Patents

Literature

99results about How to "Bake fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quick-drying self-flow iron runner castable material and application method thereof

InactiveCN101898897AExtended service lifeEasy constructionBlast furnace componentsBlast furnace detailsSilica fumeAluminium

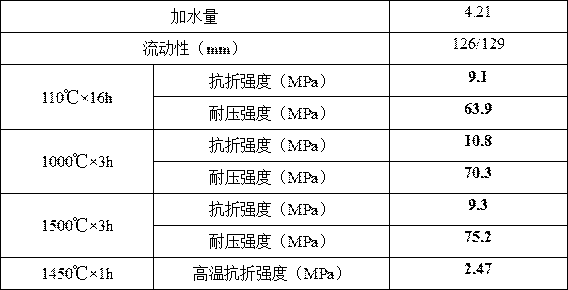

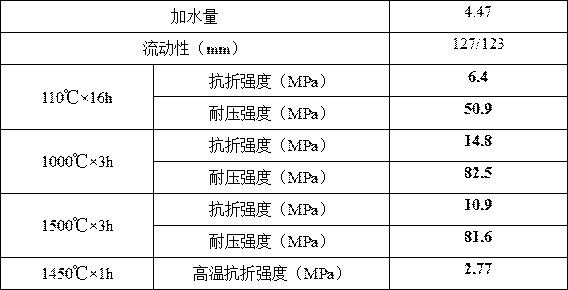

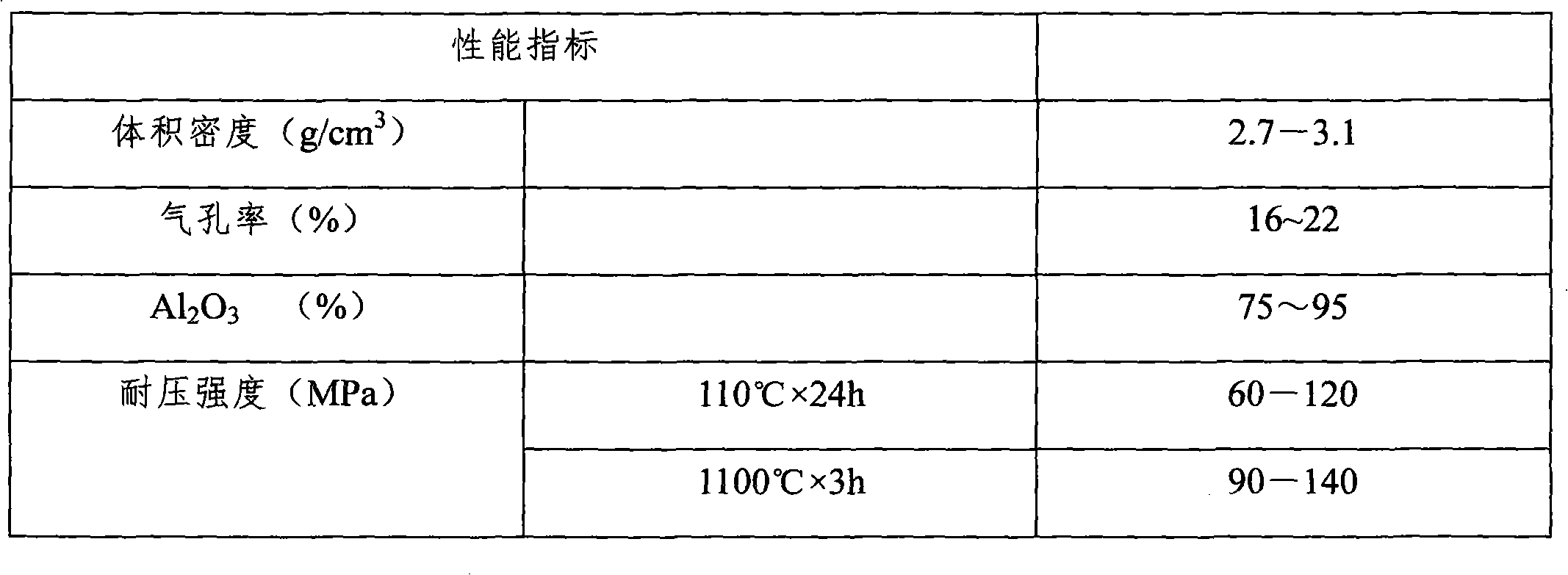

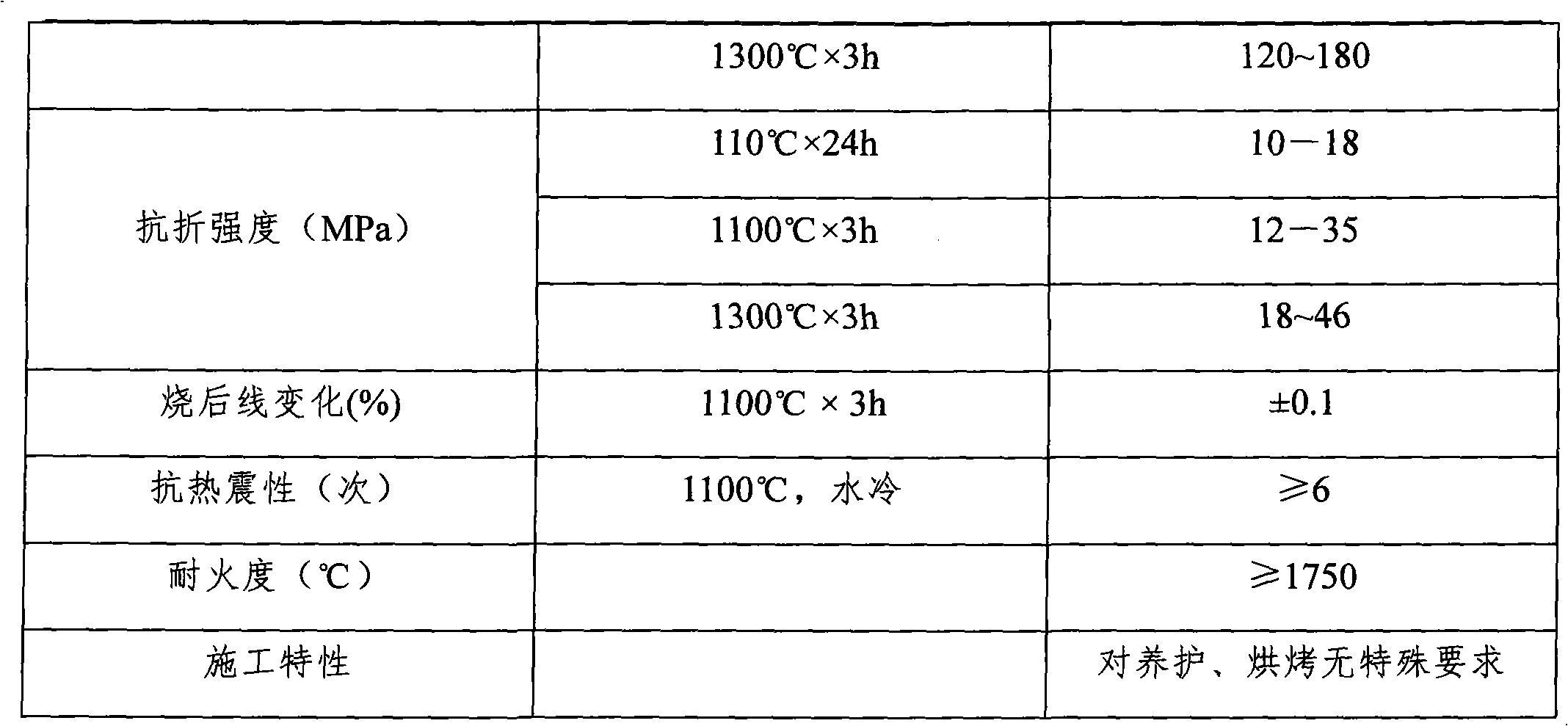

The invention relates to a quick-drying self-flow iron runner castable material which comprises the following chemical components in percentage by weight: 60-80% of brown alumina particles, 5-15% of brown alumina powder, 5-15% of silicon carbide particulate material, 3-13% of silicon carbide fine powder, 0-4% of spherical asphalt, 0-6% of silicon oxide micro powder, 1-7% of aluminum oxide micro powder, 0-6% of pure calcium aluminate cement, 0-1% of aluminium metal powder, 0-2% of silica powder, 0-0.5% of special fiber and 0-0.5% of water reducing agent, and the invention also relates to an application method thereof which comprises the steps of cooling, residue clearing, template raising, pouring and baking. The material of the invention integrates the advantages of castable materials and gunning materials into a whole, not only has the characteristic of long service life of the castable materials but also has the characteristics of convenient construction and rapid baking of the gunning materials; and a blast-furnace iron tap runner utilizes the quick-drying self-flow iron runner castable material to replace the iron runner ramming material or the iron runner castable material, and the service life of the blast-furnace iron tap runner is increased by 20%.

Owner:卿如民

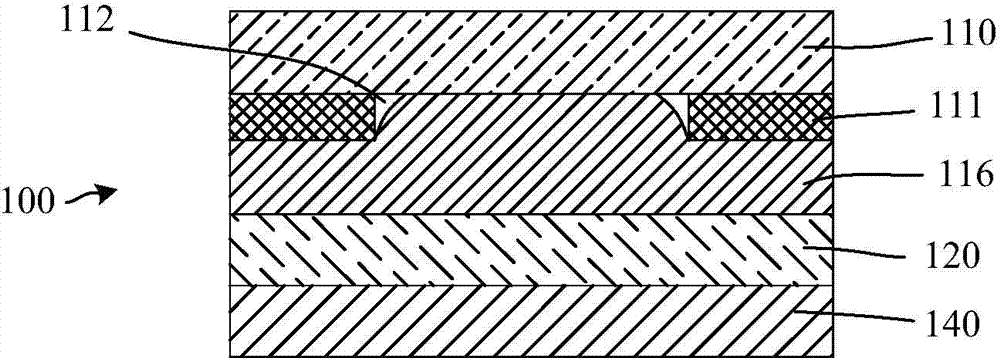

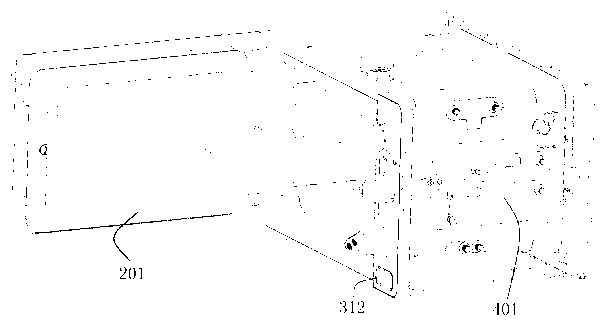

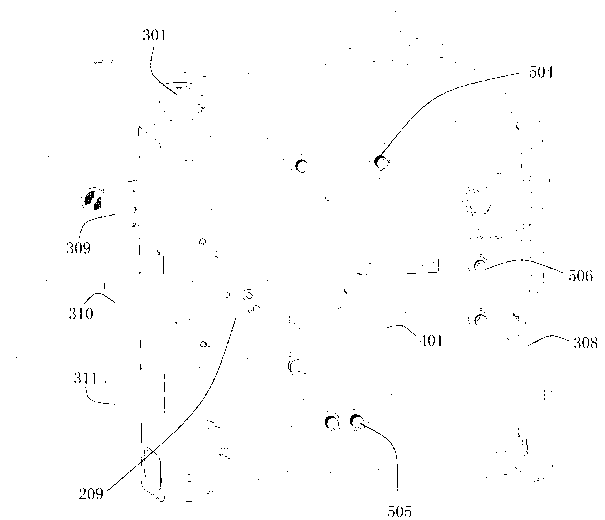

Cover plate structure, touch panel structure and protective panel structure of display device

InactiveCN103713768AReduce usageReduce thicknessInput/output processes for data processingFilling materialsDisplay device

The invention discloses a cover plate structure, a touch panel structure and a protective panel structure of a display device. The cover plate structure comprises a first substrate, a second substrate and optical cement for bonding the first substrate and the second substrate. An oil ink layer is printed on an area surrounding the first substrate. A filling material layer is filled in a recessed area defined by the oil ink layer on the first substrate in a display area and used for filling the recessed area. By filling the first substrate, namely the transparent substrate display area with window printing, namely the recessed area, use amount of the optical cement is less, and an optical cement layer is thin. Meanwhile, negative factors of bubbles, shadows in optical cement filling gaps and the like are avoided. By means of filling, the optical cement can achieve good bonding effect by using the thinner optical cement layer. The thickness of the whole cover plate structure can be reduced, slim design of the display device is facilitated, and integrity of the display area is facilitated.

Owner:黄彩娟 +1

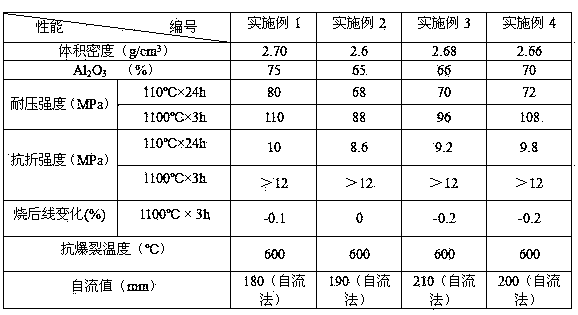

Quick-drying explosion-proof castable and producing process thereof

The invention discloses a castable used for an industrial furnace lining and a producing process thereof, and particularly relates to a quick-drying explosion-proof castable used for an industrial furnace lining and a producing process thereof. The producing process comprises four steps of raw material purchasing and testing, burdening, mixing and packaging. The producing process of the invention has the advantages of realizing quick-drying (rapid hardening) and fast stripping of the castable, and rapid baking without burst or explosion. With greatly shortened construction time and baking time, production pace is speeded up, a large quantity of energy is saved, emission of carbon dioxide and nitrogen oxide is significantly reduced and economic and social benefits are prominent.

Owner:LUOYANG KECHUANG NEW MATERIAL CO LTD

Anti-erosion iron runner castable for large blast furnace

InactiveCN111574206APrevent penetrationLow apparent porosityCeramicwareOxidation resistantCarbon black

The invention relates to an anti-erosion iron runner castable for a large blast furnace. The material comprises, according to weight percentage, 58-64 parts of compact brown fused alumina particles, 2-5 parts of white corundum particles, 16-23 parts of silicon carbide, 5-7 parts of aluminum oxide micro-powder, 2-3 parts of pure calcium aluminate cement, 2-3 parts of silicon dioxide micro-powder, 1.5-2.5 parts of spherical asphalt particles, 0.5-1.2 parts of carbon black powder, 1.5-3.5 parts of metal silicon powder, 0.2-0.6 part of boron carbide, 0.1-0.2 part of metal aluminum powder, 0.15-0.2part of a water reducing agent, 0.6-1 part of an anti-erosion agent and 0.05-0.08 part of explosion-proof fibers. According to the castable, the service life of a primary runner of a main runner is prolonged, and the stability of safe operation of an iron runner is improved. It is verified that the requirements for rapid baking without cracking, erosion resistance, oxidation resistance, slag adhesion resistance and iron flux can be met, the iron flux can reach 180000 tons or above without repairing, and good application prospects are achieved.

