Patents

Literature

162results about How to "Best ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Special pigment finishing offset paper and producing method thereof

InactiveCN1584205AReduce particle contentIncrease bulkNon-fibrous pulp additionCoatings with pigmentsGreen environmentXerography

This invention discovers a special pigment groom hectograph paper and its preparation. It utilizes the advantages of high yields machine pulp (PRC-APMP) and deink pulp (DIP) which is well thickness and green environment. That is optimizing pigment spreading formulation, optimizing pulp to materials ratio and its wet end chemical and copy making technique to reach the white value of all bleaching chemical pulp proportioning copy paper. The advantages of the products are: better printing adaptability, better relaxation thickness, better printing effect features compared with all chemical pulp hectograph paper. It's capable of producing top grade office and printing culture special pigment groom hectograph paper which is made according to different clients' requirement and selecting different optimized features' technique for different application such as laser printing, xerography and hectograph etc. So, it's capable of decreasing all chemical pulp quantity, saving wood, protecting forest, protecting environment from pollution.

Owner:YUEYANG FOREST & PAPER CO LTD

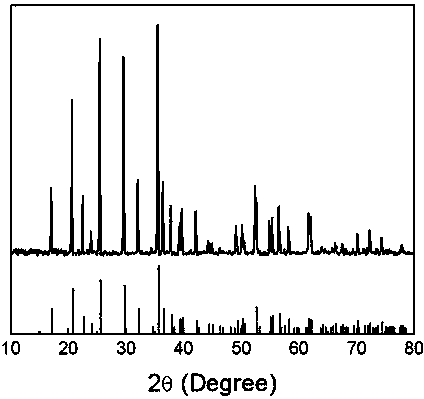

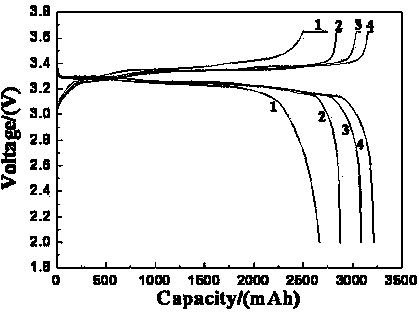

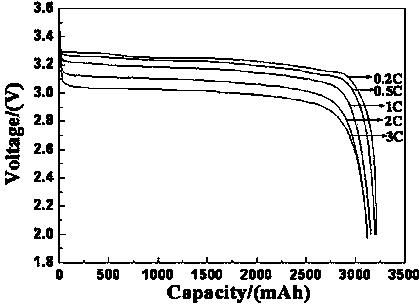

Method for manufacturing industrialized high-energy lithium iron phosphate material

The invention relates to a method for manufacturing lithium iron phosphate materials, in particular to the method for manufacturing an industrialized high-energy lithium iron phosphate material. The method is mainly used for solving the technical problems that the existing lithium iron phosphate materials in the prior art are manufactured in a laboratory, are manufactured in a complicated process and are converted into industrialized products difficultly; and high power capacity batteries are manufactured difficultly if the materials with poor particle size distribution and bad material compaction capacity are adopted because the materials are processed only after a primary ball-milling is performed. The method provided by the invention comprises the following steps: adding and mixing lithium salt, ferric salt and phosphor salt twice and performing a wet ball milling twice to obtain two groups of slurry materials with different particle sizes; mixing, drying and presintering the two groups of the slurry materials in different proportions, carrying out the third wet ball milling and sintering on the slurry materials; and finally obtaining the high-energy lithium iron phosphate material.

Owner:杭州金马新能源科技有限公司

Traditional Chinese medicine extract for nourishing heart and tranquilizing mind as well as preparation method and application thereof and heart-nourishing mind-tranquilizing ointment

ActiveCN104587167AEasy to takeRelieve pale complexion, fatigueNervous disorderPlant ingredientsInsomniaChinese drug

The invention discloses a traditional Chinese medicine extract for nourishing heart and tranquilizing mind as well as a preparation method and application thereof and a heart-nourishing mind-tranquilizing ointment. The traditional Chinese medicine extract for nourishing heart and tranquilizing mind is prepared by extracting the following raw materials in parts by weight: 1-4 parts of lotus seed, 1-4 parts of lily, 2-5 parts of spina date seed, 2-5 parts of poria cocos, 2-5 parts of longan pulp and 1-4 parts of radix puerariae. The traditional Chinese medicine extract disclosed by the invention has the functions of nourishing blood and tranquilizing mind and relieving the symptoms such as white complexion, dysphoria and insomnia and dreaminess, and is simple in formula and reasonable in proportion, suitable for large-scale production and convenient for consumers while the effect is remarkable.

