Food kiln

A food and kiln body technology, applied in the kiln field, can solve the problems of no flue, fast cooling speed of kiln body fragments, and long firing time, so as to avoid heat waste, save kiln firing time, and food even heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

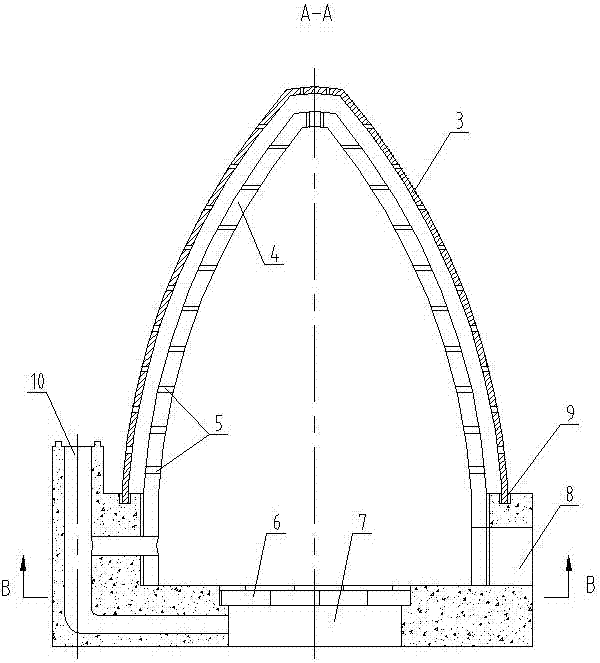

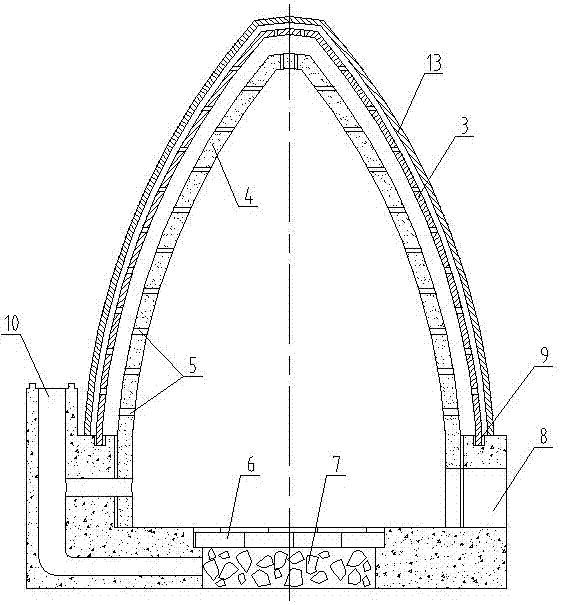

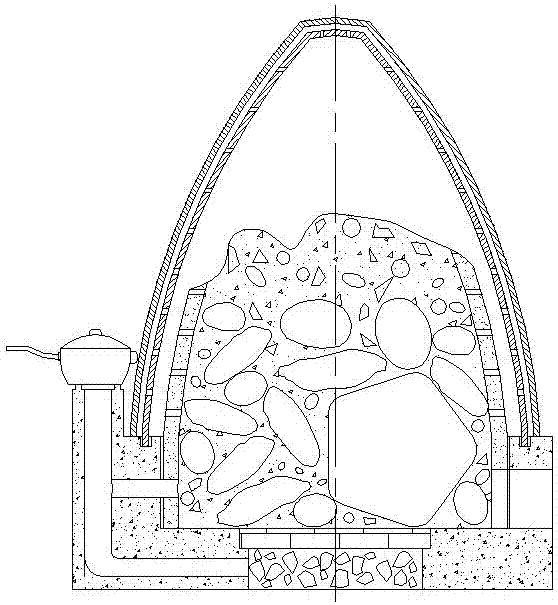

[0072] Such as Figure 1~Figure 10As shown, the food kiln of the present invention includes a furnace base 1 and a furnace kiln 2, an outer cover 3, a kiln body 4, a first ventilation hole 5, a heat penetration layer 6, a heating chamber 7, a furnace mouth 8, an annular groove 9, Flue 10, second ventilation hole 11, heating cavity mouth 12, kiln mouth 13, kiln base 14 and heat preservation cover 15, described furnace kiln 2 comprises kiln body 4 with upper end closed and lower end open kiln base 14, described kiln The corresponding opening end of the seat 14 is arranged in the U-shaped groove inner cavity of the furnace seat 1, and a furnace mouth 8 is opened on one side of the furnace seat 1, and the kiln seat 14 of the furnace kiln 2 and the furnace seat 1 A kiln mouth 13 overlapping with the opening position of the furnace mouth 8 is provided at a position corresponding to the side, and a heat penetration layer 6 of an insulating material structure is provided at the center...

Embodiment 2

[0089] Such as Figure 1~Figure 10 As shown, the food kiln of the present invention includes a furnace base 1 and a furnace kiln 2, an outer cover 3, a kiln body 4, a first ventilation hole 5, a heat penetration layer 6, a heating chamber 7, a furnace mouth 8, an annular groove 9, Flue 10, second ventilation hole 11, heating cavity mouth 12, kiln mouth 13, kiln base 14 and heat preservation cover 15, described furnace kiln 2 comprises kiln body 4 with upper end closed and lower end open kiln base 14, described kiln The corresponding opening end of the seat 14 is arranged in the U-shaped groove inner cavity of the furnace seat 1, and a furnace mouth 8 is opened on one side of the furnace seat 1, and the kiln seat 14 of the furnace kiln 2 and the furnace seat 1 A kiln mouth 13 overlapping with the opening of the furnace mouth 8 is provided on the side corresponding to the position, and a heat penetration layer 6 of brick structure is provided at the center of the bottom of the f...

Embodiment 3

[0105] Such as Figure 1~Figure 10 As shown, the food kiln of the present invention includes a furnace base 1 and a furnace kiln 2, an outer cover 3, a kiln body 4, a first ventilation hole 5, a heat penetration layer 6, a heating chamber 7, a furnace mouth 8, an annular groove 9, Flue 10, second ventilation hole 11, heating cavity mouth 12, kiln mouth 13, kiln base 14 and heat preservation cover 15, described furnace kiln 2 comprises kiln body 4 with upper end closed and lower end open kiln base 14, described kiln The corresponding opening end of the seat 14 is arranged in the U-shaped groove inner cavity of the furnace seat 1, and a furnace mouth 8 is opened on one side of the furnace seat 1, and the kiln seat 14 of the furnace kiln 2 and the furnace seat 1 A kiln mouth 13 overlapping with the opening position of the furnace mouth 8 is provided at a position corresponding to the side, and a heat penetration layer 6 of an insulating material structure is provided at the cente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com