High-efficiency baking and shaping device for vamp

A fixed device and high-efficiency technology, applied in the direction of shoe uppers, footwear, insoles, etc., can solve the problems of slow baking speed, low efficiency, and poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

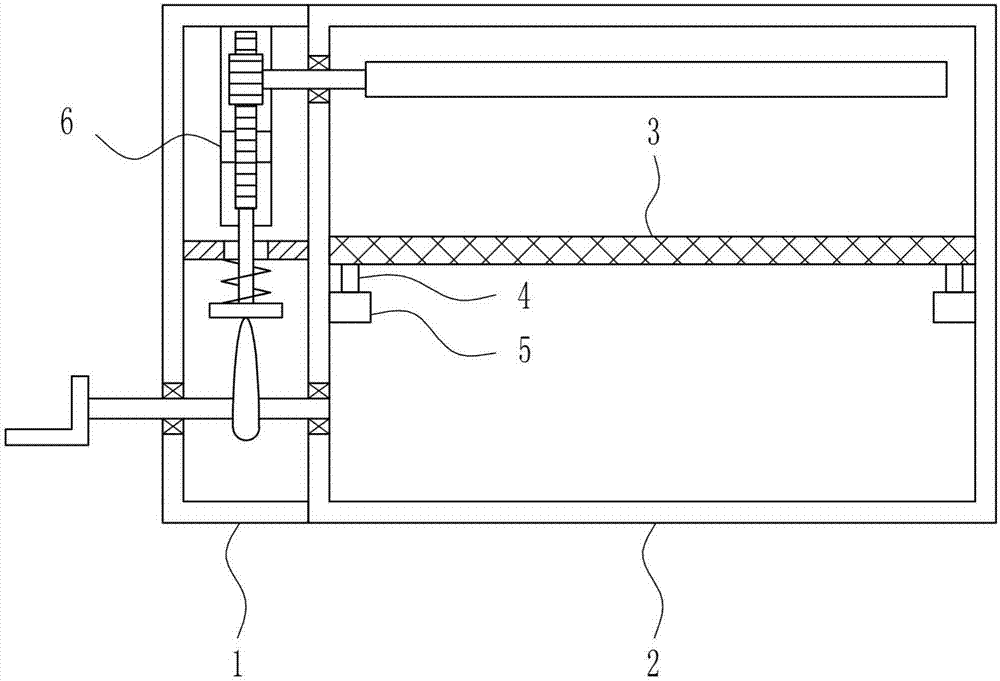

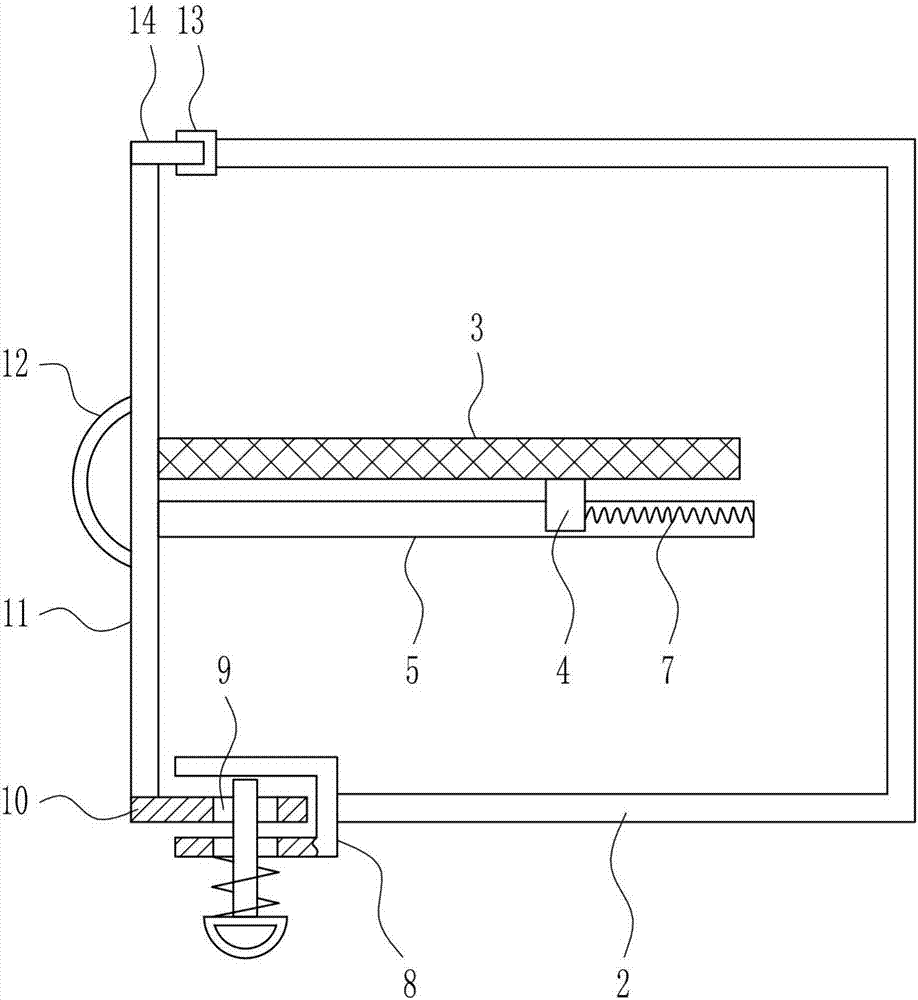

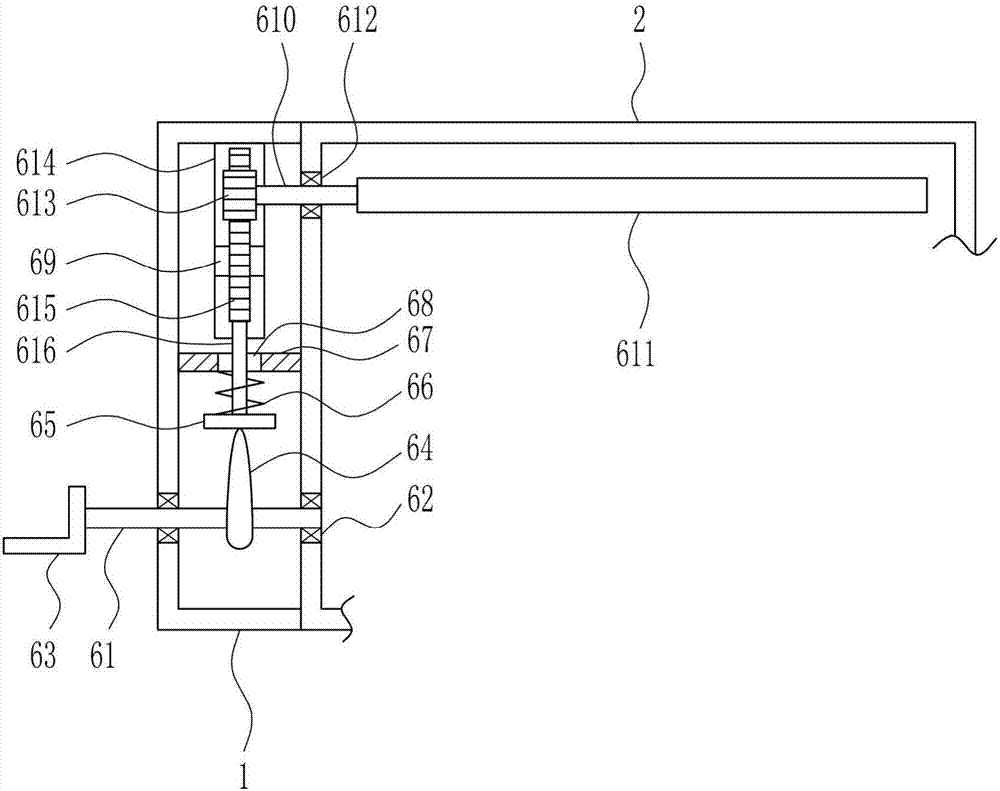

Embodiment 1

[0041] An efficient baking and setting device for shoe uppers, such as Figure 1-9 As shown, it includes a fixed groove 1, a working box 2, a placement net 3, a first slider 4, a first slide rail 5, a shaking heating device 6, a first spring 7, a fixing device 8, a fixing rod 10, and a baffle 11 , the first pull ring 12, concave electromagnet 13 and irony plug 14, the left side of the working box 2 is connected with a fixed groove 1, and the fixed groove 1 is provided with a shaking heating device 6, and the right side of the shaking heating device 6 is connected with the working box 2 connection, the left wall and the right wall in the working box 2 are symmetrically connected with the first slide rail 5, the first slide rail 5 is slidably connected with the first slide block 4, and the top of the first slide block 4 is connected with a placement net 3. The left and right ends of the net 3 are in contact with the work box 2, the first spring 7 is connected between the rear si...

Embodiment 2

[0043] An efficient baking and setting device for shoe uppers, such as Figure 1-9 As shown, it includes a fixed groove 1, a working box 2, a placement net 3, a first slider 4, a first slide rail 5, a shaking heating device 6, a first spring 7, a fixing device 8, a fixing rod 10, and a baffle 11 , the first