Diatom sand beads and high-strength, environment-friendly and thermal-insulation mortar containing same

A technology of thermal insulation mortar and diatom sand, which is applied in the field of diatom sand beads and high-strength environmental protection thermal insulation mortar containing diatom sand beads, which can solve the problems of ineffective utilization, waste of secondary and tertiary diatomite, etc. Strong, low thermal conductivity, broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 A kind of diatom sand bead

[0028] The diatom sand beads provided by the present invention are prepared by using secondary and tertiary diatomite as raw materials through four processes of drying, purification, granulation and calcination. The specific preparation method is as follows: drying the second and third grade diatomite at 150-200°C, purifying with a crushing and air separator, and using a granulator to make the diatomite with a diameter of 1-3mm. , and then calcined at 750-850 ° C to obtain diatom sand beads.

Embodiment 2

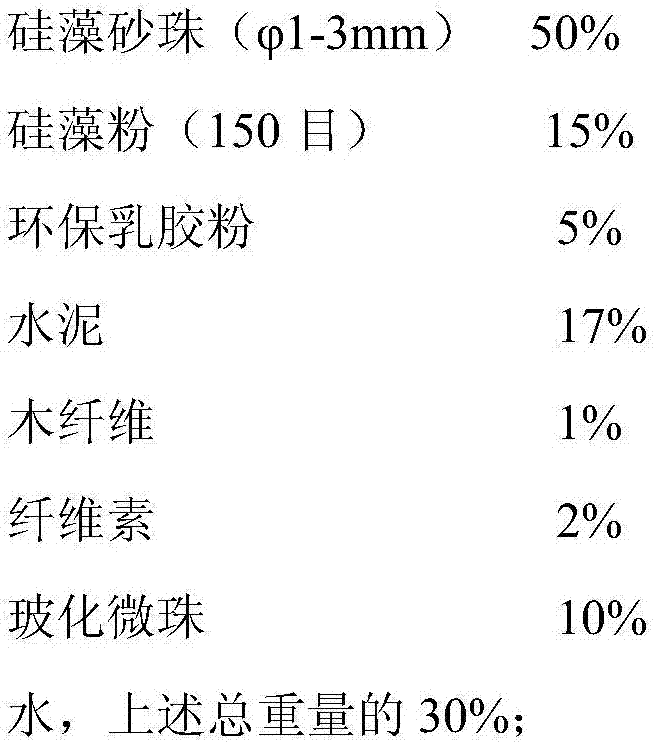

[0029] Embodiment 2 A kind of high-strength environment-friendly thermal insulation mortar containing diatom sand beads

[0030]

[0031] Wherein, the preparation method of the diatom sand beads is as follows: drying the secondary or tertiary diatomite at 150-200° C., purifying with a pulverizing air separator, and granulating the purified diatomite by air selection. Machine-made particles with a diameter of 1-3mm, and then calcined at 750-850°C to obtain diatom sand beads;

[0032]The preparation method of the diatom powder is as follows: drying the secondary or tertiary diatomite at 150-200 DEG C, and purifying it with a crushing and wind separator, and passing the diatomite after wind selection and purification through a 150-mesh sieve to obtain Diatom powder.

Embodiment 3

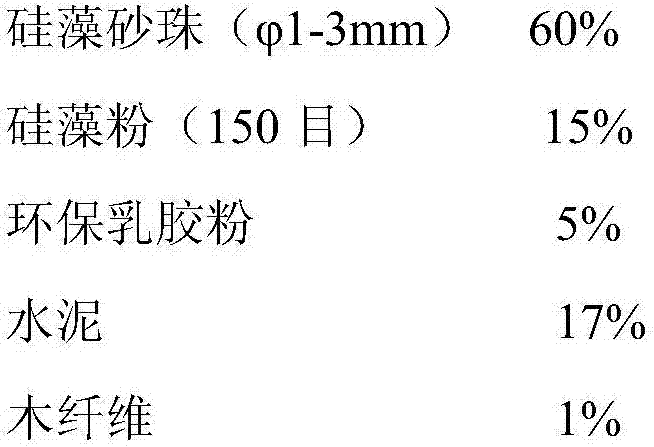

[0033] Embodiment 3 A kind of high-strength environment-friendly thermal insulation mortar containing diatom sand beads

[0034]

[0035]

[0036] Wherein, the preparation method of the diatom sand beads and the preparation method of the diatom powder are the same as those in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com