Owner:TANGSHAN GUOLIANG SPEICAL REFRACTORY MATERIAL

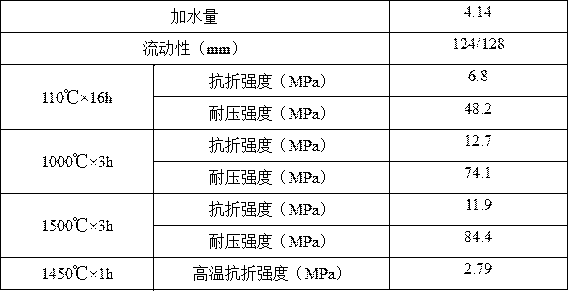

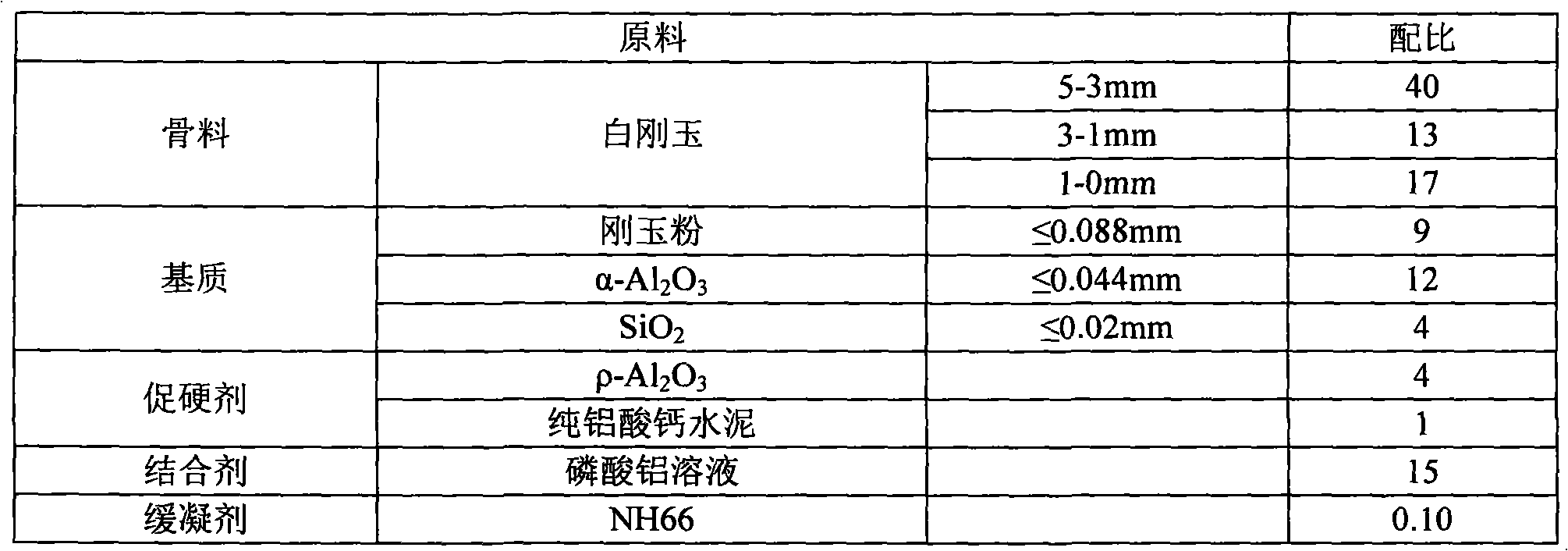

Phosphate bonded castable adopting composite hardening accelerator

ActiveCN102503460AImprove high temperature resistanceReduce cement contentPhosphateALUMINUM PHOSPHATE

The invention relates to a phosphate bonded castable adopting a composite hardening accelerator, belonging to the technical field of refractory materials. The phosphate bonded castable is prepared from the following main raw materials in percentage by mass: 55-75wt% of aggregate, 9-40wt% of powder material, 5-16wt% of composite hardening accelerator, 0.1-0.25wt% of corrosive inhibitor and 8-18wt% of bonding agent, wherein the aggregate is corundum or high-aluminum bauxite; the powder material comprises 0-37wt% of corundum powder, 0-37wt% of bauxite powder, 1-8wt% of SiO2 micropowder and 3-12wt% of alpha-Al2O3 micropowder; the composite hardening accelerator is pure calcium aluminate cement and rho-Al2O3 micropowder; the corrosive inhibitor is an NH66 type inhibitor, and comprises the main chemical component of bismuth oxyiodotannate; and the bonding agent is phosphate (aluminum phosphate solution), and the P2O5 / Al2O3 ratio is 1 / 2.5-1 / 3.8. The phosphate bonded castable has the advantages of high strength, wear resistance, thermal shock resistance, short stripping time, capability of being quickly baked and the like, and has excellent high-temperature resistance.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

