High-efficiency and energy-saving roasting device for steel ladles

A baking device, high-efficiency and energy-saving technology, used in casting melt containers, metal processing equipment, casting equipment and other directions, can solve the problems of poor environmental protection, low combustion efficiency, low heat utilization rate, etc., to improve heat utilization rate, reduce Pollutant emissions, CO and NOx emission reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

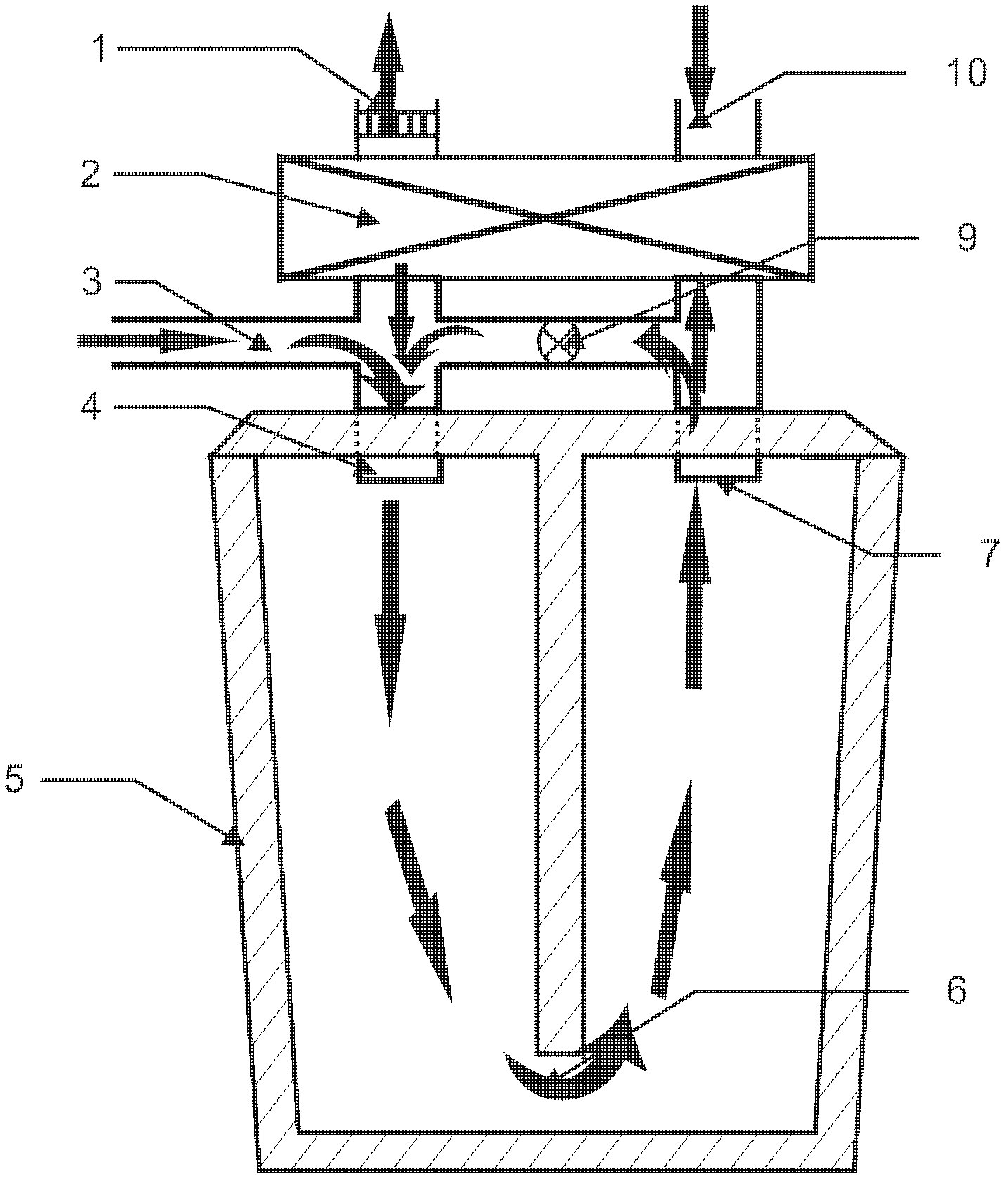

[0023] refer to figure 1 , a ladle high-efficiency and energy-saving baking device, comprising a ladle body 5, the upper part of the ladle body 5 is sealed and installed with a cover, the cover is provided with a nozzle 4 and a flue gas outlet 7, and a partition is arranged in the ladle body The plate 6 divides the interior of the ladle into two halves, and a flue gas passage is left at the bottom of the ladle body, and the nozzle 4 and the flue gas outlet 7 are respectively located on both sides of the partition plate 6 .

[0024] The flue gas passage is a plurality of semicircular notches at the bottom of the partition. Other shapes can also be selected for the flue gas channel.

