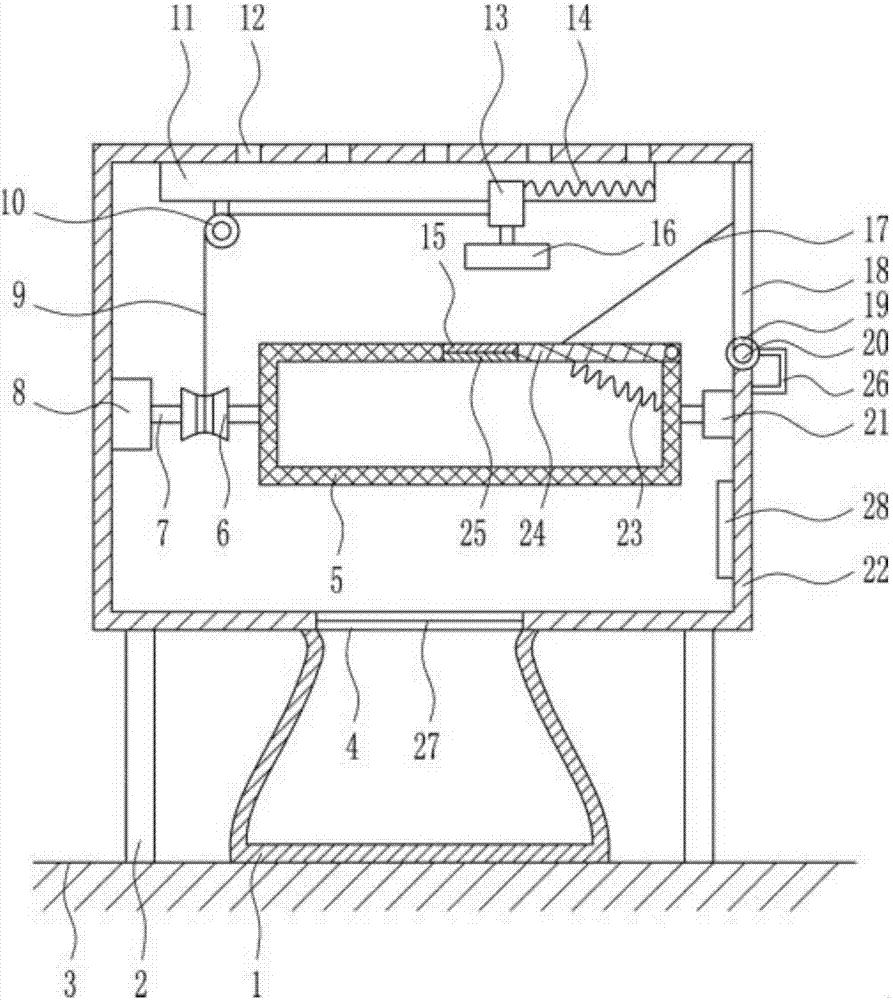

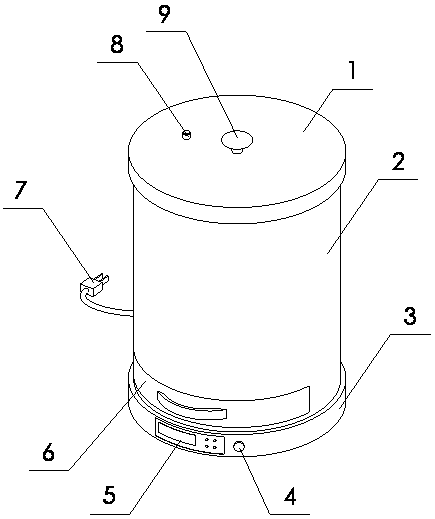

Position-adjustable automatic vertical baking furnace

InactiveCN106197003AIncrease temperatureFull and even toasting resultsPrinted circuit manufactureVertical furnacesCooking & bakingEngineering

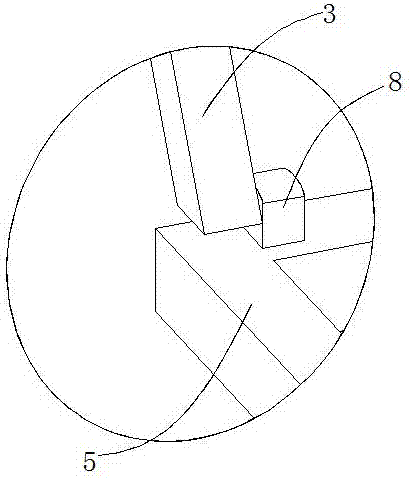

The invention discloses a position-adjustable automatic vertical baking furnace comprising a case and two racks correspondingly arranged in the case. A first baking portion and a second baking portion are arranged between the racks. The two sides of the racks are provided with a feeding module and a discharging module correspondingly. The tops of the first baking portion and the second baking portion are provided with a pushing assembly. Multiple heating modules are arranged in the case. The first baking portion and the second baking portion comprise two rotating modules which are correspondingly arranged. Each rotating module comprises a rotating roller arranged at the bottom of the corresponding rack and a rotating roller arranged on the top of the corresponding rack, wherein the two rotating rollers are correspondingly and horizontally arranged. The two ends of each rotating roller are each connected with a rotating gear in a sleeved manner. A chain ring is perpendicularly connected between each upper rotating gear and the corresponding lower rotating gear and can rotate along with the rotating gears. The two chain rings of each braking portion are parallel. A plurality of supporting strips are horizontally connected between the two chain rings of each baking portion. Lead screw modules are arranged on the two sides of supporting frames and the two sides of the two racks. The lead screw modules are used for adjusting the distance between the two racks. In this way, the position-adjustable automatic vertical baking furnace can process PCBs of different lengths.