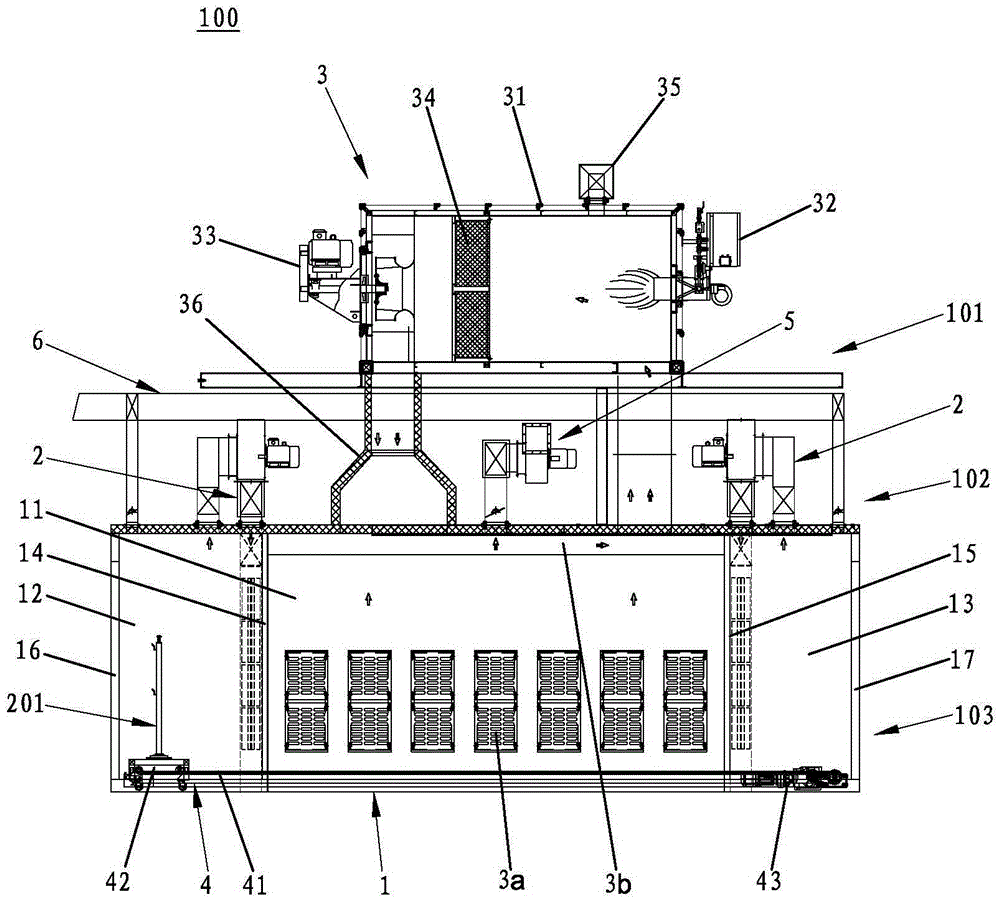

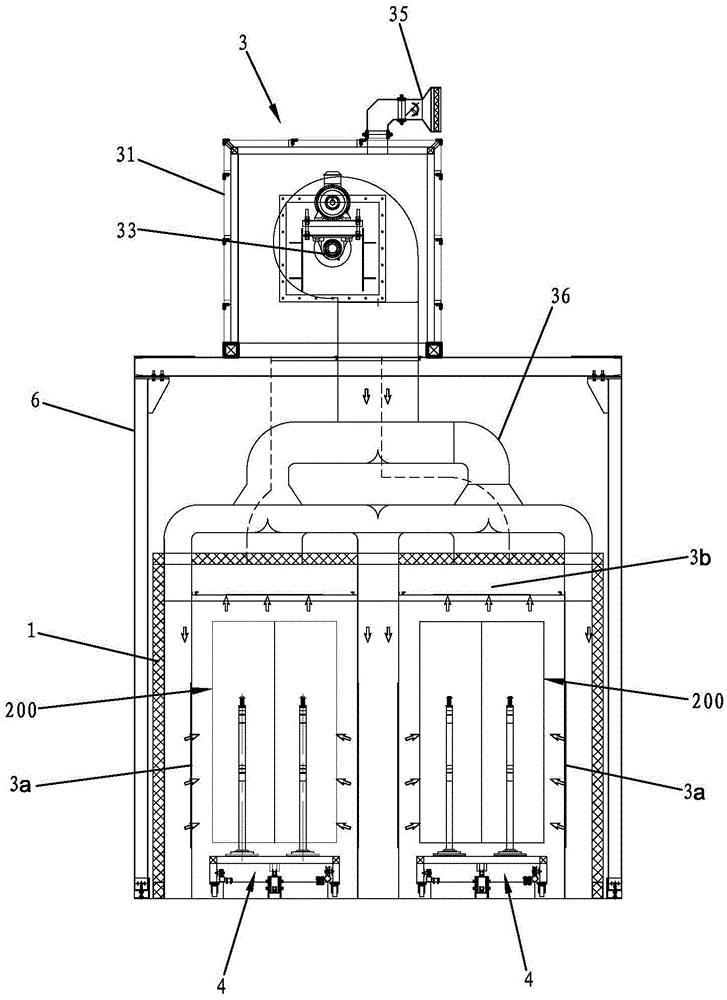

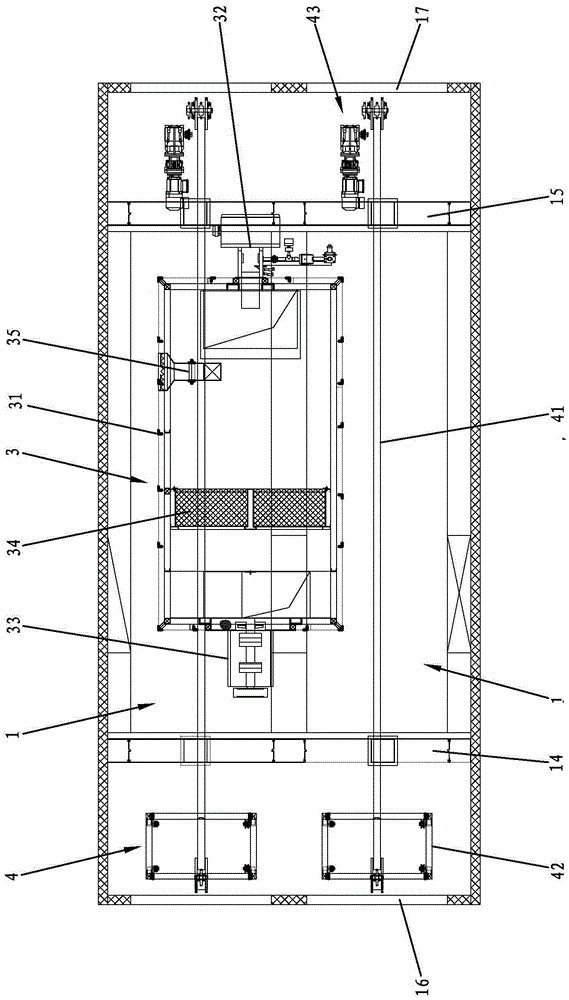

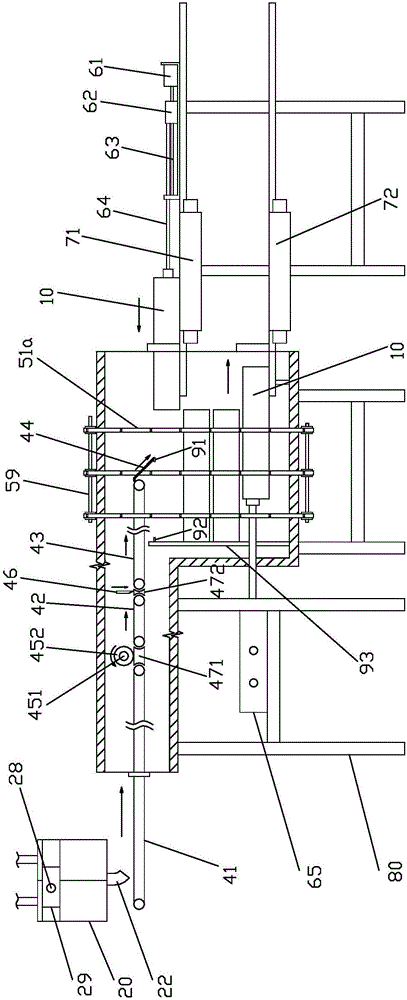

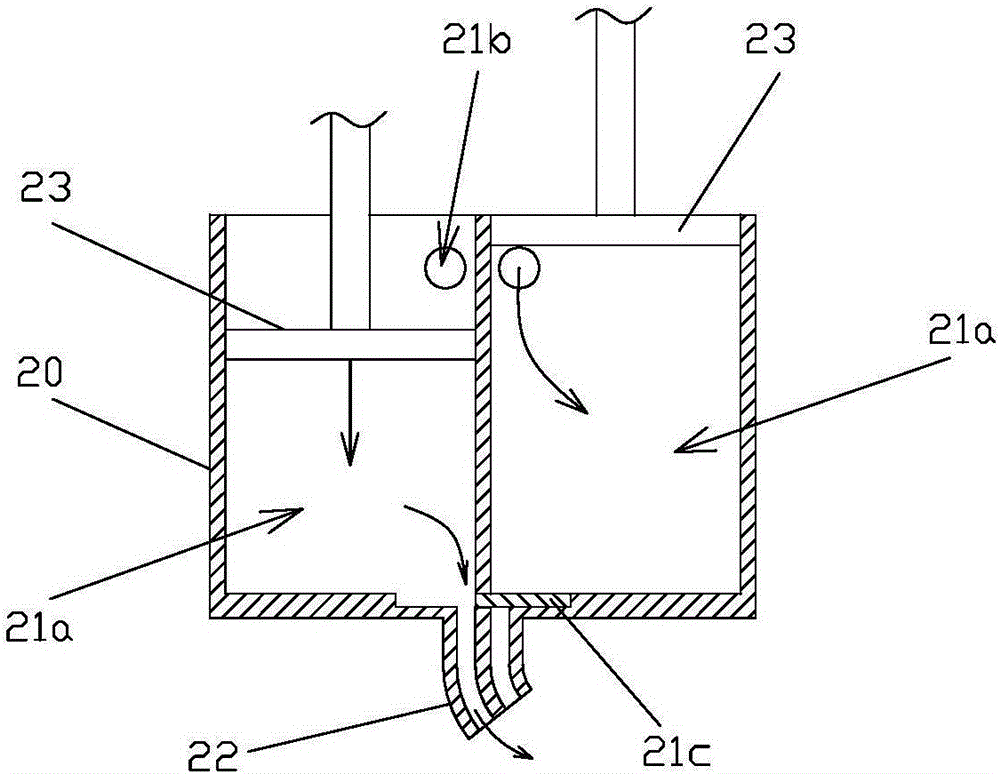

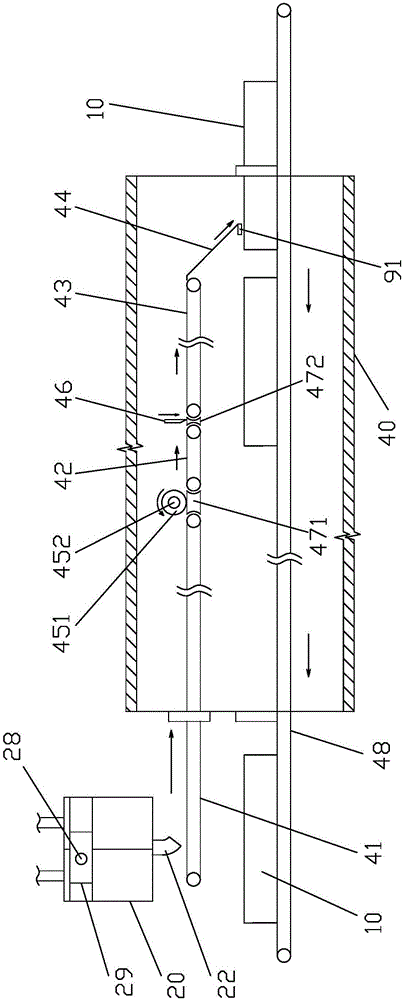

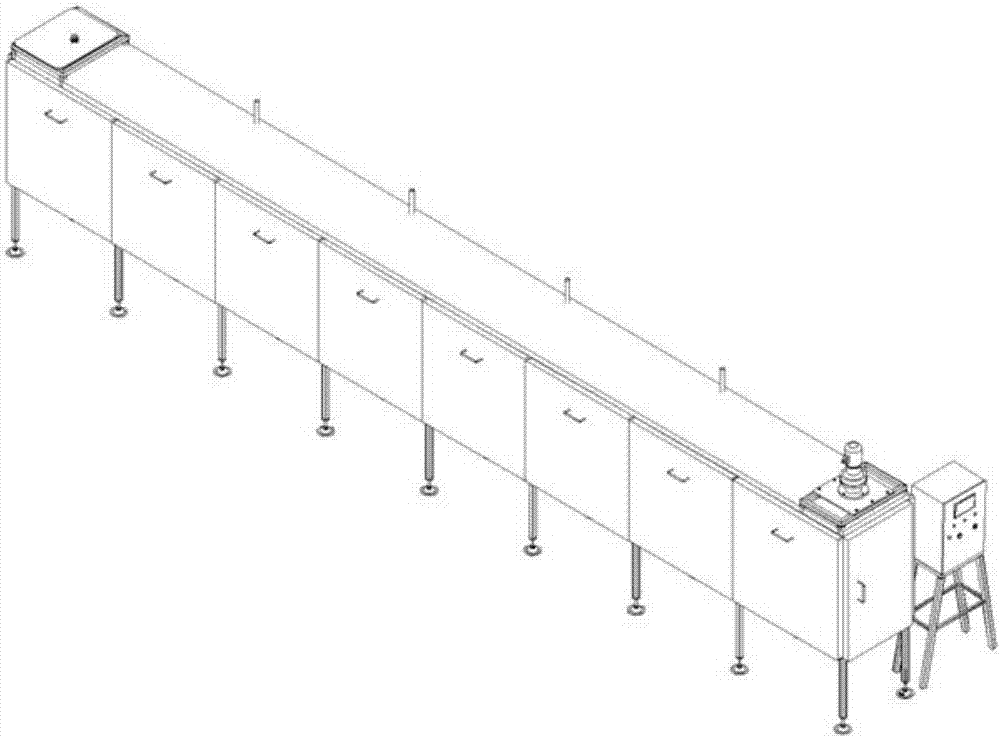

Open-type drying furnace for automobile parts

InactiveCN105486058AEliminate switching stepsBake fastDrying gas arrangementsDrying machines with progressive movementsEngineeringEnergy conservation

The invention discloses an open-type drying furnace for automobile parts. The open-type drying furnace comprises a main body of a furnace body, an air curtain machine, a hot air circulating system and a conveying chain, wherein the main body of the furnace body is provided with a drying region as well as a levelling region and a cooling region which are respectively communicated with the drying region, and the levelling region and the cooling region are respectively communicated with the outside in an open way; the air curtain machine is respectively arranged between the levelling region and the drying region and between the drying region and the cooling region so as to spray an air curtain to partition the two adjacent regions; the hot air circulating system is arranged above the main body of the furnace body, and a hot air inlet and a hot air outlet are communicated with the drying region; and the conveying chain is arranged at the inner bottom of the main body of the furnace body and is used for conveying automobile parts input from an inlet of the furnace body to an outlet of the furnace body through the levelling region, the drying region and the cooling region. The open-type drying furnace for automobile parts has the advantages of high drying speed, high production efficiency and energy saving.

Owner:东莞丰裕电机有限公司

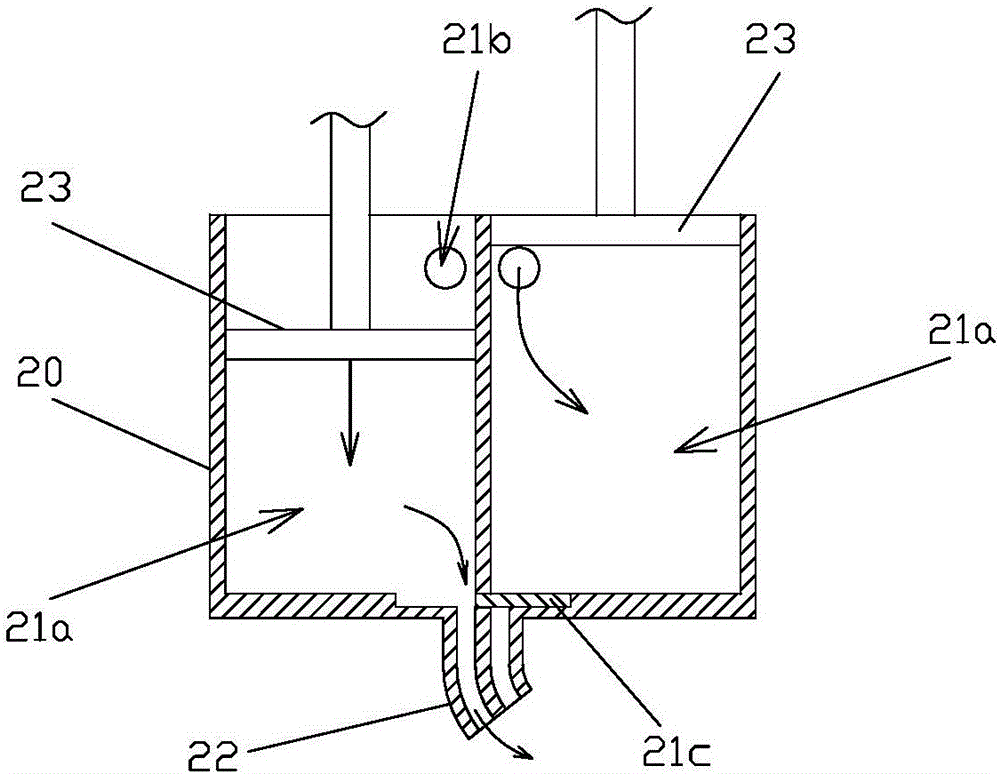

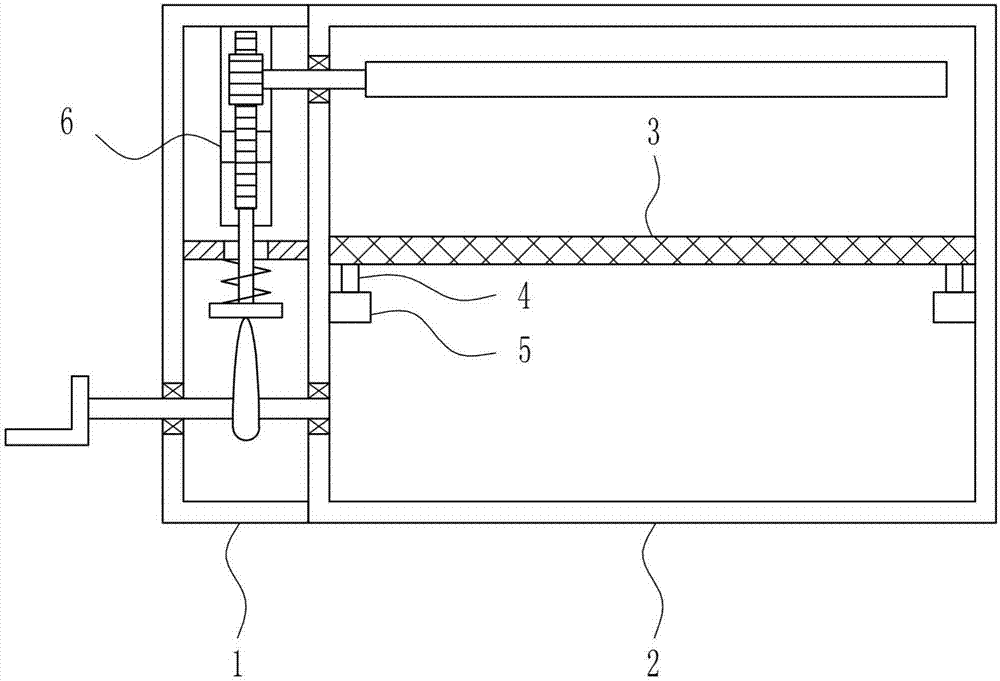

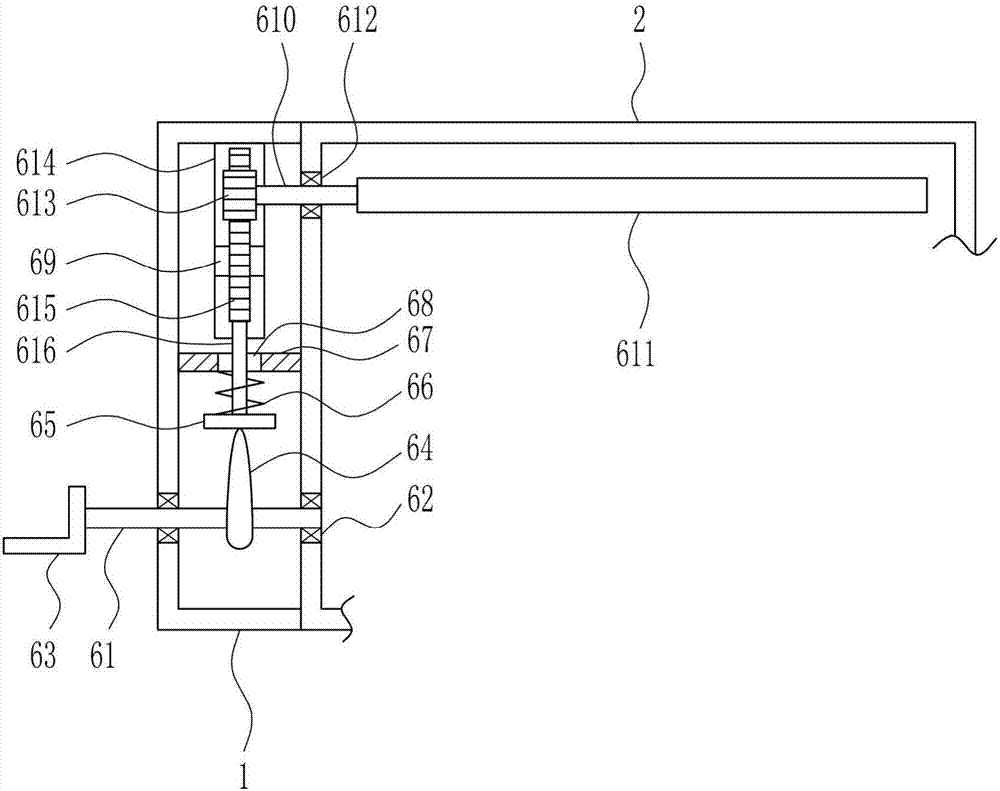

Food producing device

ActiveCN106106596AFast formingBake fastDough shaping and cutting apparatusDough extruding machinesEngineeringRapid prototyping

The invention relates to a food producing device which comprises a forming unit and a baking unit. The baking unit comprises an oven. A conveying belt A, a conveying belt B and a conveying belt C are sequentially arranged in the oven. The feed end of the conveying belt A is located outside the oven. The discharge end of the conveying belt A is located in the oven. The forming unit is arranged above the feed end of the conveying belt A. A supporting table A is arranged between the discharge end of the conveying belt A and the feed end of the conveying belt B. A segmenting mechanism for segmenting rice crust belts into rice crust thin strips is arranged above the supporting table A. A supporting table B is arranged between the discharge end of the conveying belt B and the feed end of the conveying belt C. A cut-off mechanism for cutting the rice crust thin strips into square rice crust pieces is arranged above the supporting table B. According to the technical scheme, the fried puffed glutinous-rice piece producing device can be used for producing fried puffed glutinous-rice pieces, rapid forming and baking of fried puffed glutinous-rice pieces are achieved, and the production efficiency of fried puffed glutinous-rice piece is improved.

Owner:河北鼎晨农业集团有限公司

Preparation method of cement gum for intermediate frequency furnace

The invention discloses a preparation method of cement gum for an intermediate frequency furnace. The preparation method comprises the following steps: first, uniformly mixing raw materials formed by compact brown aluminum oxide, compact brown aluminum oxide fine powder, a bonder, superfine powder, an additive and a detonation inhibitor; then, stirring the mixed raw materials and plastering the uniformly stirred cement gum around a coil; finally, after construction, naturally drying to complete hydration reaction to ensure the turn-to-turn and integral insulativity of the coil of the intermediate frequency furnace, wherein the coil has corresponding strength. The cement gum prepared by the method is long in furnace life, high in work efficiency, simple to maintain and suitable for a high-heat environment.

Owner:长兴泓矿炉料有限公司

Magnesium-calcium tundish dry vibrating material and preparation method thereof

The invention relates to a magnesium-calcium tundish dry vibrating material and a preparation method thereof. According to the technical scheme, the preparation method comprises the following steps of: mixing 68-80 percent by weight of magnesium-calcium sand, 9-16 percent by weight of magnesium sand fine powder and 4-17 percent by weight of hydrated sodium metasilicate; uniformly stirring the mixture; performing vibratory compaction on a tire membrane; baking at the temperature of 100-300 DEG C for 2-12 hours; and demolding, wherein the content of CaO of the magnesium-calcium sand is less than or equal to 60 percent by weight, the particle composition is 45-70 percent by weight when the particle size is 3-1 millimeter and 30-55 percent by weight when the particle size is less than or equal to 1 millimeter, the particle size of magnesium sand fine powder is less than 0.088 millimeter, the magnesium sand fine powder is more than one of sintered magnesium sand and electrically-molten magnesium sand, and the hydrated sodium metasilicate is more than one of sodium metasilicate pentahydrate and metasilicate nonahydrate. The vibrating material has a simple process, is environmentally-friendly and can be baked quickly. A prepared working lining has the characteristics of high intensity, high erosion resistance and long service life, and particularly has good heat preserving and molten steel purifying functions. The development requirement for clean steel smelting is met.