[0025] The separator 6 adopts a light board coated with a far-infrared radiation coating on the surface.

[0026] The partition 6 is formed by splicing a plurality of partition units. This structure is convenient for assembly. Of course, it can also be prepared as a whole.

[0027] The nozzles 4...

Embodiment 2

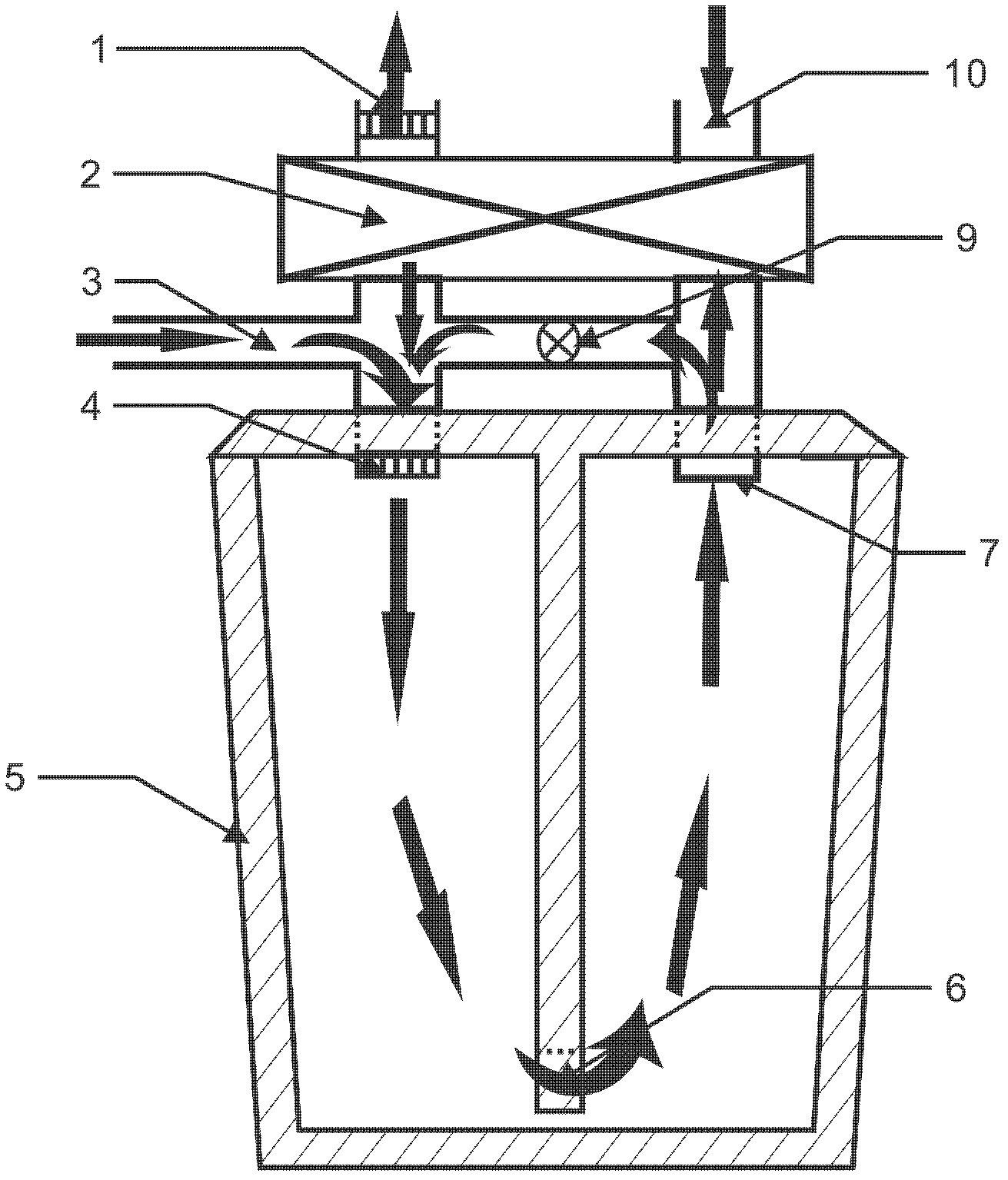

[0034] refer to figure 2 , in this embodiment, the flue gas channel is the gap between the bottom of the partition 6 and the bottom of the ladle cladding.

[0035] The baking device is also provided with a hot flue gas circulation device, a communication branch pipe is set between the inlet of the nozzle 4 and the flue gas outlet, and a hot flue gas circulation device 9 is arranged on the communication branch pipe, which can discharge the flue gas The flue gas of 7 directly flows back into the nozzle 4.

[0036] Other structures of this embodiment are the same as those of Embodiment 1.

[0037] The roaster consists of a ladle body, a clapboard inside the ladle, a cover, a burner, a catalytic combustion honeycomb, a heat exchanger, a catalytic purification device and a hot flue gas circulation device. Gas and combustion-supporting air are premixed and sprayed out through the nozzle to burn in the ladle, or enter the ladle after catalytic combustion in the catalytic honeycomb...

