Forced-exhaust-type radiant carbon stove

A carbon stove and radiant tube technology, applied in food ovens, oven air treatment devices, baking, etc., can solve problems such as low efficiency, time-consuming and laborious, and difficulty in ensuring product consistency, and achieve complete combustion and smoke exhaust Immediate, short baking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

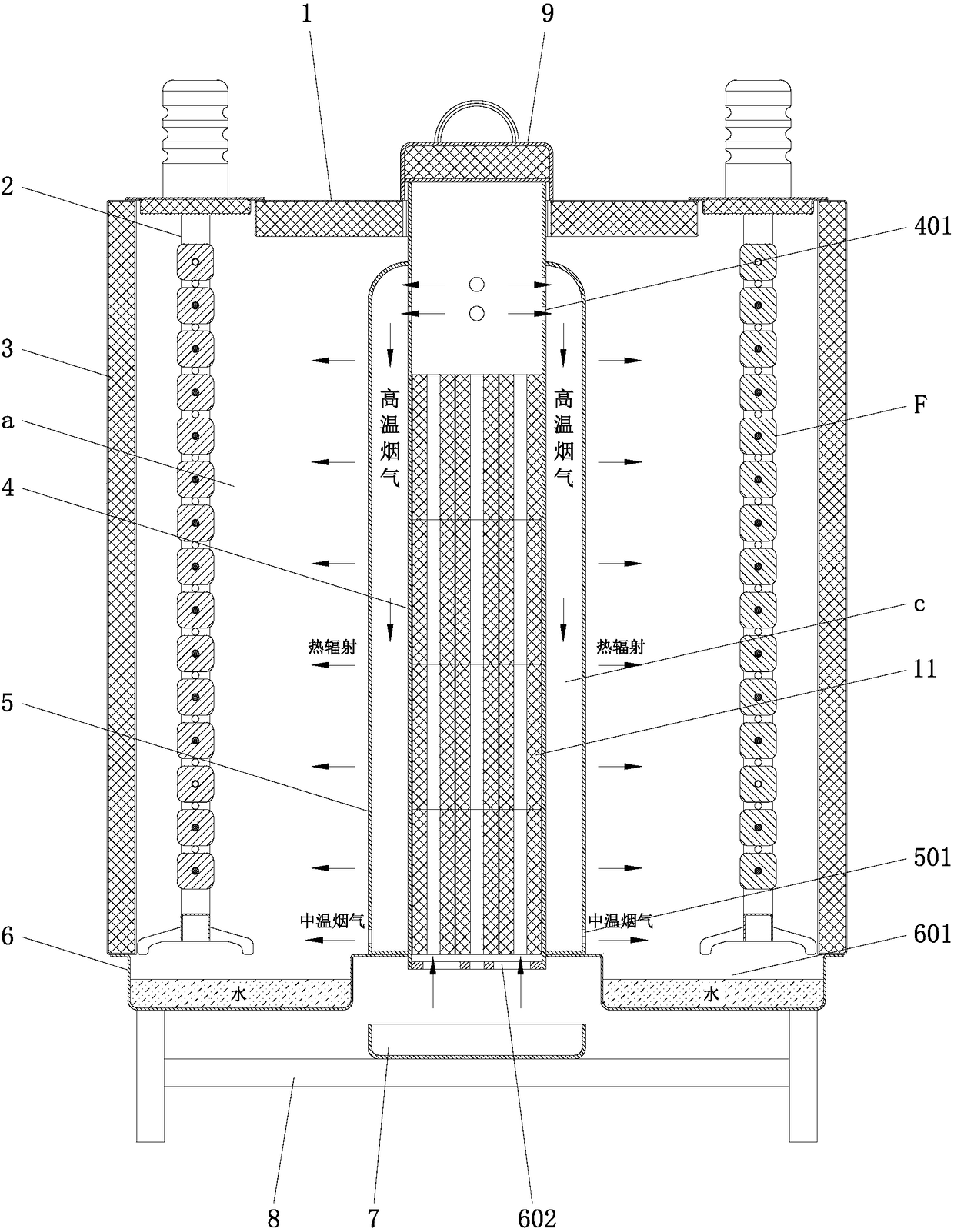

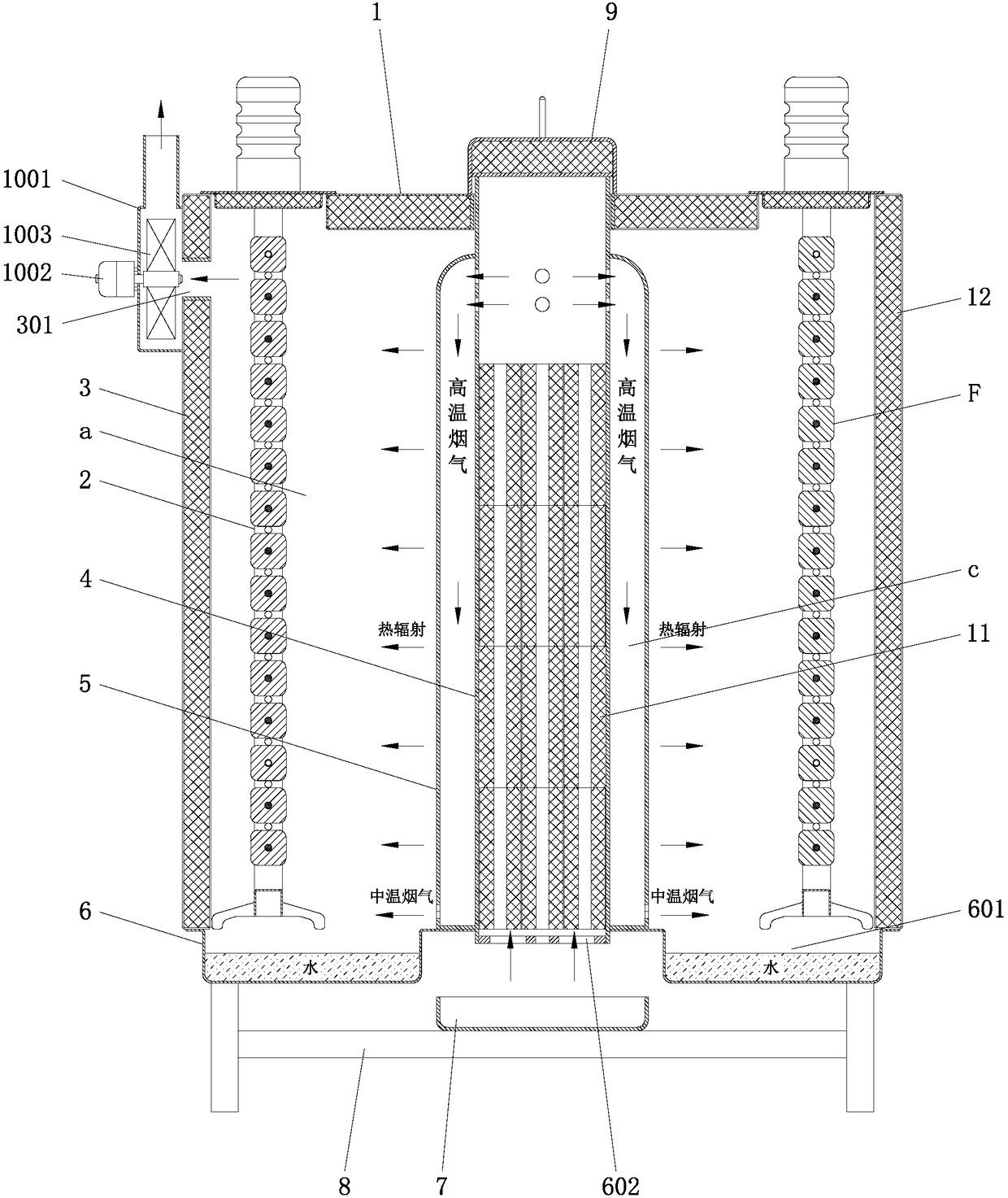

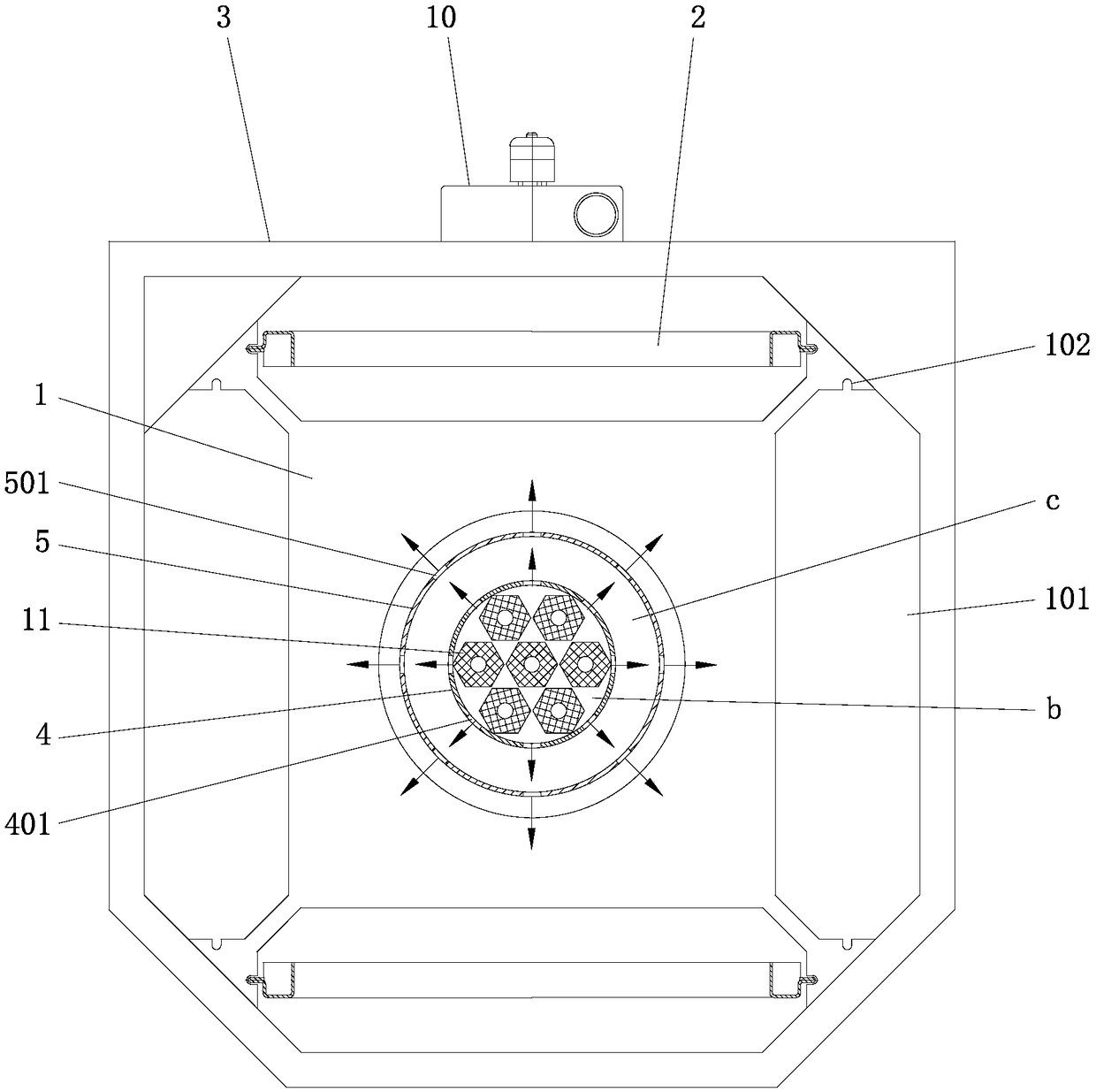

[0033] see Figure 1-Figure 3 , the strong discharge type radiant carbon stove includes a furnace body 3, a heating chamber a is arranged in the furnace body 3, and a grill 2 for hanging skewers is arranged in the heating chamber a, and the grill 2 can be set up to four according to actual needs. (not limited to four, can also be one to three, or more than five), each grill 2 is annularly distributed in the heating chamber a; a casing type radiation mechanism is arranged in the heating chamber a, and the casing type The radiation mechanism includes a sleeve-shaped combustion tube 4 and a sleeve-shaped radiation tube 5; the radiation tube 5 is sleeved on the outside of the combustion tube 4, and is spaced apart from each other to form an annular high-temperature flue gas channel c; the inner cavity of the combustion tube 4 is Combustion chamber b, combustion chamber b provides required space for charcoal 11 combustion, and the bottom of combustion chamber b communicates with the...

no. 2 example

[0063] see Figure 9 The horizontal flange grill of this embodiment is different from the first embodiment in that: the first bracket 203 and the second bracket 205 are respectively provided with left and right matching fixing grooves 2031; At the bottom of the corresponding fixing groove 2031; several sets of supporting structures composed of two matching fixing grooves 2031 are arranged, and are arranged linearly from top to bottom; in this embodiment, both ends of the baking stick 13 are supported by the fixing groove 2031 Fixed purpose, and the operation is more convenient and quicker.

[0064] Other parts not described are the same as those of the first embodiment, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com