Food producing device

A technology for production equipment and food, applied in dough forming and cutting equipment, division/slicing of baked goods, food science, etc., can solve problems such as unloading, glutinous rice cannot be formed, and crockpot cannot be collected reliably.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

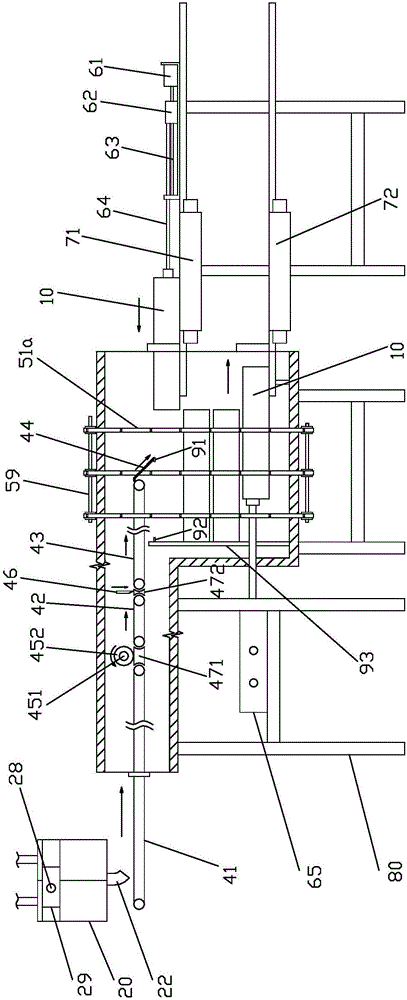

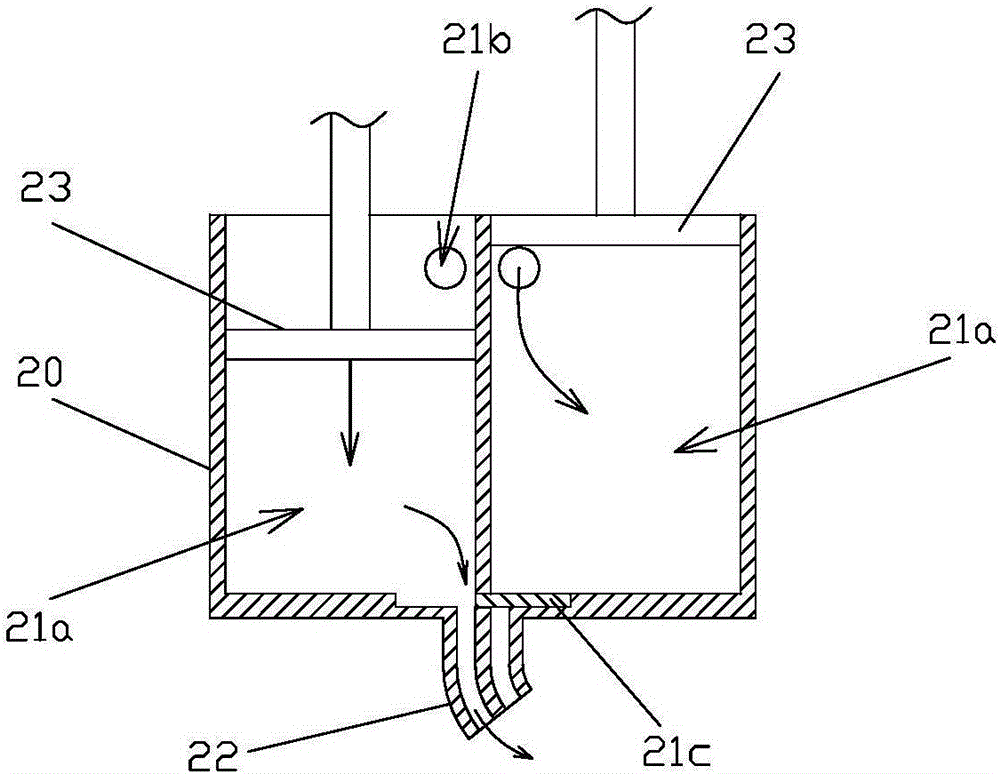

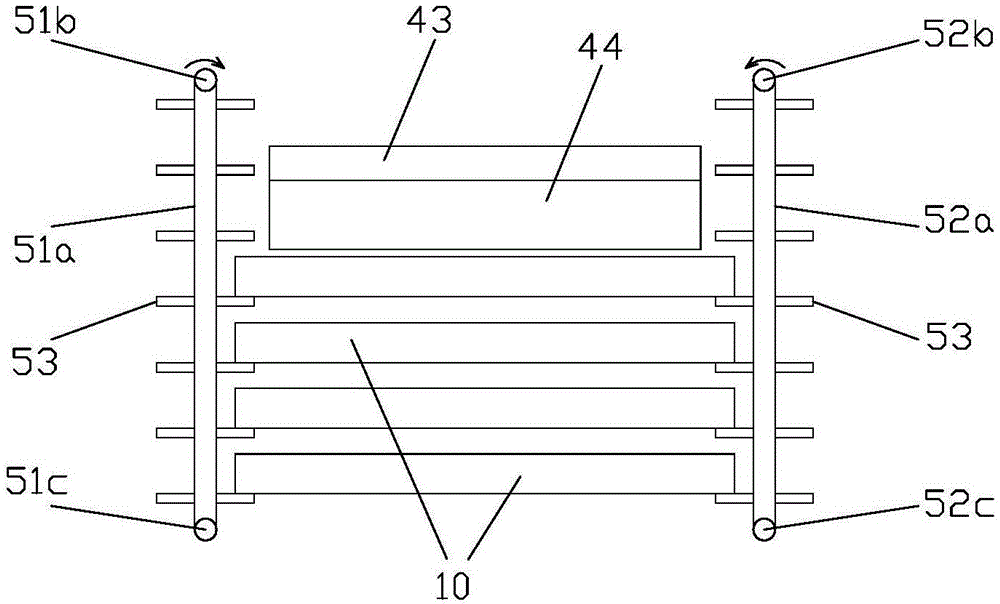

[0019] In order to make the objects and advantages of the present invention clearer, the present invention will be specifically described below in conjunction with examples. It should be understood that the following words are only used to describe one or several specific implementation modes of the present invention, and do not strictly limit the protection scope of the specific claims of the present invention.

[0020] Glutinous rice is different from indica rice in that it is extremely viscous after being cooked, so it is necessary to consider the influence of glutinous rice viscosity on the production of crispy rice. For example, glutinous rice is used as the raw material to produce crispy rice, which cannot be cut before the strips of crispy rice enter the oven. When cutting, the crispy rice will stick to the conveyor belt, making it difficult for the dried crispy rice to be separated from the conveyor belt, and reliable processing cannot be carried out. Unloading, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com