Owner:广州白云山潘高寿药业股份有限公司

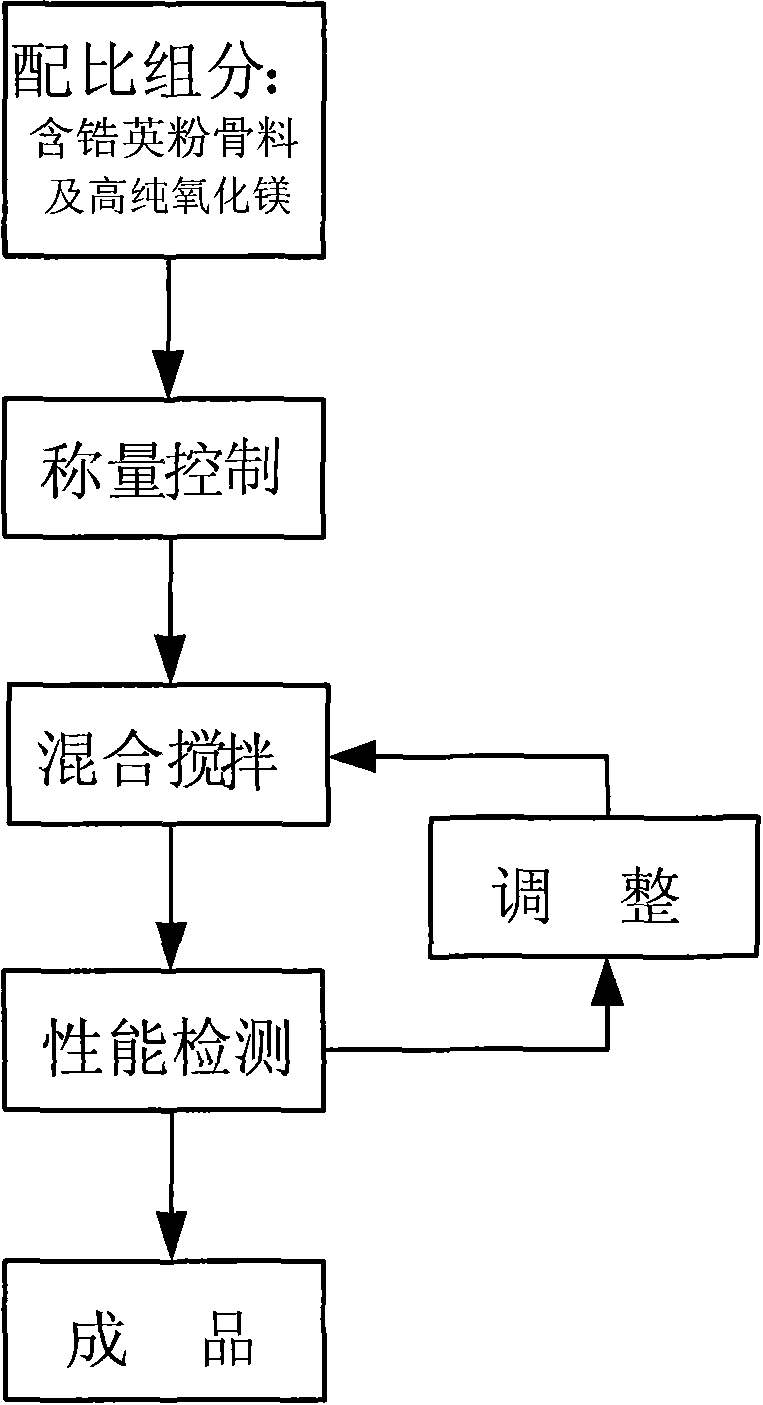

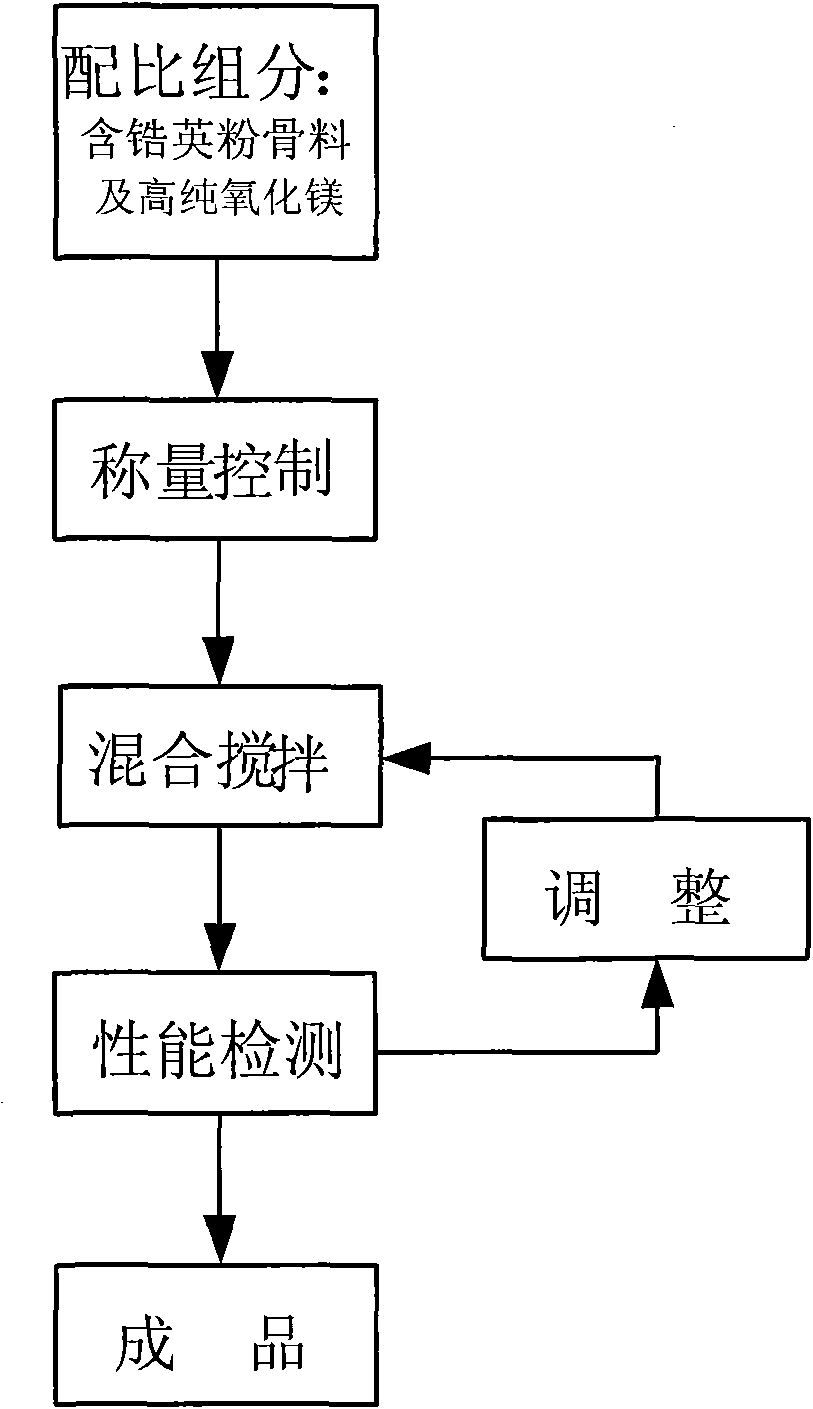

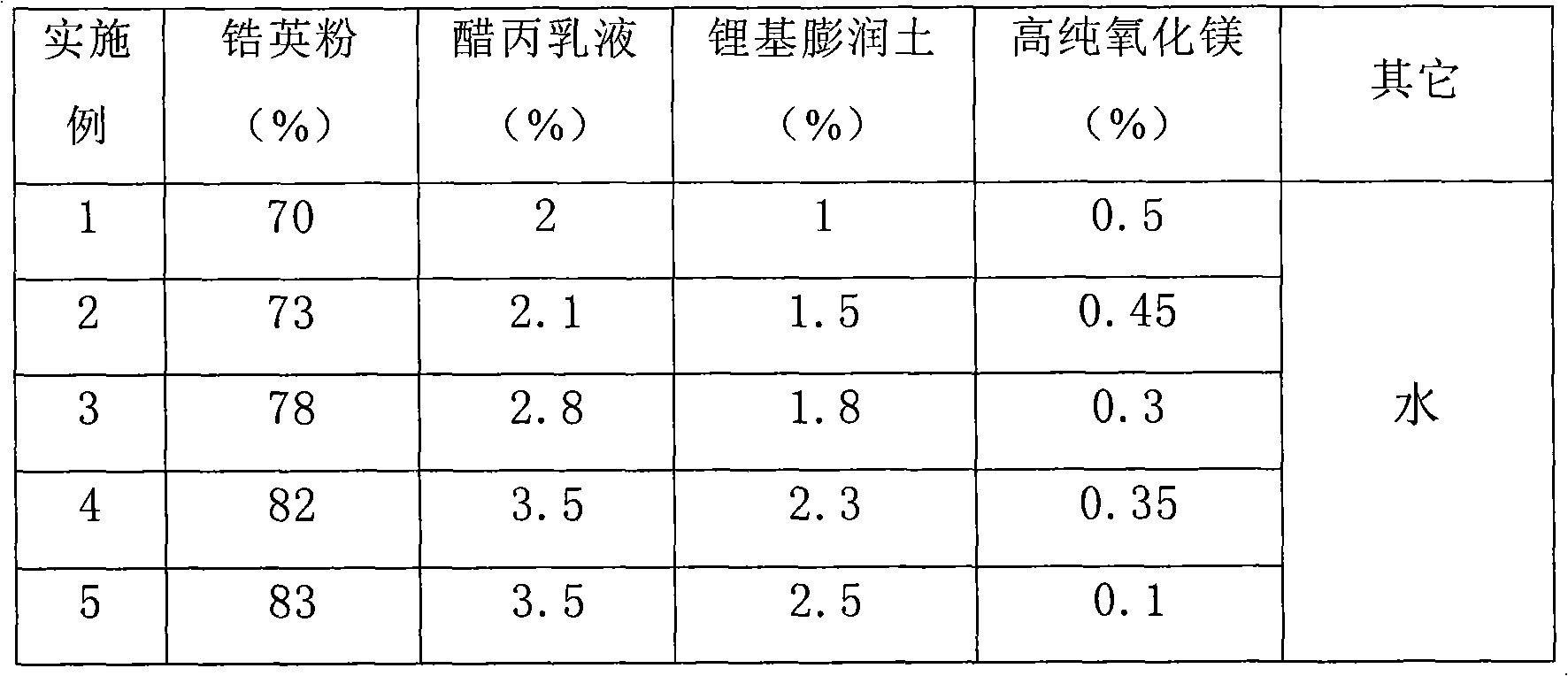

Water-based zircon powder quick drying paint for ultra-large steel casting

ActiveCN101890475AImprove fire resistanceImprove heat storage capacityFoundry mouldsFoundry coresWater basedSodium Bentonite

The invention discloses a water-based zircon powder quick drying paint for an ultra-large steel casting. The paint consists of refractory material, binder, suspending agent and water, wherein the refractory material is zircon powder; the paint also contains high-purity magnesium oxide, the MgO content of which is more than 99 percent; and the paint comprises the following components in percentage by weight: 70 to 83 percent of zircon powder, 2 to 3.5 percent of binder, 1 to 2.5 percent of suspending agent, 0.1 to 0.5 percent of high-purity magnesium oxide and the balance of water, wherein the binder is vinyl acetate / acrylic emulsion and the suspending agent is lithium-based bentonite. The paint can effectively promote moisture migration on the surface of the paint by adding a reasonable amount of magnesium oxide aid so that the paint can quicken the curing speed, the next coating of the paint can be performed without drying the paint in short time, the production process is simplified, the resource is saved and the energy consumption is reduced.

Owner:鑫工艺(上海)材料科技有限公司

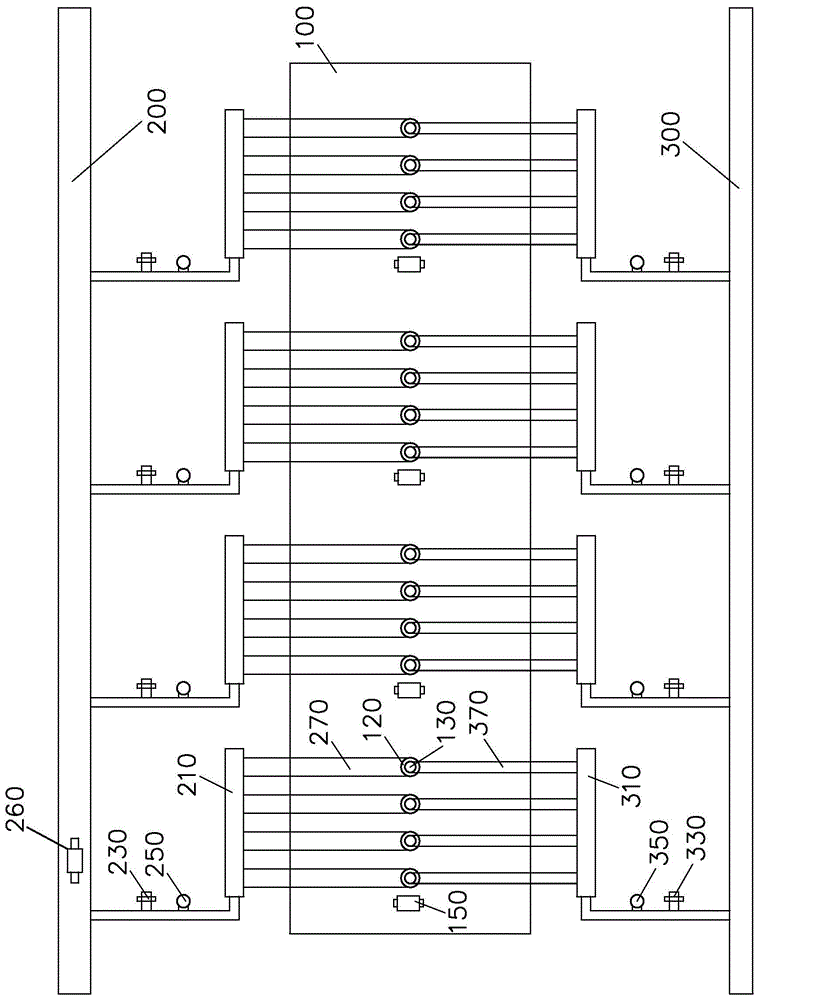

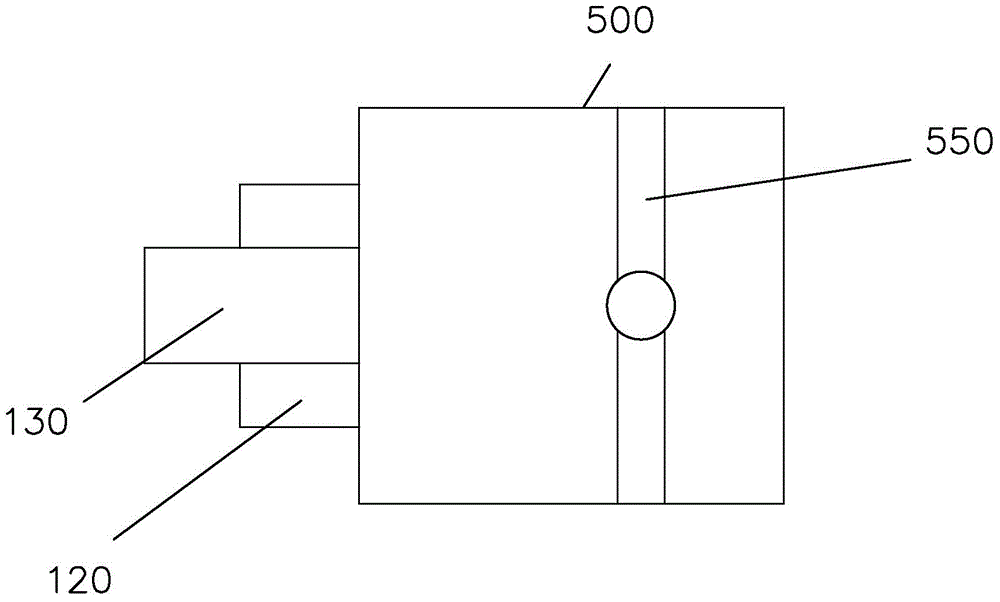

Segmented ceramic kiln fuel gas and air linkage control system

The invention discloses a segmented ceramic kiln fuel gas and air linkage control system, which comprises a kiln body, an air main pipe, a fuel gas main pipe, a first thermocouple and at least three control partitions, wherein each control partition comprises an air branch pipe, an air electric valve, a flow rate meter, at least three air input pipes, a fuel gas branch pipe, a fuel gas electric valve, a flow rate meter, at least three fuel gas input pipes and a second thermocouple, the air electric valve and the flow rate meter are arranged on a connecting pipeline arranged between the air branch pipe and the air main pipe, the air input pipes are connected between the air branch pipe and an air inlet, the fuel gas electric valve and the flow rate meter are arranged on a connecting pipeline arranged between the fuel gas branch pipe and the fuel gas main pipe, the fuel gas input pipes are connected between the fuel gas branch pipe and a fuel gas inlet, the second thermocouple is used for measuring the partition temperature inside the kiln body, and a control center couples and controls the opening degree of the air electric valve according to the fuel gas flow rate data and the obtained air temperature data in the air main pipe, so the air quality flow rate data obtained by the air flow rate meter and the fuel gas quality flow rate data obtained by the fuel gas flow rate meter reach the best air-fuel ratio preset by the system.

