Round granule ore fertilizer pelleting process and device

A technology of mineral fertilizers and round granules, applied in fertilization devices, inorganic fertilizers, calcium fertilizers, etc., can solve the problems of low strength, broken granules, and low yield of round granule mineral fertilizers, so as to improve the pelleting rate and reduce heat. Load, the effect of reducing the amount of water added

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

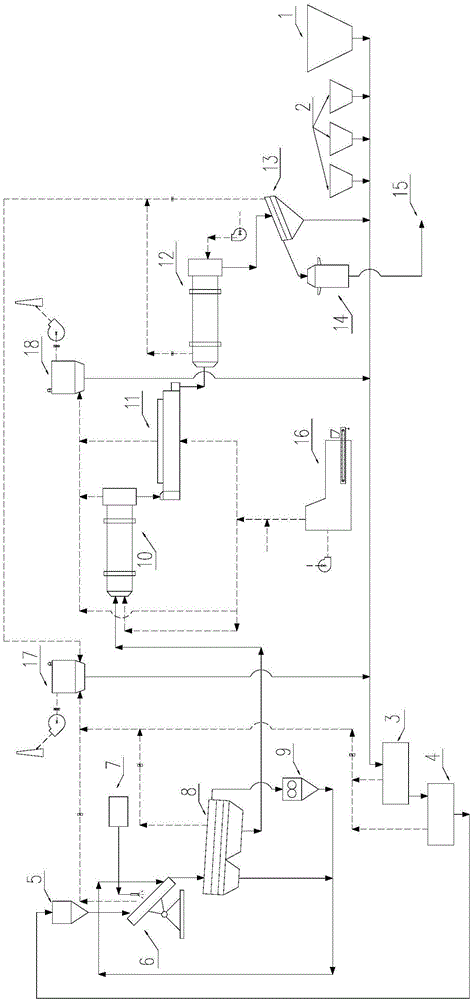

[0025] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0026] A kind of round particle mineral fertilizer granulation process, comprises the following steps:

[0027] 1) Raw material batching: the powdery mineral fertilizer and granulation additives are used to measure and batch the raw materials according to a certain proportion;

[0028] 2) Stirring and mixing: each prepared material is mixed and stirred evenly in the mixer to obtain the mixed material;

[0029] 3) Granulation: transport the mixed material to the disc granulator for spray granulation, and the wet granules are discharged from the discharge port of the granulation disc;

[0030] 4) Screening of wet granules: pass the above wet granules through a grading drum sieve, and sieve them into three parts with a particle size of 5mm resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com