Owner:WUHAN UNIV OF SCI & TECH

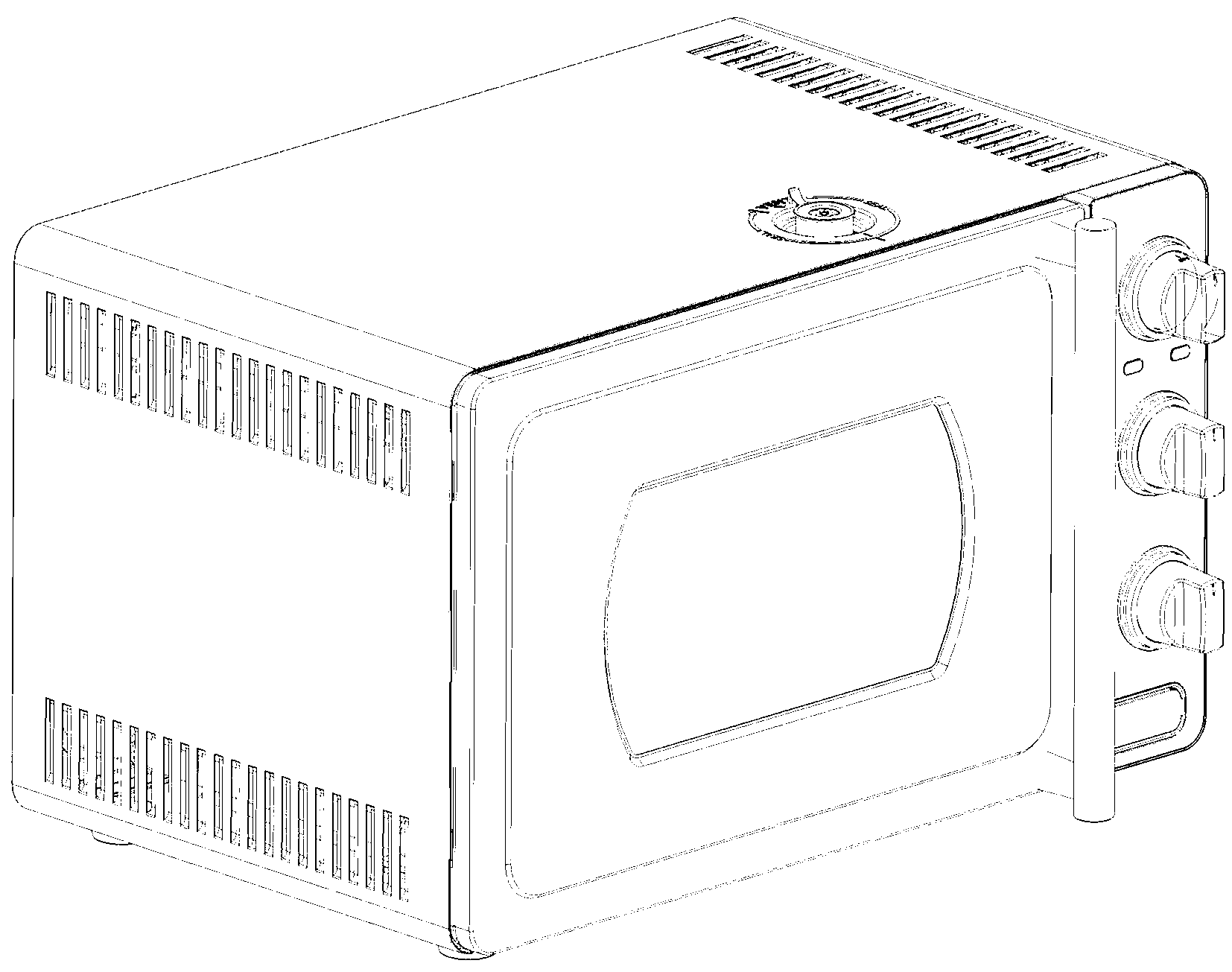

Oven

InactiveCN103211519APrevent heat lossIncrease temperatureRoasters/grillsProcess engineeringBoiling point

The invention relates to the technical field of oven manufacturing, and provides an oven, wherein the oven is sealed completely, loss of heat energy is avoided, required time of food baking is shortened greatly, energy is saved, and the environment is protected. The oven comprises an inner container assembly, a door assembly, a heating assembly and a control assembly, wherein the door assembly, the heating assembly and the control assembly are installed on the inner container assembly, the inner container assembly is a cavity formed in a seamless connection mode, sealing parts are installed at the joints between the door assembly and the inner container assembly, the joints between the heating assembly and the inner container assembly, and the joints between the control assembly and the inner container assembly, and a sealed container is formed. The oven is sealed completely, loss of the heat energy is avoided to the maximum, and the purposes of rapid baking, energy conservation and environment protection are achieved. Meanwhile, when the oven is used, air inside the oven is heated to expand and generate a certain amount of pressure, the boiling temperature of moisture of food inside the oven is raised, the temperature of the baked food is increased, and the required time of food baking is shortened greatly.

Owner:泰克厨房有限责任公司

Rapid drying casting material for blast furnace iron runner, and preparation method thereof

The present invention provides a rapid drying casting material for a blast furnace iron runner, and a preparation method thereof. According to the casting material, bauxite clinker, corundum, silicon carbide powder, corundum powder, and alumina micro-powder are adopted as main materials, a binder and explosion-proof fibers are adopted as auxiliary materials, the bauxite clinker, the corundum and the silicon carbide are subjected to material preparing according to a certain ratio, and added to a mixer to carry out stirring mixing, then the explosion-proof fibers prepared according to a certain ratio are added to the mixer to stir, the corundum powder and the alumina micro-powder are added to mix, the binder is added to mix the powder, uniform mixing is performed, the mixed rapid drying casting material is filled into a moisture-proof package bag, and the bag is sealed and placed in a dry place. Compared with the rapid drying casting material in the prior art, the rapid drying casting material of the present invention has the following advantages that: the preparation method is simple, rapid construction, rapid baking and rapid iron discharging can be achieved, characteristics of good rapid drying explosion-proof performance, good slag iron erosion resistance, and good thermal shock stability are provided, material cost is reduced, the iron runner construction and maintenance time is shortened, the blast furnace utilization coefficient and the yield can be effectively increased, and a service life of the iron runner casting material working layer can be prolonged.

Owner:孙志红

High-performance composite refractory material for kiln opening

The invention discloses a high-performance composite refractory material for a kiln opening. The high-performance composite refractory material is prepared from ingredients in percentage by weight: 30 to 44 percent of tabular corundum, 12 to 17 percent of rubing grain, 7 to 12 percent of composite alundum powder, 10 to 15 percent of andalusite, 5 to 10 percent of aluminum oxide micro powder, 3 to 8 percent of zircon sand, 2 to 4 percent of cyanite, 1 to 3 percent of silicon micro powder, 3 to 7 percent of nanometer silicon carbide powder, 3 to 6 percent of pure calcium aluminate cement, 4 to 6 percent of zirconium carbonate powder, 1 to 2 percent of zinc silicate powder, 1 to 2 percent of additives, 0.3 to 0.5 percent of additive heat-resistant steel fiber and 0.1 to 0.2 percent of dispersants. The high-performance composite refractory material for the kiln opening has the beneficial effects that the refractory material ingredients in the prior art are improved; the tabular corundum, the rubing grain and the composite alundum powder are used as aggregate ingredients; powder materials such as the nanometer silicon carbide powder, the zircon sand, the cyanite, the composite additives, the zirconium carbonate powder and the zinc silicate additive heat-resistant steel fiber are added; the obtained high-performance composite refractory material for the kiln opening has the advantages that bursting does not occur after fast baking; the wear-resistant performance at high temperature is good; the performance of resisting the erosion of cement clinker atmosphere generated by different raw materials is realized.

Owner:北京兰海金诚耐火材料有限责任公司

Cement for intermediate frequency furnace lining

InactiveCN104030704AImprove structural strengthOptimize material functionIntermediate frequencyCorundum

The invention discloses cement for an intermediate frequency furnace lining. The cement is prepared from the components in percentage by mass: 70%-80% of dense corundum, 10%-20% of dense corundum powder, 5%-15% of a binder, 0.5%-2% of superfine powder, 0.5%-3% of an additive and 0.1%-5% of an explosion-proof agent. The cement has the characteristics of prolonged service life of the intermediate frequency furnace, high operation efficiency and simple maintenance and adapts to a highly heat environment.

Owner:长兴泓矿炉料有限公司

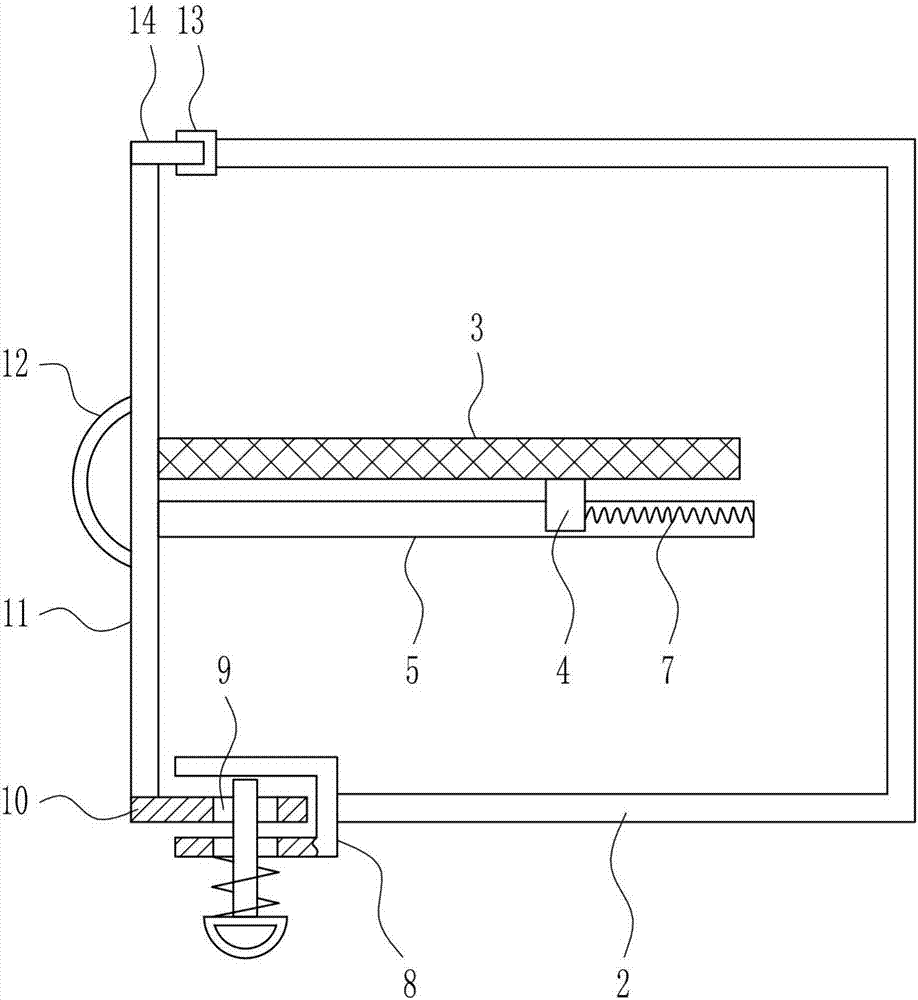

Food forming and baking integrated production equipment

The invention relates to food forming and baking integrated production equipment which comprises a forming unit and a baking unit. The baking unit comprises a baking oven, a conveyor belt A, a conveyor belt B and a conveyor belt C are sequentially arranged in the baking oven in an extension manner, a feed end of the conveyor belt A is positioned outside the baking oven, a discharge end of the conveyor belt A is positioned in the baking oven, the forming unit is arranged above the feed end of the conveyor belt A, a support table A is arranged between the discharge end of the conveyor belt A and a feed end of the conveyor belt B, a splitting mechanism for splitting rice crust bands into various rice crust strips is arranged above the support table A, a support table B is arranged between a discharge end of the conveyor belt B and a feed end of the conveyor belt C, and a cutting-off mechanism for splitting the rice crust strips into square rice crust pieces is arranged above the support table B. According to the technical scheme, the food forming and baking integrated production equipment has the advantages that the food forming and baking integrated production equipment which is glutinous rice crust production equipment can be used for producing glutinous rice crust, the glutinous rice crust can be quickly formed and baked, and accordingly the glutinous rice crust production efficiency can be improved.

Owner:ANQING WANCAO QIANMU AGRI TECH

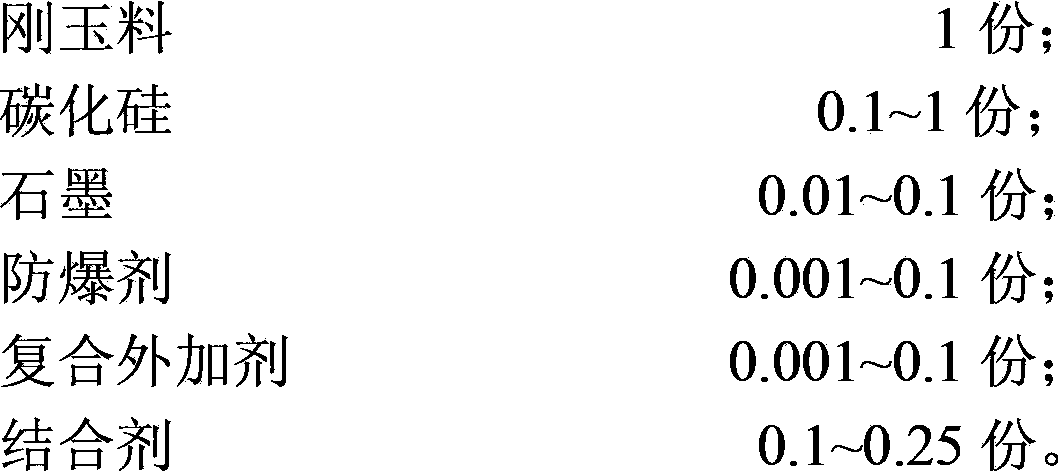

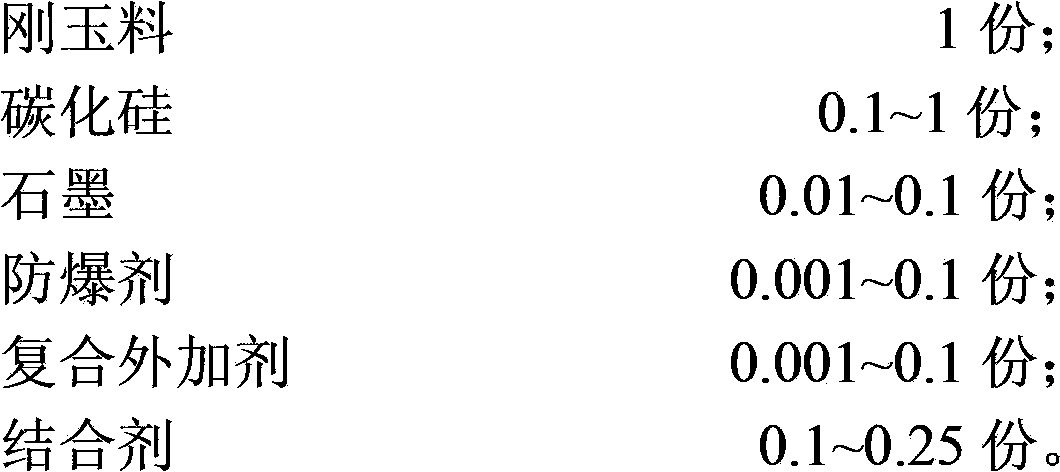

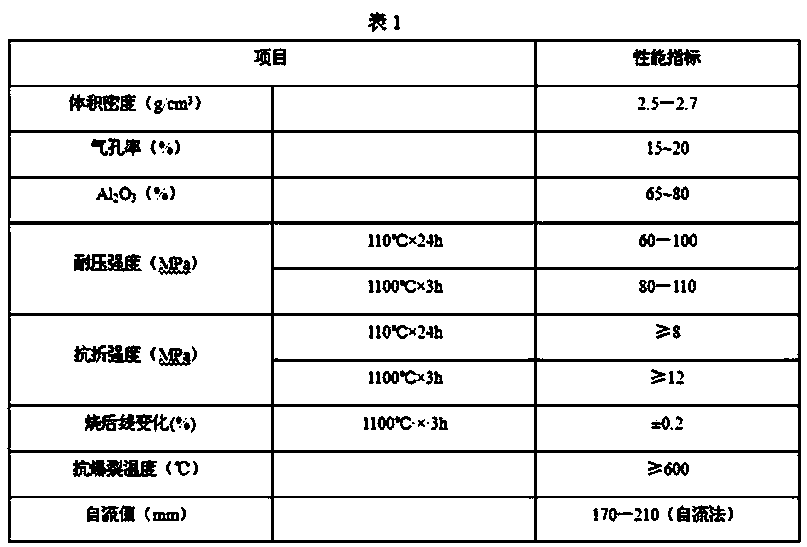

Wear resistance casting material for ladle

The present invention relates to a wear resistance casting material for ladle. The wear resistance casting material comprises, by weight, 1 part of a corundum material, 0.1-1 part of silicon carbide, 0.01-0.1 part of graphite, 0.001-0.1 part of an explosion-proof agent, 0.001-0.1 part of a composite additive, and 0.1-0.25 part of a binding agent. According to the present invention, the cement component-free inorganic nanometer binding agent is adopted, good quality electrofusion or sintering corundum or special grade alumina clinker is adopted as the main material, silicon carbide, graphite, an explosion-proof agent and the like are added, and variety and the number of a composite additive are optimized to prepare the wear resistance casting material with characteristics of rapid baking, high high-temperature strength, good high-temperature wear resistance, excellent thermal shock stability and good construction performance; and ladle bottom of the bottom washing type ladle with a capacity of one ton is used in gray iron casting, wherein the service life can be more than 3000 times and is more than two times the service life of the conventional material, and slag removing is easy.