Owner:GUANGDONG UNIV OF TECH +2

Welding repairing process for extrusion die

The invention discloses a welding repairing process for an extrusion die. The welding repairing process comprises the following steps that firstly, failure analyzing is carried out on the abandoned die, linear cutting and observation analyzing are carried out on failure parts, and failure forms are determined; secondly, different welding repairing principles are selected for different defects; thirdly, appropriate welding methods are selected for detect forms of a working tape; fourthly, physical and chemical property analyzing is carried out on welded tissues; fifthly, machining and post-treating are carried out on welded work; and sixthly, die testing and spot actual extruding are carried out on the repaired die, the actual extruding situation of the die is explored, an extruding result is analyzed, and repairing is carried out again. According to the welding repairing process, an electric pulse low-temperature welding new technology is adopted for repairing, a solid element diffusion layer will be produced in a base surface layer, high-binding performance is shown, disengaging will not occur, the workpiece repairing efficiency is high, and after-treatment is convenient.

Owner:黄石市宏佳模具有限公司

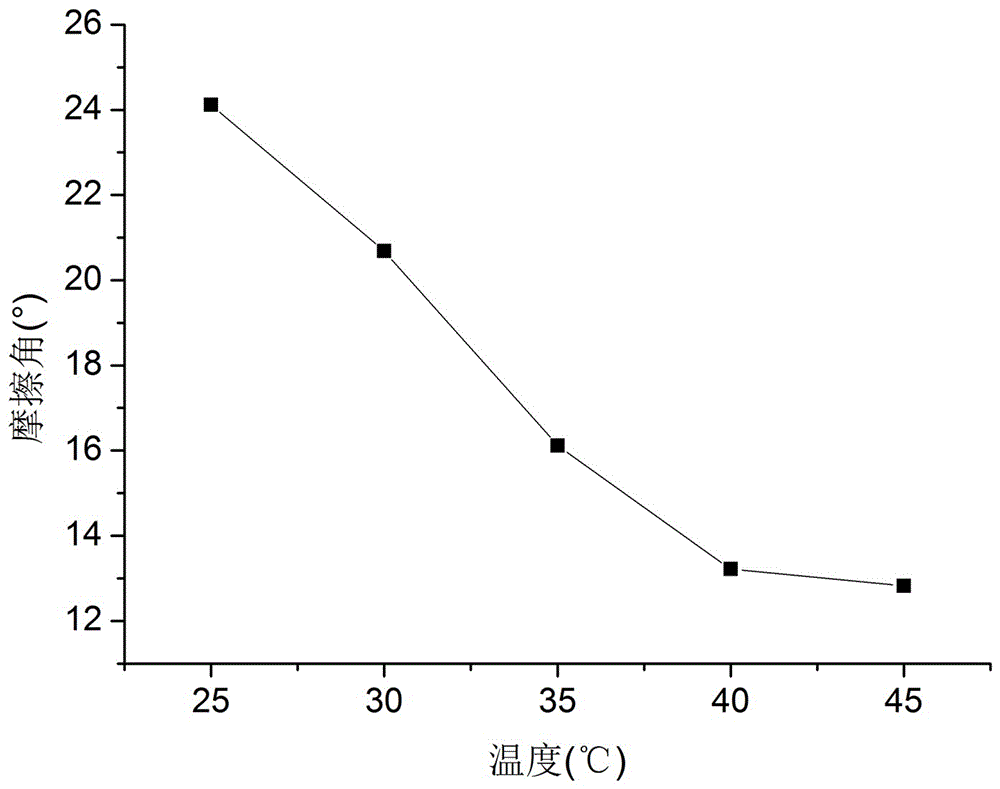

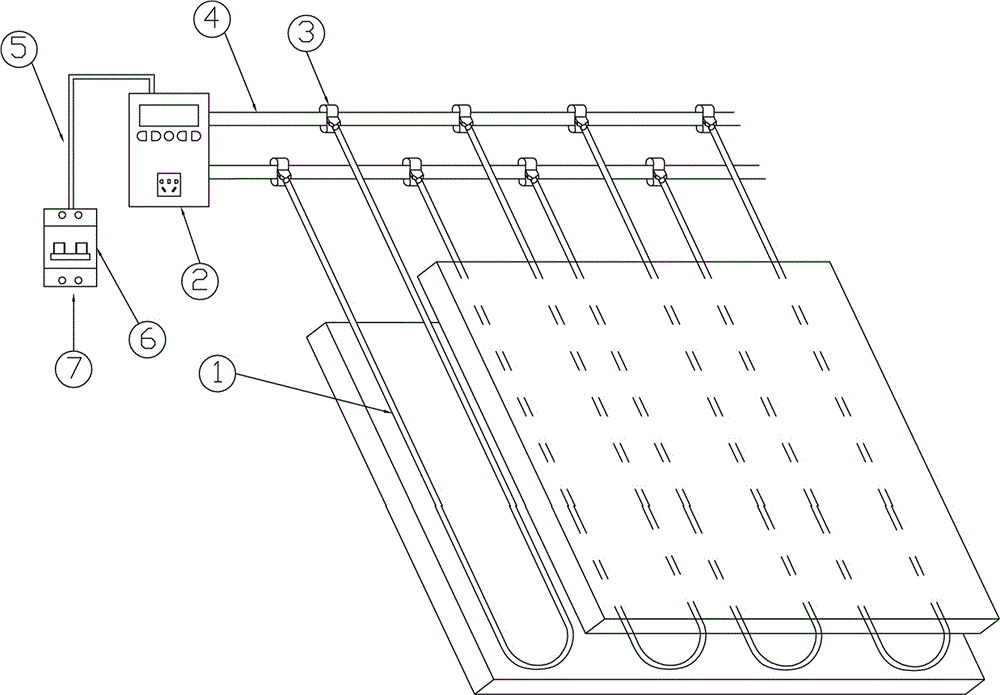

Geological temperature sensitive material capable of simulating weak bedding plane, making method and temperature control system thereof

InactiveCN105675385AWorkability is goodCompactMaterial strength using steady shearing forcesParaffin oilsWire breakage

The invention relates to the field of geomechanics, in particular to a geomechanical temperature sensitive material capable of simulating a weak bedding plane, and a making method and a temperature control system thereof. The material comprises the following components by weight: 45-55 parts of barite powder, 1.8-2.5 parts of cement, 1-4 parts of water, 1-5 parts of 46# waste hydraulic oil, 2-6 parts of paraffin, and 0.5-2 parts of rubber powder. The making method of the material consists of: mixing barite powder, rubber powder and cement uniformly, adding paraffin, 46# waste hydraulic oil and water into the obtained material 1, stirring the materials evenly and conducting molding. The material provided by the invention can be used in a temperature control system for temperature control experiment, and the system includes carbon fiber heating wires, a high precision temperature controller, non-wire breakage T type wiring terminals, a first group of lead, an air switch and a power supply. Multiple groups of the carbon fiber heating wires are placed in the geomechanical temperature sensitive material capable of simulating a weak bedding plane, and is connected to the first group of lead by a parallel connection mode. The geomechanical temperature sensitive material provided by the invention can simulate mechanical testing of the weak bedding plane.

Owner:CHINA THREE GORGES UNIV

Preparation method of diced meat-mustard pickle

The invention discloses a preparation method of diced meat-mustard pickle. The preparation method comprises the following steps: cutting the mustard into mustard shreds, and drying until the moisture content is 8-12% by weight; carrying out deep-frying on the diced pork until the diced pork is in toast tan; weighing diced pepper, Sichuan pepper powder and sugar in a weight ratio of 7:4:4 and uniformly mixing to obtain a mixture I; weighing peanut oil in a weight ratio of peanut oil to the mixture I being1.5:1, and pouring the peanut oil into the mixture I to obtain a mixture II; steaming the mustard shreds in a steam box at 100 DEG C for 10 minutes; putting the steamed mustard shreds, the diced pork and edible salt into a closed container, and fermenting for 6-8 days; weighing the fermented mustard shreds and the mixture II in a weight ratio of (95-100):(13-16); and uniformly stirring and sterilizing to obtain the diced meat-mustard pickle. In the preparation method disclosed by the invention, the drying is performed before steaming, the steamed mustard shreds easily get tasty and are soft with tenacity, and the mouthfeel is great; the diced meat-mustard pickle is suitable for different people at all ages. The preparation method disclosed by the invention is simple in the processing technology and suitable for automatic production in a factory.

Owner:刘诗茵

Spleen-invigorating and dampness-eliminating traditional Chinese medicine extract and preparation method and application thereof as well as spleen-invigorating and dampness-eliminating cream

ActiveCN104587311ABest ratioEdible with a long historyDigestive systemFood preparationFlavorMedicine

The invention discloses a spleen-invigorating and dampness-eliminating traditional Chinese medicine extract and a preparation method and an application thereof as well as a spleen-invigorating and dampness-eliminating cream. The spleen-invigorating and dampness-eliminating Chinese medicine extract is prepared by extracting the following raw materials in parts by weight: 3 to 4 parts of poria, 4 to 5 parts of yams, 3 parts of coix seeds, 3 to 4 parts of malt, and 1 part of tangerine peels. The poria, yams, coix seeds, malt, and tangerine peels are added to achieve the efficacies of invigorating the spleen and strengthening the middle energizer, and benefiting Qi and eliminating dampness, and can be used for alleviating the loss of appetite, abdominal distension, loose stools, dyspepsia, fatigue and weakness and other symptoms caused by the excessive dampness due to deficiency in spleen. The traditional Chinese medicinal materials in a formula are mutually synergized in property, flavor and function aspects, and the traditional Chinese medicine extract can be taken by people having excessive dampness due to deficiency in spleen.

Owner:广州白云山潘高寿药业股份有限公司

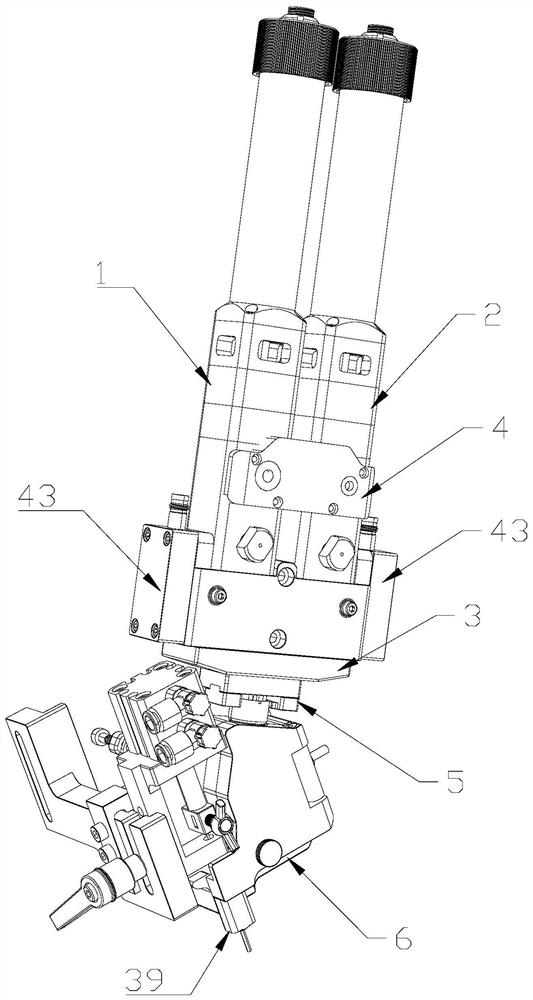

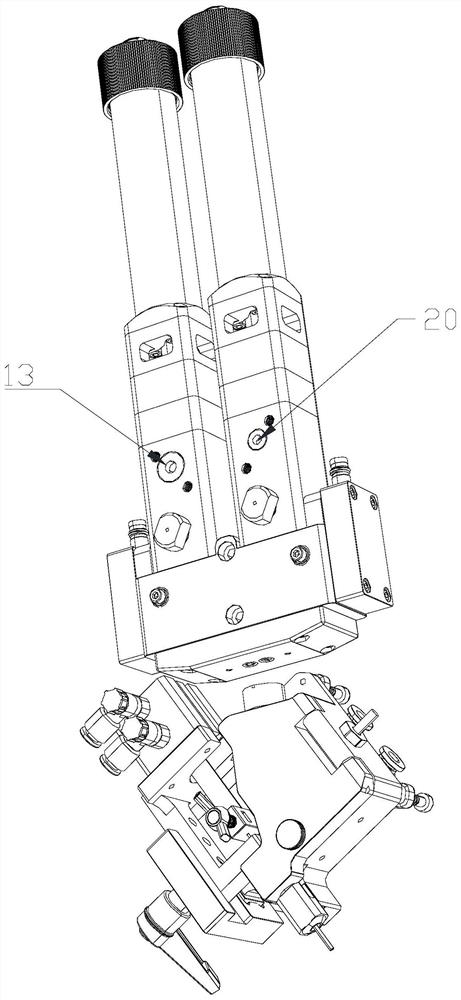

Liquid mixing method capable of accurately controlling flow

ActiveCN112827766AHigh trafficBest ratioLiquid surface applicatorsCoatingsEngineeringMechanical engineering

