High-weather-resistance coiled material coating composition and application thereof

A coil coating and weather resistance technology, used in polyester coatings, antifouling/underwater coatings, coatings, etc., can solve problems such as insufficient corrosion resistance, inability to apply high corrosion resistance environments, etc., and achieve interlayer adhesion. Strong, excellent MEK wiping effect, excellent weather resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

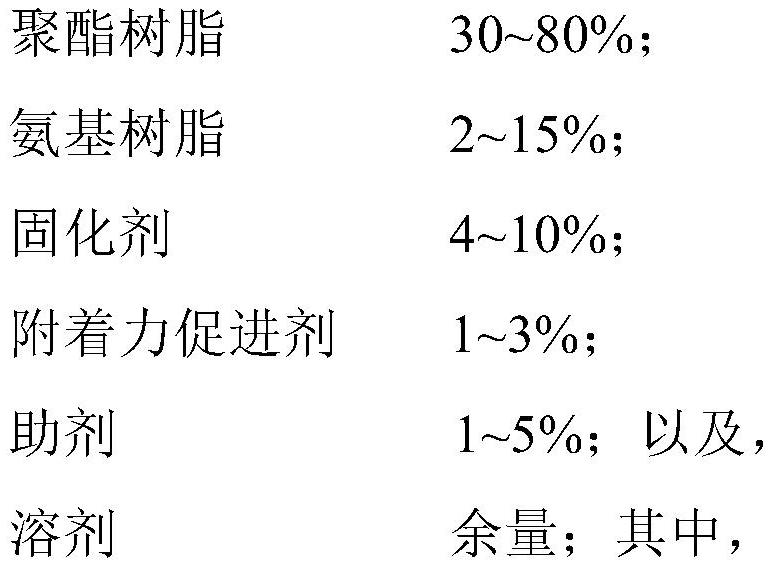

Method used

Image

Examples

Embodiment 1

[0073] Prepare the high weather resistance coil coating composition of the present invention according to the formula of following table 1:

[0074] Table 1 Example 1 High weather resistance coil coating composition composition

[0075] components name Dosage (wt%) polyester resin NP 5055 65% amino resin Cymel 303 6% Hardener DESMODUR BL3175A 4% catalyst AAC2500 1.0% adhesion promoter SN7063 1.5% Defoamer L-T 0.5% leveling agent L-C 1% solvent S-100 4% solvent Propylene glycol methyl ether acetate 10% solvent DBE 6%

[0076] Add saturated polyester resin, amino resin, and curing agent to the container in turn, mix and stir evenly, then add catalyst, adhesion promoter, leveling agent and defoamer under stirring, stir evenly, and finally add solvent, adjust the gloss as needed , viscosity, adjust the viscosity of the mixture to be 100-140 seconds, measure it with a coating-4 cup, filt...

Embodiment 2

[0079] Prepare the high weather resistance coil coating composition of the present invention according to the formula of following table 2:

[0080] Table 2 Example 2 Composition of high weather resistance coil coating composition

[0081] components name Dosage (wt%) polyester resin NP 5055 54% amino resin Cymel 325 4% Hardener DESMODUR BL3175A 4% catalyst Nacure 1051 0.4% adhesion promoter SN7063 1.5% Defoamer L-T 0.5% leveling agent L-C 1% solvent S-100 4% solvent Propylene glycol methyl ether acetate 10% solvent DBE 6%

[0082] Add saturated polyester resin, amino resin, and curing agent to the container in turn, mix and stir evenly, then add acid catalyst, adhesion promoter, leveling agent and defoamer under stirring, stir evenly, and finally add solvent, adjust as needed Gloss, viscosity, adjust the viscosity of the mixture to be 100-140 seconds, measure with Tu-4 cup, filter ...

Embodiment 3

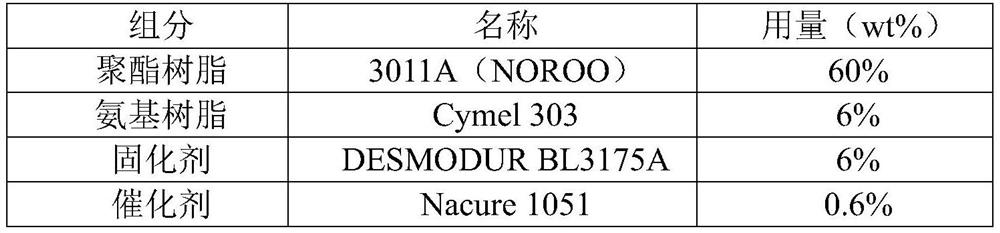

[0085] Prepare the high weather resistance coil coating composition of the present invention according to the formula of following table 3:

[0086] Table 3 Example 3 Composition of high weather resistance coil coating composition

[0087] components name Dosage (wt%) polyester resin NP 5055 60% amino resin Cymel 688 4% Hardener DESMODUR BL3175A 6% catalyst Nacure 1051 0.6% adhesion promoter SN-7063 1.5% Defoamer L-T 0.5% leveling agent L-C 1% solvent S-100 4% solvent Propylene glycol methyl ether acetate 10% solvent DBE 6%

[0088] Add saturated polyester resin, amino resin, and curing agent to the container in turn, mix and stir evenly, then add acid catalyst, adhesion promoter, leveling agent and defoamer under stirring, stir evenly, and finally add solvent, adjust as needed Gloss, viscosity, adjust the viscosity of the mixture to be 100-140 seconds, measure with Tu-4 cup, filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com