Paper-like vegetables processing method

A processing method and technology of paper-shaped vegetables, which are applied in the field of food processing, can solve the problems of high energy consumption and long production time, and achieve the effects of low energy consumption, hygiene and convenience, and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Green Paper Vegetables (Original)

[0031] The formula is:

[0032] Greens 100Kg

[0033] The forming ingredient solution is calculated as the weight percentage of the green vegetables:

[0034] Sodium alginate 0.15Kg (0.15%)

[0035] Carboxymethyl cellulose 0.4Kg (0.4%)

[0036] Starch 0.475Kg (0.475%)

[0037] Soy protein isolate 0.125Kg (0.125%)

[0038] Water 9Kg(9%)

[0039] The seasoning solution is calculated as the weight percentage of the green vegetables:

[0040] Maltodextrin 2.0Kg (2.0%)

[0041] Table salt 0.35Kg (0.35%)

[0042] MSG 0.05Kg (0.05%)

[0043] Guanylic acid 0.04Kg (0.04%)

[0044] Soy protein hydrolyzed protein 0.006Kg (0.006%)

[0045] Shrimp powder 0.1Kg (0.1%)

[0046] Sugar 0.125Kg (0.125%)

[0047] Water 3.75Kg (3.75%)

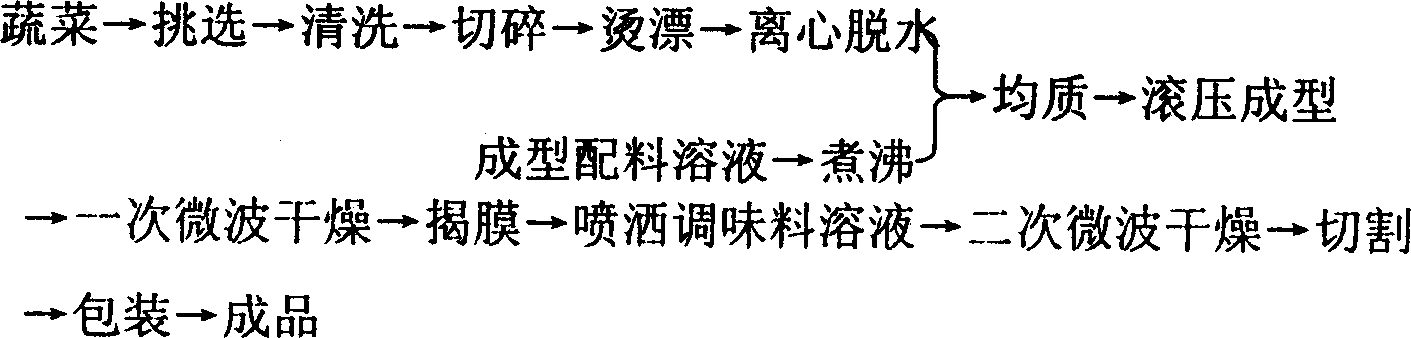

[0048] Processing technology such as figure 1 As shown below:

[0049] (1) Choose fresh and high-quality vegetables, wash and chop them;

[0050] (2) Send the green vegetables into 0.3% NaHCO 3 (According to the weight percent...

Embodiment 2

[0060] Celery paper vegetable (scallion flavor)

[0061] The formula is:

[0062] Celery 100Kg

[0063] The forming ingredient solution is based on the weight percentage of celery:

[0064] Sodium Alginate 0.8Kg (0.8%)

[0065] Carboxymethyl cellulose 0.1Kg (0.1%)

[0066] Starch 0.2Kg (0.2%)

[0067] Soy protein isolate 1.0Kg (1.0%)

[0068] Water 13Kg(13%)

[0069] The seasoning solution is calculated by weight percentage of celery:

[0070] Maltodextrin 0.6Kg (0.6%)

[0071] Table salt 0.25Kg (0.25%)

[0072] MSG 0.025Kg (0.025%)

[0073] Guanylic acid 0.08Kg (0.08%)

[0074] Soy protein hydrolyzed protein 0.002Kg (0.002%)

[0075] Shrimp powder 0.05Kg (0.05%)

[0076] White sugar 0.05Kg (0.05%)

[0077] Chive flavor 0.15Kg (0.15%)

[0078] Water 1.5Kg (1.5%)

[0079] The processing technology is as follows:

[0080] (1) Choose fresh and high-quality celery, wash and chop;

[0081] (2) Send celery to 0.1% NaHCO 3 (According to the weight percentage of the blanching water), blan...

Embodiment 3

[0091] Bitter Gourd Paper Vegetable (Spicy)

[0092] The formula is:

[0093] Bitter melon 100Kg

[0094] The forming ingredient solution is calculated by weight percentage of bitter gourd:

[0095] Sodium Alginate 0.4Kg (0.4%)

[0096] Carboxymethyl cellulose 0.8Kg (0.8%)

[0097] Starch 0.8Kg (0.8%)

[0098] Soy protein isolate 0.5Kg (0.5%)

[0099] Water 6Kg(6%)

[0100] The seasoning solution is calculated by weight percentage of bitter gourd:

[0101] Maltodextrin 3.0Kg (3.0%)

[0102] Table salt 0.12Kg (0.12%)

[0103] MSG 0.01Kg (0.01%)

[0104] Guanylic acid 0.01Kg (0.01%)

[0105] Soy protein hydrolyzed protein 0.02Kg (0.02%)

[0106] Shrimp powder 0.20Kg (0.20%)

[0107] White sugar 1.00Kg (1.00%)

[0108] Chili powder 0.20Kg (0.20%)

[0109] Water 4.5Kg (4.5%)

[0110] The processing technology is as follows:

[0111] (1) Wash and chop fresh and high-quality bitter gourd;

[0112] (2) Send bitter gourd into 0.5% NaHCO 3 (According to the weight percentage of the blanchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com