Owner:SUZHOU TERUITE ROBOT CO LTD

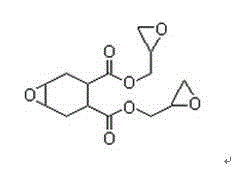

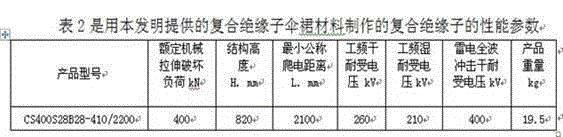

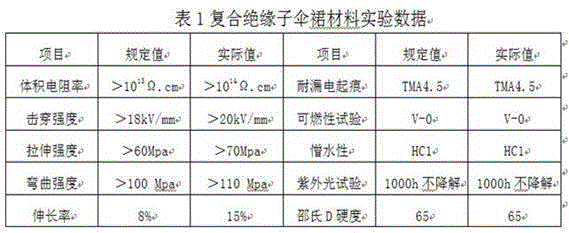

Shed material of composite insulator

The invention relates to a shed material of a composite insulator. The shed material is made from the following raw materials in parts by weight: 100 parts of component A, 80-120 parts of component B and 200-400 parts of component C, wherein the component A comprises diglycidyl cyclohexane dicarboxylate and flexible epoxy resin in the weight ratio of (70-90):(30-10); the component B comprises a curing agent and an accelerator in the weight ratio of 100:(1-5); and the component C comprises at least one of silicon dioxide or aluminium hydroxide. The shed material of the composite insulator, provided by the invention, is not prefabricated and is fabricated on site when pouring the shed mould of the insulator in the process of fabricating the insulator. The shed sheath of the composite insulator, fabricated by adopting the material provided by the invention, has the advantages of good toughness, tread resistance, difficulty in damage and good sealing property.

Owner:甘肃省电力公司检修公司 +2

Preparation method of sodium acetate

InactiveCN103833543ABest ratioRelaxed process conditionsOrganic compound preparationCarboxylic acid salt preparationSodium acetateGranularity

The invention discloses a preparation method of sodium acetate. According to the preparation method, optimal reactant ratio is determined based on researches on sodium acetate synthesis and crystallization technology, strong alkaline liquid filtration is not needed, condensation or proportion adjustment is not needed, conventional sample equipment is adopted, heating is not needed by technical processes, technical conditions are mild and stable, and requirements on equipment are low. Quality of obtained products is capable of meeting with requirements of Chinese pharmacopoeia 2010 and reagent grade standards; crystal size is uniform; yield is high; the preparation method is suitable for GMP industrial production of pharmaceutic adjuvants, and food-grade and reagent-grade industrial production.

Owner:TIANJIN KERMEL CHEM REAGENT

Etching method for silver-copper solder

The invention relates to an etching method for silver-copper solder. The etching method comprises the following steps of (1) alkaline oil removal, specifically, a brazed semi-finished product outer shell is put into an alkaline oil removal solution to be cleaned up; (2) water washing, specifically, the brazed semi-finished product outer shell is washed by tap water firstly and then washed by usingdeionized water; (3) pickling, specifically, the water-washed outer shell is put into a pickling liquid to be washed; (4) drying, specifically, a high-temperature blast drying box is used for high-temperature drying the water-washed outer shell; (5) etching, specifically, the outer shell is placed in an etching solution; and (6) final processing, specifically, the outer shell is taken out after etching is finished, the step (2) water washing and the step (4) drying are repeated. The etching method has the advantages that (1) the silver-copper solder is etched without any corrosion damage, thecoverage of outer shell brazing appearance, size, solder and subsequent plating reliability are high; (2) the etching process is slowed down, and the etching time range is increased; (3) environmental pollution is relieved; (4) the etching method is low in cost, simple and easy to operate; and (5) the problem of silver displacement of radio frequency power device outer shells is solved, and the effect is remarkable.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

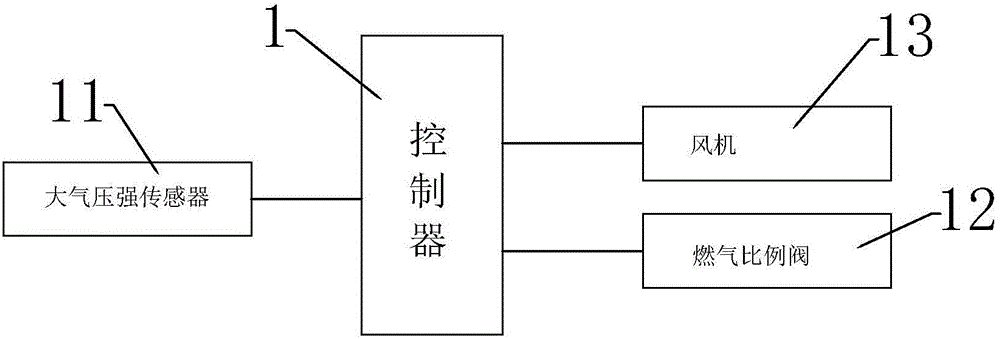

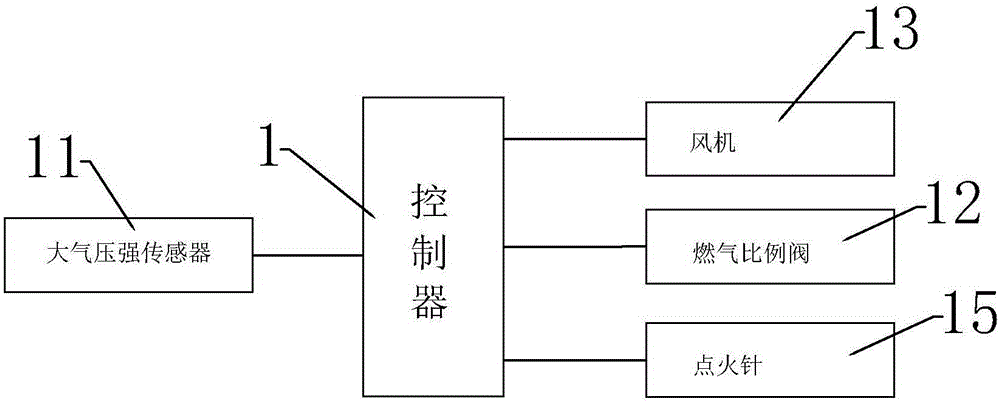

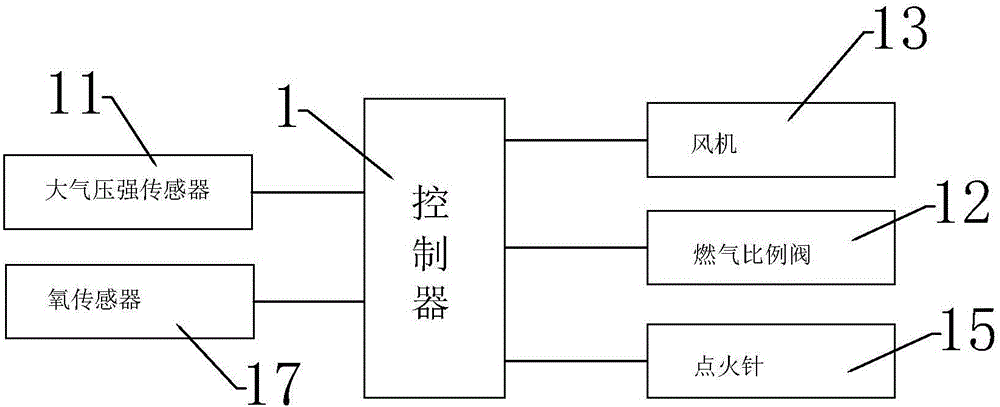

Energy-saving environment-friendly combustion heating control device

InactiveCN105091347ABest ratioSimple structureFluid heatersCombustion regulationElectrical conductorAtmospheric air

The invention discloses an energy-saving environment-friendly combustion heating control device. The energy-saving environment-friendly combustion heating control device comprises a controller, and the controller is connected with an atmospheric pressure sensor, a gas proportional valve and a fan through power conductors. The energy-saving environment-friendly combustion heating control device is simple in structure, and in the working process, according to atmospheric pressure data led in advance, the atmospheric pressure sensor detects the atmospheric pressure value of the exterior environment, and through the real-time atmospheric pressure value, the corresponding atmospheric pressure data which are led in advance can be found out; according to the corresponding atmospheric pressure data, power for starting the fan is determined, meanwhile, the controller determines the opening proportion of the gas proportional valve according to the preset data, and the proportion of entering of gas is controlled; and in the ignition process, gas and oxygen in the air are mixed so as to achieve the optimum gas and oxygen proportion needed by optimum ignition starting, and the mixed gas is fully combusted in a combustion heat exchanger.

Owner:广东奇林电气股份有限公司

Method for preparing microorganism organic fertilizer

InactiveCN105601391ABest ratioGood material to water ratioBioloigcal waste fertilisersFertilizer mixturesRice strawEnvironmental chemistry

The invention relates to the technical field of fertilizer preparation, in particular to a method for preparing microorganism organic fertilizer. The method comprises the following steps that firstly, a solid fermentation culture medium is prepared; secondly, rapidly-available phosphorus content is measured; thirdly, fertilizer production technological conditions are determined; fourthly, the fertilizer is prepared. According to the method, phosphorus ore waste tailing powder is utilized with waste resources such as rice straw and soybean sauce residues as auxiliary materials, the phosphate-containing organic fertilizer is prepared through microorganism fermentation treatment, a microorganism nitrogen source is provided through soybean sauce residues, on the premise that the straw is beneficial to the air permeability of the culture medium, single factor experiments and response surface experiments are adopted for optimizing the phosphate-solubilizing process of the phosphate-containing organic fertilizer prepared through fermentation based on a composite zymocyte prepared from aspergillus niger, lactic acid bacteria, acetic bacteria and bacillus megaterium, the optimal proportion of phosphorus ore waste tailing powder, rice straw and soybean sauce residues, the material and water ratio, the fermentation temperature and the fermentation time are determined, and necessary technological parameters and a certain technological base are provided for preparing the phosphate-containing organic fertilizer.