Owner:SUZHOU CONBER ELECTRONICS EQUIP

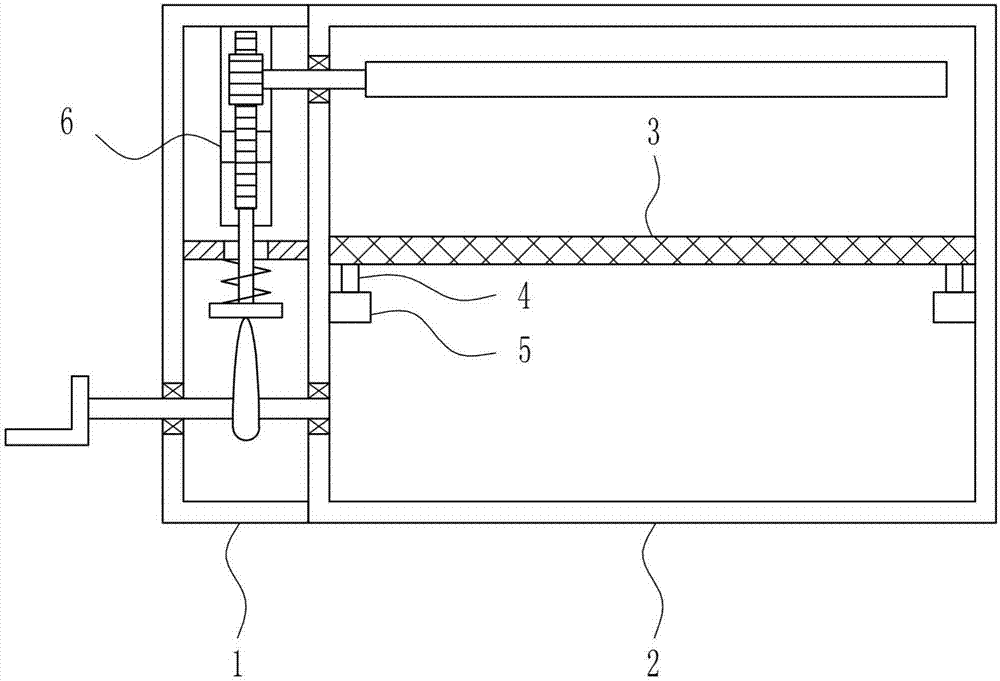

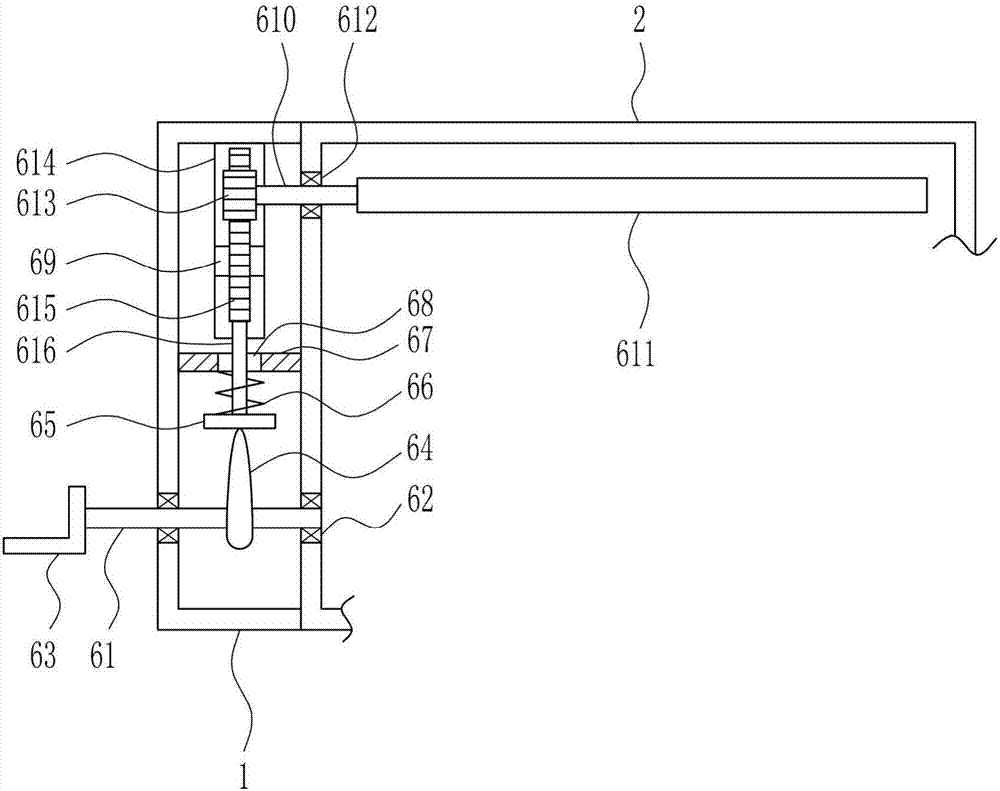

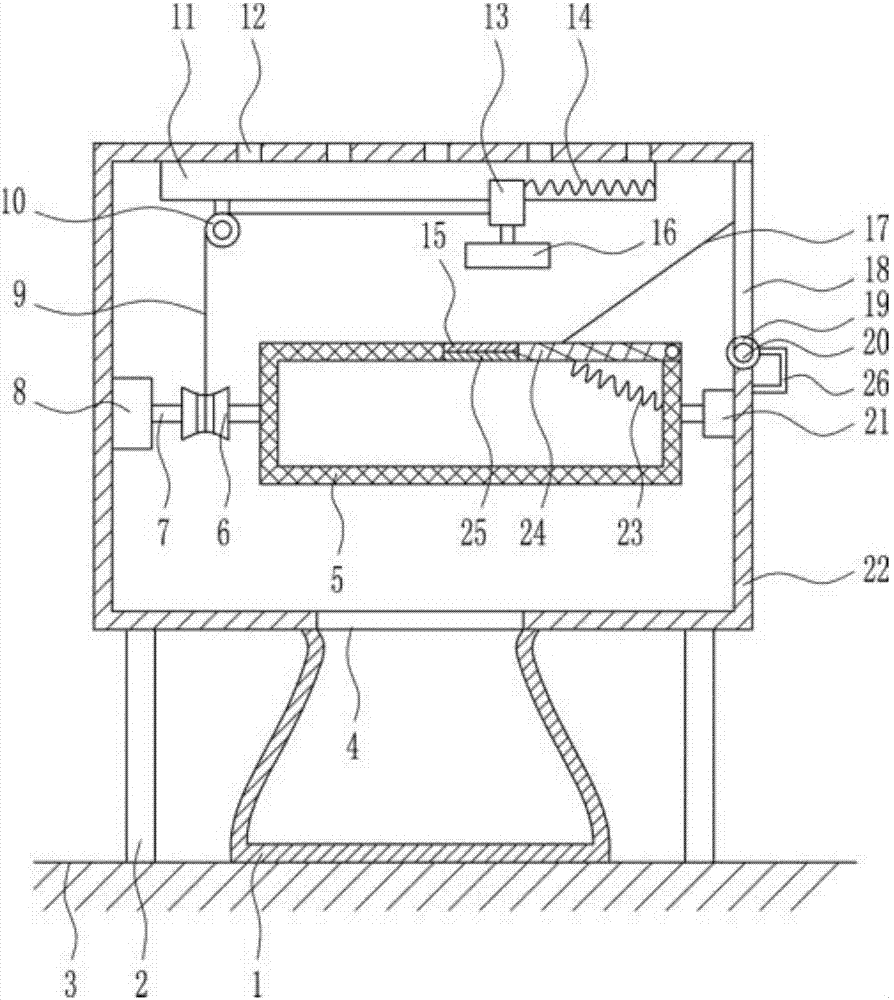

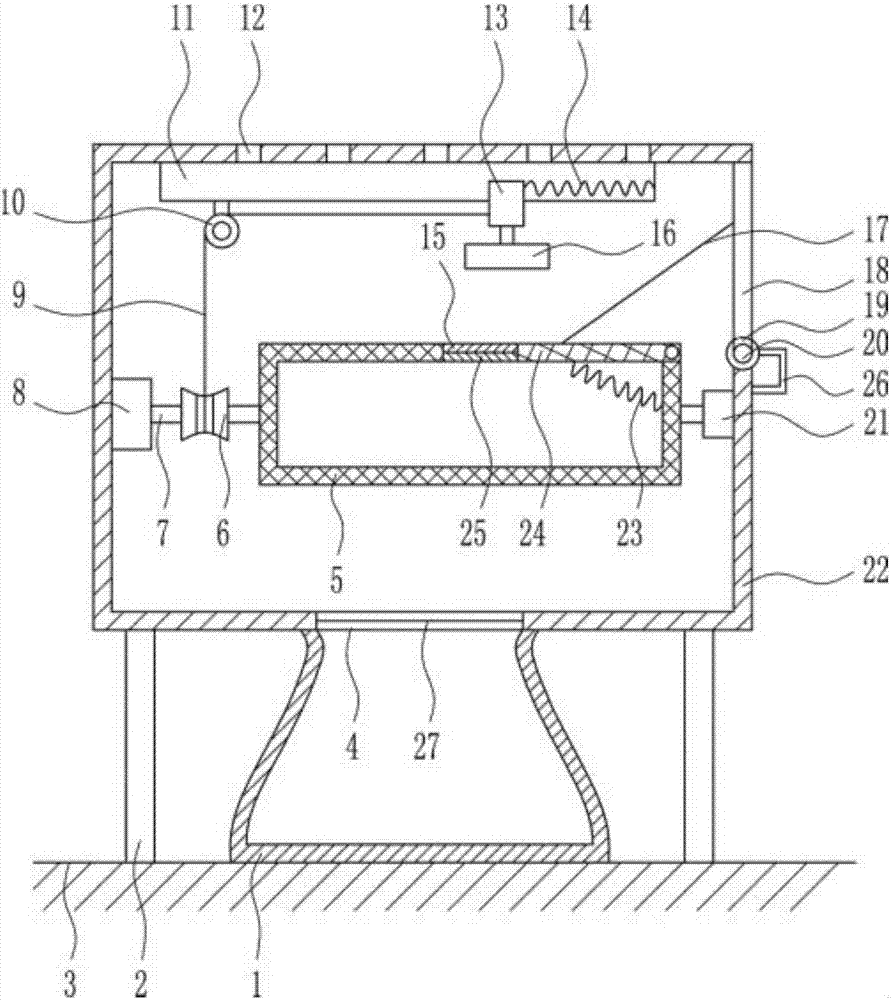

High-efficiency baking and shaping device for vamp

The invention relates to a baking and shaping device, and particularly relates to a high-efficiency baking and shaping device for a vamp. The invention aims at solving the technical problem to provide the high-efficiency baking and shaping device for the vamp; the device has the advantages of quick baking speed and uniform heating. In order to solve the technical problem, the invention provides thesuch a high-efficiency baking and shaping device for the vamp. The high-efficiency baking and shaping device comprises a fixing groove, a working box, a placing net, a first sliding block, first sliding rails, a rocking heating device, a first spring, a fixing device, a fixing rod, a baffle plate, a first pull ring and the like, wherein the left side of the working box is connected with the fixing groove; the rocking heating device is arranged in the fixing groove; the right side of the rocking heating device is connected with the working box; a left wall and a right wall in the working box are symmetrically connected with the first sliding rails. By using the high-efficiency baking and shaping device, the effects that the baking speed is quick and the heating is uniform are achieved; a rotating rod is artificially rocked with a hand to make a heating plate radiate heat to bake and shape the vamp; the fixing device is used for making the baffle plate more stable; meanwhile, an air heater swings upwards, downwards, leftwards and rightwards.

Owner:浙江天宏鞋业有限公司

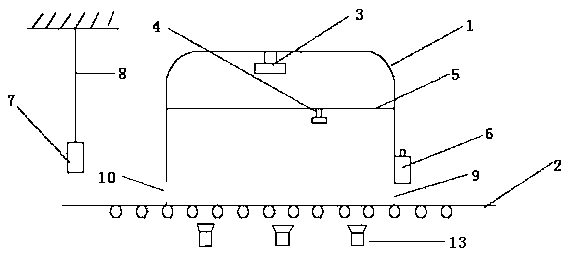

Automobile spare and accessory part baking assembly line

InactiveCN105371627ABake thoroughlyEvenly bakedDrying gas arrangementsDrying machines with progressive movementsAssembly lineEngineering

The invention relates to the field of automobile spare and accessory part casting, in particular to an operation assembly line used for baking automobile spare and accessory parts. The assembly line is composed of a baking chamber and a conveying device. The conveying device comprises a conveying belt and conveying wheels. The baking chamber is arranged above the conveying belt and provided with an inlet and an outlet. A heater is arranged at the top end of the baking chamber. A guide rail transversely penetrating through the baking chamber is arranged in the middle of the baking chamber. The guide rail is provided with a track. A sliding block is installed on the track and can freely slide front and back in the track. The sliding block is fixedly provided with a first fan. A power switch is arranged on the outer side of the baking chamber and is used for controlling the sliding block on the track of the guide rail to move forwards or backwards. The baking speed is increased, baking is more uniform, and the situation that due to the insufficient local braking degree, the product quality is affected, then products are reworked or scrapped, the production cost is increased, and the production efficiency is reduced is avoided.