Embodiment 3

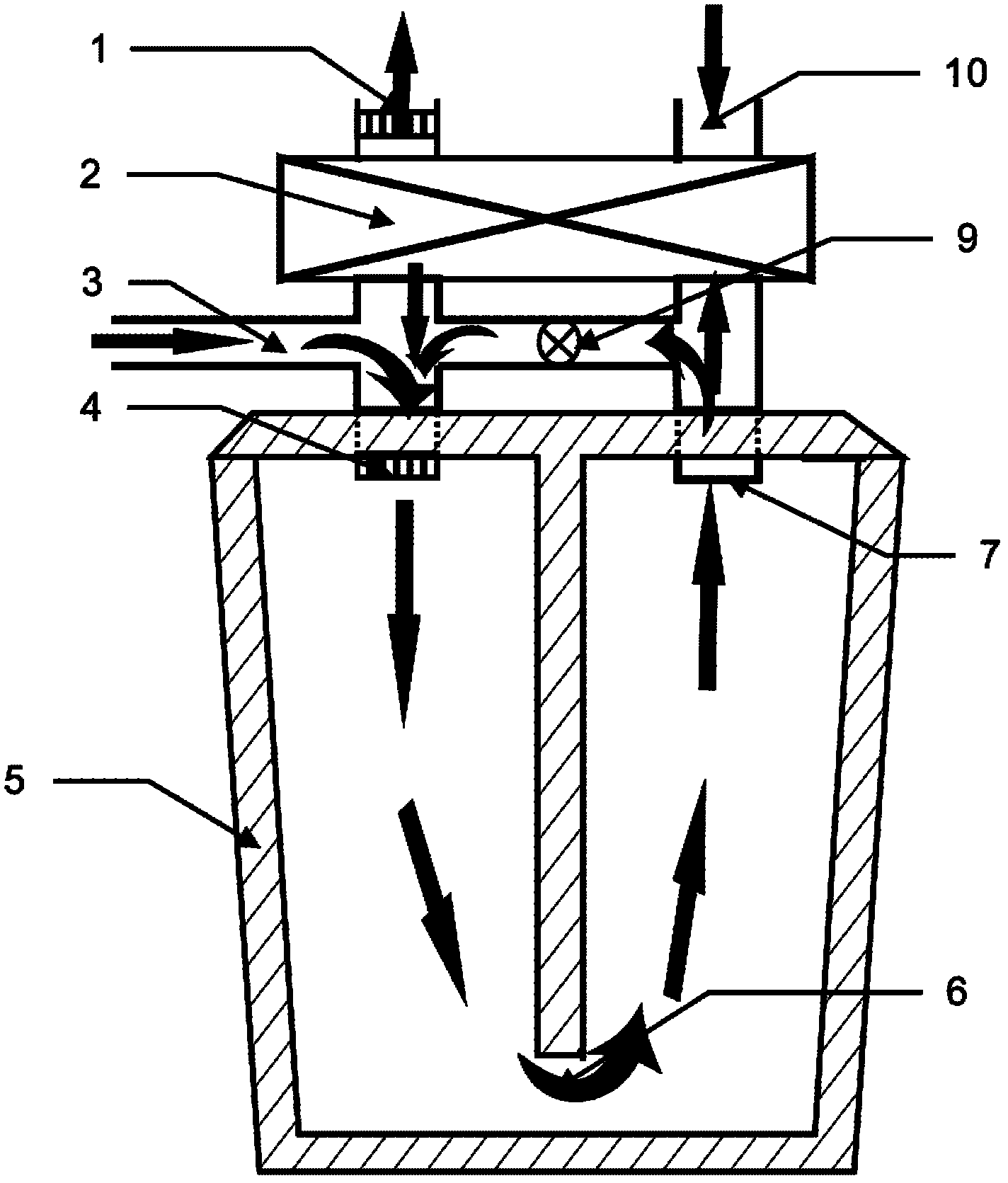

[0039] refer to image 3, the separator 6 is made of silicon carbide material with high radiation characteristics.

[0040] Other structures of this embodiment are the same as those of Embodiment 1.

[0041] The roaster consists of a ladle body, a clapboard inside the ladle, a cover, a burner, a catalytic combustion honeycomb, a heat exchanger, a catalytic purification device and a hot flue gas circulation device. The gas and combustion-supporting air enter the ladle after catalytic combustion in the catalytic honeycomb. The flue gas after combustion will not flow out of the ladle immediately, but will flow along the flue formed by the inner partition of the ladle, and first pass downward through the bottom of the ladle and the partition to form a The flue gas aisle, and then upwards into the flue gas inlet of the heat exchanger set on the cover, exchanges heat with the cold air in the heat exchanger, and is discharged after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com