Owner:安徽新天地生物肥业有限公司

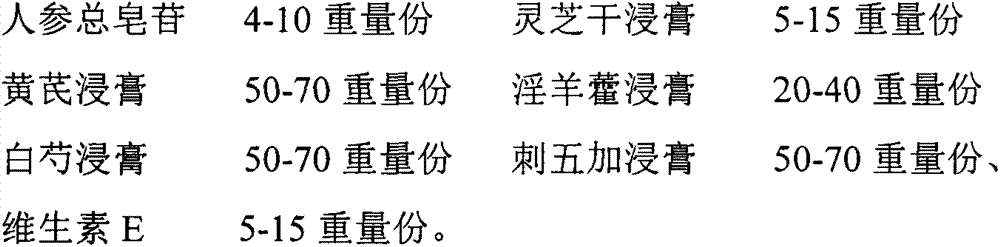

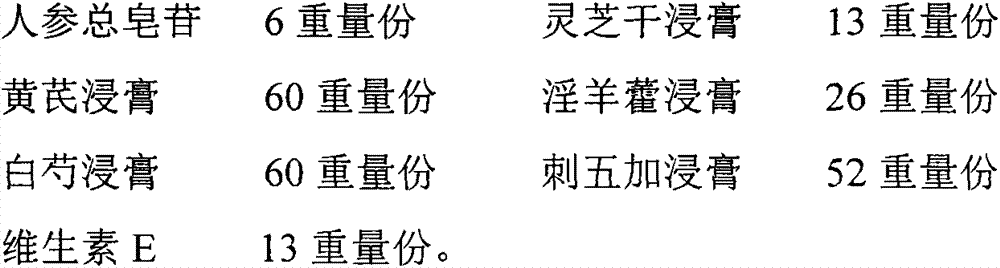

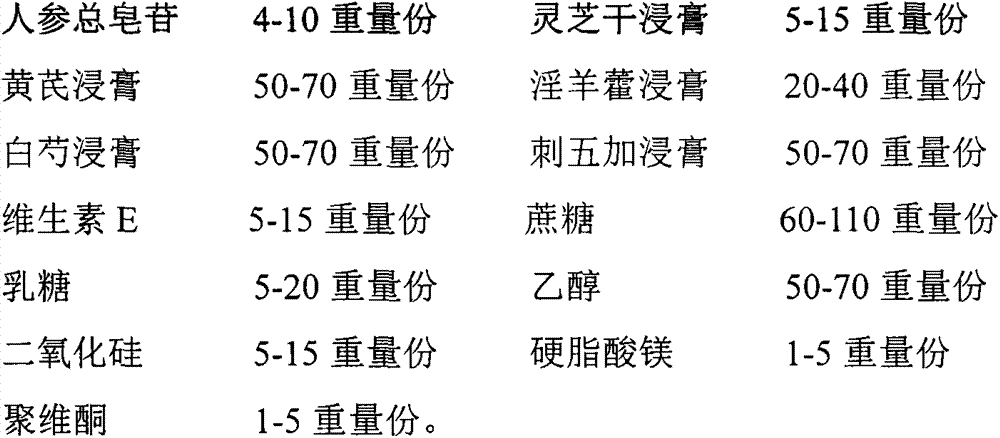

Pharmaceutical composition having functions of defying age and enhancing physique, preparation method and detection method thereof

ActiveCN104288245ABest ratioGood treatment effectOrganic active ingredientsNervous disorderEfficacyPharmaceutical drug

The invention relates to a pharmaceutical composition having functions of defying age and enhancing physique, a preparation method and a detection method thereof. The pharmaceutical composition is prepared by the following components: total saponins of panax ginseng, dry extract of lucid ganoderma, an extract of astragalus membranaceus, an extract of white peony root, an extract of acanthopanax and vitamin E. The pharmaceutical composition has the efficacy of invigorating spleen and nourishing kidney, nourishing yin and blood, and developing intelligence and tranquillizing. The pharmaceutical composition is suitable for fatigue, palpitaition, insomnia, forgetfulness and frequent micturition due to old and feeble physique.

Owner:GUANGZHOU BAIYUSN GUANGHUA PHARMA

Distribution method of heat consumption of fuel gas and steam combined cycle combined heat and power generation unit

InactiveCN108644858AImprove power generation efficiencyBest ratioLighting and heating apparatusSpace heating and ventilation detailsDistribution methodCogeneration

Owner:南京瑞松信息科技有限公司

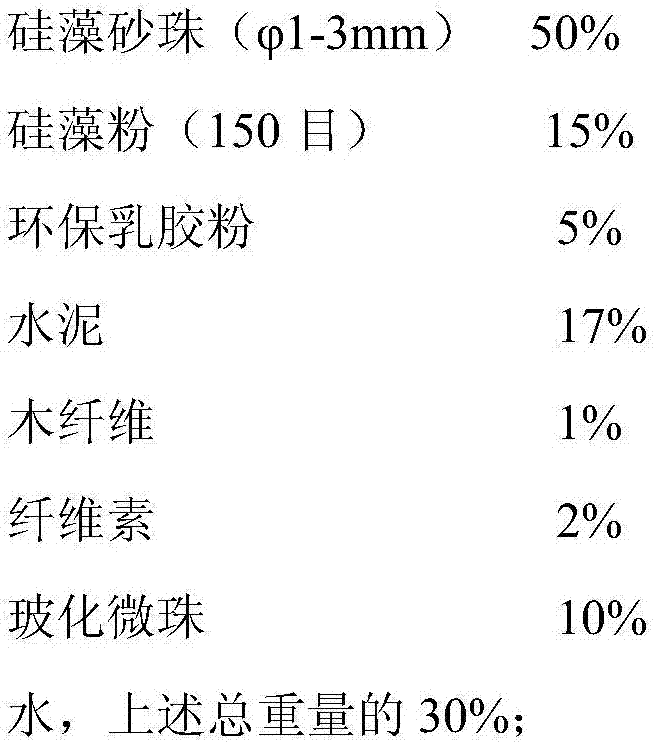

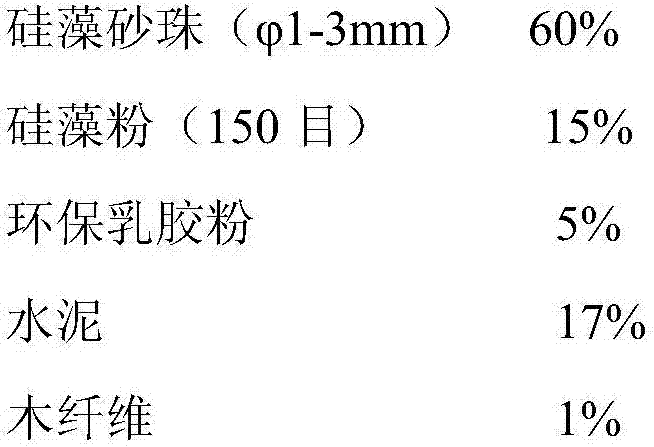

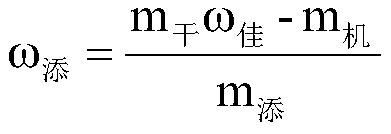

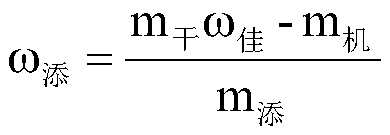

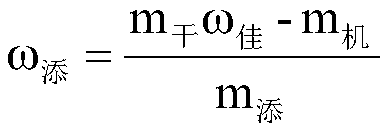

Diatom sand beads and high-strength, environment-friendly and thermal-insulation mortar containing same

The invention relates to diatom sand beads and high-strength, environment-friendly and thermal-insulation mortar containing the same. The diatom sand beads are prepared from second-class and third-class diatomite used as a raw material through four steps including drying, purification, granulation and roasting. The diatom sand beads are light in weight, environment-friendly and high in adsorbability and have the advantages of damp prevention, fire prevention, purification, thermal insulation and the like. The thermal-insulation mortar is prepared from 50%-60% of the diatom sand beads, 10%-20% of diatom powder, 5%-8% of environment-friendly latex powder, 10%-20% of cement, 1% of wood fiber, 2% of cellulose, 0-10% of glass beads and water. The thermal-insulation mortar can replace cement mortar to be directly applied to building wall brick surfaces, when the thermal-insulation mortar is used for an exterior wall, other decoration processes can be performed directly on the thermal-insulation mortar, and when the thermal-insulation mortar is used for an interior wall, the thermal-insulation mortar can well adsorb indoor formaldehyde produced during decoration, is environment-friendly and can purify indoor air; the thermal-insulation mortar has the advantages of being light in weight, low in heat conductivity coefficient, environment-friendly, thermal-insulation, high-temperature-resistant, fireproof, low-temperature-resistant, noise-reducing, damp-proof, mildew-proof, anti-condensation, free of radioactive substances, stable in physical and chemical property and the like.

Owner:长白朝鲜族自治县玉鑫硅藻土有限公司

Nutrient solution for instantly repairing skin

ActiveCN104784092AHigh nutritional valueNo side effectsCosmetic preparationsToilet preparationsSide effectThird generation

The invention discloses a nutrient solution for instantly repairing skin. The nutrient solution for instantly repairing skin is characterized by being prepared by mixing the following raw materials by weight: 75-100g of water, 5-10g of butanediol, 2-5g of glycerol, 1-3g of diethoxyethyl succinate, 0.2-2g of a snail extract, 0.1-1g of panthenol, 0.2-2g of nicotinamide, 0.1-1g of sodium hyaluronate, 0.08-0.1g of dipeptidyl diamino butyryl benzylamide diacetate, 0.1-0.3g of phenoxyethanol, 0.05-0.15g of octylene glycol and 0.1-0.2g of chlorphenesin. The nutrient solution for instantly repairing skin has the advantages that the snail is a health food and is free of toxic and side effects, and the snail meat is high in content of protein and low in content of fat being only 2%, contains more than 20 different amino acids essential to human body and also contains calcium, phosphorus, alkaloid, selenium, boron, zinc and other trace elements, so that the snail is high in nutritional value.

Owner:SHENYANG YIFEILIN BIOTECH CO LTD

In-situ cold recycling construction method for premixed foamed asphalt base layer and subbase layer

ActiveCN111485468AAvoid driftingGuaranteed qualityIn situ pavingsRoads maintainenceProcess engineeringEnvironmental geology

The invention provides an in-situ cold recycling construction method for a premixed foamed asphalt base layer and a subbase layer, and relates to the technical field of road engineering. The method sequentially comprises the following steps: S1, closing traffic; S2, preparing an original road; S3, putting a regeneration train unit in place; S4, performing premixing, adding and paving; S5, performing milling and mixing by a cold regenerator; S6, paving a regenerated mixture; S7, performing grinding; S8, carrying out joint treatment; and S9, maintaining the product. According to the method, thedemand quantity of gravels, mineral powder, cement and foamed asphalt according to the quantity of recycled aggregate milled on the original path, the mixing water demand quantity of a premixed additive is calculated and determined in combination with the optimal water content of a recycled mixture; and pre-mixing the calculated and determined required amount of water, powdery cement, gravel aggregate and mineral powder to form the premix additive. Therefore, the powder cement is prevented from drifting away, the cement, the crushed stone aggregate and the mineral powder with the optimal ratioare effectively added, and the optimal water content of the recycled mixture and the quality of the foamed asphalt are also ensured, so that the recycled mixture has high-quality performance indexes.