Owner:安徽永茂泰汽车零部件有限公司

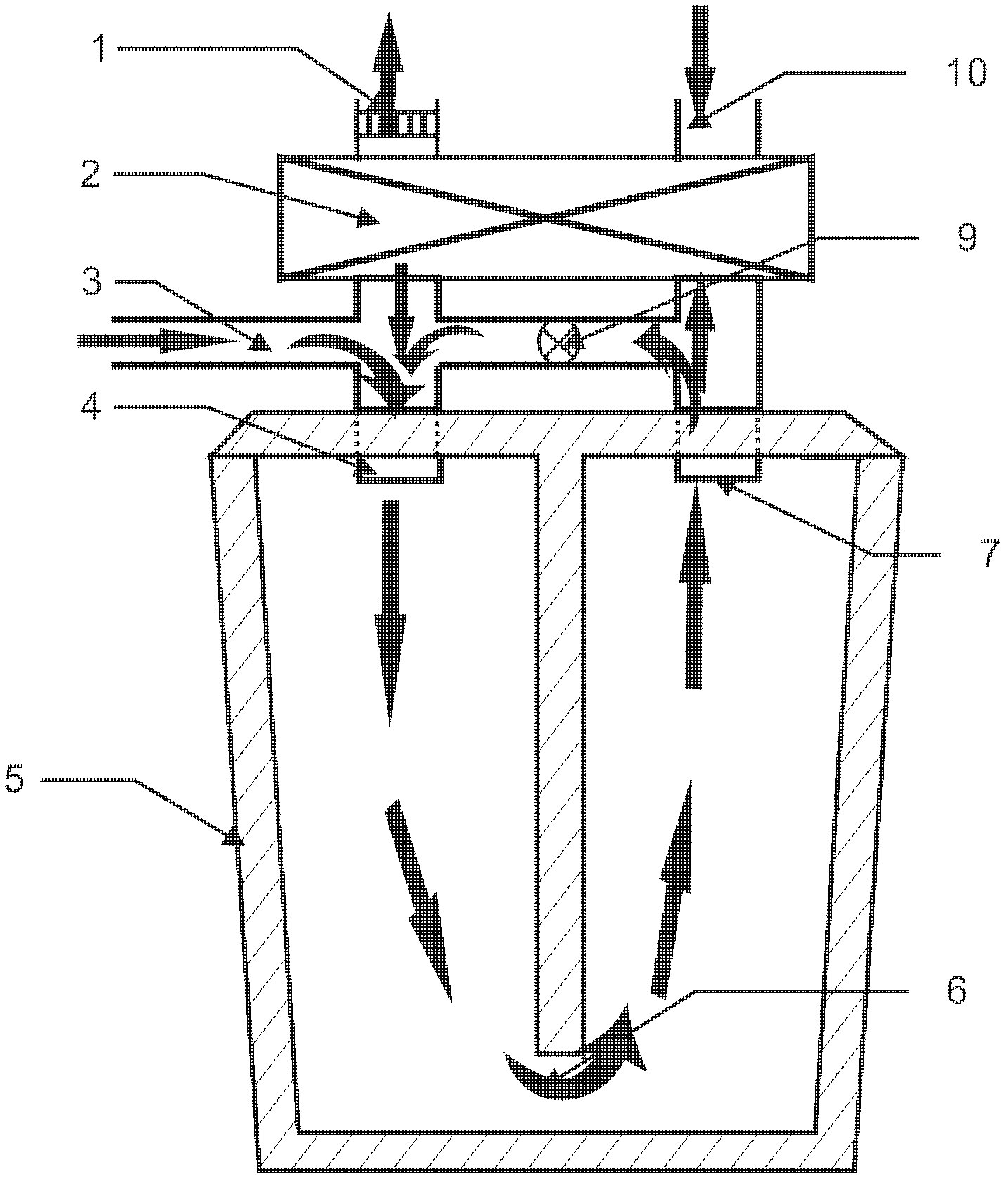

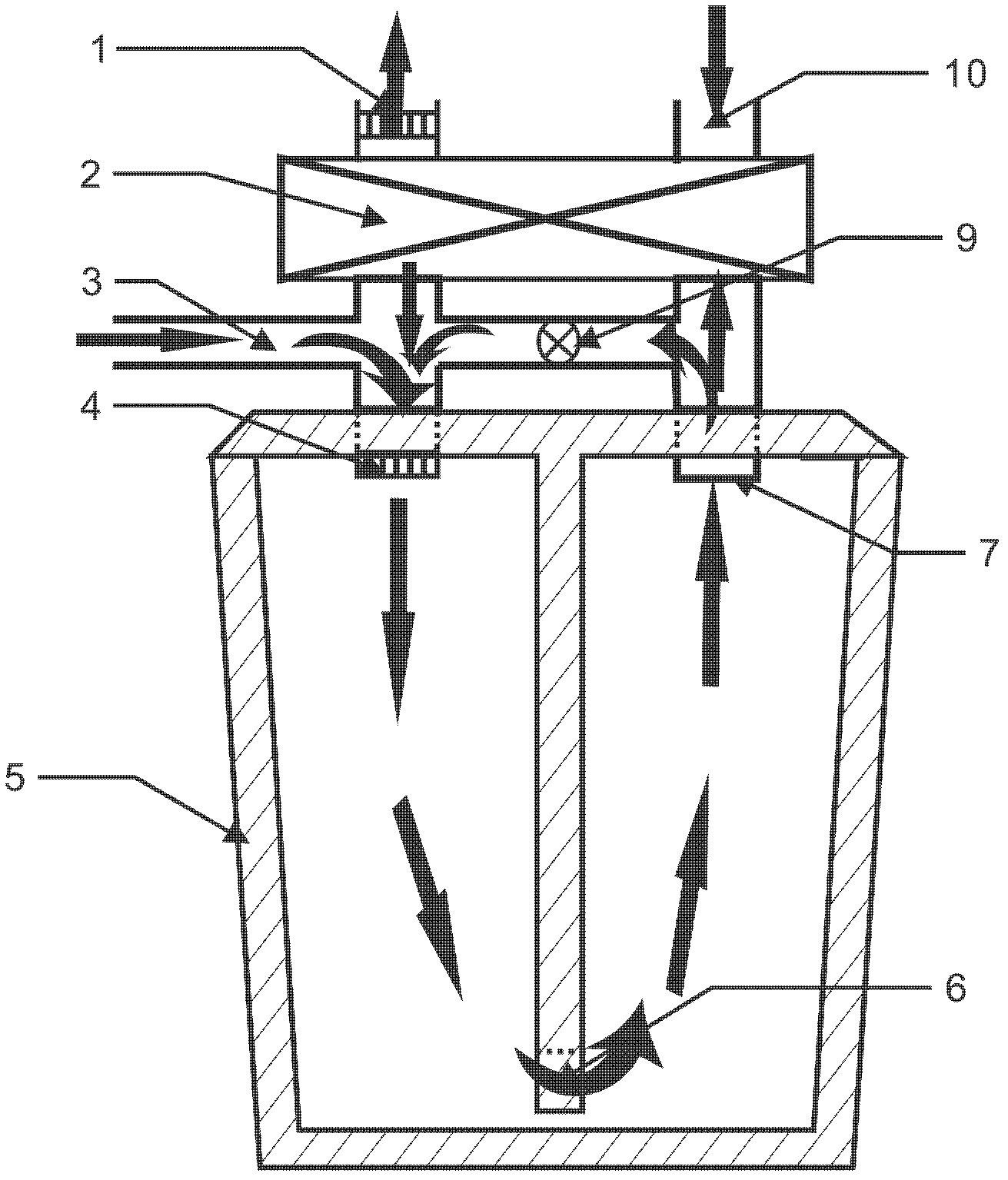

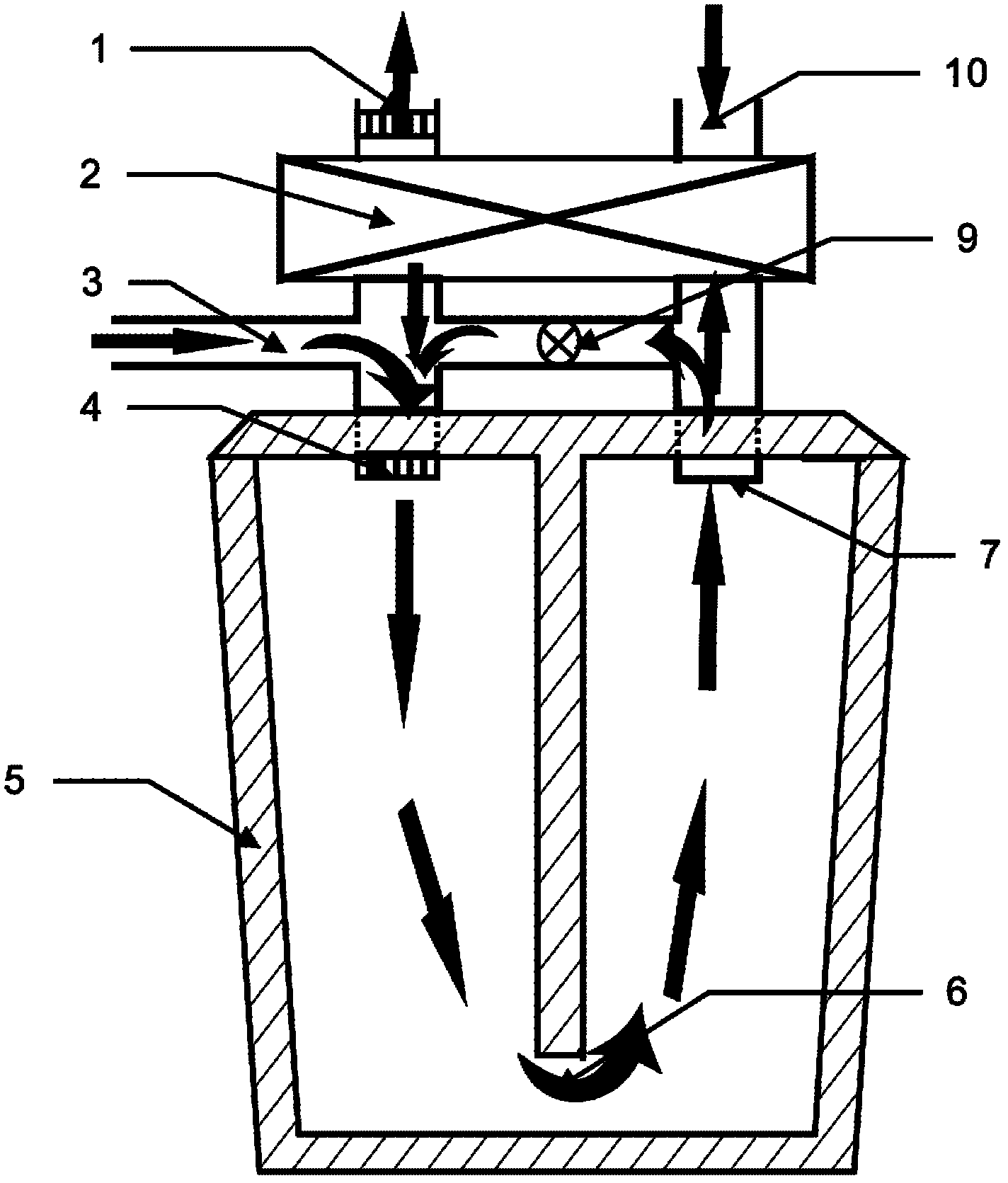

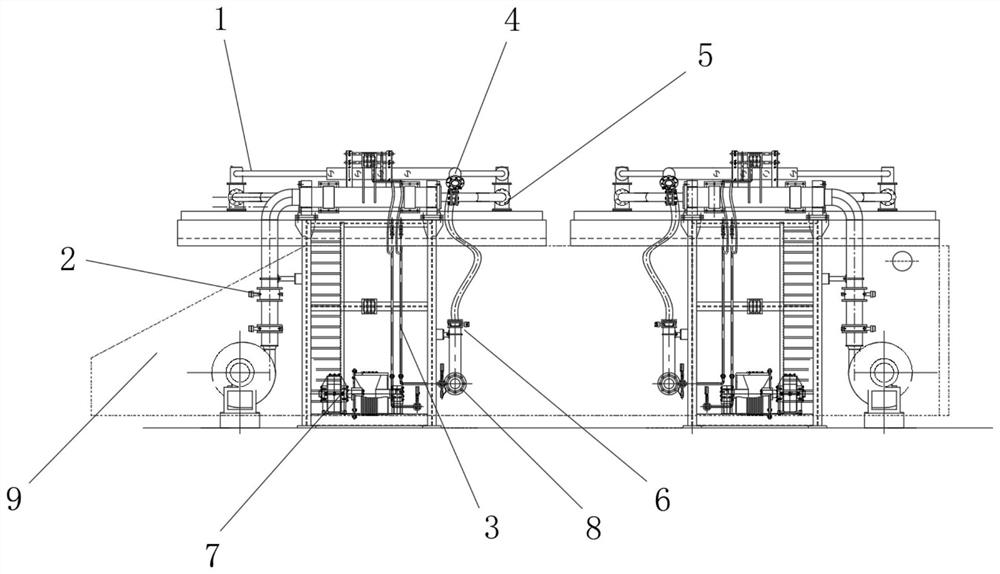

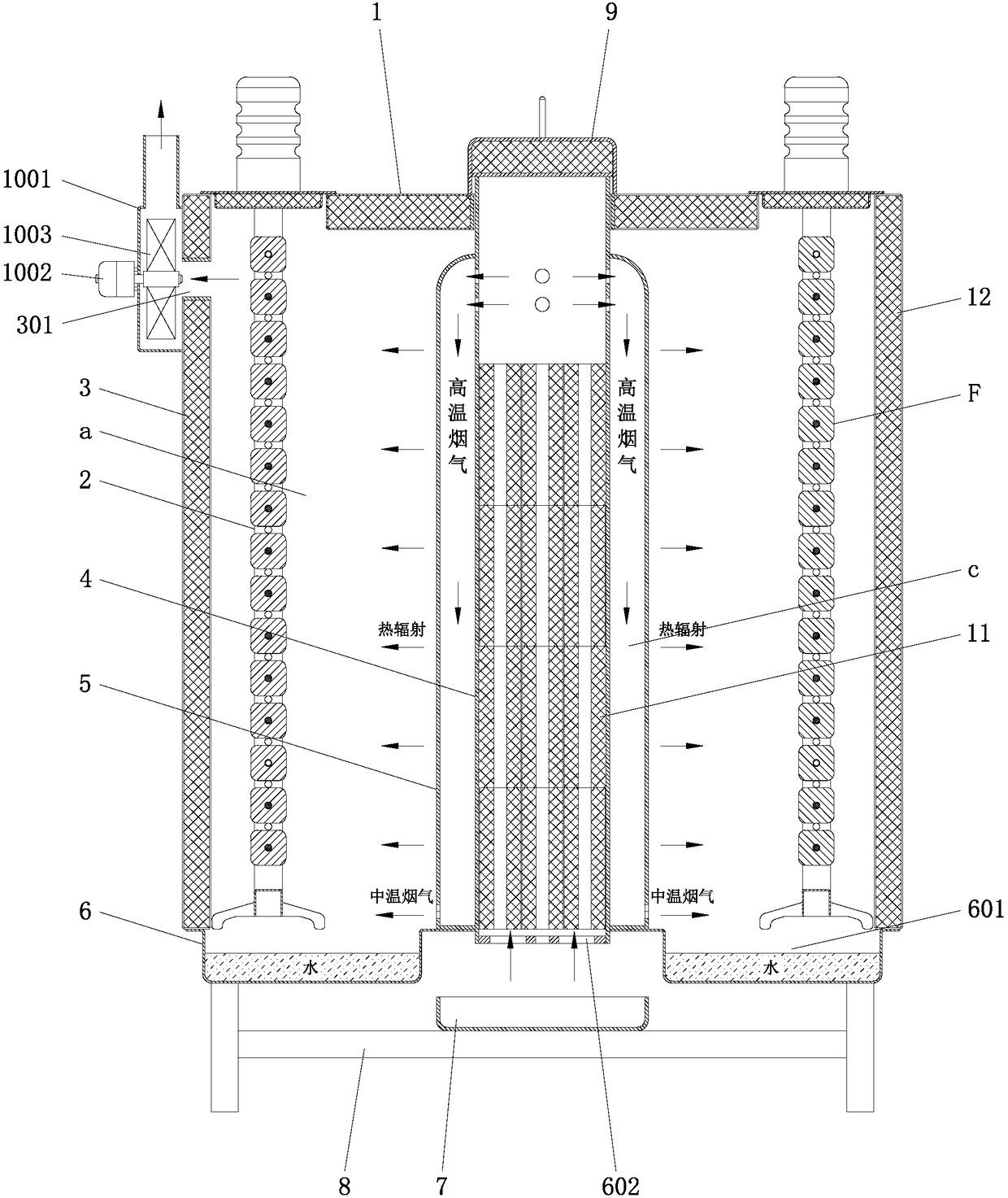

High-efficiency and energy-saving roasting device for steel ladles

InactiveCN102218526AMake full use of high temperature waste heatImprove efficiencyMelt-holding vesselsCombustionMetallurgy

The invention provides a high-efficiency and energy-saving roasting device for steel ladles, comprising a steel ladle body; a cover is hermetically arranged on the upper part of the steel ladle body; a nozzle and a smoke gas outlet are arranged on the cover; the steel ladle body is internally provided with a clapboard that divides the internal space of the steel ladle into two halves; a smoke gas passage is remained at the bottom of the steel ladle body; and the nozzle and the smoke gas outlet are arranged at two sides of the clapboard. The high-efficiency and energy-saving roasting device for steel ladle has high combustion efficiency, high thermal utilization ratio, and excellent environment-friendly performance.

Owner:ZHEJIANG UNIV

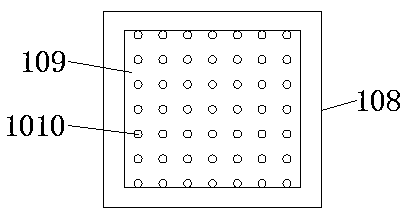

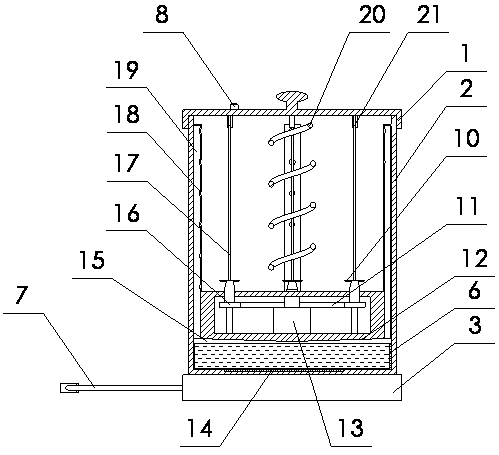

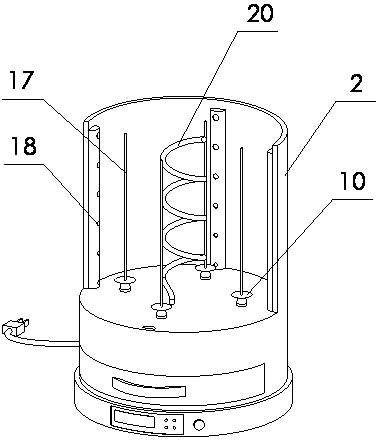

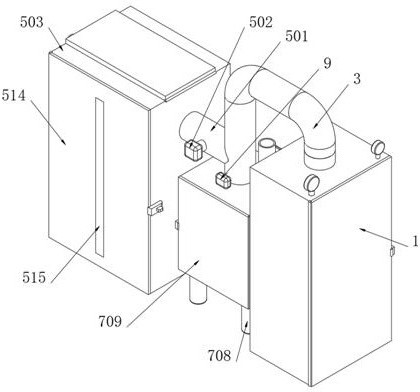

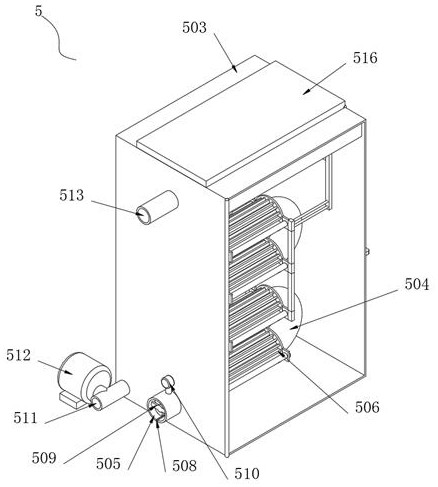

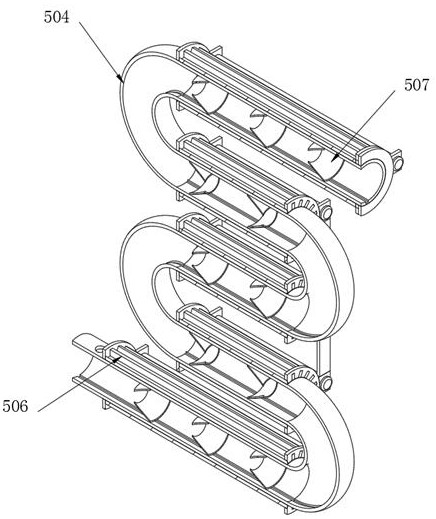

Energy-saving ventilation oven high-efficiency in roasting

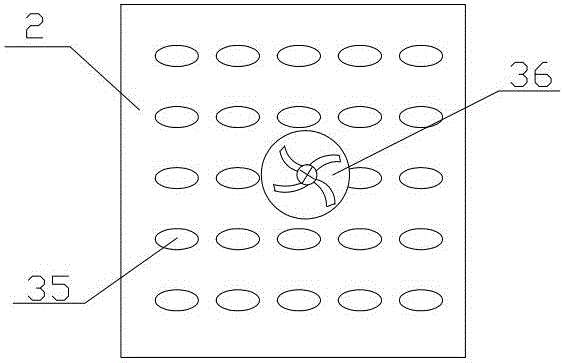

PendingCN108353954AHigh degree of visualizationIncrease contact areaFood processingBaking ovenSterile environmentEngineering

The invention belongs to the technical field of food production equipment, and relates to an energy-saving ventilation oven high-efficiency in roasting. According to the energy-saving ventilation ovendisclosed by the invention, a tank body is divided into an upper chamber, a middle chamber and a lower chamber by an upper horizontal partition plate and a lower horizontal partition plate, so that the effect of mutual isolation and protection is achieved, and the situation that cross contamination is generated, and the equipment is corroded is avoided; thermal wind generated in a heating deviceis blown to foods in an oven body through an air heater; the contact area of thermal wind and the foods is large, so that the heating is uniform, and the roasting effect is good; a sterilizing deviceis used for sterilizing roasted foods, so that the sterile environment in a drying oven is guaranteed, and the pollution to food caused by microorganisms of bacteria and the like is reduced to the maximum limit; a rotating motor is used for driving a rotating tray to rotate to drive a carrying frame and carrying disks to rotate, so that the contact area of the thermal wind and the roasted foods isfurther enlarged, and the roasting speed is accelerated; and a PLC control device is high in visualization degree, convenient to operate, and convenient to observe; and the energy-saving ventilationoven is simple in structure and high in practicality.