Owner:天津振普筑炉衬里工程有限公司

Early strength anti-detonation fireproof self-flow material

The invention belongs to the technical field of refractory materials, and particularly discloses an early strength anti-detonation fireproof self-flow material. The material comprises the following raw materials: alumina or flint clay, pyrophyllite, silicon carbide, alumina based alpha-Al2O3 micropowder, SiO2 micropowder and the like. Aluminate cement serves as a binding agent, and a composite additive and an antidetonator are added. The self-flow material has the advantages of early strength, high strength, detonation resistance, shortened demold time, rapid baking and the like, and has good resistance to high temperature.

Owner:郑州瑞泰耐火科技有限公司

Quick-drying self-flowing castable used for blast furnace casting runner and made from reclaimed waste castable

InactiveCN108046814AReduce manufacturing costComply with environmental policySilicon dioxideWater reducer

The invention discloses quick-drying self-flowing castable used for a blast furnace casting runner and made from reclaimed waste castable. The quick-drying self-flowing castable is mainly made from, by weight, 48-52% of reclaimed waste castable, 15-20% of compact corundum, 14-18% of black silicon carbide, 3-7% of silicon nitride, 1-2% of a composite water reducer, 1-2% of a composite anti-knock agent, 1-3% of SiO2 sol, 1-3% of silicon dioxide micropowder, 2-4% of activated aluminium oxide micropowder and 2-4% of silica micropowder. Waste self-flowing castable used for an iron runner is taken as a main raw material to prepare quick-drying self-flowing castable which is high in additional value and good in performance, is superior and is used for a blast furnace casting runner. The production cost of an enterprise is reduced, the natural environment is protected, the national environmental protection policy is met, and a great amount of energy is saved. The quick-drying self-flowing castable is significant in economic and social benefit.

Owner:河南欣昌耐材股份有限公司

Bake-free casting material for ladle online roaster cladding lining and preparation method thereof

The invention relates to bake-free casting material for ladle online roaster cladding lining and a preparation method thereof, belonging to the technical field of nonmetal material fireproof materials; the preparation method comprises the following steps: using sintered mullite and andalusite as raw materials, and using hydration heating action of metal aluminum powder and water at a room temperature and action mechanisms of self-reaction, self-sintering and self-expansion of Al203 and SiO2 of ingredient on a low temperature condition so as to manufacture a product; the bake-free casting material manufactured by above-mentioned components has excellent performances such as large combination strength, good thermal shock resistance and the like and is used for manufacturing the ladle onlineroaster cladding lining; in addition, life cycle is more than 3 months.

Owner:LAIWU IRON & STEEL GRP

Continuous casting tundish cover pouring material and preparation method thereof

The invention discloses a continuous casting tundish cover pouring material and a preparation method thereof, and belongs to the technical field of refractory materials. The continuous casting tundish cover pouring material is prepared through the following raw materials in parts by weight: 60 to 80 parts of black aloxite, 10 to 30 parts of fine high alumina bauxite powder, 2 to 5 parts of silica powder, 2 to 5 parts of cement, 0 to 3 parts of stainless steel fiber, 0 to 0.2 part of detonation inhibitor, and 0.1 to 0.4 part of water reducing agent. The invention also discloses the preparation method of the continuous casting tundish cover pouring material. According to the continuous casting tundish cover pouring material prepared by the method, the cost can be greatly reduced; in addition, the tundish cover product can be quickly roasted, so that the cost of roasting can be decreased, and as a result, the economic benefit can be effectively increased for an enterprise.