Owner:北京城建远东建设投资集团有限公司 +1

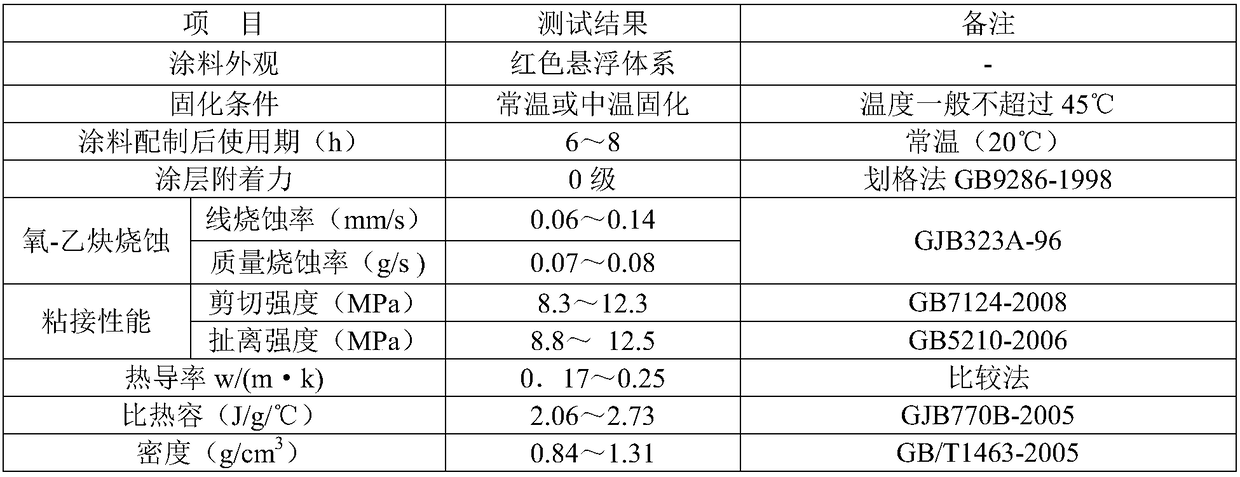

High efficiency heat prevention and heat insulation coating material and making method thereof

InactiveCN109021785ALow densityGood ablation resistanceChemical industryEpoxy resin coatingsSolventPolyamide

The invention provides a high efficiency heat prevention and heat insulation coating material and a making method thereof. The method includes: weighing and mixing 650 low molecular polyamide, 651 lowmolecular polyamide, 2-ethyl-4-methylimidazole evenly; adding a diluent composed of an X-12 solvent, ethyl acetate and anhydrous ethanol, fully mixing the substances to prepare a 50% low molecular polyamide composite curing agent system so as to form a component B; drying glass beads, iron oxide, mica powder, amine polyphosphate, aluminum hydroxide, silica and silicon carbide in a 80DEG C dryingoven for 5h, and conducting natural cooling to obtain a component C; and during use, fully mixing the component C, the component B and 100 mass parts of ES-06 epoxy silicone resin. The high efficiencyheat prevention and heat insulation coating material provided by the invention has the characteristics of low density, good ablation resistance, no swelling or cracking after coating curing, etc., and has excellent comprehensive performance.

Owner:西安长峰机电研究所

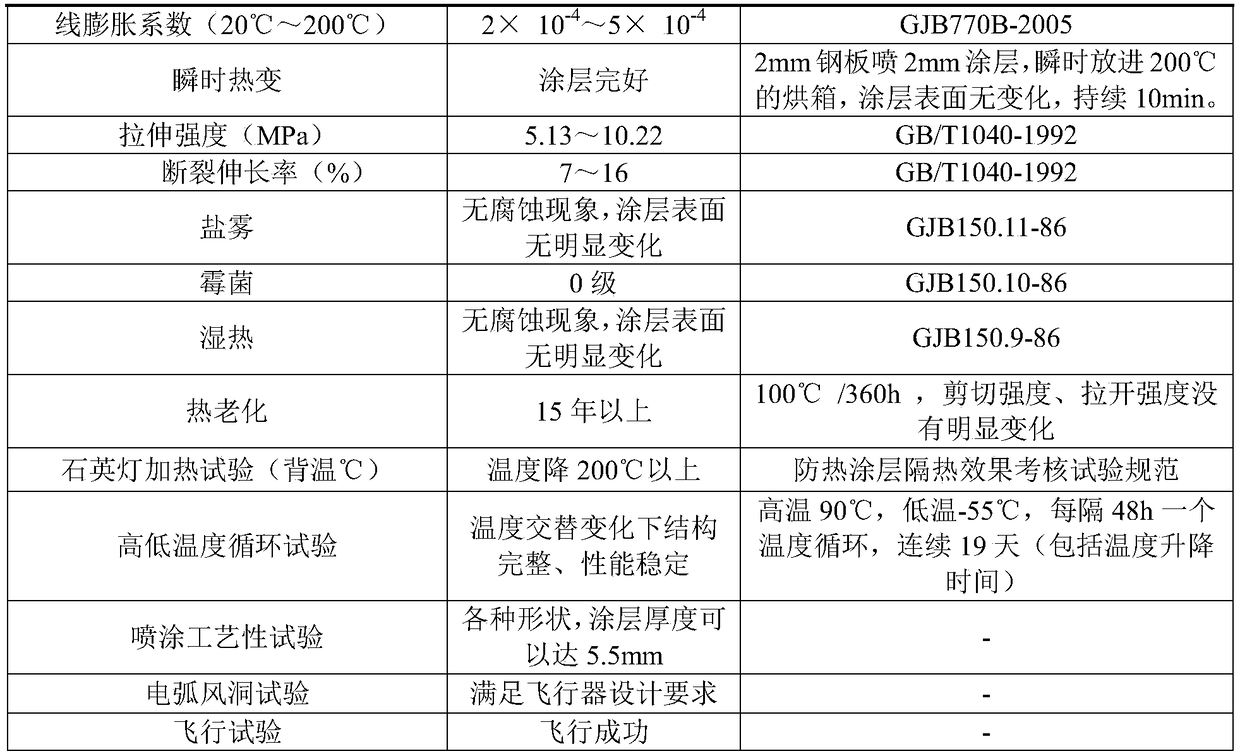

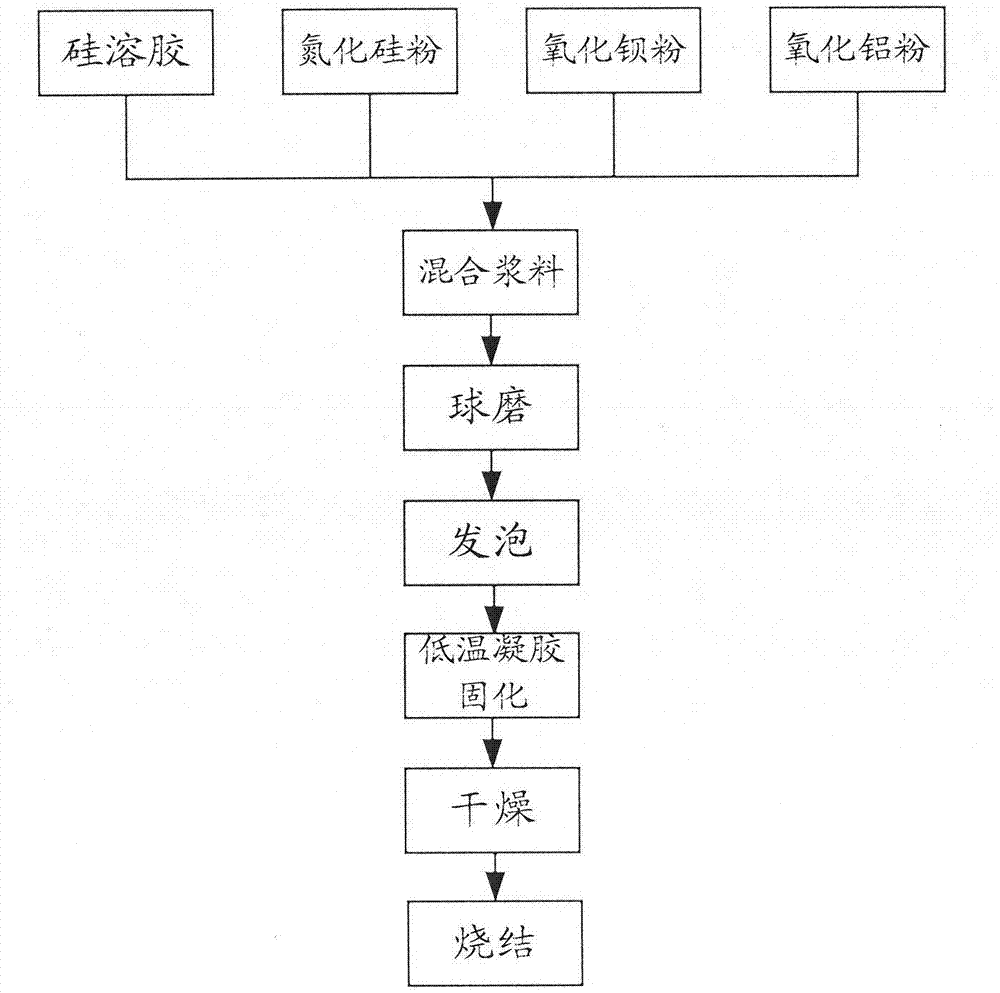

Method for preparing Si3N4/BAS foamed ceramic material

The invention provides a method for preparing a Si3N4 / BAS foamed ceramic material. The method is characterized in that a silicon sol is used as a liquid phase for preparing slurry; silicon nitride powder, barium oxide powder, aluminum oxide powder, and few dispersing agents and adhesives are added, and the quantity of added barium oxide and aluminum oxide references to the mass of silicon dioxide in the silicon sol; the materials are added in stoichiometric ratio of BaO-Al2O3-2SiO2 to prepare the slurry; the materials are mechanically agitated to be foamed, and then silicon sol is frozen at the low temperature for gelatinization so as to enable the ceramic foams to be quickly cured and formed, thus obtaining Si3N4 / BAS foamed ceramic.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

