High-strength self-flow type explosionproof refractory castable

A refractory castable, high-strength technology, applied in the field of refractory materials, can solve the problems that affect the normal production of cement kilns, reduce the strength of castables, burst and fall off castables, etc., achieve the effects of shortening the bonding time, reducing the amount of water added, and improving shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

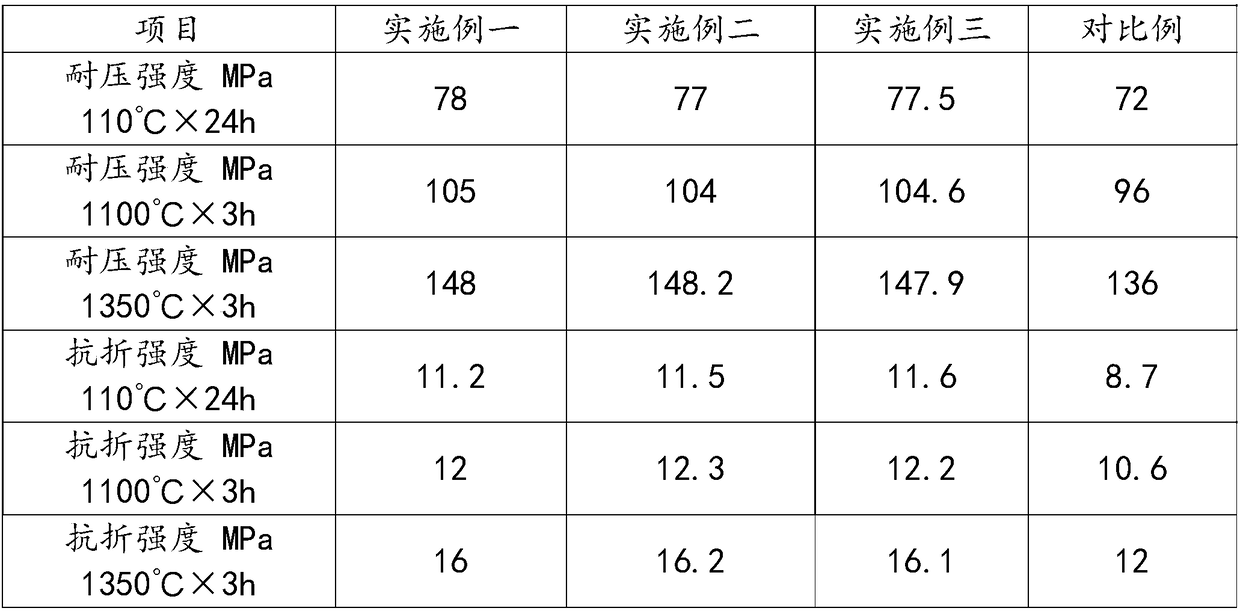

Embodiment 1

[0021] For the high-strength self-flowing explosion-proof refractory castable in this embodiment, the following components by mass percentage can be mixed evenly: 6% of brown corundum with a particle size of 0-1mm, 19.7% of brown corundum with a particle size of 1-3mm, and Brown corundum 30% for 3-5mm, SiC particles 10% for particle size 0-1mm, SiO 2 Micro powder 3%, SiC fine powder 7%, white corundum powder 8%, α-Al 2 o 3 Micro powder 6%, pure calcium aluminate cement 8%, sodium tripolyphosphate 0.1%, polypropylene fiber 0.1%, metal aluminum powder 2%, silicone leveling agent 0.1%.

[0022] In this embodiment: the SiC fine powder has a particle size of 0.06 mm.

Embodiment 2

[0024] For the high-strength self-flowing explosion-proof refractory castable in this embodiment, just mix the following components in mass percentages: weigh the following mass fractions of materials: 15% brown corundum with a particle size of 0-1mm, and a particle size of 1-3mm 10% of brown corundum, 29.8% of brown corundum with a particle size of 3-5mm, 5% of SiC particles with a particle size of 0-1mm, SiO 2 Micro powder 4.8%, SiC fine powder 3%, white corundum powder 15.6%, α-Al 2 o 3 Micro powder 5.9%, pure calcium aluminate cement 7.9%, sodium tripolyphosphate 0.4%, polypropylene fiber 0.6%, metal aluminum powder 0.1%, silicone leveling agent 1.9%.

[0025] In this embodiment: the SiC fine powder has a particle size of 0.05 mm.

Embodiment 3

[0027] For the high-strength self-flowing explosion-proof refractory castable in this embodiment, just mix the following components in mass percentages: Weigh the following mass fractions of materials: 14.45% of brown corundum with a particle size of 0-1mm and a particle size of 1-3mm 20% of brown corundum, 15% of brown corundum with a particle size of 3-5mm, 9.8% of SiC particles with a particle size of 0-1mm, SiO 2 Micro powder 5%, SiC fine powder 6.9%, white corundum powder 18%, α-Al 2 o 3 Micropowder 3%, pure calcium aluminate cement 3%, sodium tripolyphosphate 0.38%, polypropylene fiber 0.57%, metal aluminum powder 1.9%, silicone leveling agent 2%.

[0028] In this embodiment: the SiC fine powder has a particle size of 0.08mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com