Owner:太仓鼎膳食品有限公司

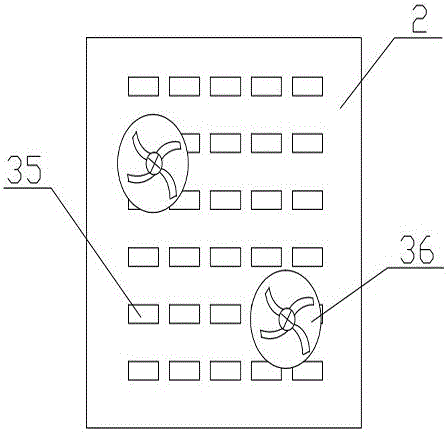

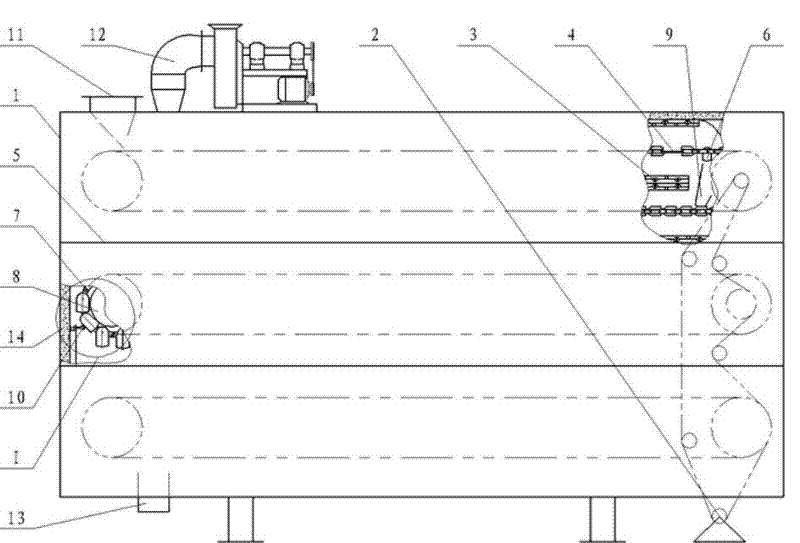

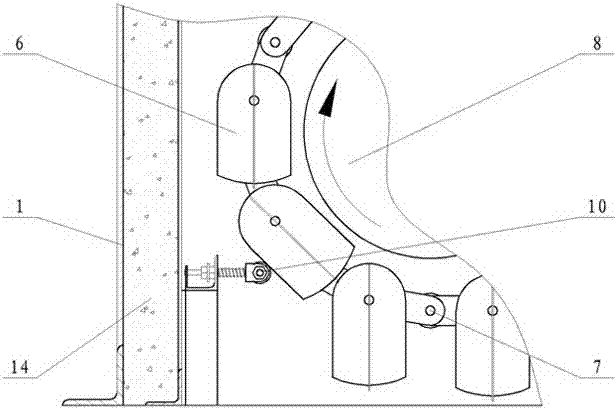

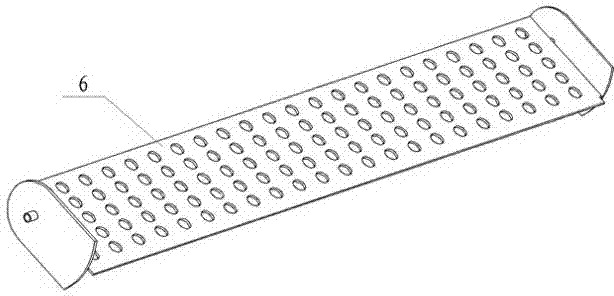

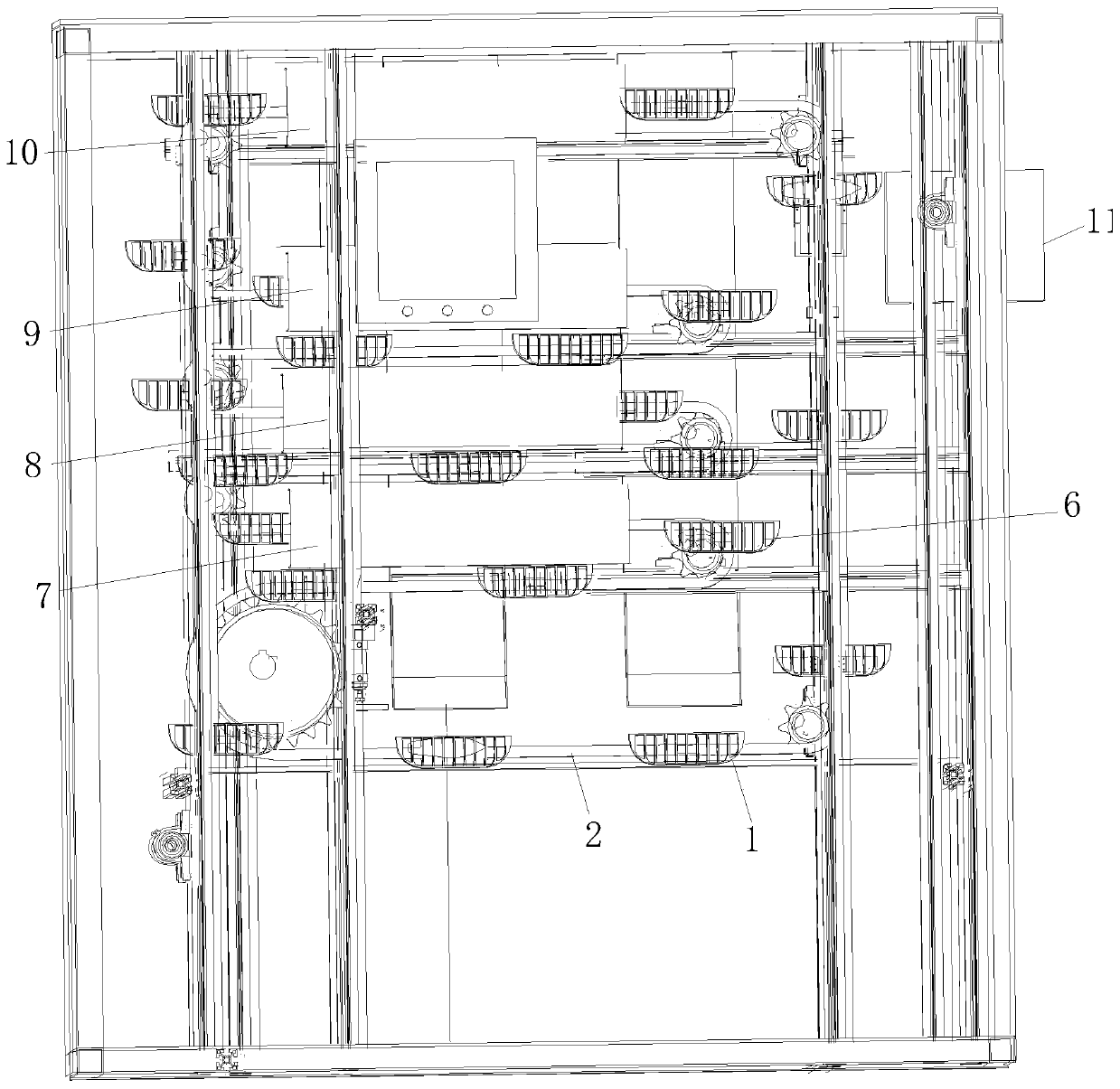

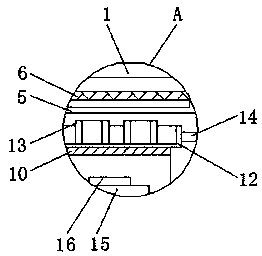

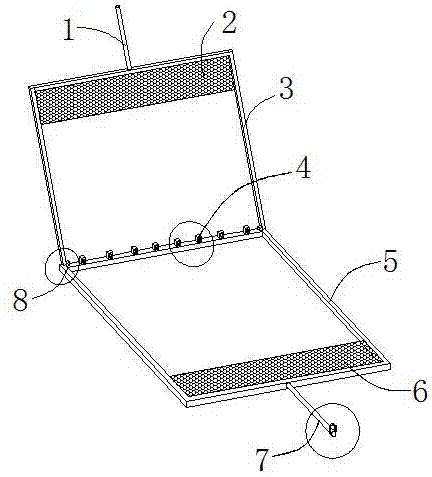

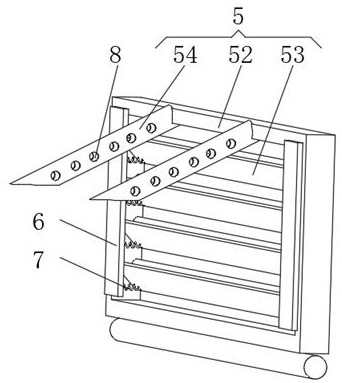

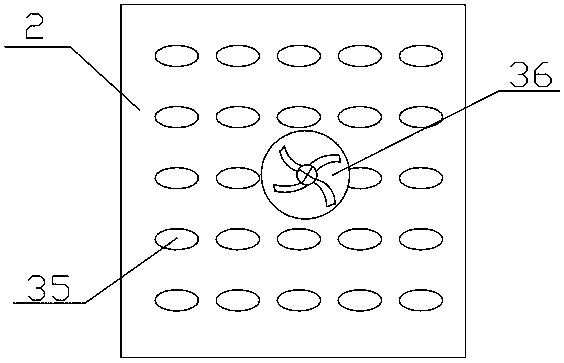

Pulsating infrared peanut baking process and equipment

The invention provides a pulsating infrared peanut baking process and equipment, which are characterized in that the pulsating infrared peanut baking equipment is adopted; peanuts are baked by using the pulsating infrared peanut baking process; the pulsating infrared peanut baking process is as follows: the infrared radiation intensity is 1-3 kW / m2; the pulsating power supply duration is 8-12 s; the pulsating power-off duration is 8-12 s; the baking temperature is 178-188 DEG C; the baking duration time is 6.8-9.2 min; the interior part of a box body is horizontally divided into a plurality of layers through clapboards; a set of conveying device driven by a transmission device is arranged in each layer; a plurality of small holes are arranged on conveying chain plates; various conveying chain plates are supported on a guide rail to form groove-shaped material channels; far infrared radiation devices are arranged above and below various channels; a guide groove is arranged below the ends of the channels; a plate shifting mechanism is respectively arranged at the reversing positions at the two ends of the conveying device; a feeding hole is arranged on the top of the box body; a fan is installed on the box body; and a discharging hole is arranged at the bottom of the box body. The pulsating infrared peanut baking process and equipment disclosed by the invention have the advantages of being rapid in baking speed, high in thermal efficiency and good in product quality.

Owner:SHANDONG UNIV OF TECH

Processing method of sweet osmanthus-flavored instant fish fillets

InactiveCN105231330ABeautyUnique flavorNatural extract food ingredientsFood ingredient as mouthfeel improving agentFlavorAdditive ingredient

The invention discloses a processing method of sweet osmanthus-flavored instant fish fillets and relates to the technical field of instant aquatic food processing. The processing method comprises the following nine major steps: extracting green prickleyash juice, removing fishy smell of fish meat, preparing minced fish meat, steaming and cooking sweet osmanthus soup, making accessory ingredients, mixing materials, making fillets, further seasoning the fillets and toasting the fillets. The processing method utilizes the sweet osmanthus juice as the accessory ingredient, so that the produced fish fillets have the aroma of the sweet osmanthus flowers; thus, the osmanthus-flavored instant fish fillets are unique in flavor. Moreover, the processing method is capable of integrating medicinal values of the sweet osmanthus flowers into the fish fillets, so that the prepared fish fillets have the functions of skin-caring, beautifying, soothing the throat, alleviating the symptoms of phlegm and cough, preventing ozostomia and the like.

Owner:XIAMEN WOFENG FOOD CO LTD

Intelligent unmanned baking and selling machine

InactiveCN109816881AReduce baking timeImprove securityApparatus for meter-controlled dispensingRoasters/grillsProcess engineeringEngineering

The invention discloses an intelligent unmanned baking and selling machine. The machine comprises a feeding mechanism, a baking mechanism, a discharging mechanism and a conveying mechanism, wherein the conveying mechanism is used for conveying to-be-baked food on the feeding mechanism into the baking mechanism and conveying the food to the discharging mechanism after baking is finished; the conveying mechanism comprises an object loading table and a conveying chain used for conveying the object loading table, wherein puncture needles inserted into the to-be-baked food are arranged on the object loading surface of the object loading table. The baking mechanism comprises a baking chamber, a hot air mechanism and a coil, wherein the hot air mechanism is used for providing a hot air source forthe baking chamber, and the coil is used for heating the puncture needles of the object loading table in the baking chamber. The baking chamber is cylindrical, and automatic doors which are opened when the object loading table enters the baking chamber and closed after the object loading table enters the baking chamber are arranged at the two end openings of the baking chamber. According to the machine, hot air and the puncture needles are used for heating the to-be-baked food simultaneously, and correspondingly internal and external heating are achieved simultaneously. Compared with a traditional baking process requiring 30 minutes for baking, the machine has the advantages that a baking process can be completed in 8 minutes, so that the baking time is greatly shortened.