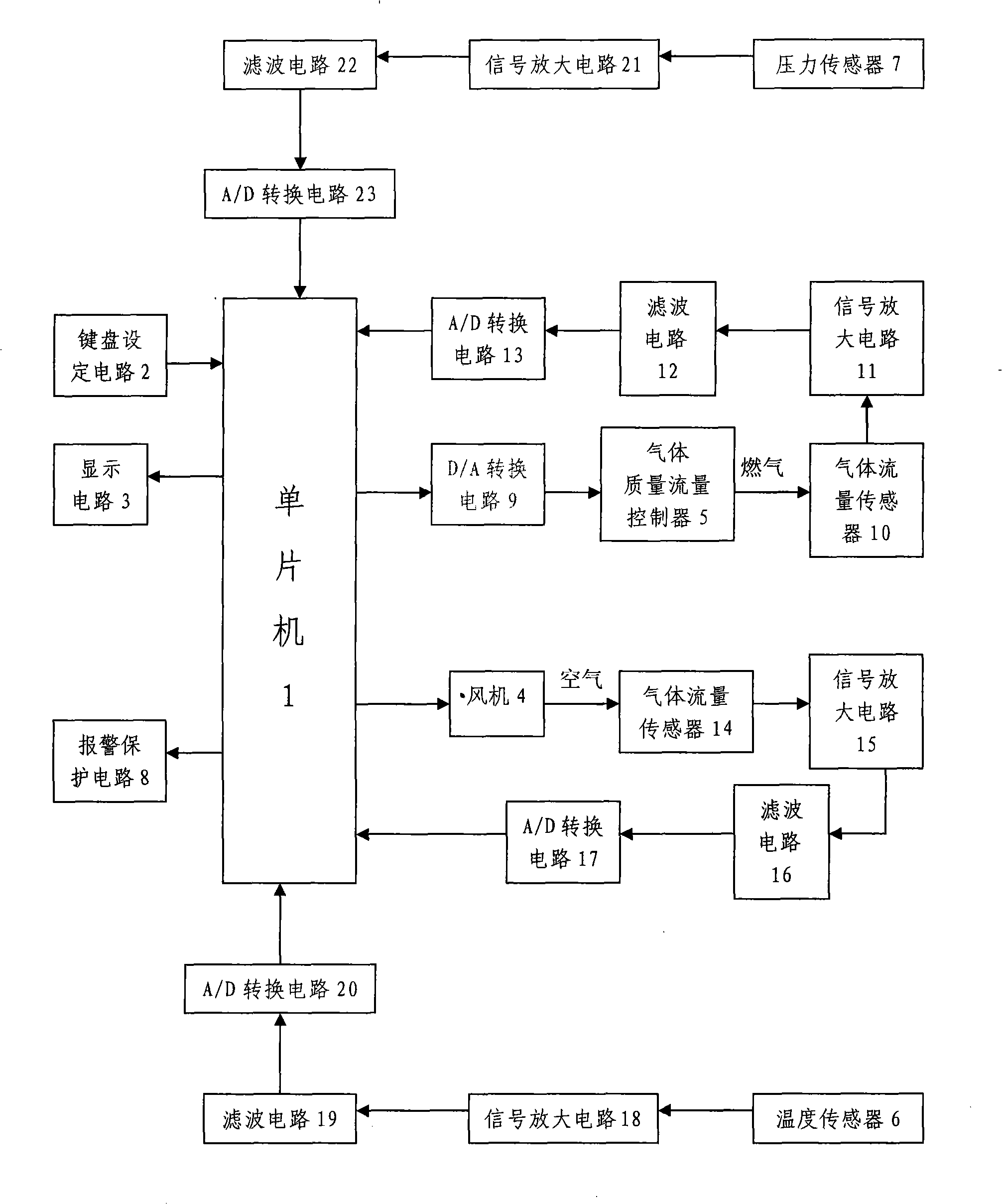

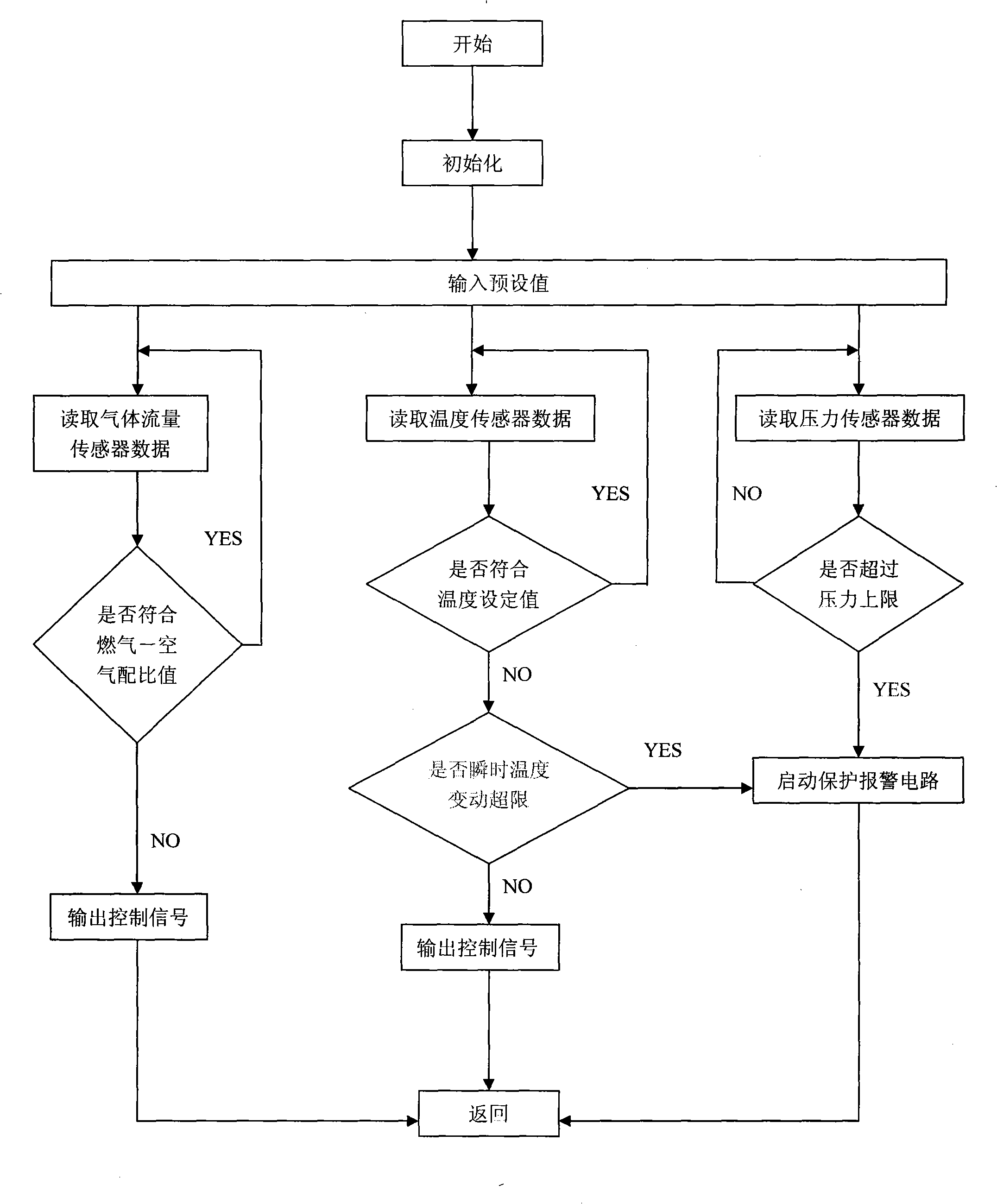

Complete pre-mixing type combustion system

InactiveCN101280918AUniform velocity fieldSimple structureCombustion apparatusCombustion regulationCombustion systemEngineering

The invention discloses a totally premixed combustion system, comprising a single-chip, a display circuit, a keyboard setting circuit, a signal amplification circuit, a wave filter circuit, an A / D translation circuit, a D / A translation circuit, a gas flow sensor, a draught fan and gaseous mass flow controller. The single-chip and display circuit, keyboard setting circuit are respectively connected; the single-chip are connected in sequence with the D / A translation circuit, gaseous mass flow controller, gas flow sensor, the signal amplification circuit, the wave filter circuit and the A / D translation circuit, the output end of the A / D translation circuit is connected onto the single-chip; the single-chip also are connected in sequence with the draught fan, the gas flow sensor, the signal amplification circuit, the wave filter circuit and the A / D translation circuit. The output end of the A / D translation circuit is connected onto the single-chip. The system has simple structure, safety and credibility, accurate control, the system can get optimum matching of gas and air in reason, thereby obtaining good energy-saving effect.

Owner:深圳市保力加燃气设备有限公司

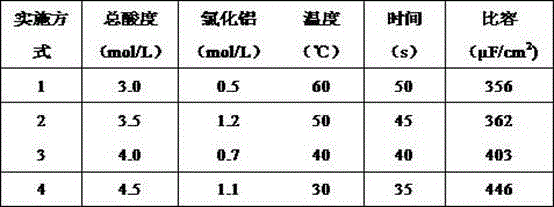

Manufacturing method of producing high-purity cathode foil by virtue of electrochemical corrosion

ActiveCN104480520AImprove superiorityIncrease specific volumeCapacitor electrodesCapacitancePower flow

The invention relates to a manufacturing method of producing a high-purity cathode foil by virtue of electrochemical corrosion and belongs to the technical field of manufacturing aluminum foils. The manufacturing method comprises the following technological process steps: pretreatment, primary corrosion, multi-stage corrosion, middle treatment, post-treatment, foil rewinding by drying and the like, wherein the multi-stage corrosion is the core of the whole process, is the key process for high specific capacitance and is a process of continuous electrolytic corrosion by virtue of different current densities, generally corrosion by virtue of 3-6 different alternating currents; during the multi-stage corrosion, the current densities change from small to large, the phenomena of powder dropping and polarization are avoided in the continuous electrochemical corrosion, and the production efficiency is relatively high. With the adoption of the manufacturing method, the produced high-purity cathode foil is low in content of impurity, the phenomenon of leakage current is relatively reduced as for an electrolytic capacitor, the production process is simplified, and the technological process is reduced due to the continuous electrochemical corrosion.

Owner:GUANGDONG HUAFENG NEW ENERGY TECH CO LTD +1

Duck circovirus and adenovirus bivalent inactivated vaccine and preparation method of yolk antibody thereof

InactiveCN111420042ASolving Manufacturing ChallengesBest ratioEgg immunoglobulinsViral antigen ingredientsAntigenAdjuvant

The invention relates to a duck circovirus and adenovirus bivalent inactivated vaccine and a preparation method of a yolk antibody thereof. A duck circovirus antigen is obtained by infecting 1-day-oldhealthy cherry valley ducklings and collecting infected duck livers at the age of 25 days to obtain antigen tissues, and an adenovirus antigen is obtained by infecting SPF chickens of 20 days old to30 days old and collecting livers of dead chickens; an antigen of the vaccine consists of liver tissues infected with the duck circovirus and liver tissues infected with the adenovirus in a mass ratioof (1-5):1, and an antigen solution for the vaccine is prepared; and a pine pollen polysaccharide with a concentration of 5-40mg / mL is added into the antigen solution to serve as an immunopotentiator, and the antigen solution is emulsified with a conventional white oil adjuvant to obtain the vaccine. The yolk antibody is obtained by immunizing laying hens with the vaccine, and then performing extracting and purifying on egg yolks of high-immunity laying hens, and the yolk antibody simultaneously contains two antibodies against the duck circovirus and the adenovirus. The vaccine and yolk antibody provided by the invention have the advantages of simple preparation process, low cost, good action effect, stable dosage form and easy storage, and has a wide application prospect.

Owner:山东百瑞凯来生物科技有限公司

Bagged instant Lingshui sour noodle sauce

The invention discloses a bagged instant Lingshui sour noodle sauce. The bagged instant Lingshui sour noodle sauce is prepared from the following ingredients in parts by weight: edible vegetable oil, shallot fragments, smashed garlic, smashed ginger, smashed chilli, onion fragments, smoked plum sauce, fermented bean curd, soybean paste, dark soy sauce, capsicum chinense sauce, sesame, peanut powder, white sugar, rice vinegar, brown granulated sugar, salt, oyster sauce, sesame oil, an appropriate amount of cold water, starchy flour and flour. The bagged instant Lingshui sour noodle sauce achieves a good effect by a good ratio, is natural and comfortable in sour and piquancy, is very suitable for instant Lingshui sour noodles as a seasoning, and has the advantages of being simple to prepare, natural and strong in flavour, and the like.