pull ring 12, concave electromagnet 13 and irony plug 14, the left side of the working box 2 is connected with a fixed groove 1, and the fixed groove 1 is provided with a shaking heating device 6, and the right side of the shaking heating device 6 is connected with the working box 2 connection, the left wall and the right wall in the working box 2 are symmetrically connected with the first slide rail 5, the first slide rail 5 is slidably connected with the first slide block 4, and the top of the first slide block 4 is connected with a placement net 3. The left and right ends of the net 3 are in contact with the work box 2, the first spring 7 is connected between the rear si...

Embodiment 3

[0046] An efficient baking and setting device for shoe uppers, such as Figure 1-9As shown, it includes a fixed groove 1, a working box 2, a placement net 3, a first slider 4, a first slide rail 5, a shaking heating device 6, a first spring 7, a fixing device 8, a fixing rod 10, and a baffle 11 , the first pull ring 12, concave electromagnet 13 and irony plug 14, the left side of the working box 2 is connected with a fixed groove 1, and the fixed groove 1 is provided with a shaking heating device 6, and the right side of the shaking heating device 6 is connected with the working box 2 connection, the left wall and the right wall in the working box 2 are symmetrically connected with the first slide rail 5, the first slide rail 5 is slidably connected with the first slide block 4, and the top of the first slide block 4 is connected with a placement net 3. The left and right ends of the net 3 are in contact with the work box 2, the first spring 7 is connected between the rear sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com