Owner:GUANGDONG TECHN COLLEGE OF WATER RESOURCES & ELECTRIC ENG

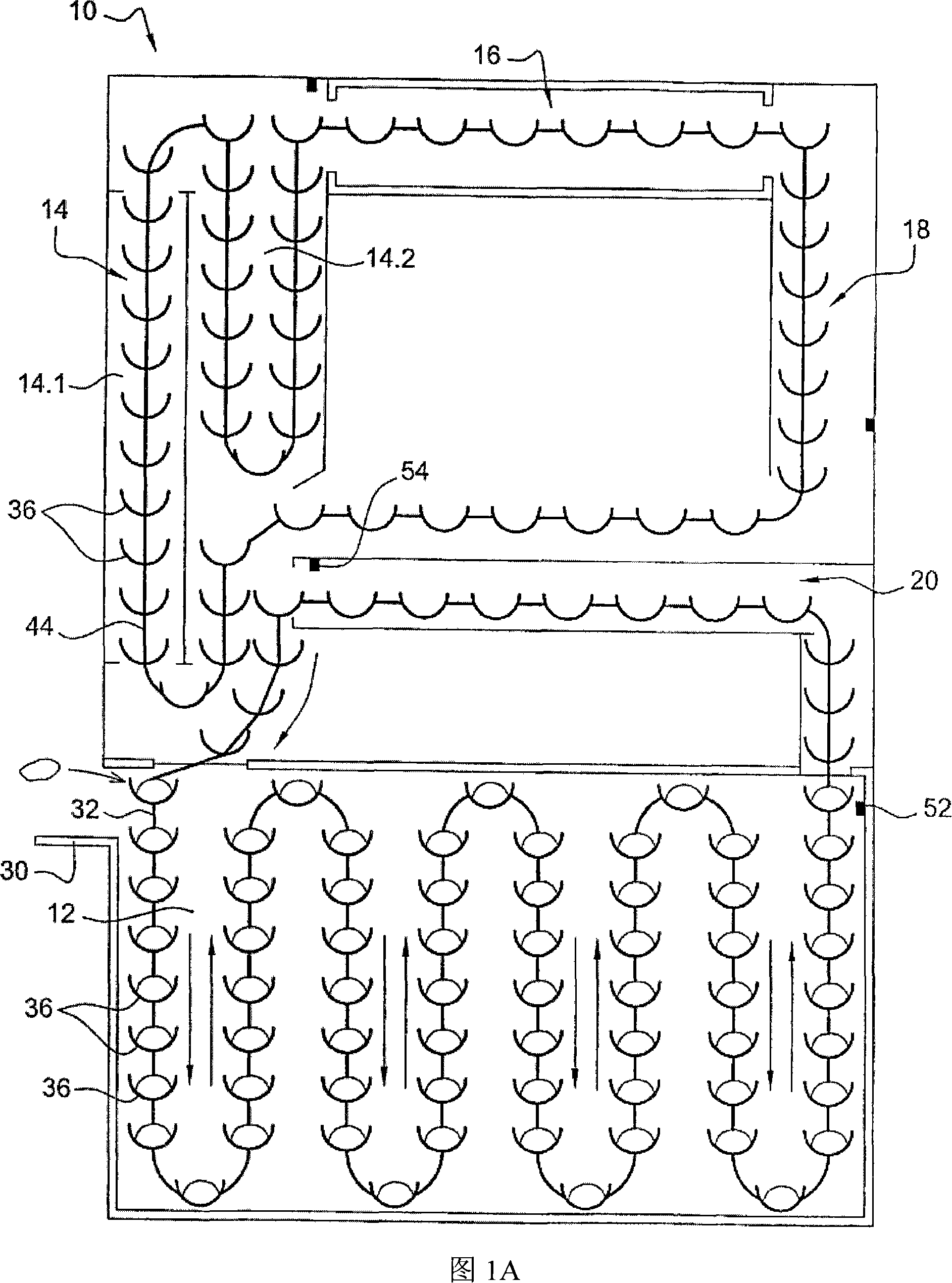

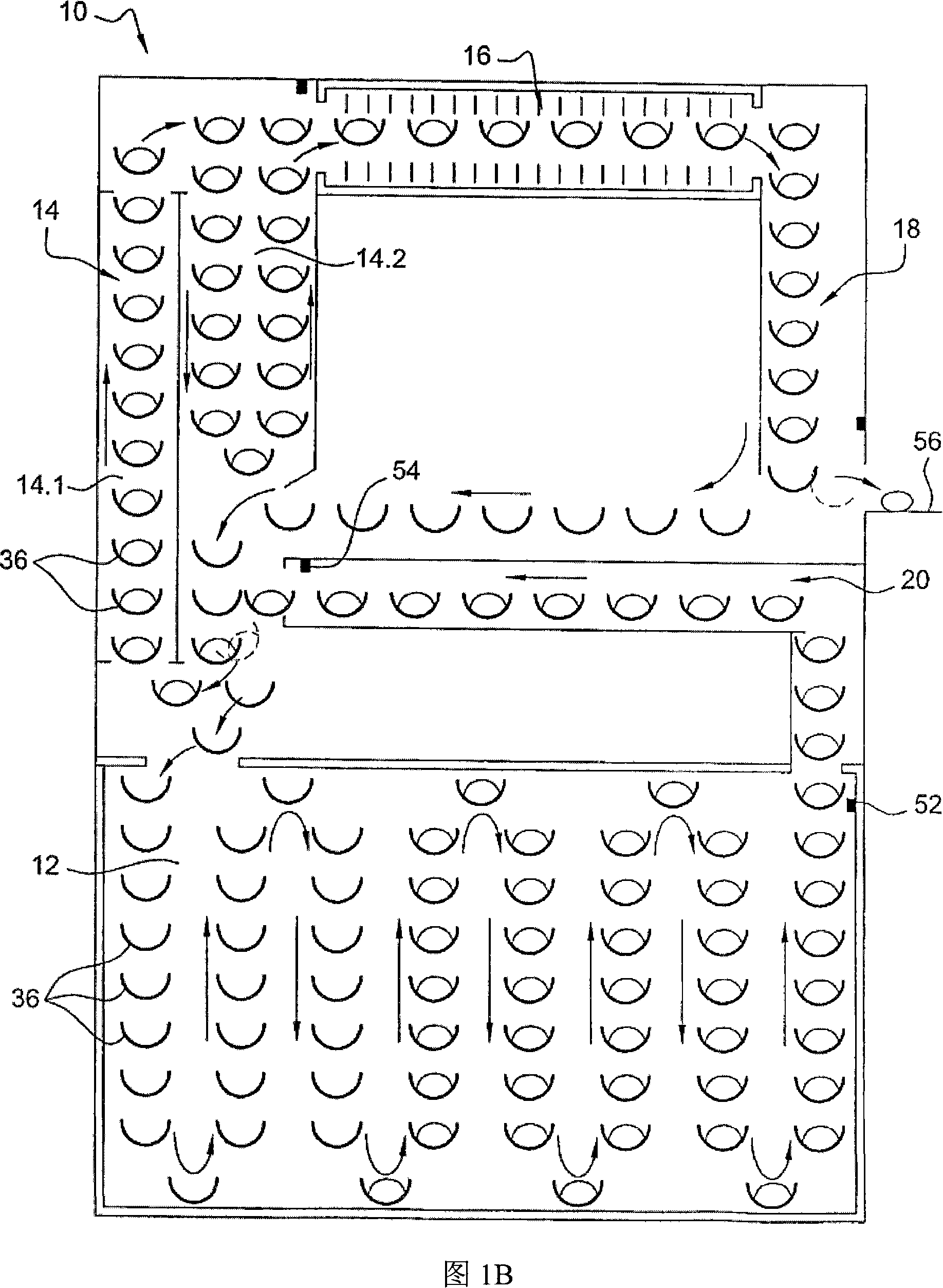

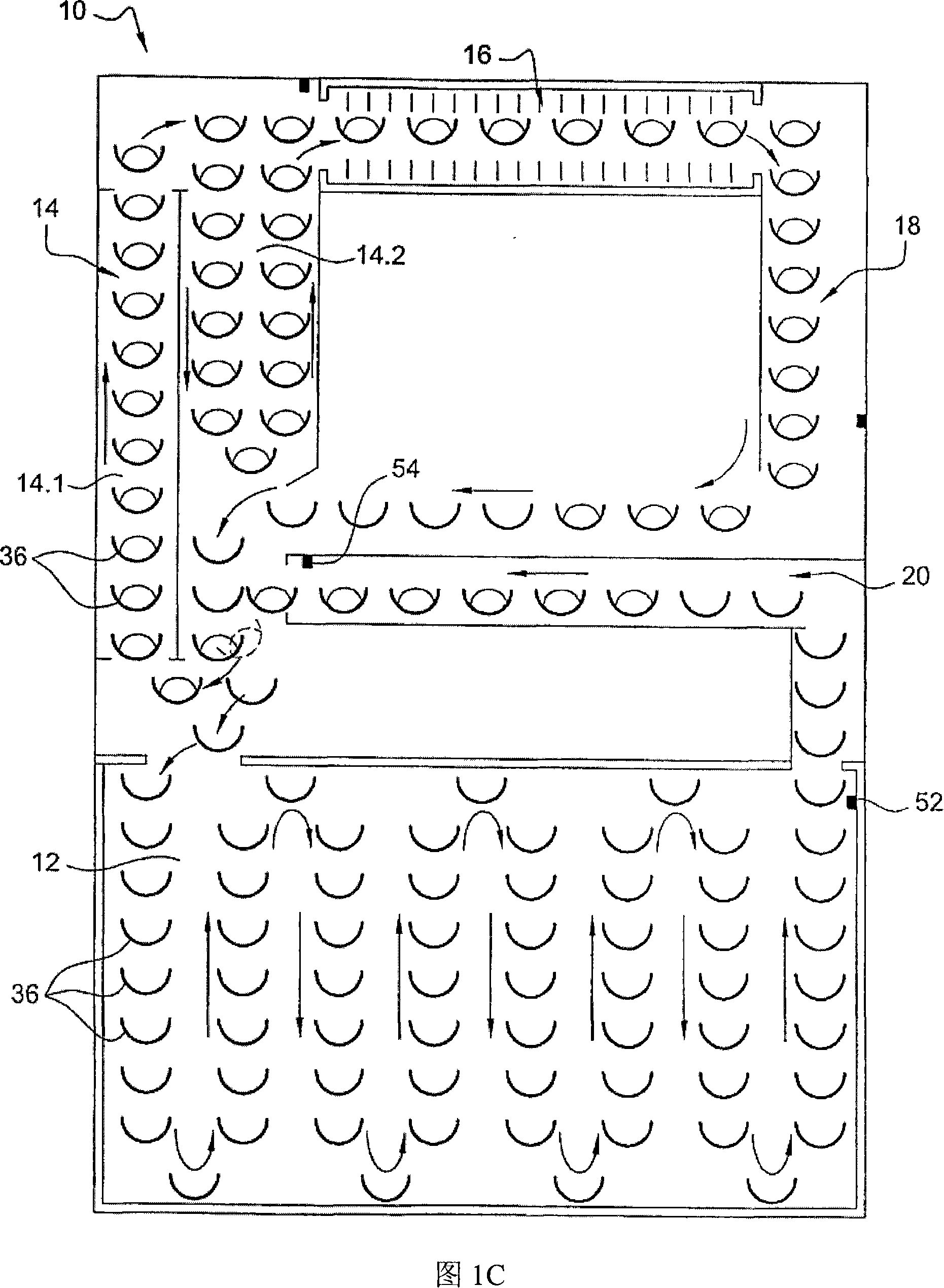

Device for preserving, cooking and automatically dispensing dough-based products, especially bread

InactiveCN101150957AFast bakingShort wavelengthCoin-freed apparatus detailsBaking ovenLength waveMechanical engineering

The invention relates to a device for preserving, cooking and automatically dispensing dough-based products, such as bread. The inventive device is characterised in that it comprises an area (12) for storing frozen products and an area (16) for cooking same with at least one source of short waves having a wavelength of less than 2 mum for quick cooking.

Owner:埃里克·卡尼卡斯 +1

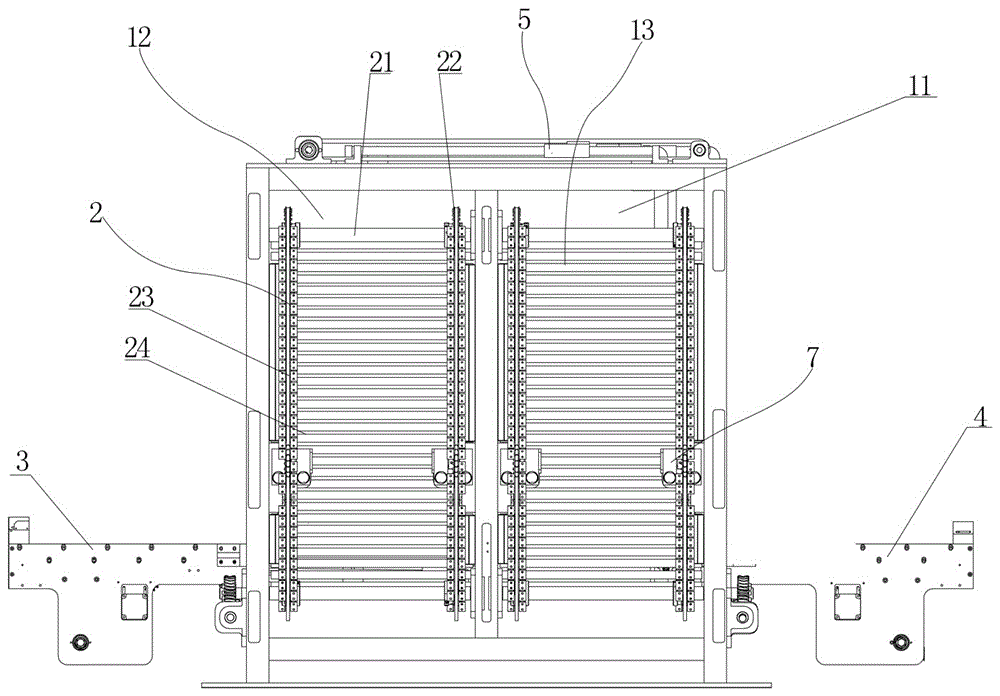

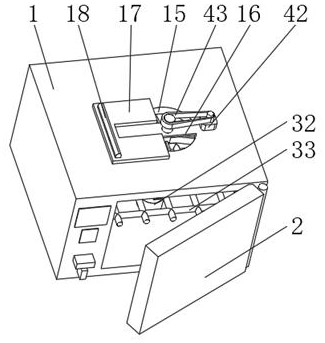

Vertical type oven capable of collecting materials automatically

InactiveCN106197004AIncrease temperatureFull and even toasting resultsPrinted circuit manufactureVertical furnacesCooking & bakingEngineering

The invention discloses a vertical type oven capable of collecting materials automatically. The vertical type oven capable of collecting materials automatically comprises an oven box, and two frames are arranged in the oven box correspondingly. The vertical type oven is characterized in that a first baking part and a second baking part are arranged between the frames; a feeding module and a discharging module are arranged on two sides of the frames correspondingly; pushing assemblies are arranged at the tops of the first baking part and the second baking part; a plurality of heating modules are arranged in the oven box; the first baking part and the second baking part each comprise two corresponding rotary modules; a supporting frame is arranged on one side of the oven box; rotary lead screws are arranged on two corresponding lateral surfaces of the supporting frame; a storage bin is arranged between the rotary lead screws on two sides and connected with the rotary lead screws; driving devices for driving the lead screws to rotate are arranged at the tops of the rotary lead screws; a plurality of connecting strips are arranged on the lateral surface of the storage bin at equal intervals; and a pushing assembly is arranged at the top of the discharging module and comprises vertical plates arranged on the discharging module, and a transverse rod is arranged between the vertical plates and connected with a push rod.