Owner:北京利尔高温材料股份有限公司

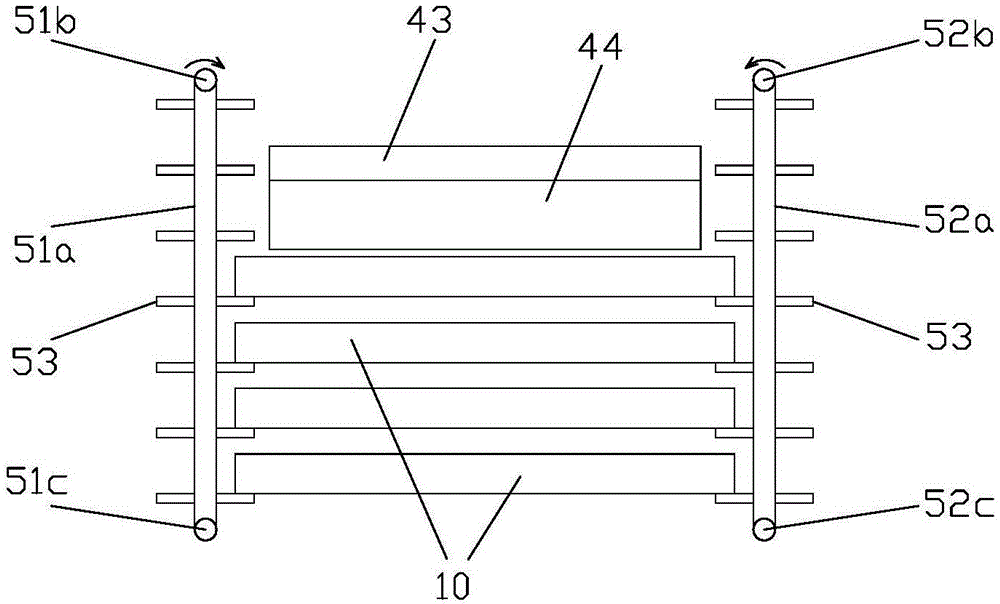

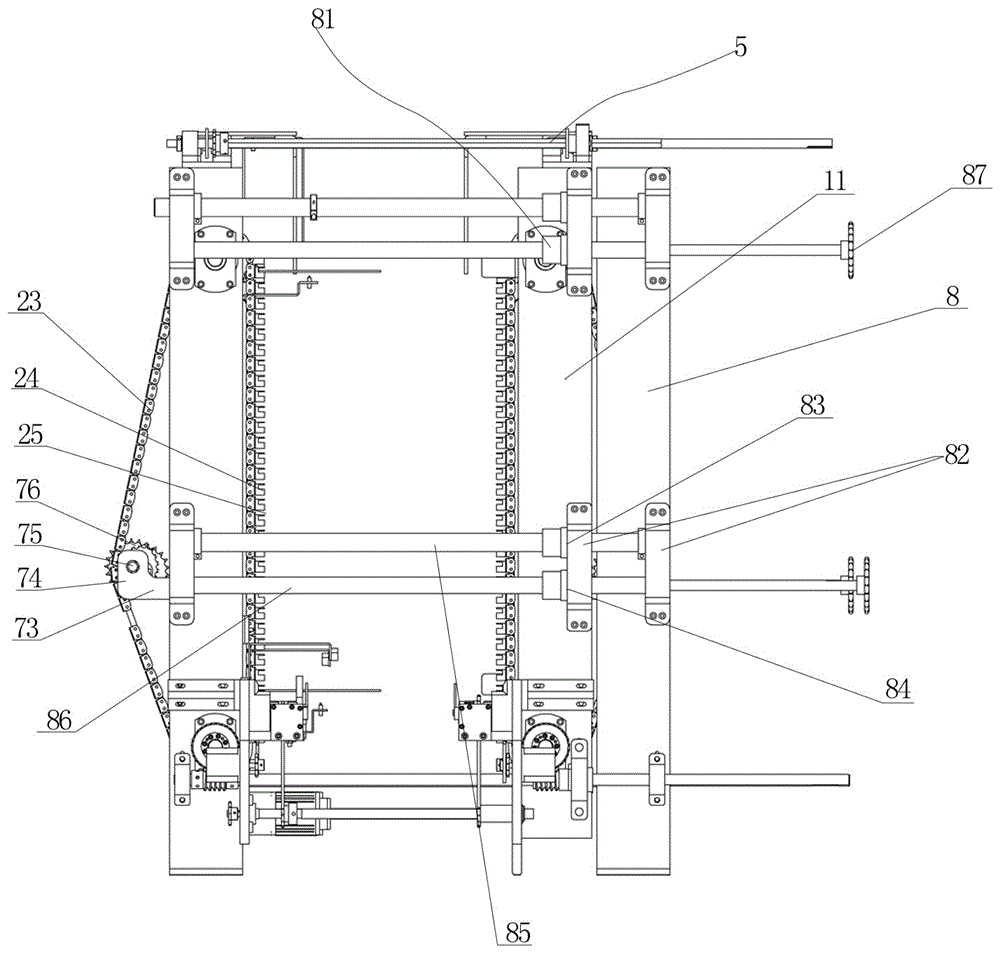

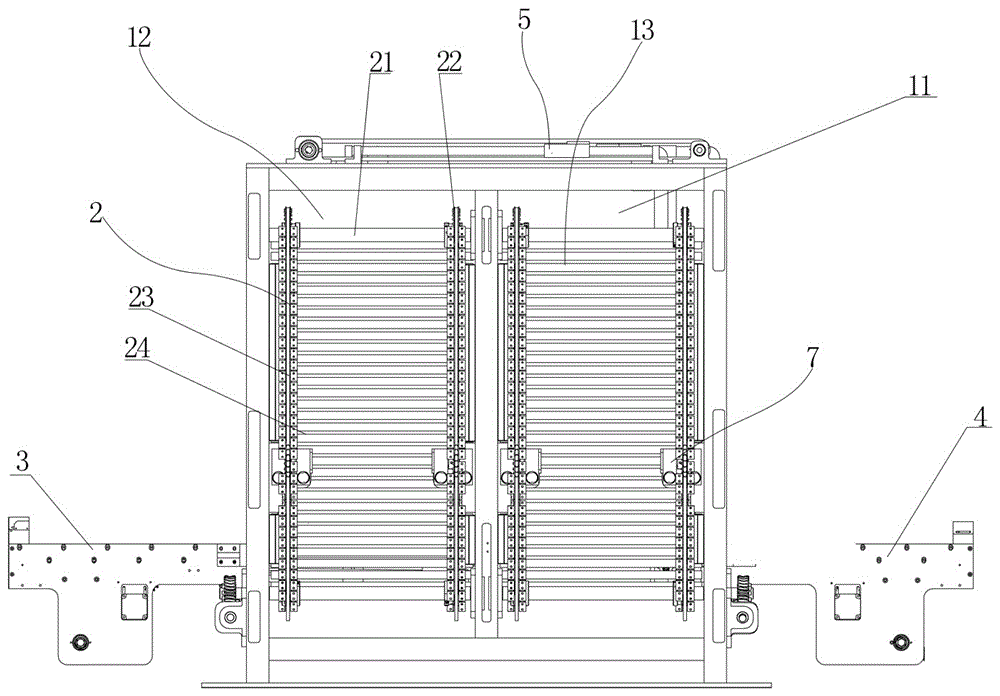

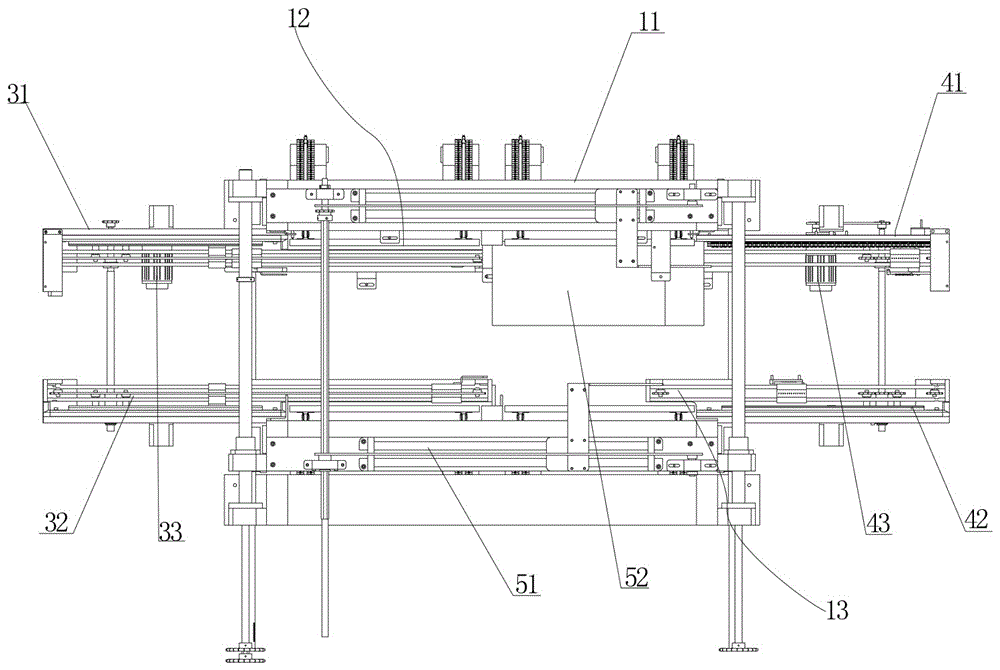

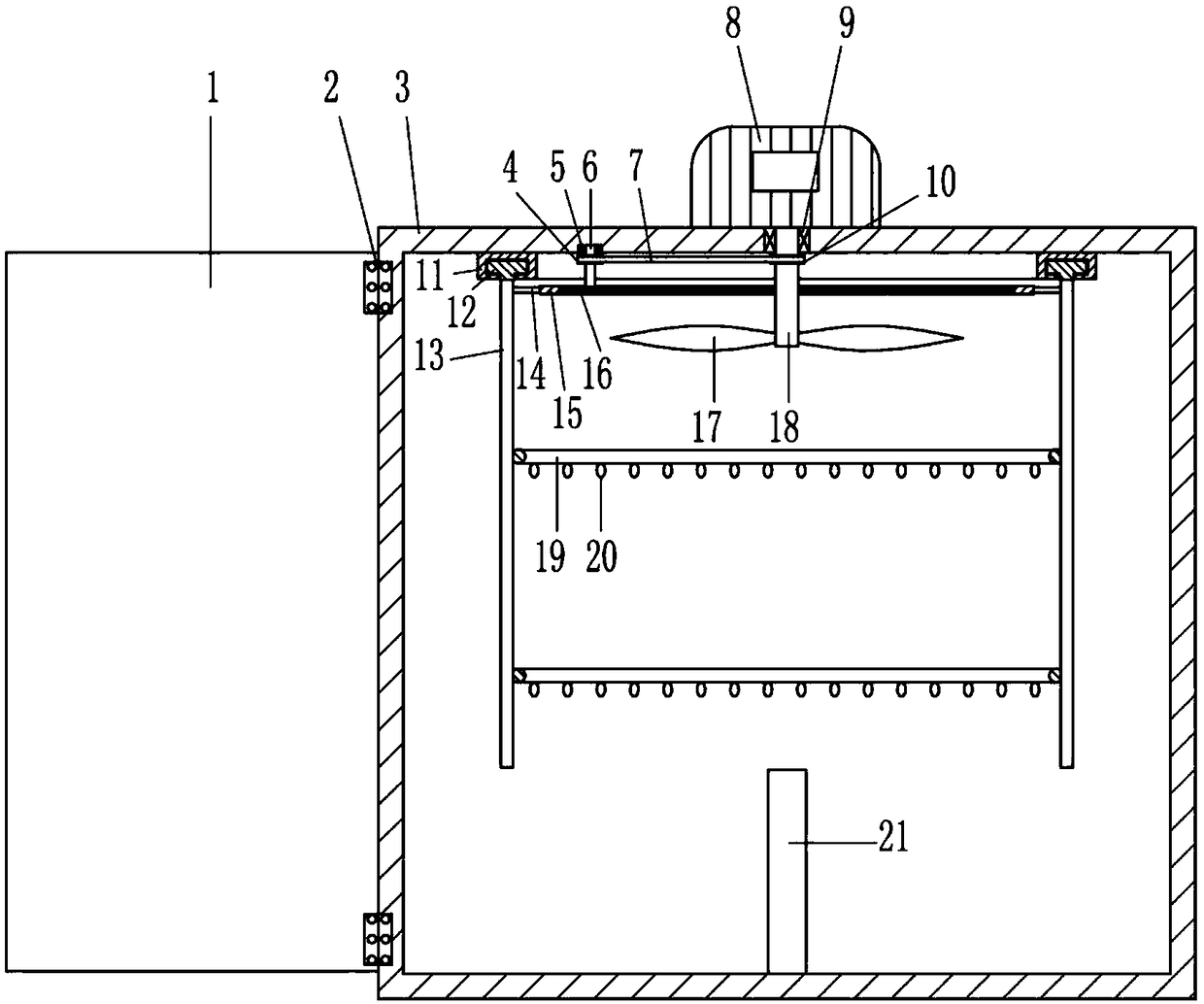

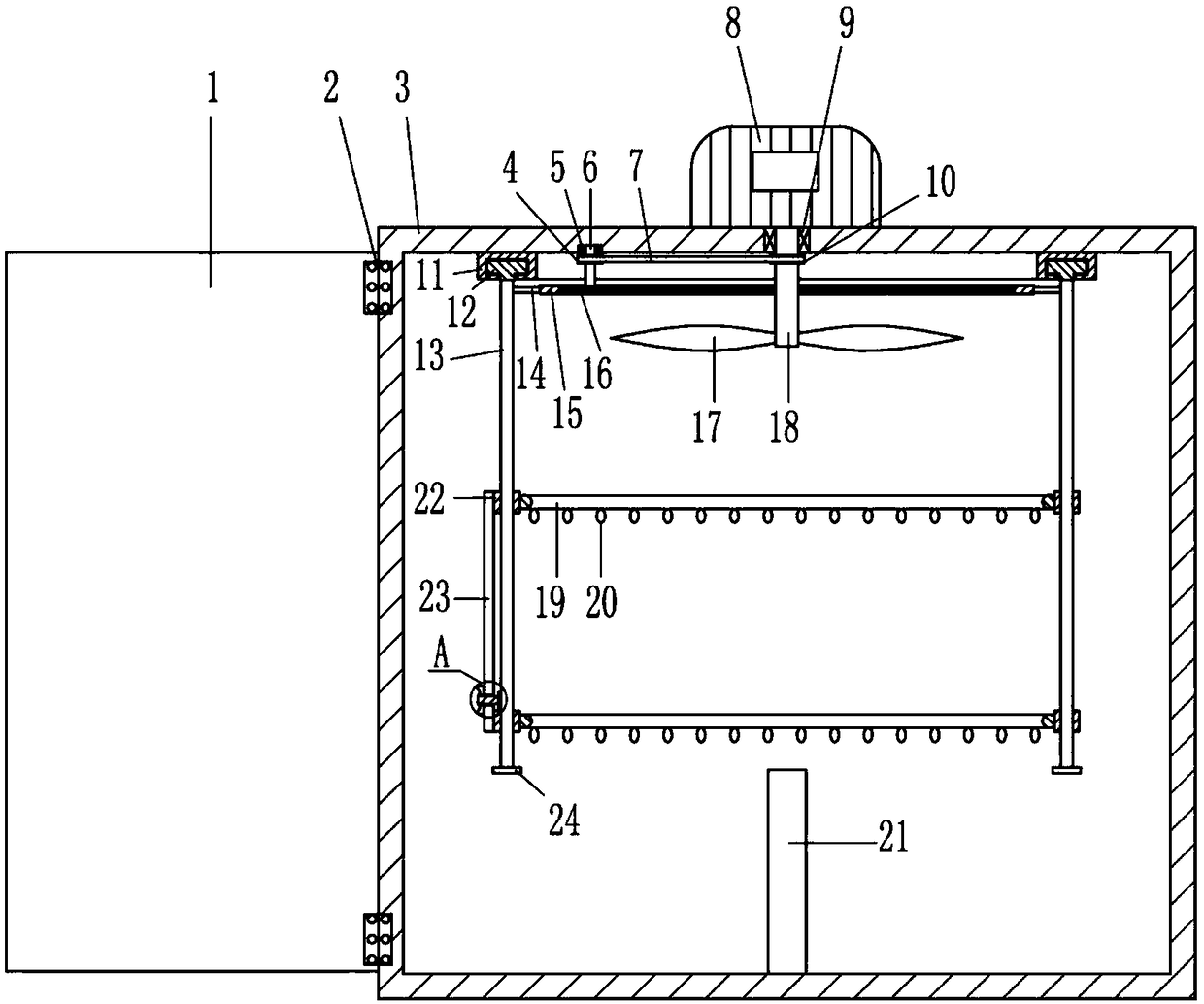

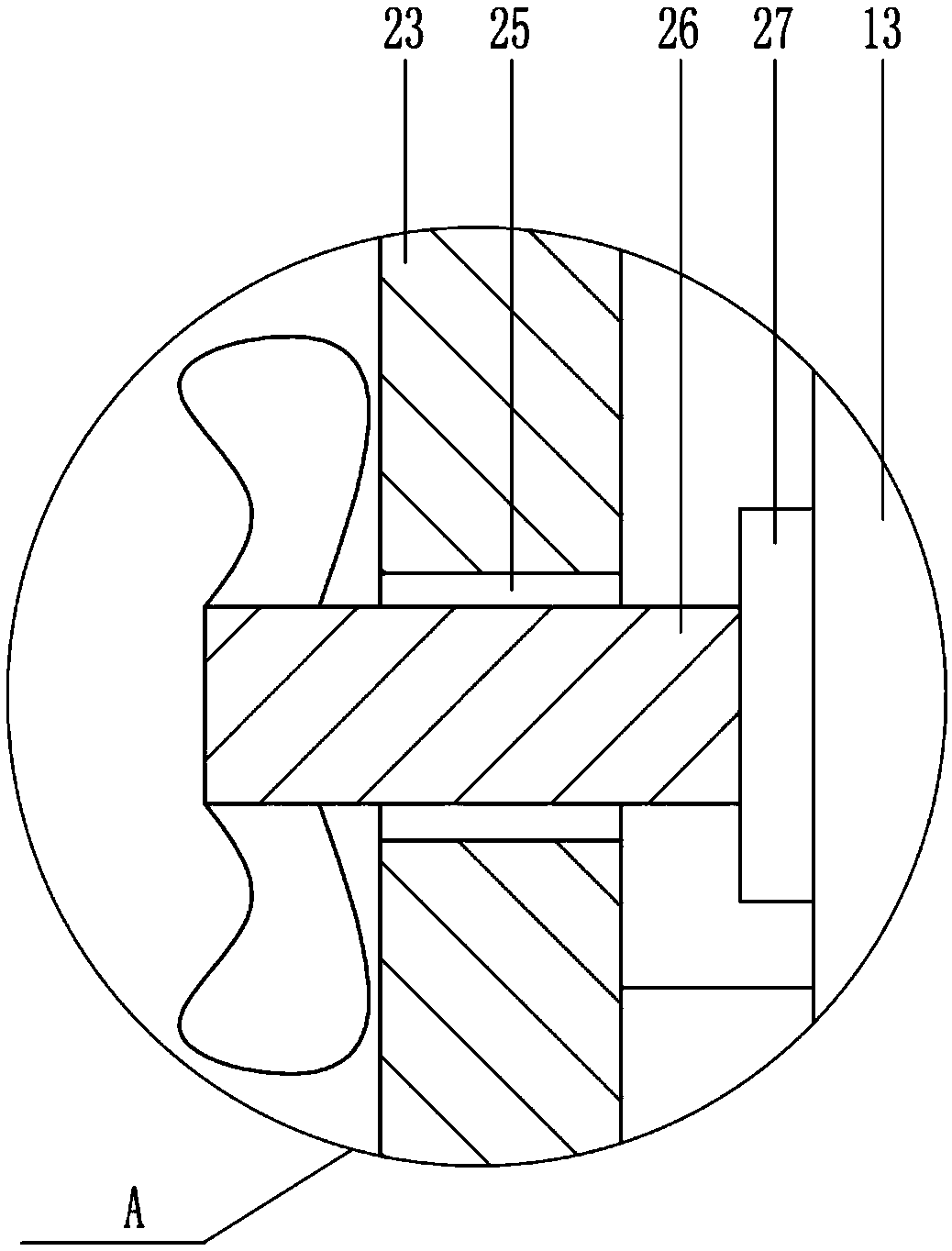

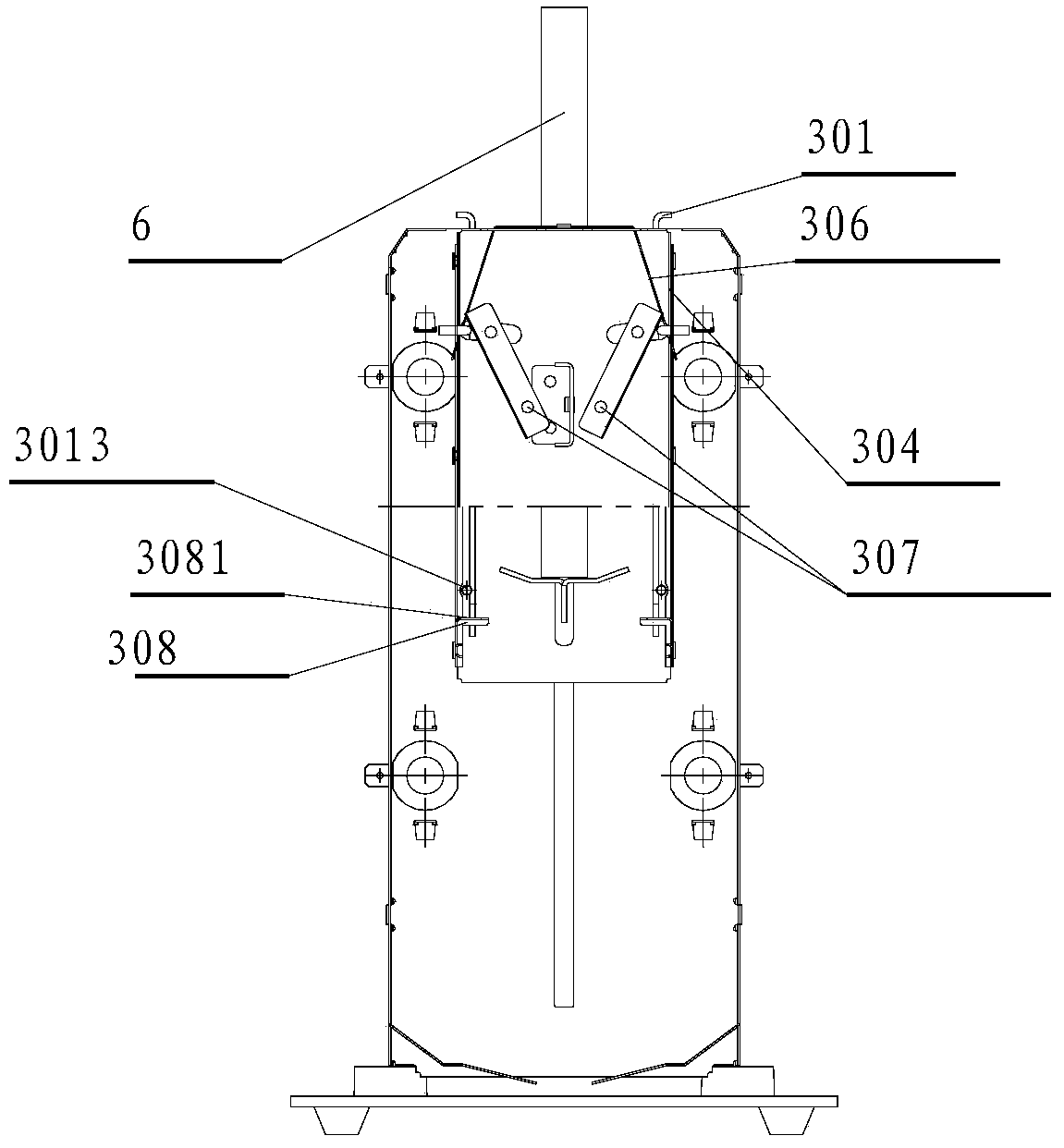

Position-adjustable automatic vertical baking furnace

InactiveCN106197003AIncrease temperatureFull and even toasting resultsPrinted circuit manufactureVertical furnacesCooking & bakingEngineering

The invention discloses a position-adjustable automatic vertical baking furnace comprising a case and two racks correspondingly arranged in the case. A first baking portion and a second baking portion are arranged between the racks. The two sides of the racks are provided with a feeding module and a discharging module correspondingly. The tops of the first baking portion and the second baking portion are provided with a pushing assembly. Multiple heating modules are arranged in the case. The first baking portion and the second baking portion comprise two rotating modules which are correspondingly arranged. Each rotating module comprises a rotating roller arranged at the bottom of the corresponding rack and a rotating roller arranged on the top of the corresponding rack, wherein the two rotating rollers are correspondingly and horizontally arranged. The two ends of each rotating roller are each connected with a rotating gear in a sleeved manner. A chain ring is perpendicularly connected between each upper rotating gear and the corresponding lower rotating gear and can rotate along with the rotating gears. The two chain rings of each braking portion are parallel. A plurality of supporting strips are horizontally connected between the two chain rings of each baking portion. Lead screw modules are arranged on the two sides of supporting frames and the two sides of the two racks. The lead screw modules are used for adjusting the distance between the two racks. In this way, the position-adjustable automatic vertical baking furnace can process PCBs of different lengths.

