Adsorption material for adsorption air dryer and combined adsorption method

An air dryer and adsorption material technology, applied in the field of adsorption materials, can solve problems such as single use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

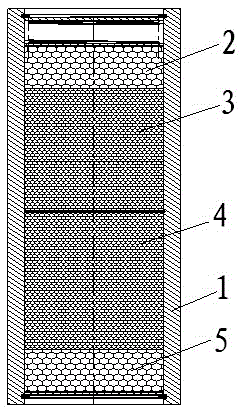

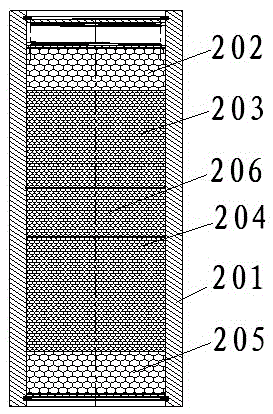

[0027] by attaching figure 1 It can be seen that the present invention is an adsorption material for an adsorption air dryer, including two adsorption materials of alumina and molecular sieve, wherein alumina with a particle size of ¢5-¢8mm accounts for 10-20% of the adsorption material, and ¢3-¢8mm Alumina with a particle size of ¢5mm accounts for 50-60% of the adsorption material, molecular sieves with a particle size of ¢3-¢5mm account for 15-40% of the adsorption material, molecular sieves with a particle size of ¢5-¢8mm account for 10-30% of the adsorption material %. The above-mentioned adsorption materials are layered in the order of ¢5-¢8mm particle size alumina, ¢3-¢5mm particle size alumina, ¢3-¢5mm particle size molecular sieve, ¢5-¢8mm particle size molecular sieve Fill it into the adsorption tower of the adsorption air dryer to form a 4-stage composite adsorption material assembly.

[0028] After testing; when the inlet temperature is 40°C and the inlet pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com