Owner:SUZHOU CONBER ELECTRONICS EQUIP

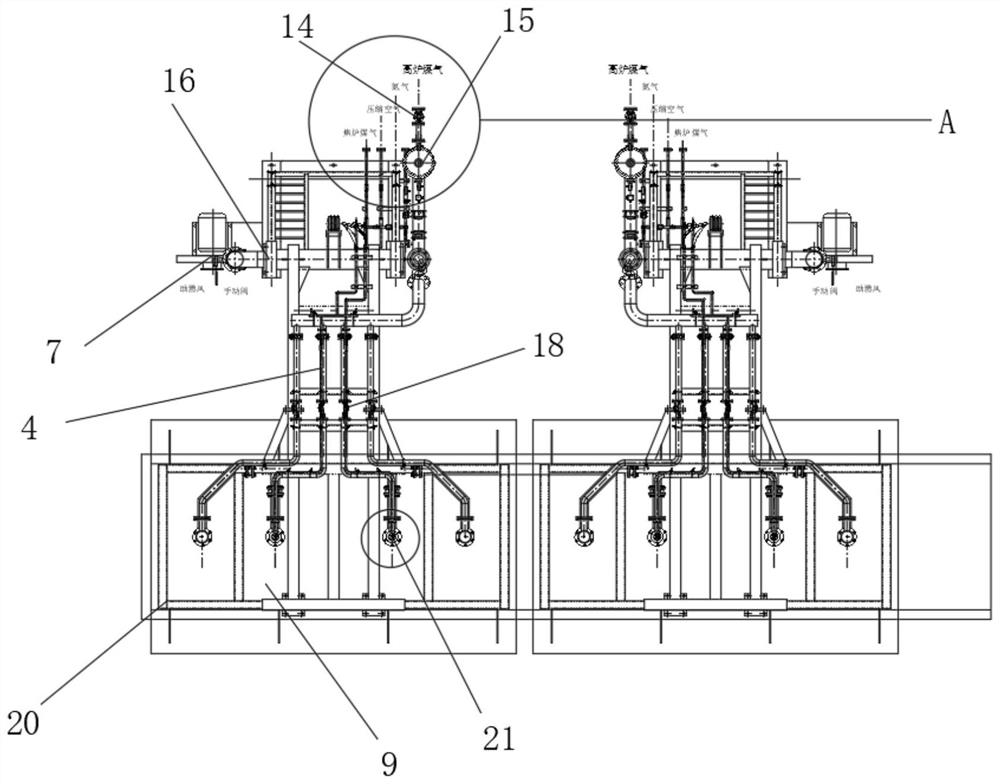

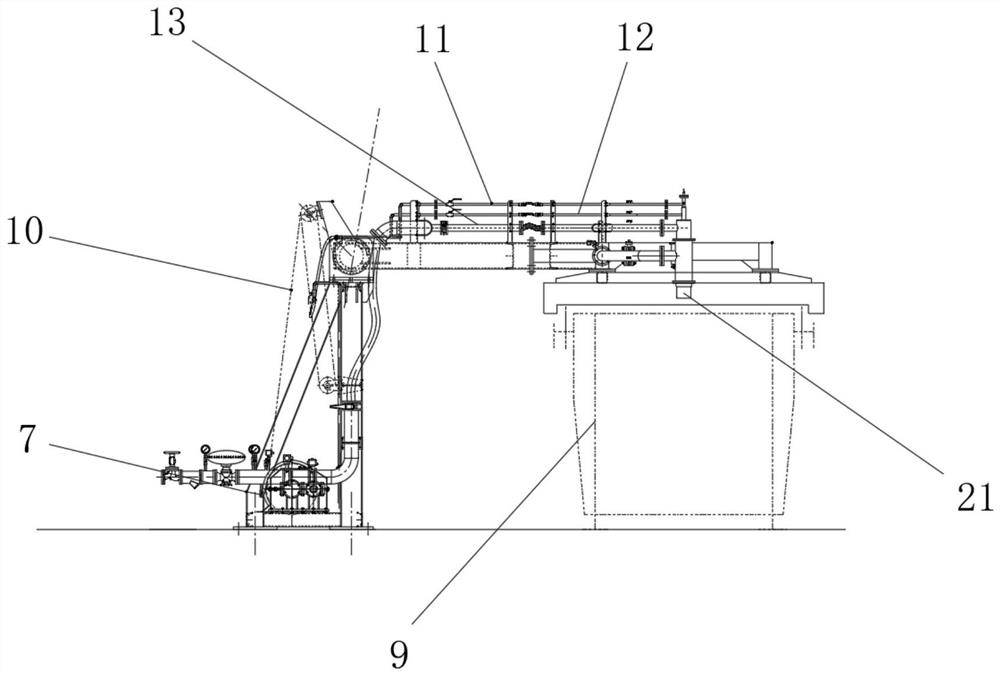

Direct hopper baking device for scrap steel

PendingCN112981040ASave turnaround timeAvoid turnaround coolingPreheating chargesSteelmakingProcess engineering

The invention discloses a direct hopper baking device for scrap steel. The direct hopper baking device comprises a combined burner turning cover, wherein a valve is arranged below the combined burner turning cover; a lifting connecting rod is arranged on one side of the valve; a gas pipeline is mounted on one side of the combined burner turning cover; a fan pipeline is mounted at the lower end of the gas pipeline; a combustion-supporting air valve is arranged below the fan pipeline; a high-pressure fan is arranged at the lower end of the combustion-supporting air valve; a lifting motor is arranged on one side of the lifting connecting rod; a scrap steel containing hopper is arranged below the combined burner turning cover; a steel cable is connected to the upper portion of the lifting motor; and a burning torch gas pipeline is arranged on one side of the steel cable. According to the direct hopper baking device, by means of the combination of a main burner gas pipeline, a main burner and the scrap steel containing hopper, scrap steel can be directly baked without kiln baking equipment, the baking time is shortened, the turnover frequency after kiln baking of the scrap steel is omitted, time is saved, cooling of the baked scrap steel is reduced, energy is saved, the steelmaking period is shortened, and the smelting efficiency is improved.

Owner:堵敏贤

Rose cake baking device

InactiveCN108770892AEasy BakingFully bakedOven doors/gatesHollow article bakingEngineeringDrive motor

The invention discloses a rose cake baking device. The rose cake baking device comprises an operating board body, wherein support columns are fixedly connected with the bottom of the operating board body; an oven is fixedly connected with the upper surface of the operating board body; a heating box is fixedly connected with the inner side surface of the oven; a heating pipe is arranged in the heating box; a bearing is fixedly inlaid in the left side surface of the oven; an inner ring of the bearing is fixedly connected with a shaft lever; one end, close to the bearing, of the shaft lever penetrates through the baring and extends to the outside of the oven; one end, extending to the outside of the oven, of the shaft lever is fixedly connected with a drive motor; one end, away from the drivemotor, of the shaft lever is fixedly connected with an overturning box which is located in the oven, sliding chutes are formed in the symmetric outer side surfaces of the overturning box, a tray matched with the sliding chutes is clamped in the sliding chutes, and a plurality of fixed molds are fixedly connected with the inner bottom wall of the tray. The rose cake baking device has the advantages of being conveniently overturned by a user and high in baking speed and facilitating market promotion.

Owner:无锡市鹅湖玫瑰园艺文化有限公司

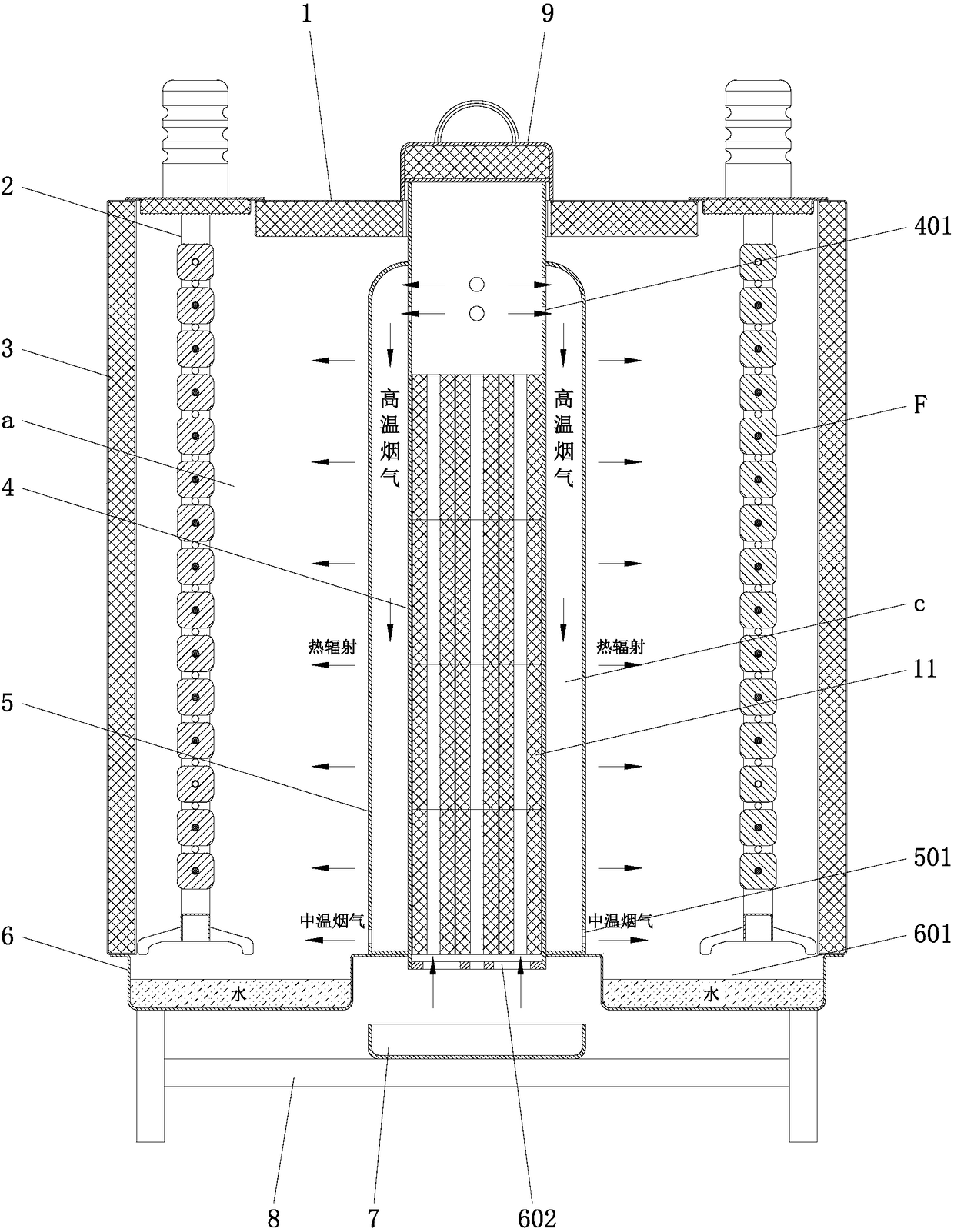

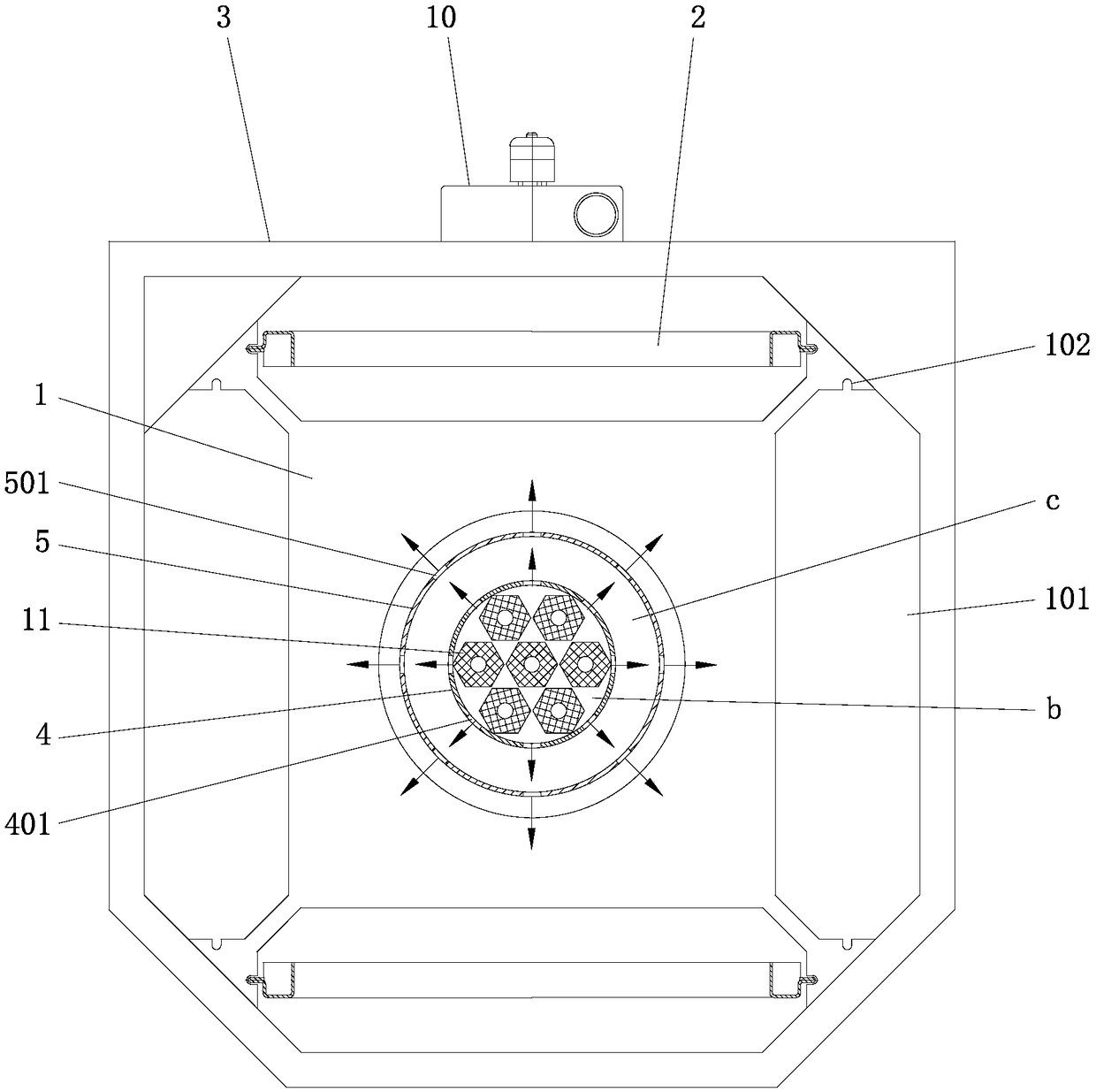

Forced-exhaust-type radiant carbon stove

InactiveCN108402111AReduce pollutionReduce contentOven air-treatment devicesCombustion chamberEngineering

The invention relates to a forced-exhaust-type radiant carbon stove. The forced-exhaust-type radiant carbon stove comprises a stove body, wherein a heating chamber is arranged in the stove body; a sleeve-type radiation mechanism is arranged in the heating chamber, and is composed of a combustion tube and a radiation tube; the radiation tube sleeves the outer side of the combustion tube, and a high-temperature smoke passage is formed between the combustion tube and the radiation tube; the inner chamber of the combustion tube is a combustion chamber, and a bottom of the combustion chamber communicates with the outside; high-temperature smoke outlets are formed in the combustion tube, and the combustion chamber communicates with the high-temperature smoke passage via the high-temperature smoke outlets; medium-temperature smoke outlets are formed in the radiation tube, and the high-temperature smoke passage communicates with the heating chamber via the medium-temperature smoke outlets; anda smoke exhaustion mechanism is arranged on the stove body. During operation, smoke produced by charcoal combustion in the combustion chamber enters the high-temperature smoke passage via the high-temperature smoke outlets, and then, enters the heating chamber via the medium-temperature smoke outlets; and then, forced exhaustion of the smoke in the heating chamber is realized by the smoke exhaustion mechanism. The forced-exhaust-type radiant carbon stove is capable of realizing completely enclosed radiant barbecue, and is convenient and practical in operation; moreover, the forced-exhaust-type radiant carbon stove is enhanced in heating performance, low in pollution, high in heat utilization rate, good in heating effect, and high in heating efficiency.

Owner:胡丽君

Novel main iron runner casting material

The invention discloses a novel main iron runner casting material which is prepared from alumina, corundum, SiC, SiO2 micropowder, alpha-Al2O3 micropowder, modified nano carbon powder, explosion-proof fiber, metallic silicon powder, calcium aluminate cement and sodium tripolyphosphate. According to the invention, since the modified nano carbon powder, of which the activity is much higher than that of asphalt carbon residues, is substituted for the asphalt, so the oxidation resistance effect is better. In addition, the modified nano carbon powder used as a substitute for asphalt can improve the bursting resistance of the product in the baking process.