Owner:吉卫星

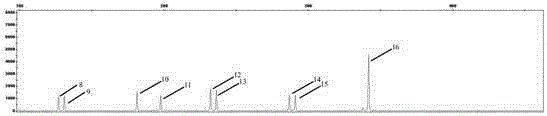

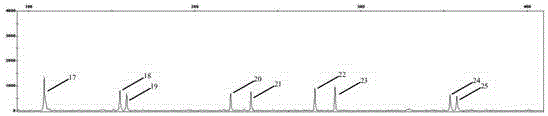

Primers, kit and method for detecting short tandem repetitive sequence

ActiveCN106701988AImprove accuracyReduced slip peak ratioMicrobiological testing/measurementDNA/RNA fragmentationHematopoietic stem cell transplantationBioinformatics

The invention belongs to the gene engineering technical field, and discloses a primer combination for detecting a short tandem repetitive sequence, a kit containing the primer combination and a method for detecting the short tandem repetitive sequence. Gene loci having high China people genetic polymorphism are selected and are more suitable for China people; the number of the selected tandem repetitive units is four, five or six, the slip peak ratio can be effectively reduced, and the accuracy of test results is higher; a fluorescent labeling composite amplification system is used for amplification, and amplified products can be subjected to electrophoresis in a same capillary, to achieve detection analysis of all the gene loci at the same time; a fluorescent label with mature technology is used for fluorescent labeling, and thus the cost is low; the detection method has good specificity and can be used for qualitative analysis such as individual identification, paternity identification, population genetic studies and the like, and can also be used for qualitative analysis of detection of the chimerism rate after hematopoietic stem cell transplantation.

Owner:SHANGHAI TISSUEBANK MEDICAL LAB CO LTD +3

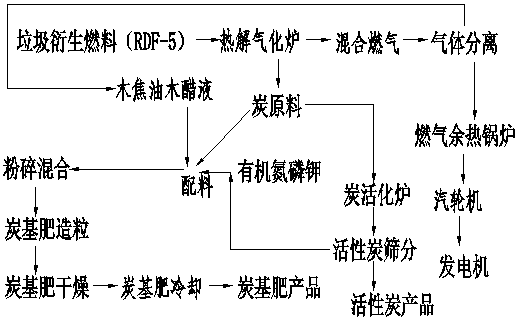

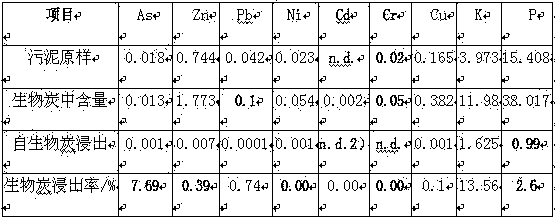

Heat and power cogeneration process for charcoal fertilizer and activated charcoal by taking municipal refuse derived fuel RDF-5 as raw material

InactiveCN108033446ACombined heat and powerEasy to storeCarbon compoundsOrganic fertilisersRefuse-derived fuelResource utilization

The invention discloses a heat and power cogeneration process for a charcoal fertilizer and activated charcoal by taking municipal refuse derived fuel RDF-5 as a raw material. The heat and power cogeneration process comprises the steps: 1) pyrolysis and gasification, namely delivering the fuel RDF-5 into a gasification furnace, carrying out pyrolysis and gasification under micro-aerobic conditionsthat the temperature is 600-800 DEG C and the equivalent ratio of air is 0.18-0.25 to obtain biomass mixed fuel gas and a biochar raw material, and discharging the biomass mixed fuel gas and the biochar raw material; 2) separation, namely purifying the biomass mixed fuel gas, and removing wood tar oil and a wood vinegar liquid to obtain a mixed liquid of the wood tar oil and the wood vinegar liquid and purified fuel gas; 3) combustion, namely delivering the purified fuel gas into a gas-fired boiler for combusting to generate steam; and 4) charcoal raw material treatment, namely delivering a part of the biochar raw material into a charcoal activation furnace to be heated to 900-960 DEG C, meanwhile, introducing the steam to the charcoal activation furnace to obtain activated charcoal; andmixing the other part of the biochar raw material with the mixed liquid of the wood tar oil and the wood vinegar liquid and an organic nitrogen, phosphorus and potassium fertilizer. The heat and powercogeneration process has the advantages of high calorific value utilization ratio and low emission pollution level and is not only capable of effectively solidifying poisonous heavy metals in the derived fuel, but also capable of obtaining a high-quality charcoal-based compound fertilizer or activated charcoal and increasing the resource utilization rate and the comprehensive economic benefit.

Owner:四川雷鸣生物环保工程有限公司

Method for manufacturing industrialized high-energy lithium iron phosphate material

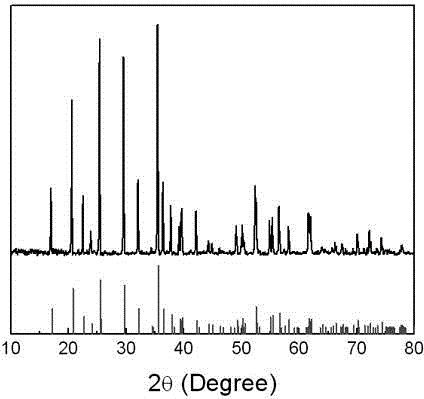

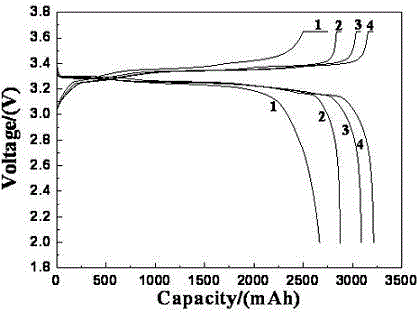

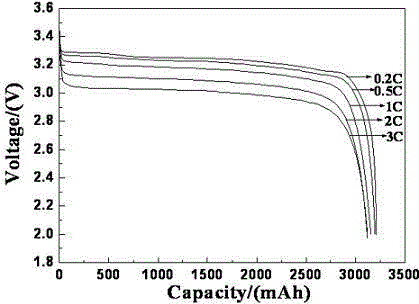

ActiveCN102916179BImprove compactionIncrease capacityCell electrodesState of artLithium iron phosphate

The invention relates to a method for manufacturing lithium iron phosphate materials, in particular to the method for manufacturing an industrialized high-energy lithium iron phosphate material. The method is mainly used for solving the technical problems that the existing lithium iron phosphate materials in the prior art are manufactured in a laboratory, are manufactured in a complicated process and are converted into industrialized products difficultly; and high power capacity batteries are manufactured difficultly if the materials with poor particle size distribution and bad material compaction capacity are adopted because the materials are processed only after a primary ball-milling is performed. The method provided by the invention comprises the following steps: adding and mixing lithium salt, ferric salt and phosphor salt twice and performing a wet ball milling twice to obtain two groups of slurry materials with different particle sizes; mixing, drying and presintering the two groups of the slurry materials in different proportions, carrying out the third wet ball milling and sintering on the slurry materials; and finally obtaining the high-energy lithium iron phosphate material.

Owner:杭州金马新能源科技有限公司

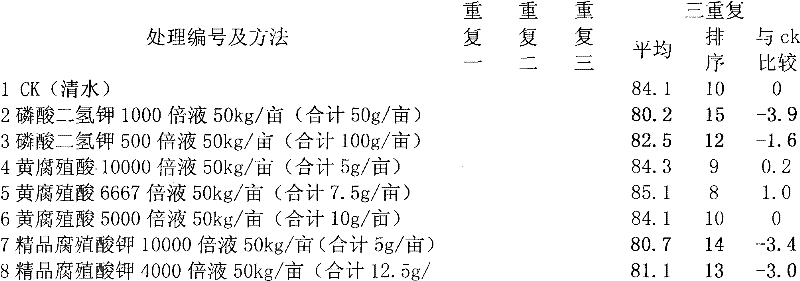

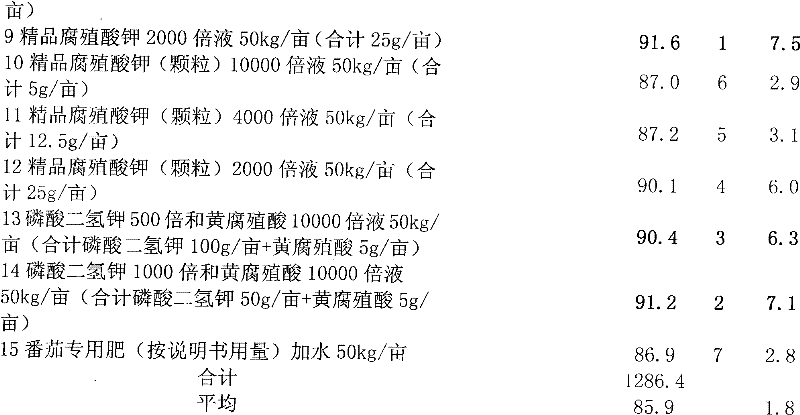

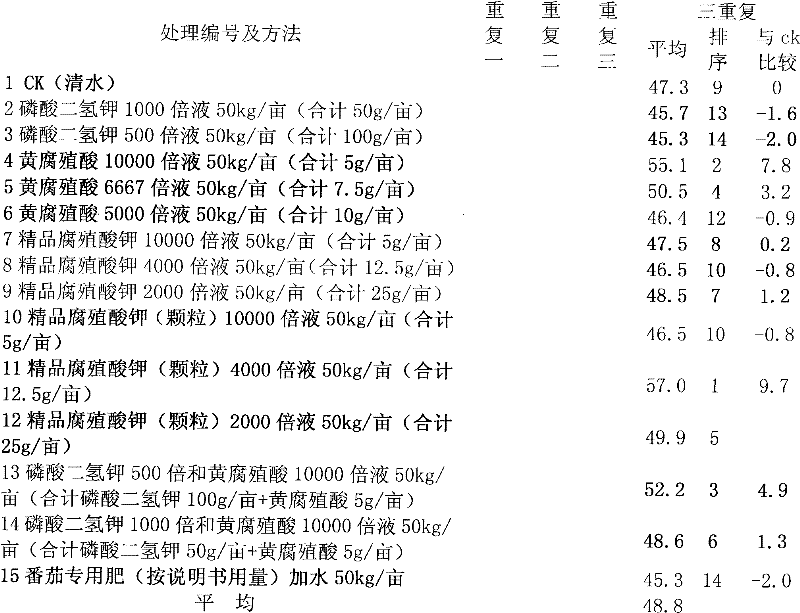

Foliar fertilizer special for tomatoes

The invention relates to a foliar fertilizer special for tomatoes. The foliar fertilizer special for tomatoes contains not less than 80% of humic acid (by HA dry basis), not less than 10% of K2O, and not more than 15% of H2O in percentage by weight, wherein the pH value is 8-11. The foliar fertilizer special for tomatoes is in the shape of a black sheet or a powder; the diluted foliar fertilizer can be brown sauce-shaped liquid, and the effective concentration is reduced with the increment of diluting factor. The foliar fertilizer for tomatoes has the advantages of saving the production cost, increasing the yield and realizing simple and convenient use method.

Owner:XINJIANG AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com