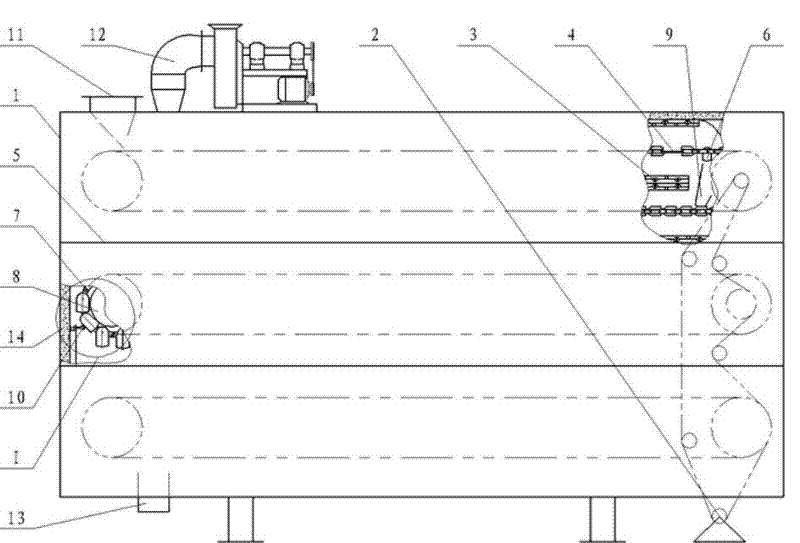

Pulsating infrared peanut baking process and equipment

A technology of baking technology and baking equipment, applied in the fields of application, food processing, food science, etc., can solve the problems of unformed baking technology and equipment, difficult actual production, etc., to shorten the baking time and save energy , the effect of improving brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

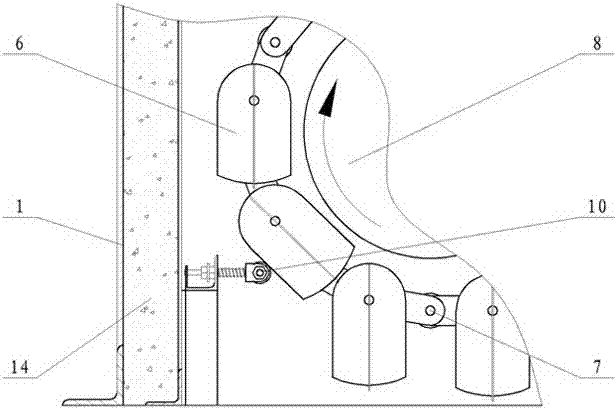

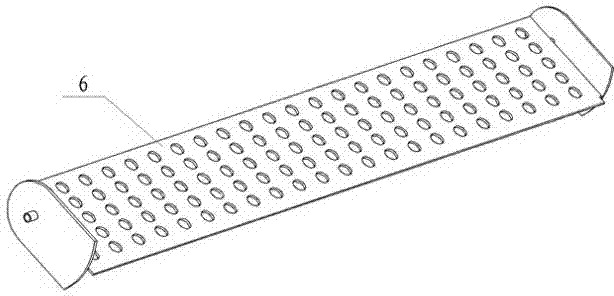

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: The infrared radiation intensity of each layer from top to bottom is 3.0kW / m of layer I 2 , 2.0kW / m2 on the second floor 2 , Ⅲ layer 1.5kW / m 2 , the duration of pulsating power supply is 8s, the duration of pulsating power failure is 10s, the baking temperature is 186°C, and the baking duration is 7.2min.

Embodiment 2

[0018] Embodiment 2: The infrared radiation intensity of each layer from top to bottom is 2.5kW / m of layer I 2 、 1.5kW / m2 for layer II 2 , Ⅲ layer 1.0 kW / m 2 , the duration of pulsating power supply is 10s, the duration of pulsating power failure is 10s, the baking temperature is 182°C, and the baking duration is 8.0min.

Embodiment 3

[0019] Embodiment 3: The infrared radiation intensity of each layer from top to bottom is 2.0kW / m of layer I 2 、 1.5kW / m2 for layer II 2 , Ⅲ layer 1.0 kW / m 2 , the duration of pulsating power supply is 12s, the duration of pulsating power failure is 8s, the baking temperature is 180°C, and the baking duration is 8.8min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com