Owner:长兴云峰炉料有限公司

Novel clamping rack for barbecue

InactiveCN107095588AGood for fallingWon't fallBaking vesselsRoasting apparatusEngineeringMechanical engineering

The invention discloses a novel clamping rack for barbeque. The novel clamping rack comprises a first support and a second support and is characterized in that a rotary seat is fixedly mounted on each of the left side and the right side of the rear portion of the top end face of the second support, two sides of the bottom end of the first support are respectively rotatably hinged to the rotary seats of the second support, a first handle is vertically welded to the middle section of the top end of the first support, a first grid plate is welded to the top of the first support, a second handle is welded to the middle section of the front end of the second support, a fixing ring is rotatably connected to each of the left side and the right side of the tip end of the second handle through a pin, a second grid plate is welded to the front portion of the second support, a plurality groups of limit blocks are welded to the rear side of the top end face of the second support, every two limit blocks are evenly distributed at interval, and a limit groove is formed in the top of lateral end face of each limit block. The novel clamping rack has the advantages that a large amount of food materials stringed by bamboo sticks can be clamped conveniently, barbecuing is facilitated, and manual turning of the bamboo sticks one by one is avoided.

Owner:宿迁市楚源休闲用品有限公司

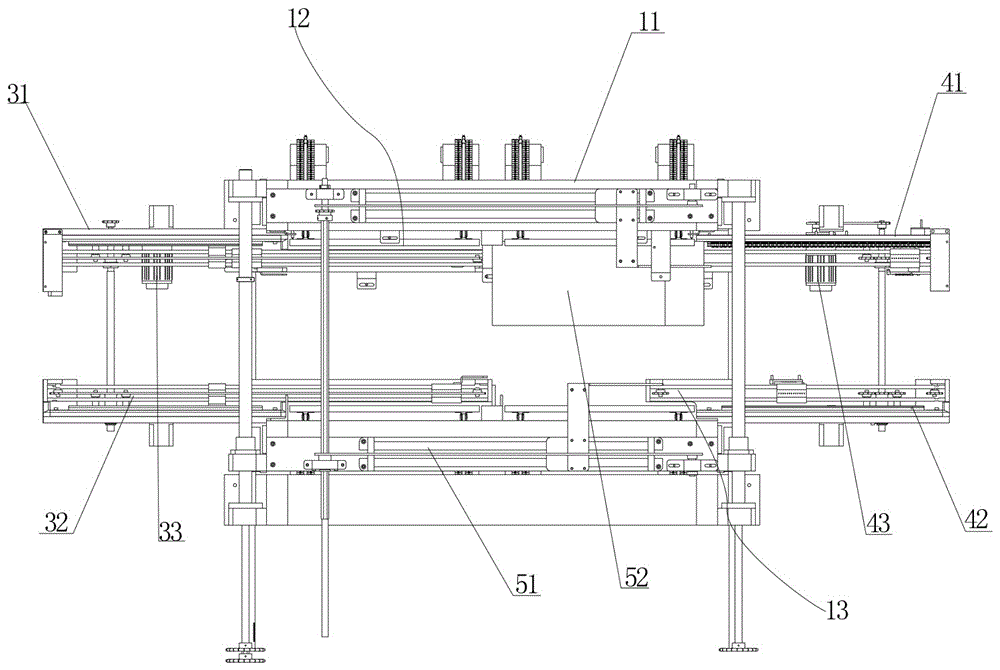

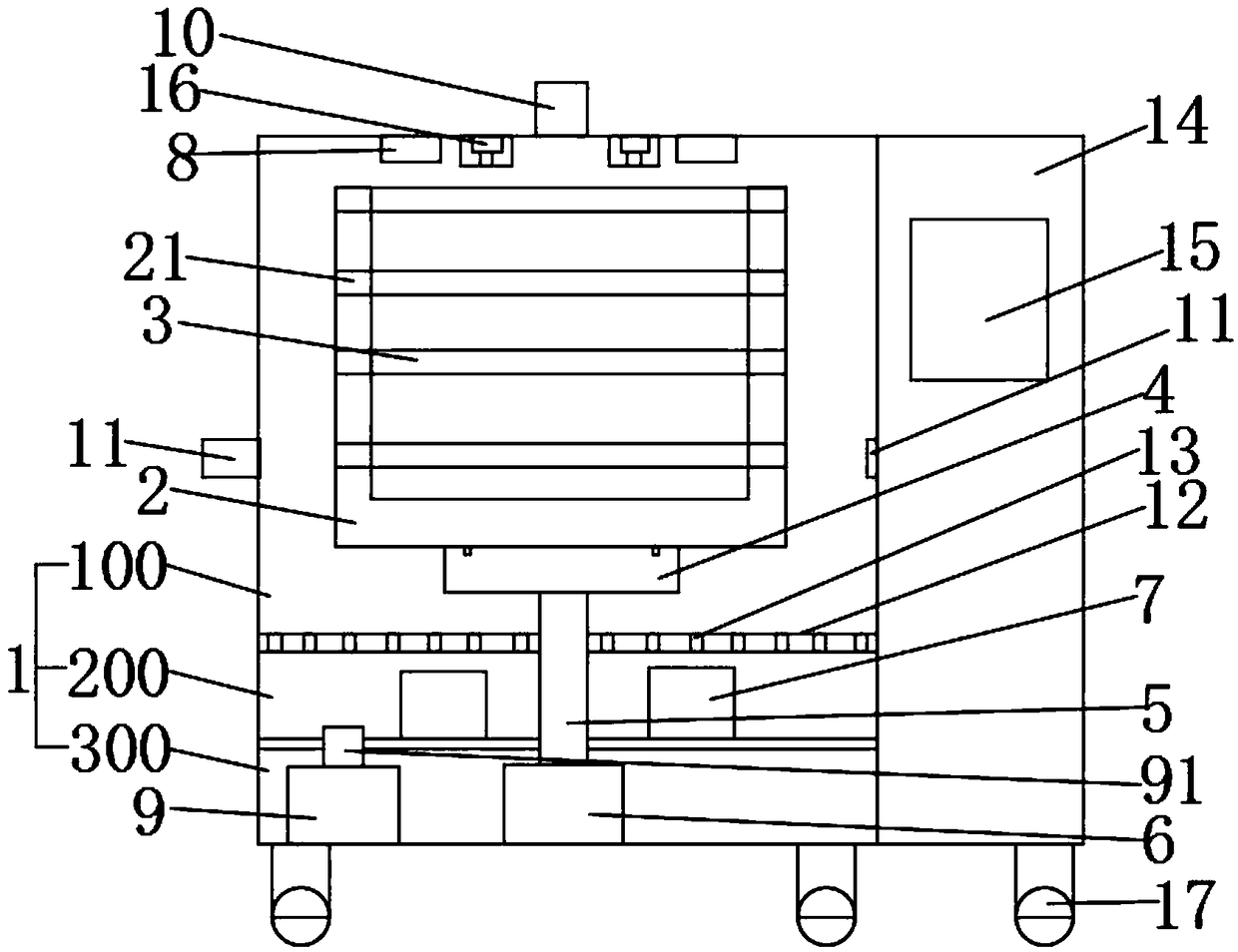

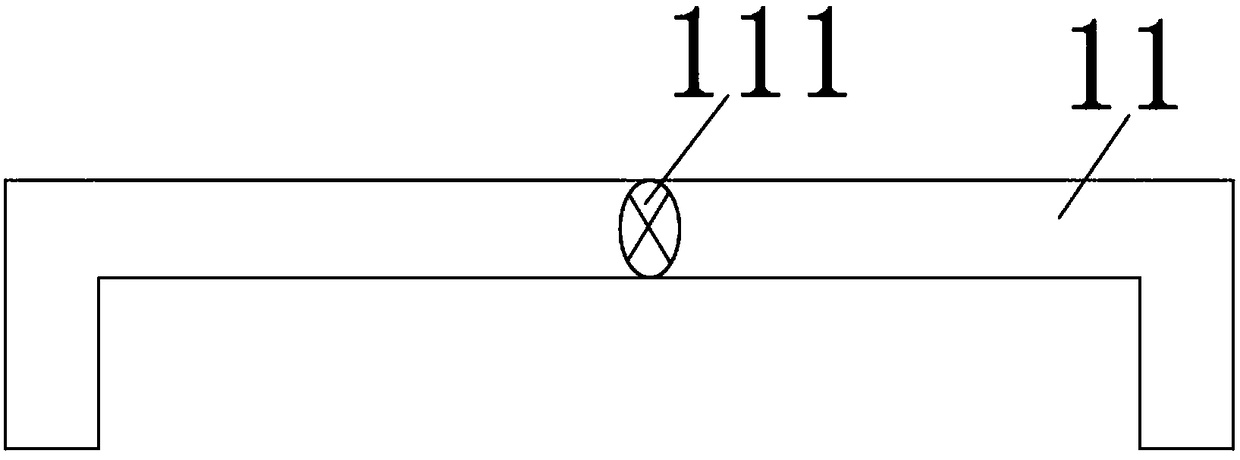

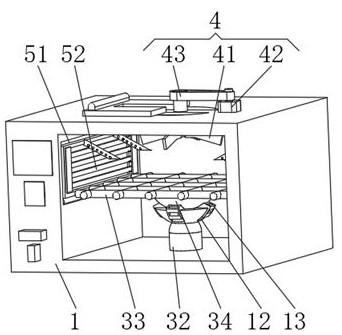

Movable automatic vertical oven

InactiveCN106123570AEnsure stabilityIncrease temperaturePrinted circuit manufactureVertical furnacesCooking & bakingHydraulic cylinder

The invention discloses a movable automatic vertical oven. The movable automatic vertical oven comprises a machine box, wherein two opposite racks are arranged in the machine box; a first baking part and a second baking part are separately arranged between the racks; a material inlet module and a material outlet module are separately arranged on two sides of each rack; multiple heating modules are arranged in the machine box; each of the first baking part and the second baking part comprises two rotation modules which are correspondingly arranged; each rotation module comprises rotation rolls which are separately arranged on the bottom and the top of the corresponding rack, and the two rotation rolls are correspondingly and horizontally arranged; two ends of each rotation roll are separately sleeved with a rotation gear; a chain circle is vertically connected with every two corresponding vertical rotation gears and can rotate along with the rotation gears; the two chain circles are parallelly arranged; a plurality of supporting ribs are horizontally connected between every two chain circles; and hydraulic cylinders are arranged at the bottom of the machine box, are connected with universal wheels and are used for driving the universal wheels to move downwards, so that the movable automatic vertical oven can be conveniently moved as needed, and meanwhile, conveying is convenient.

Owner:SUZHOU CONBER ELECTRONICS EQUIP

Tea leaf processing system and processing method

InactiveCN108991158AReasonable designPromote fermentationGas current separationPre-extraction tea treatmentEngineeringTea leaf

The invention relates to the related technical field of tea leaf processing, and in particular, relates to a tea leaf processing system, wherein the tea leaf processing system comprises a fermentationdevice for tea leaf processing, a kneading device for tea leaf processing, a drying device for tea leaf processing, a wind separation device for tea leaf processing and a tea roasting device for tealeaf processing. The tea leaf processing operation is carried out through reasonable setting of the processes, so that the tea leaf processing system is more perfect, and the tea leaf processing is more fine and convenient.

Owner:长沙光宙科技有限公司

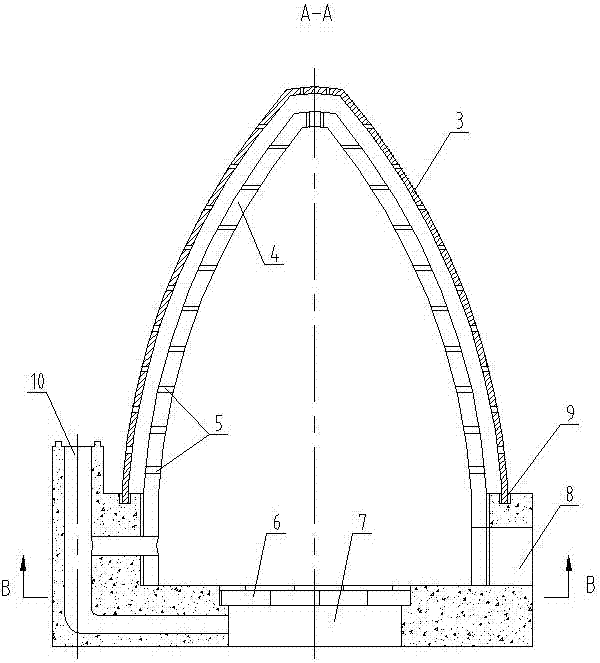

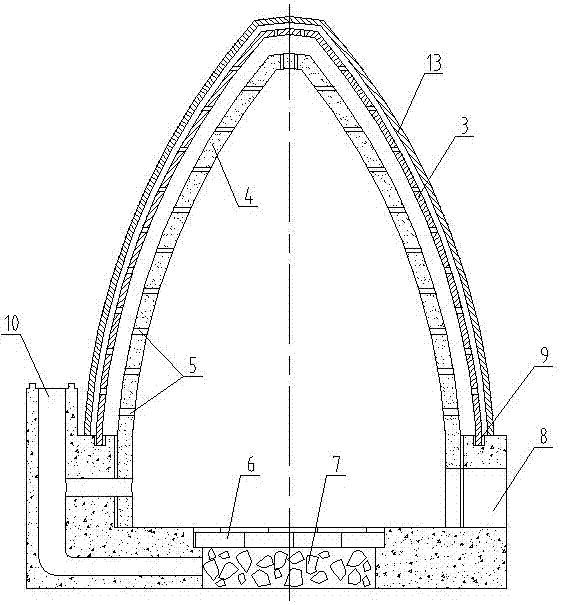

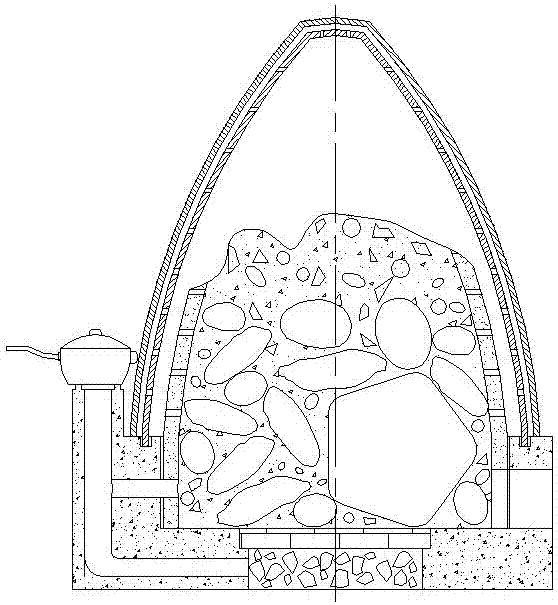

Food kiln

The invention relates to a kiln furnace for baking foods, in particular to a food kiln. The food kiln comprises a furnace system and a furnace kiln. The food kiln is characterized by comprising a kiln body of which the upper end is closed, and a kiln seat of which the lower end is open, an open end corresponding to the kiln seat is arranged in a U-shaped groove cavity of the furnace seat, a furnace opening is formed in one side of the furnace seat, and a kiln opening of which the position is overlapped with the position of the opening of the furnace opening is formed in a position, corresponding to the side surface of the furnace seat, of the kiln seat of the furnace kiln; a heat quantity penetrating layer in a structure of bricks or heat-insulating materials is arranged in the center of the bottom of the furnace seat, a heating cavity is arranged under the heat quantity penetrating layer, and the heating cavity is provided with a heating cavity opening; first ventilation holes are formed in the kiln wall of the kiln body; and the kiln wall of the kiln body is manufactured from the components of 40-60 parts of sand, 20-40 parts of yellow mud, 0.1-5 parts of gypsum, 8-15 parts of fruit tree charcoal and 2-5 parts of cinnamomum kotoense charcoal, and the kiln seat is manufactured from the components of 50-70 parts of sand, 20-40 parts of yellow mud and 0.1-5 parts of gypsum. The food kiln disclosed by the invention has the characteristics of being high in kiln body firing speed, good in heat preservation effects, energy-saving, environmental-friendly, capable of being repeatedly utilized and the like.