Owner:SUZHOU CONBER ELECTRONICS EQUIP

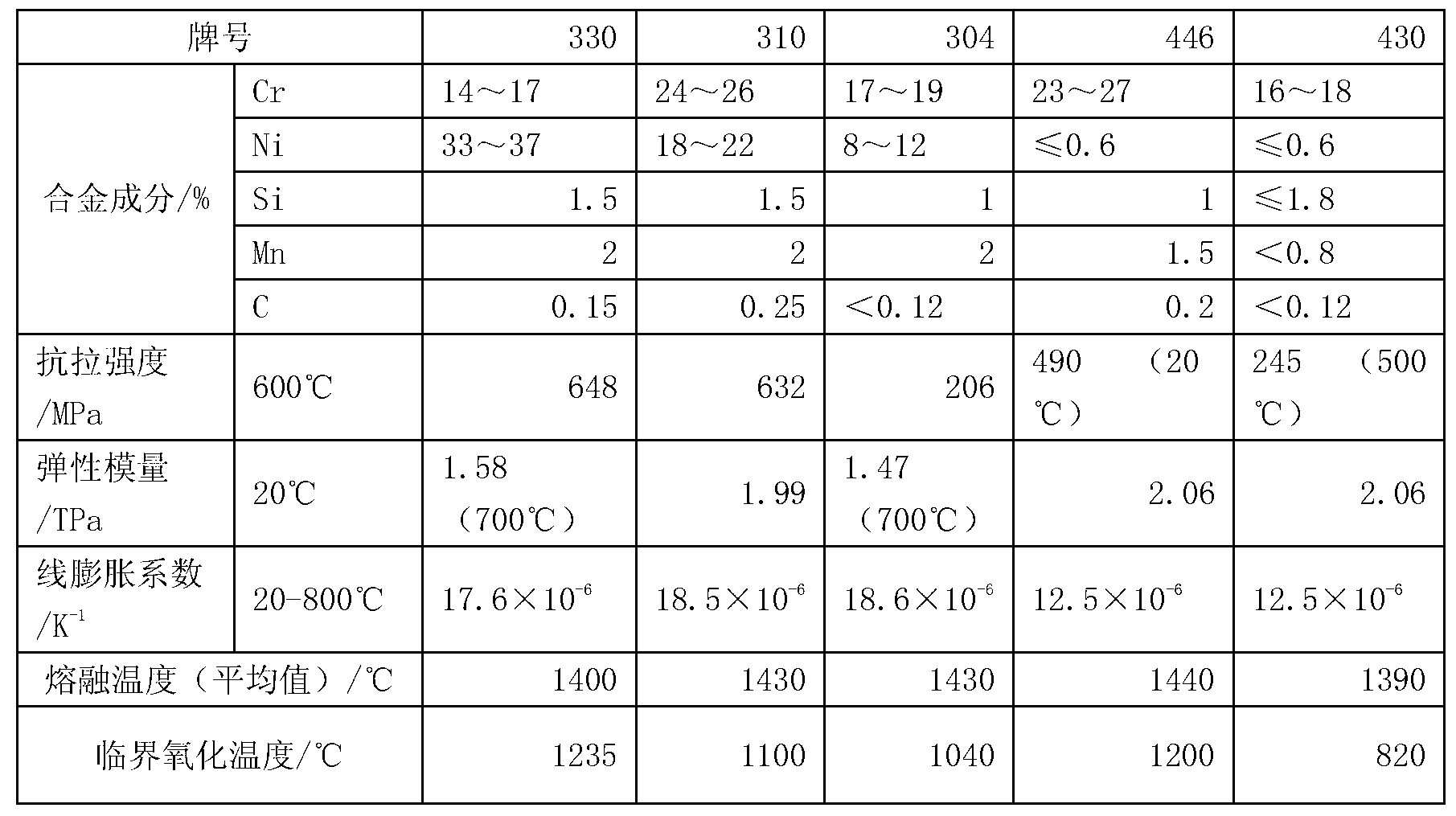

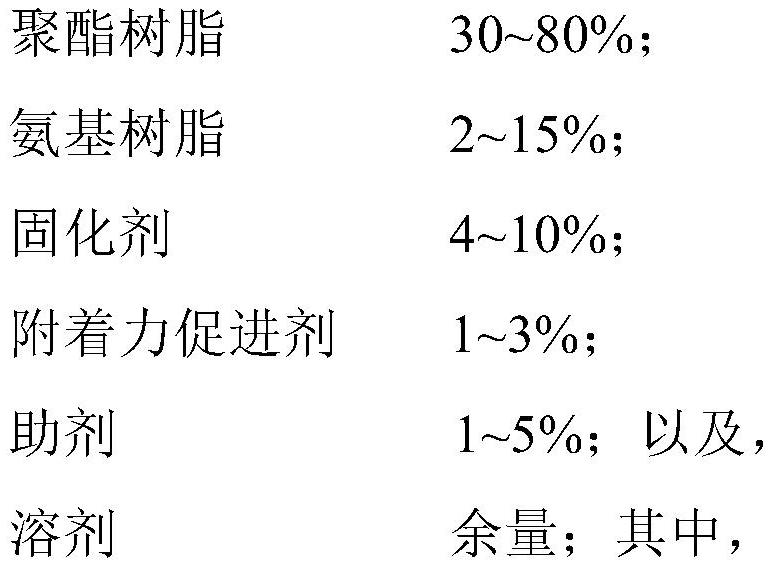

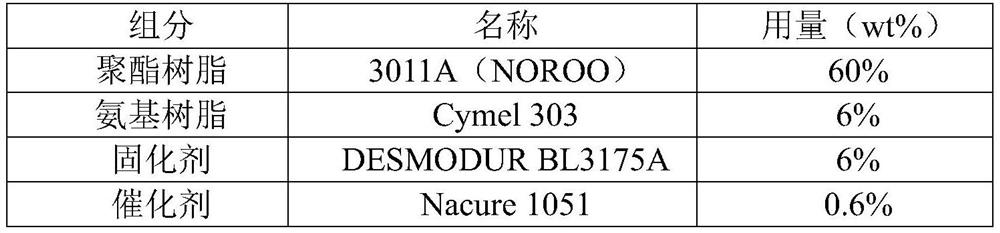

High-weather-resistance coiled material coating composition and application thereof

PendingCN114426796ASolve easy pulverizationResolve gloss lossLiquid surface applicatorsAntifouling/underwater paintsPolymer scienceWeather resistance

The invention provides a high-weather-resistance coiled material coating composition, which comprises the following components in percentage by mass: 30-80% of polyester resin, 10-20% of a curing agent, 1-10% of a curing agent, 1-10% of a curing agent, 1-10% of a curing agent and 1-10% of a curing agent. 2-15% of amino resin; 4-10% of a curing agent; 1-3% of an adhesion promoter; 1-5% of an auxiliary agent; and the balance of a solvent, wherein the polyester resin is saturated polyester resin, the number-average molecular weight Mn of the polyester resin is 3000-20000, the hydroxyl value of the polyester resin is 30-70 mg KOH / g, the acid value of the polyester resin does not exceed 10 mg KOH / g, and a molecular chain of the polyester resin contains a neopentyl structure. The high-weather-resistance coiled material coating composition does not need pretreatment, can be directly coated on a metal substrate such as stainless steel and the like, and has excellent machinability and adhesive force, meanwhile, a cured paint film has excellent weather resistance, pollution resistance, MEK resistance, corrosion resistance and wear resistance, and the high-weather-resistance coiled material coating composition is mainly applied to external coating of metal coiled materials such as stainless steel and the like.

Owner:NIPPON PAINT IND COATINGS SHANGHAI

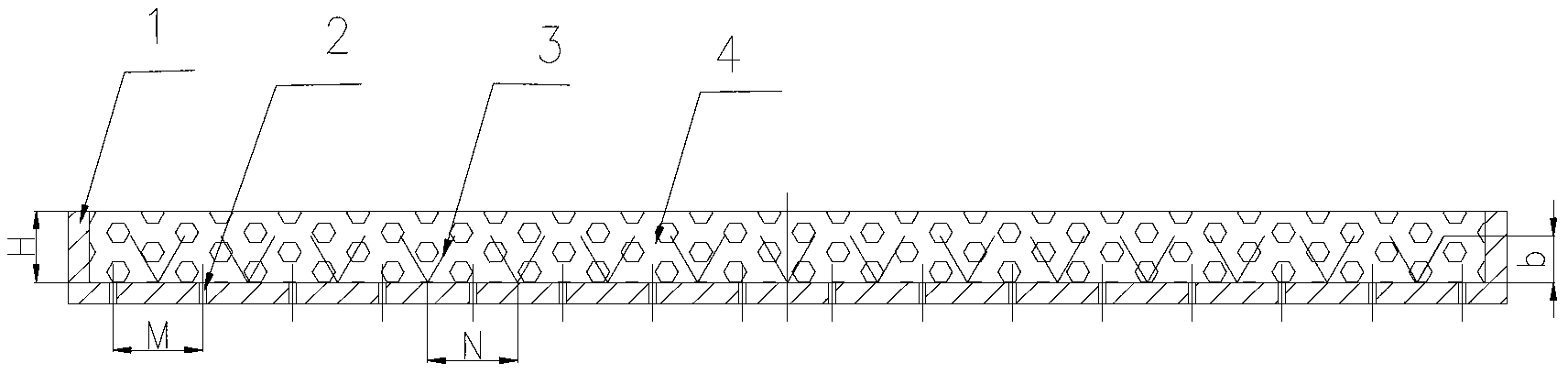

High-strength self-flow type explosionproof refractory castable

The invention relates to the field of refractory materials and specifically relates to high-strength self-flow type explosionproof refractory castable. The high-strength self-flow type explosionproofrefractory castable disclosed by the invention is prepared from the following ingredients in mass percent: 6% to 15% of brown fused alumina with the particle diameter as 0 to 1 mm, 10% to 20% of brownfused alumina with the particle diameter as 1 to 3 mm, 15% to 30% of brown fused alumina with the particle diameter as 3 to 5 mm, 5% to 10% of SiC particle with the particle diameter as 0 to 1 mm, 3%to 5% of SiO2 micropowder, 3% to 7% of SiC fine powder, 8% to 18% of white fused alumina powder, 3% to 6% of alpha-Al2O3 micropowder and 3% to 8% of pure calcium aluminate cement. According to the high-strength self-flow type explosionproof refractory castable disclosed by the invention, the brown fused alumina raw materials with different particle diameters are utilized as the main materials, sothat compact performance and compression strength are enhanced; furthermore, cost is reduced; by means of adding polypropylene fiber composite metal aluminum powder, oxidation resistance is achieved;meanwhile, toughness of the castable is enhanced, shock resistance and explosionproof performance are improved, and self-flow performance is better.

Owner:JIANGSU HENGNAI FURNACE CHARGE GRP

Continuous casting tundish preformed unit pouring material and preparation method thereof

The invention provides a preparation method of a continuous casting tundish preformed unit pouring material, and solves the problems that a tundish preformed unit in the prior art is high in cost and cracks easily. The continuous casting tundish preformed unit pouring material comprises the following raw materials in parts by weight: 60-80 parts of a black aloxite high-aluminum material, 10-20 parts of sintered bauxite and spinel fine powder, 2-8 parts of sintered magnesite fine powder, 4-8 parts of alpha-Al2O3 micro-powder, 2-6 parts of rho-Al2O3 micro-powder, 0.5-1.5 parts of silica micro-powder, 0-3 parts of stainless steel fibers, 0-0.2 part of a detonation inhibitor and 0.1-0.5 part of a water reducer. Compared with a preformed unit which is prepared from high bauxite and magnesite in the traditional way, the prepared continuous casting tundish preformed unit has the advantages that the cost of the preformed unit can be greatly reduced, the prepared tundish preformed unit can be baked rapidly, the baking cost of preformed unit products can be reduced, and the economic benefit of enterprises can be improved effectively.

Owner:北京利尔高温材料股份有限公司

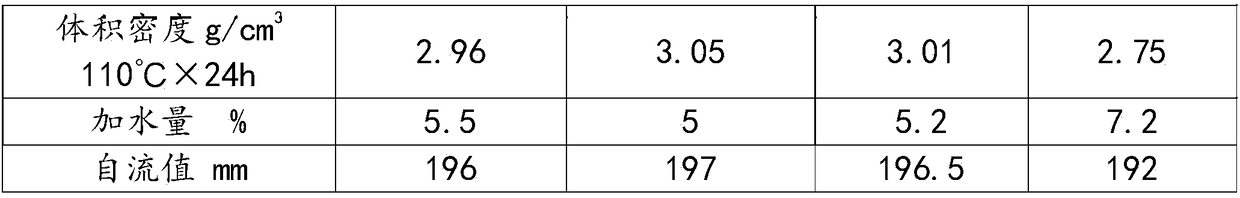

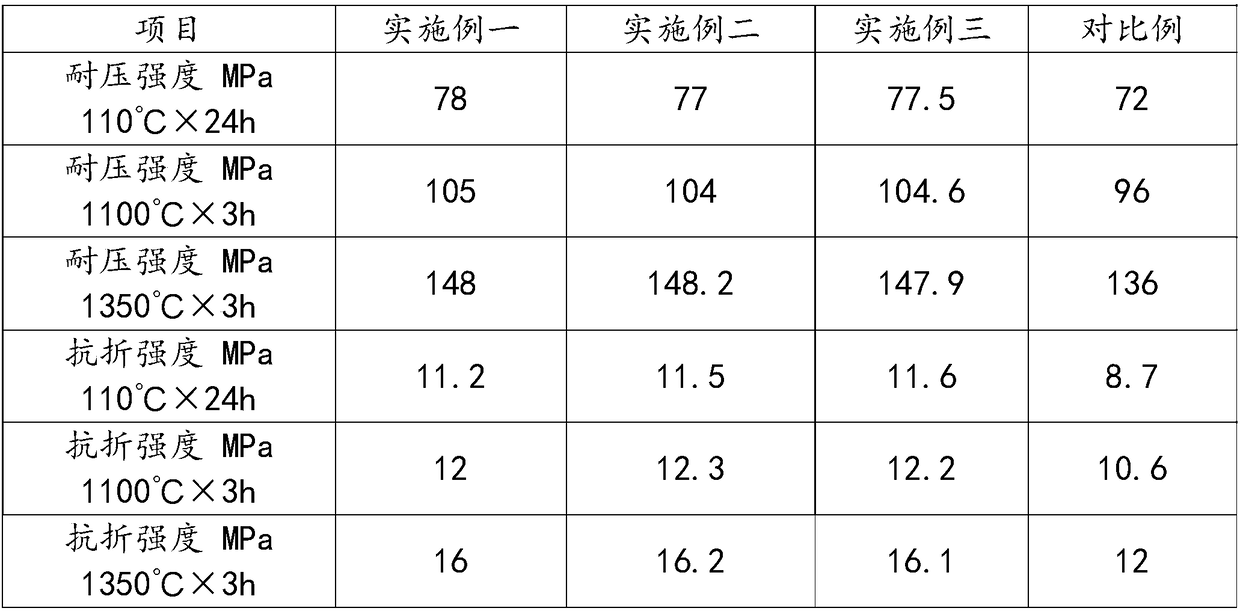

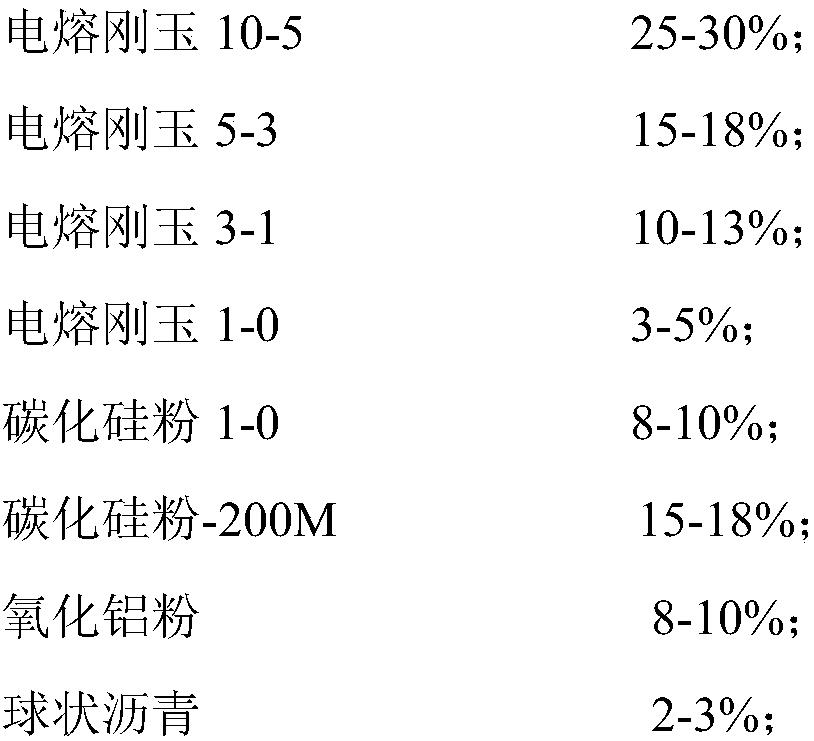

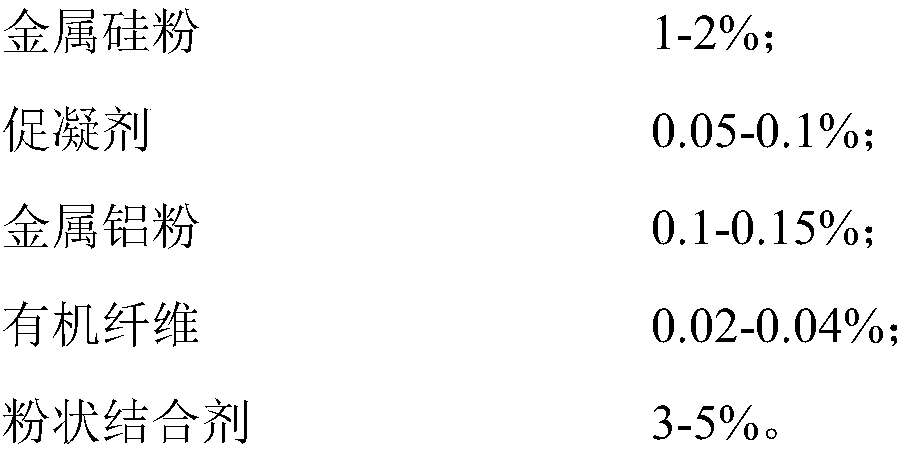

Refractory castable

The invention relates to the field of metallurgy, in particular to a refractory castable. The refractory castable provided by the invention comprises the following components of electro-melting corundum 10-5, electro-melting corundum 5-3, electro-melting corundum 3-1,electro-melting corundum 1-0, a carborundum powder 1-0, a carborundum powder -200M, an aluminum oxide powder, pelleted pitch, a metallic silicon powder, a coagulant, a metallic aluminum powder, organic fibers and a powdery bonding agent. The refractory castable and iron tap channel refractory materials formed through the refractory castable disclosed by the invention have the main advantages that the high temperature properties are better, liquid phases formed through a reaction of cement and SiO2 are avoided mainly due to theformation of mullite phases during high-temperature treatment of casting materials, and the high-temperature properties of the material are improved.

