Liquid mixing method capable of accurately controlling flow

A technology of precise control and flow, applied in the field of machinery, can solve the problems of inability to accurately control the mixing ratio of glue, low precision of the flow monitoring module, and inability to realize accurate monitoring of the mixing ratio of glue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

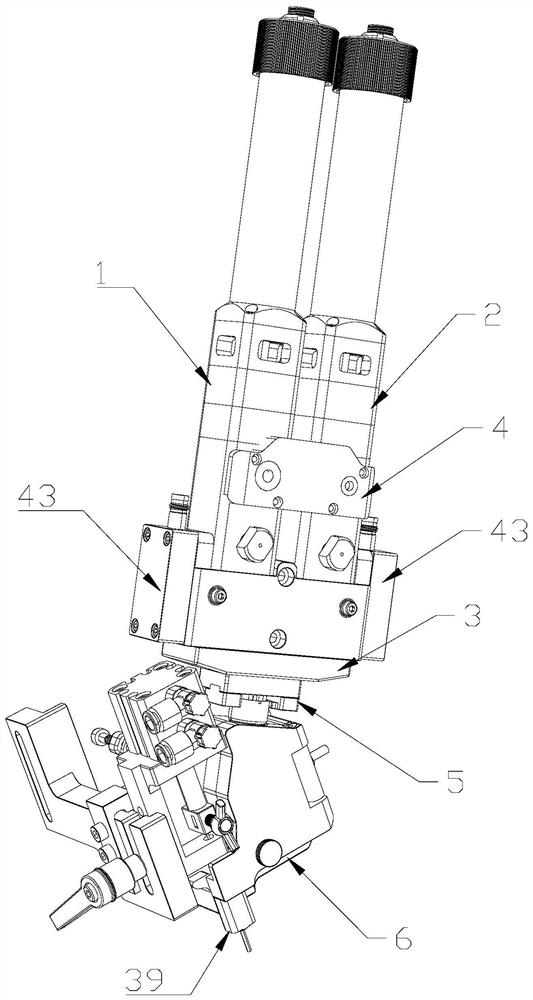

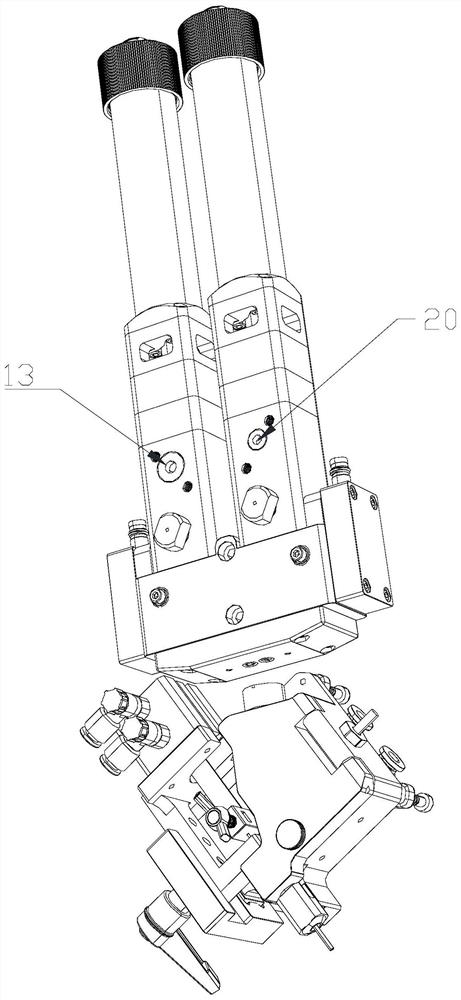

[0066] Example 1: A dual-liquid screw valve capable of precise flow control

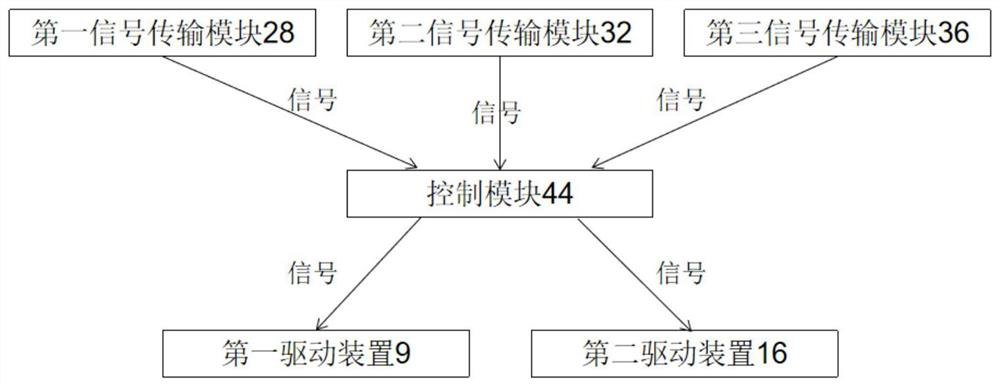

[0067] Such as Figure 1-23 , the present invention provides a dual-liquid screw valve that can precisely control the flow rate, the double-liquid screw valve includes a first liquid inlet module 1, a second liquid inlet module 2, a liquid outlet module 3, a first monitoring module 4, a second liquid inlet module The second monitoring module 5, the third monitoring module 6 and the control module 44;

[0068] The first liquid inlet module 1 includes a first screw pump 7 and a first liquid inlet block 8, the first screw pump 7 includes a first drive device 9, a first rotor 10 and a first stator 11, and the first liquid inlet block 8 includes a first inner chamber 12 and a first liquid inlet hole 13 communicating with the first inner chamber 12, the first rotor 10 is inserted into the first inner chamber 12 from the top of the first liquid inlet block 8, and the first stator 11 is inserted into the fi...

Embodiment 2

[0089] Embodiment 2: A kind of liquid mixing method that can precisely control the flow rate

[0090] The present invention provides a liquid mixing method capable of precisely controlling the flow, which is used in the double-liquid screw valve capable of precisely controlling the flow described in Example 1; wherein, the liquid mixing method includes:

[0091] The control module calculates the liquid pumping volume per unit time of the first liquid inlet module and the pumping volume of the second liquid inlet module per unit time according to the mixing ratio of the two liquids to be mixed;

[0092] The control module controls the output flow rate of the first liquid inlet module by controlling the rotation speed of the first rotor according to the liquid pumping volume per unit time of the first liquid inlet module, and controls the output flow rate of the first liquid inlet module according to the The pump output per unit time is controlled by controlling the rotation spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com