Early strength anti-detonation fireproof self-flow material

A self-flowing material and refractory technology, applied in the field of refractory materials, can solve the problems of castables not dense, affecting construction quality, voids, etc., and achieve the effects of increased structural stability, shortened demoulding time, and convenient construction

Active Publication Date: 2014-12-10

郑州瑞泰耐火科技有限公司

View PDF2 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The top cover of the cement kiln preheater, the top cover of the grate cooler, the top cover of the kiln door cover, etc., the construction of refractory castables is generally carried out by opening the hole. When pouring vibration, the vibrating rod must be inserted through the hole. The tamping rod is limited by the size and location of the opening, and the tamping rod cannot vibrate in place, which often results in local incompactness or voids in the castable, which seriously affects the construction quality

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

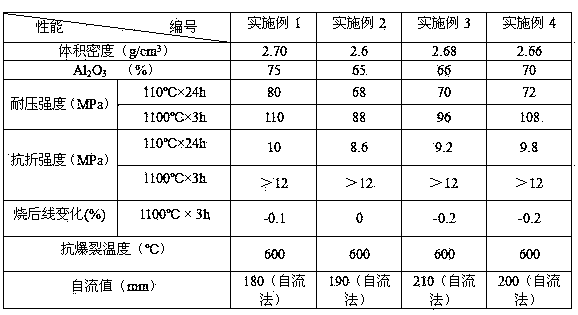

Embodiment 1

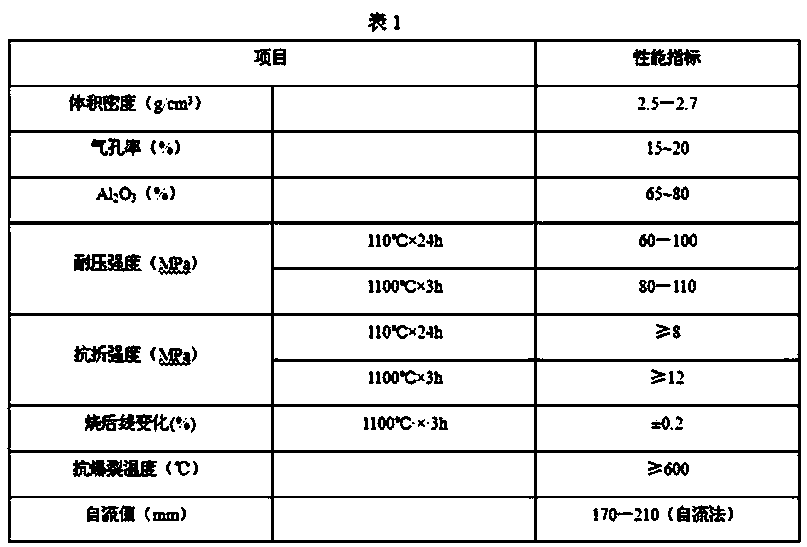

[0022] An early-strength explosion-proof refractory self-flowing material, the specific proportion (%, mass percentage) is as follows:

[0023]

Embodiment 2

[0025] An early-strength explosion-proof refractory self-flowing material, the specific proportion (%, mass percentage) is as follows:

[0026]

Embodiment 3

[0028] An early-strength explosion-proof refractory self-flowing material, the specific proportion (%, mass percentage) is as follows:

[0029]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to the technical field of refractory materials, and particularly discloses an early strength anti-detonation fireproof self-flow material. The material comprises the following raw materials: alumina or flint clay, pyrophyllite, silicon carbide, alumina based alpha-Al2O3 micropowder, SiO2 micropowder and the like. Aluminate cement serves as a binding agent, and a composite additive and an antidetonator are added. The self-flow material has the advantages of early strength, high strength, detonation resistance, shortened demold time, rapid baking and the like, and has good resistance to high temperature.

Description

technical field [0001] The invention belongs to the technical field of refractory materials, and in particular relates to an early-strength anti-explosion refractory self-flowing material. Background technique [0002] The top cover of the cement kiln preheater, the top cover of the grate cooler, the top cover of the kiln door cover, etc., the construction of refractory castables is generally carried out by opening the hole. When pouring vibration, the vibrating rod must be inserted through the hole. The tamping rod is limited by the size and location of the opening, and the tamping rod cannot vibrate in place, which often results in local incompactness or voids in the castable, which seriously affects the construction quality. Contents of the invention [0003] The technical problem to be solved by the present invention is to provide an early-strength anti-explosion refractory self-flowing material. [0004] In order to solve the problems of the technologies described ab...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B35/66

Inventor 赵洪亮李全有郑建立郑丹丹曹伟

Owner 郑州瑞泰耐火科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com