Owner:甘德强

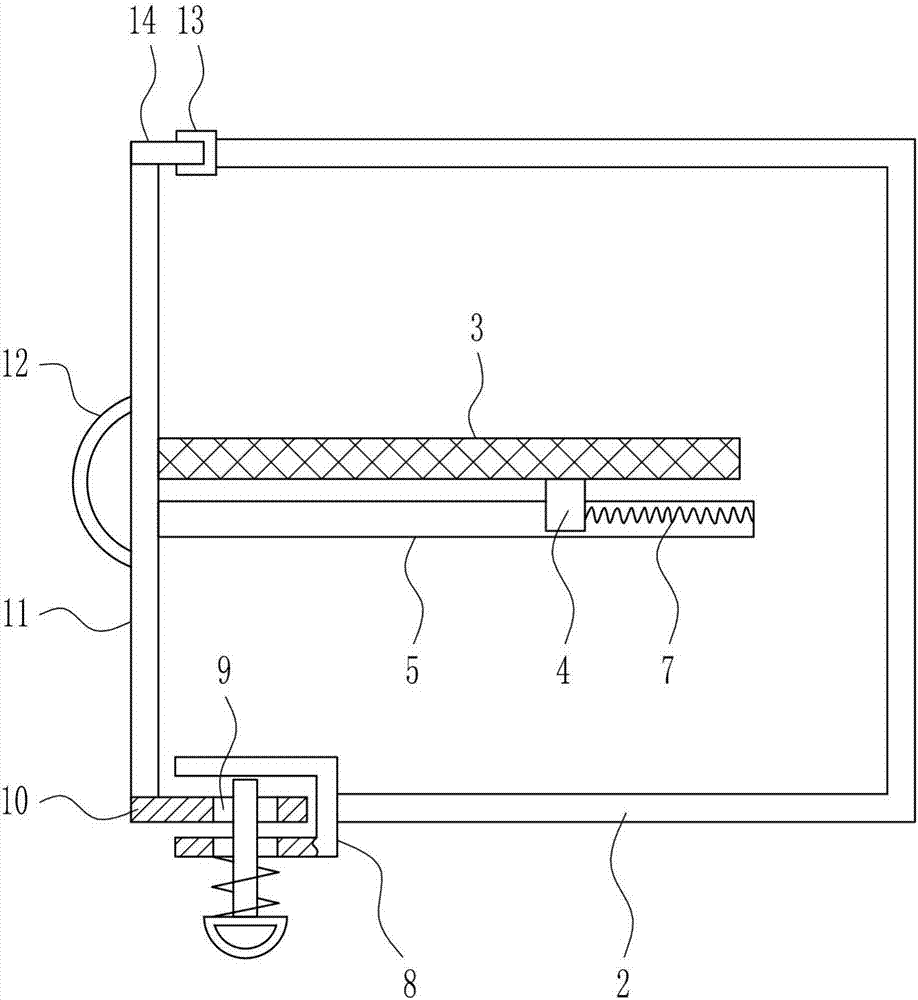

Industrial tobacco baking device

The invention relates to a tobacco baking device, in particular to an industrial tobacco baking device. The industrial tobacco baking device achieves the technical purpose of thorough tobacco baking.In order to achieve the technical purpose, the industrial tobacco baking device comprises an oven, first supports, a filter net box, a reel, a second rotating shaft, a bearing pedestal, a second pullrope, a fixed pulley, a sliding rail, a sliding block, a first spring, an iron block and the like; the grounds of the left side and the right side of the oven are each provided with one first support,an baking oven is arranged on the tops of the first supports, a heating opening is formed in the bottom of the baking oven, the heating opening is formed over the oven, and a second support is arranged on the right outer wall of the baking oven. The industrial tobacco baking device achieves the purposes of thorough tobacco baking, uniform tobacco heating and high baking speed.

Owner:TIANJIN KECHUANG FUXIN TECH CONSULTING CO LTD

An environment-friendly exhaust gas purification treatment device for a spray roasting machine

ActiveCN113606893BAvoid secondary pollutionImprove baking efficiencyDrying gas arrangementsDrying chambers/containersBaked goodsExhaust fumes

The invention discloses an environment-friendly exhaust gas purification treatment device for a spraying oven, which comprises an oven, one side of the oven is rotatably connected with a door, and the interior of the oven is provided with: a placement device, the The placement device has a fixed column, and the outside of the fixed column is provided with a limit frame, and a display frame is installed above the limit frame; a blower device, the blower device has a blade plate, and the blade plate The rotating shaft of the oven runs through the oven and extends to the outside of the oven; the guide device has a storage groove, and the invention relates to the technical field of exhaust gas purification equipment. The environmental-friendly exhaust gas purification treatment device of the spray roasting machine achieves the purpose of improving the adaptability to the shape of the baked items, and can guide the airflow to bake the baked items of different shapes, which reduces the difficulty of cleaning inside the roasting equipment and improves With a higher degree of intelligence, it can automatically trigger the airflow close to the baked items after putting in the baked items.

Owner:南通卡森环境科技有限公司

Household steaming and baking type sweet potato baking machine

PendingCN110960110AFast bakingImprove efficiencySteam cooking vesselsRoasters/grillsMechanical engineeringSteaming

The invention discloses a household steaming and baking type sweet potato baking machine. A baking step is performed through a baking assembly, the baking machine is matched with a driving assembly todrive the sweet potatoes to rotate in the steaming and baking process to uniformly steam and bake the potato; the baking machine comprises a baking box, the driving assembly, a steam assembly and thebaking assembly, wherein the steam assembly is arranged on the lower portion of a baking oven, the driving assembly is arranged on the lower portion of the baking oven and located above the steam assembly, the baking assembly is arranged in the baking oven, and the sweet potato baking machine is characterized in that sweet potatoes are steamed through the steam assembly, baked through the bakingassembly and driven to rotate in cooperation with the driving assembly in the steaming and baking process.

Owner:徐州橙空间厨具有限公司

A method for baking ladles during silicon smelting

The invention discloses a roasting method of ladle in silicon smelting process. The roasting method comprises the following steps: S1. constructing a special tower body for roasting the ladle in a silicon smelting and pouring place, wherein the height of the tower body is 9.6 meters, the largest width bottom is 8.4 meters, the narrowest width of the upper end is 6.3 meters, three sides of the tower body are constructed, another side is hinged with an encapsulation plate, the top of the tower body is closed, two partition plates and four baffles are arranged, each partition plate is provided with a plurality of first openings at equal intervals, the width of each first opening is 175mm-265mm, the baffle is 3.6 meters high, and a plurality of second openings are formed in each baffle. The roasting method facilitates the cyclic utilization of energy resources, the sustainable development and green production can be realized, and the generation of waste gas and dust in combustion can be prevented from polluting the environment, so that the environment protection is facilitated, the roasting time is greatly shortened, the roasting speed is quickened, the roasting efficiency is efficiently improved, and the labor intensity of working staffs can be effectively lowered.

Owner:云南省龙陵县龙山硅有限责任公司

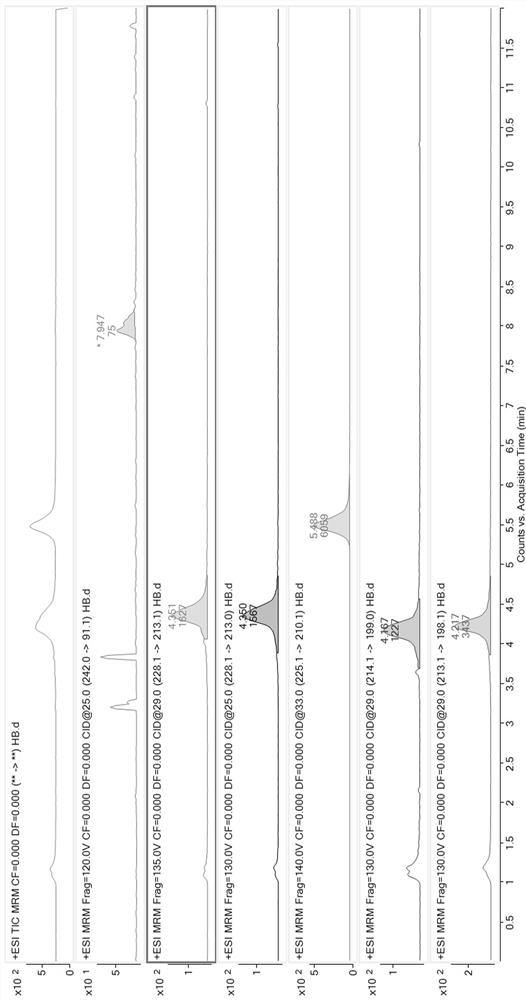

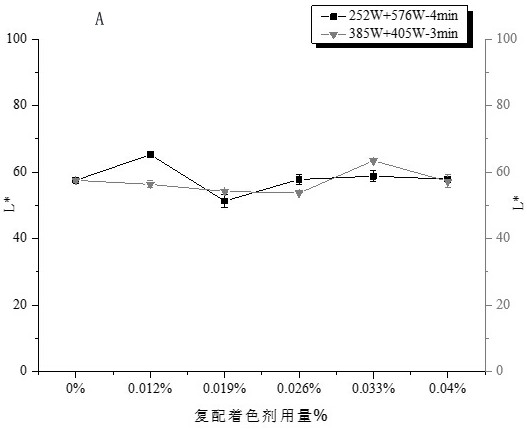

Pork steak roasting method capable of reducing polycyclic aromatic hydrocarbons and heterocyclic amines

PendingCN114343136ARich flavorSoft and juicy textureFood scienceBiotechnologyPolycyclic aromatic hydrocarbon

The invention provides a pork chop baking method capable of reducing polycyclic aromatic hydrocarbon and heterocyclic amine, which comprises the following steps of: pickling pork chop by adopting a wet pickling method; the use amount of the salt is 1.3%-1.6% of the weight of the meat loaves, the compound coloring agent is an aqueous solution, and in each kilogram of the aqueous solution, the use amount of the monascus red is 0.010-0.030 g, the use amount of the allura red is 0.001-0.005 g, and the use amount of the cochineal red is 0.001-0.005 g; and then pre-drying, cooking, post-drying and baking, namely baking the pork chops under the baking power of M-L1 (385W + 405W) or M-L2 (252W + 576W) by adopting a radio frequency and light wave combined baking mode. The prepared pork chop is rich in flavor and soft and juicy in texture, the original quality of the pork chop is kept to a large extent, the time is short, the efficiency is high, polycyclic aromatic hydrocarbon and heterocyclic amine are not generated or are low in content, and the product quality is more stable and the safety is higher.

Owner:河南双汇投资发展股份有限公司

A new type of oven

The invention discloses a novel oven. The novel oven comprises an oven body, a casing, an inner container, an oven door and an outer wall, wherein second ventilation holes are formed in the rear side of the casing; first ventilation holes and clamping grooves are formed in two side surfaces of the inner container, a lamp is arranged at the top of the inner container, and a rotary support is arranged at the bottom of the inner container; supporting legs are arranged at the bottom of the oven body, a plug is arranged on the rear side of the oven body, and the oven door and a control panel are arranged on the front of the oven body; a glass panel and a handle are arranged on the oven door; the outer wall comprises an air exchange layer, a thermal insulation layer and a cooling layer, heaters are arranged on the air exchange layer, and a filtering guide tube, a magnetic control tube, a high-voltage rectifier tube and a transformer are arranged on the cooling layer; supporting columns are arranged between the air exchange layer and the thermal insulation layer and between the thermal insulation layer and the cooling layer. When food is baked, instant heating is performed through microwaves firstly, so that the inside of baked food expands quickly, then far infrared heating is adopted, time is saved, uniform heating is realized, the quality is improved, and the cost is reduced.

Owner:XUCHANG UNIV

Heat energy recovery and treatment system for baking seaweed products

ActiveCN111854353BEasy to collectSlow down the flowDomestic cooling apparatusClimate change adaptationWater storage tankMechanical engineering

The invention discloses a heat energy recovery and processing system for baking seaweed products. An outlet pipe is installed on the top of the oven, an output pipe is installed on the top of the outlet pipe, an exhaust pipe is installed on one side of the output pipe, and one end of the exhaust pipe is installed on a storage tank. On the top of the water tank, the exhaust pipe is connected to the heat exchange pipe through an adapter. The outer surface of the heat exchange pipe is covered with a number of heat conduction strips, and the inner side of the heat exchange pipe is installed with a deceleration ring. Water pipe, a booster pump is installed on one side of the water inlet pipe, through the exhaust pipe, the first restriction valve, the heat exchange pipe, the discharge pipe, the heat conduction strip, the deceleration ring, the air outlet fan and the temperature detector, the water vapor with heat Input into the heat exchange tube, reduce its flow speed, accelerate its heat exchange in the heat exchange tube, make the heat exchange effect more perfect, and circulate water supply through the water inlet pipe, booster pump and outlet pipe to ensure the temperature difference between inside and outside, and accelerate heat exchange.

Owner:苏迪(福建)生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com