Owner:BAOJIUHE REFRACTORY +1

Aluminum silica sol composite combined aluminum silicon carbide castable and preparation method thereof

The invention discloses an aluminum silica sol composite combined aluminum silicon carbide castable and a preparation method thereof. The castable is prepared from the following raw materials in percentage by weight: 25-35% of 12-8mm bauxite aggregate, 10-15% of 8-3mm bauxite aggregate, 15-20% of 3-0mm bauxite aggregate, 15-25% of <88 mu m corundum fine powder or alumina fine powder, 5-12% of <88 mu m SiC fine powder, 1-5% of <5 mu m silicon micropowder and 5-10% of <5 mu m alpha-Al2O3 micropowder. An aluminum silica sol composite binder accounting for 10-15 wt% of all the raw materials is also added. The castable has the characteristics of high moderate-temperature strength, favorable thermal shock resistance and high corrosion resistance, can implement flash baking, and enhances the turnaround efficiency of the iron ladle; and since the service life is doubled, the castable can effectively save the consumption of the refractory material.

Owner:河南竹林耐材有限公司

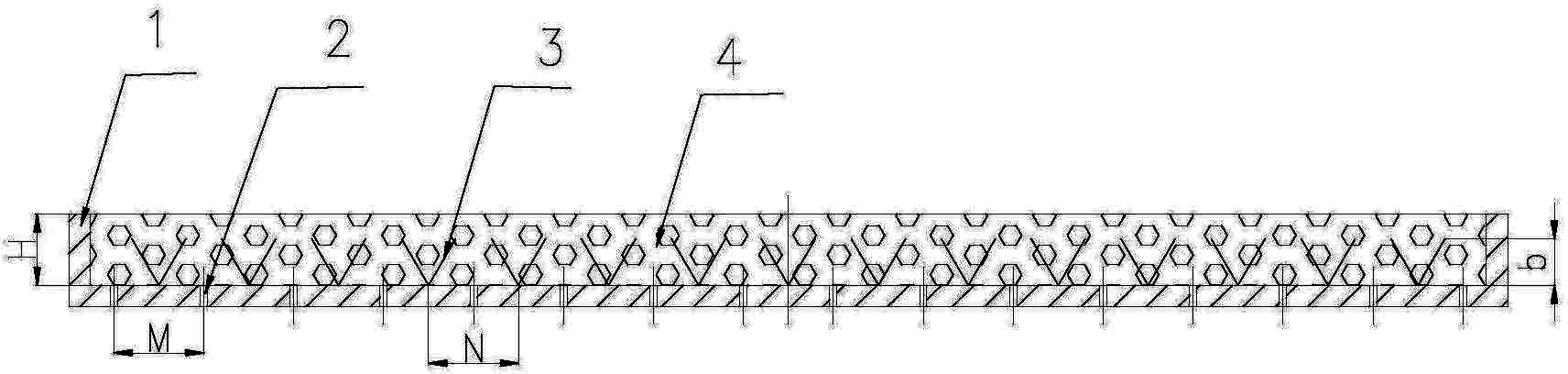

Swinging chute working lining castable of composite material and preparation method of castable

The invention relates to a swinging chute working lining castable of a composite material and a preparation method of castable. The castable is prepared from the following raw materials in percent by weight: main materials: 40%-55% of fused alumina, 20%-28% of silicon carbide, 5%-12% of alundum powder and 4%-8% of activated alumina micro powder; and auxiliary materials: 8%-12% of B4C composite binding agent and 0.2%-0.35% of antidetonant. The preparation method of the castable is simple and easy to realize, product construction is simple and convenient, drying is speedy after casting construction, so that a swinging chute working lining can be rapidly baked and put in tapping for use, and the once iron influx is eighty to ninety thousand tons; the castable has the characteristics of excellent scrap iron flushing resistance, excellent corrosion resistance, good thermal shock stability, lowered comprehensive cost, greatly-increased product benefit, and the like; and the comprehensive benefits of the swinging chute working lining and the requirement on once iron influx can be effectively increased and prolonged.

Owner:孙志红

Tunnel type continuous superheated steam baking device

ActiveCN107361088ARealize mechanized transportationReduce contentBaking ovenFood processingThermodynamicsProcess engineering

The invention provides a tunnel type continuous superheated steam baking device which comprises a baking tunnel system, a temperature sensor, a humidity sensor, a superheated steam generating system and a central intelligent regulation and control system. The baking tunnel system is provided with a baking tunnel, a conveying chain, chain wheels and hooks; superheated steam can be formed after steam is secondarily heated by heaters in the superheated steam generating system, accordingly, heat can be stereoscopically and comprehensively transferred inside foods such as baked meat in the tunnel, and the foods can be quickly and efficiently baked in an energy-saving manner. The tunnel type continuous superheated steam baking device has the advantages that effects of saving energy, reducing consumption, labor and the contents of pollutants and enhancing the quality such as flavor and texture of the baked foods can be realized by the tunnel type continuous superheated steam baking device, the foods can be continuously and intelligently baked in a standard manner, the tunnel type continuous superheated steam baking device is high in baking capacity, production requirements on different types of products such as the baked meat and baked fish can be completely met, and the baking efficiency can be effectively improved.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

High-efficiency baking and shaping device for vamp

The invention relates to a baking and shaping device, and particularly relates to a high-efficiency baking and shaping device for a vamp. The invention aims at solving the technical problem to provide the high-efficiency baking and shaping device for the vamp; the device has the advantages of quick baking speed and uniform heating. In order to solve the technical problem, the invention provides thesuch a high-efficiency baking and shaping device for the vamp. The high-efficiency baking and shaping device comprises a fixing groove, a working box, a placing net, a first sliding block, first sliding rails, a rocking heating device, a first spring, a fixing device, a fixing rod, a baffle plate, a first pull ring and the like, wherein the left side of the working box is connected with the fixing groove; the rocking heating device is arranged in the fixing groove; the right side of the rocking heating device is connected with the working box; a left wall and a right wall in the working box are symmetrically connected with the first sliding rails. By using the high-efficiency baking and shaping device, the effects that the baking speed is quick and the heating is uniform are achieved; a rotating rod is artificially rocked with a hand to make a heating plate radiate heat to bake and shape the vamp; the fixing device is used for making the baffle plate more stable; meanwhile, an air heater swings upwards, downwards, leftwards and rightwards.

Owner:浙江天宏鞋业有限公司

Preserved meat drying box for food processing

ActiveCN108935623AReduce labor burdenSpeed up heat flowMeat/fish preservation by dryingHinge angleEngineering

The present invention belongs to the field of food processing and particularly relates to a preserved meat drying box for food processing. A technical problem to be solved is to provide the preservedmeat drying box for the food processing, which can improve baking efficiency of preserved meat and ensure that the preserved meat can be evenly baked. The preserved meat drying box for the food processing comprises a door panel, two hinges, an oven, a first belt pulley, a first bearing seat, a first rotating shaft, a first flat belt, a motor, a second bearing seat, a second belt pulley, a circularsliding rail, a first sliding block, fixed rods, a first connecting rod, an inner gear ring, a cylindrical gear, fan blades, a second rotating shaft, annular hanging rods, hanging rings and a heatingplate; the door panel is hinged with the oven through the hinges; the motor is fixedly connected with the top part of the oven; and the second bearing seat is embedded in the top part of the oven. The preserved meat drying box for the food processing achieves effects of rapidly baking the preserved meat and ensuring the baking process of the preserved meat to be even.

Owner:SICHUAN RUNYU FOOD

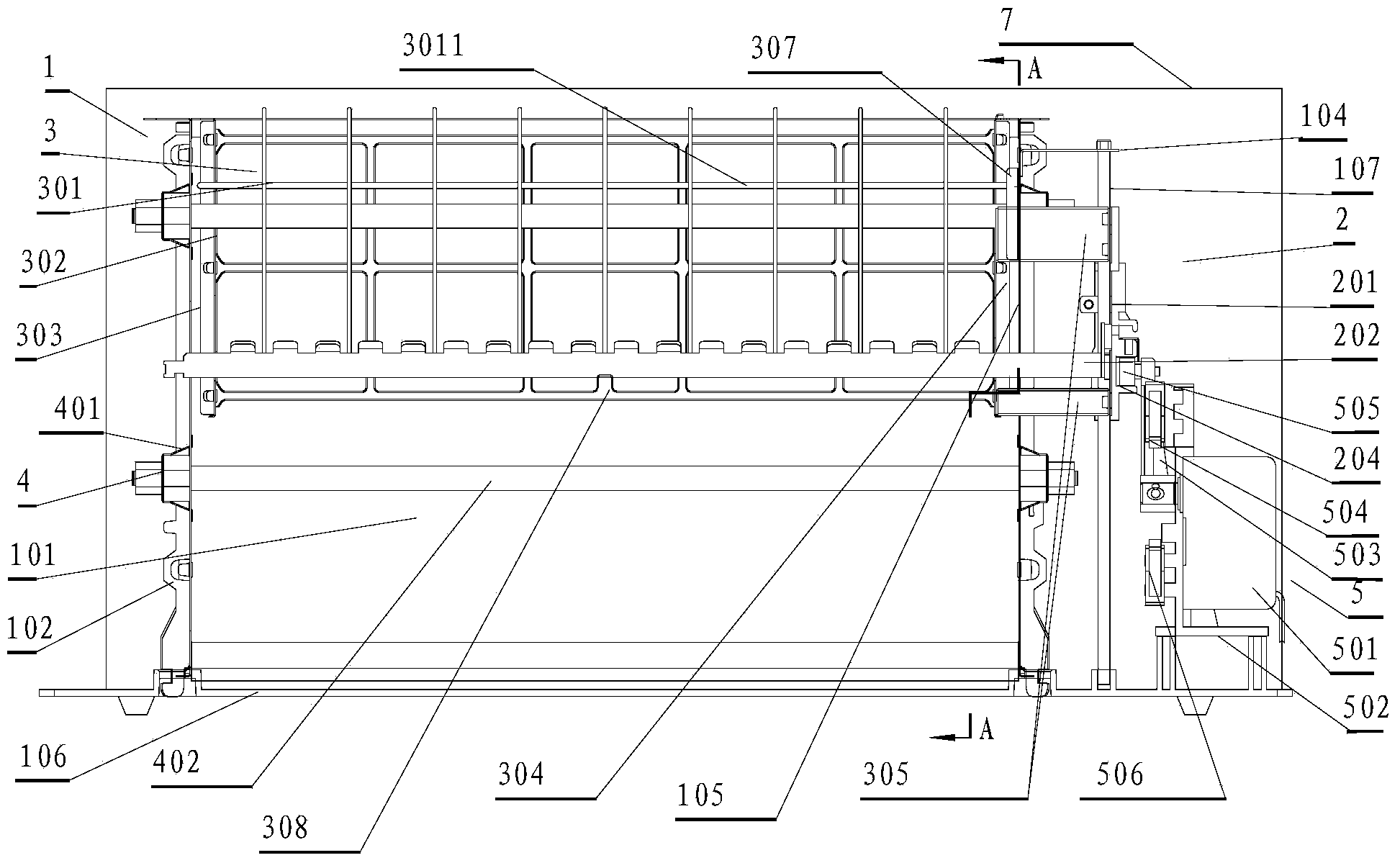

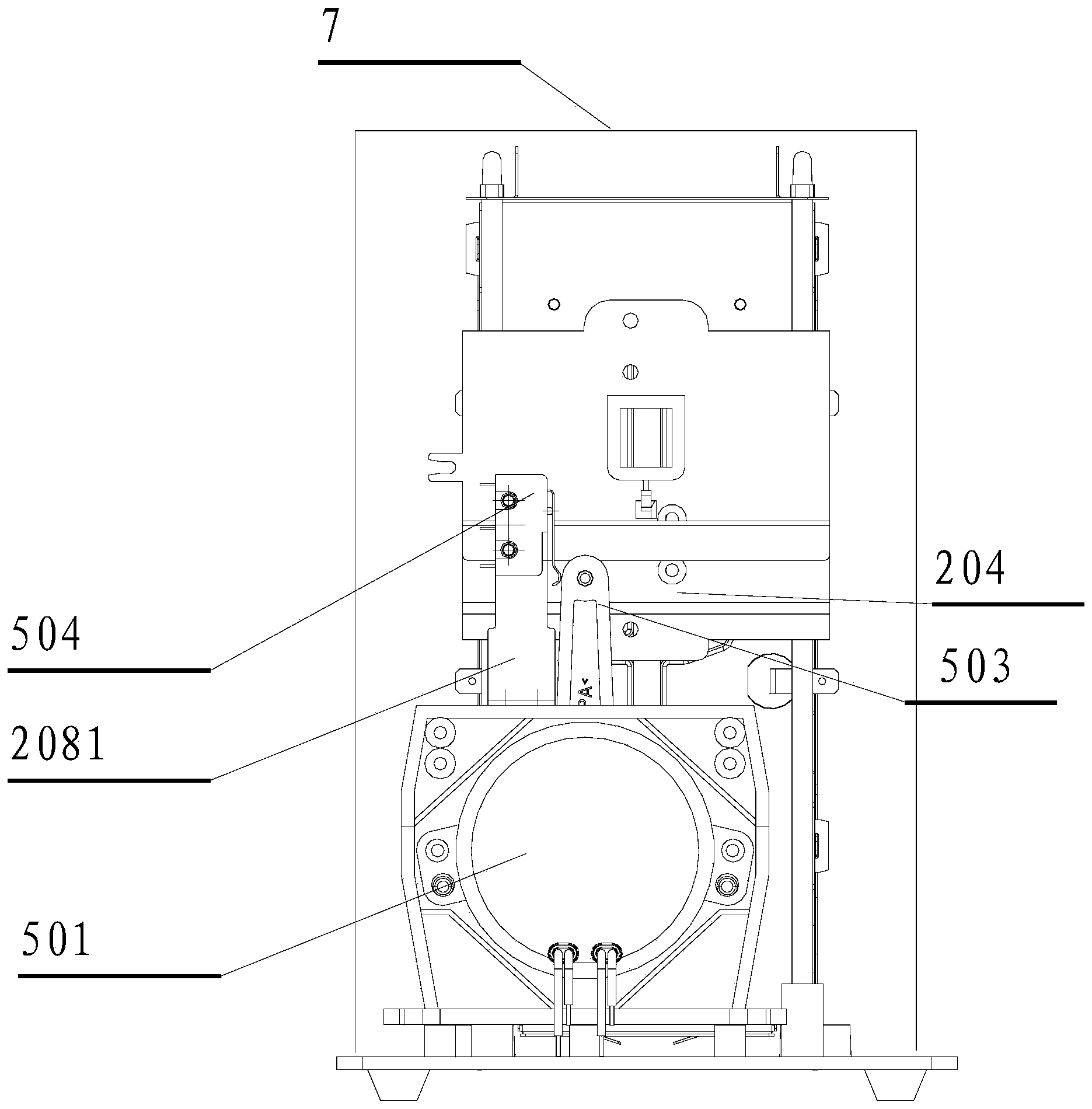

Rapid baking toaster and control method thereof

ActiveCN103690064AEvenly heatedEvenly bakedFood processingBread-toastersRear quarterCooking & baking

The invention discloses a rapid baking toaster and a control method thereof and relates to rapid baking toasters. The toaster comprises a core component (1), a sliding frame component (2), a heating tube component (4), an outer casing (7) fixed on the base and a drive component (5). A front side plate (105), side plates (101) and a rear side plate (102) of the core component (1) are fixedly connected to form a core to be further fixed on a base (106). The heating tube component (4) is fixed on the front side plate (105) and the rear side plate (102) and disposed between the front side plate (105) and the rear side plate (102). The sliding frame component (2) comprises a sliding frame (201) and a support frame (202) fixed on the sliding frame (201). The drive component (5) comprises a motor (501) and a drive mechanism, wherein the motor (501) drives the sliding frame component (2) to move vertically through the drive mechanism. According to the toaster and the control method, bread can be baked rapidly, sliced bread can be uniformly baked, and a rapid and good effect is achieved.

Owner:深圳市北鼎晶辉科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com