Method for producing sodium thiosulfate

A sodium thiosulfate and production method technology, applied in the direction of thiosulfate/dithionite/polythionate, etc., can solve the problem of increased steam and electricity consumption, unfavorable material oxidation, reduced product concentration, etc. problems, to achieve the effect of reducing steam and electricity consumption, reducing production costs, and reducing evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

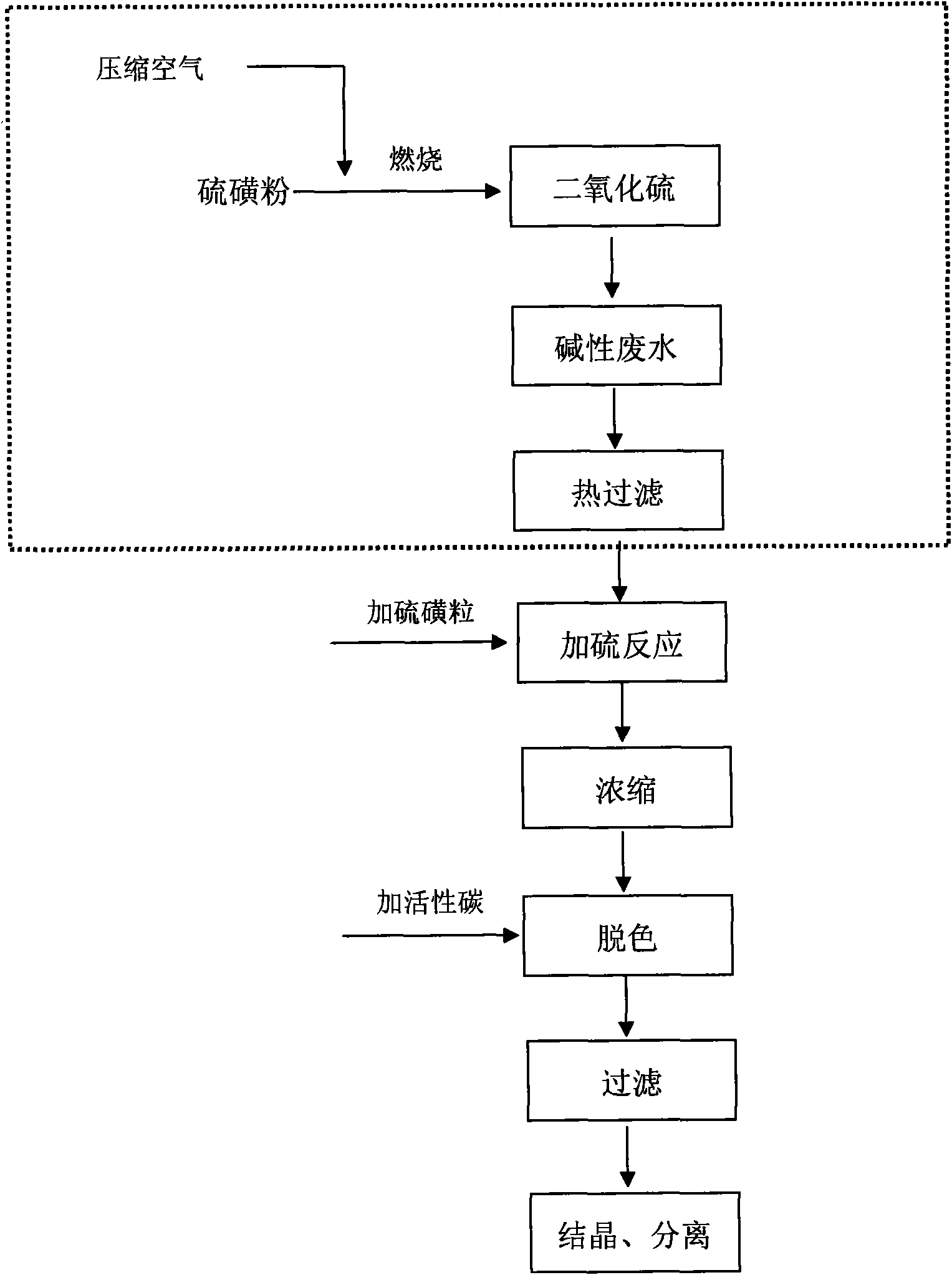

[0011] Such as figure 1 As shown, taking the annual production of 10,000 tons (33 tons / day) of sodium thiosulfate as an example, 80 tons / day of waste water reduced by aromatic nitro compound alkali sulfide is used as raw material, and the solid sulfur is first pulverized and then input into the combustion furnace (also known as SO 2 Generator), and 0.05Mpa compressed air is introduced to oxidize sulfur powder into sulfur dioxide gas under the condition of 600°C, and the generated sulfur dioxide gas is passed into the reaction kettle, and the alkaline wastewater (containing Na 2 S 2 o 3 、Na 2 Na in S, NaOH) 2 S, NaOH react to form Na 2 SO 3 , and then carry out hot filtration, sulfuration, concentration, decolorization, filtration, crystallization, separation, etc. according to the conventional process, and finally get the qualified product Na 2 S 2 o 3 .

Embodiment 2

[0013] Using the alkaline waste water reduced by aromatic nitro compound alkali sulfide as raw material, the solid sulfur is pulverized first and then input into the combustion furnace, and the compressed air of 0.2Mpa is introduced, and the sulfur powder is oxidized into sulfur dioxide gas under the condition of 800°C to produce The sulfur dioxide gas is passed into the first reaction kettle to react with the relevant components in the alkaline wastewater in the reaction kettle for the first time, and the remaining gas enters the second reaction kettle for the second reaction, and the bottom of the second reaction kettle is pumped into the The first reactor circulates, and there is an overflow pipe on the second reactor top so that the qualified intermediate product flows into the intermediate tank, and the intermediate product is carried out to obtain the qualified product by the follow-up conventional process among the embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com