High efficiency heat prevention and heat insulation coating material and making method thereof

A thermal insulation coating, an efficient technology, applied in coatings, epoxy coatings, sustainable manufacturing/processing, etc., can solve the problems of high temperature curing bulging cracks, poor thermal insulation of coatings, high brittleness, and achieve ablation resistance. Good performance, good toughness and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

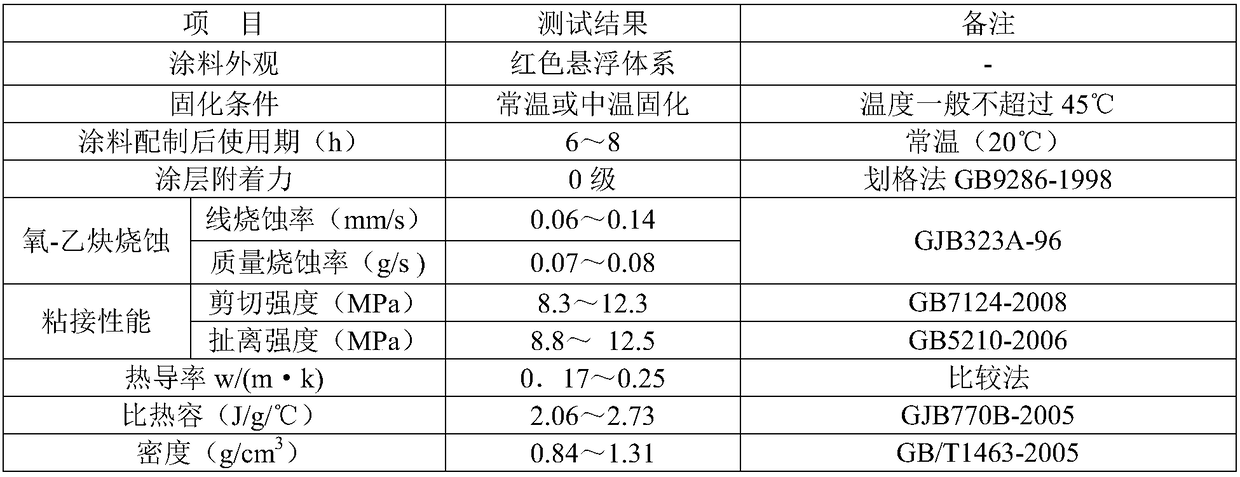

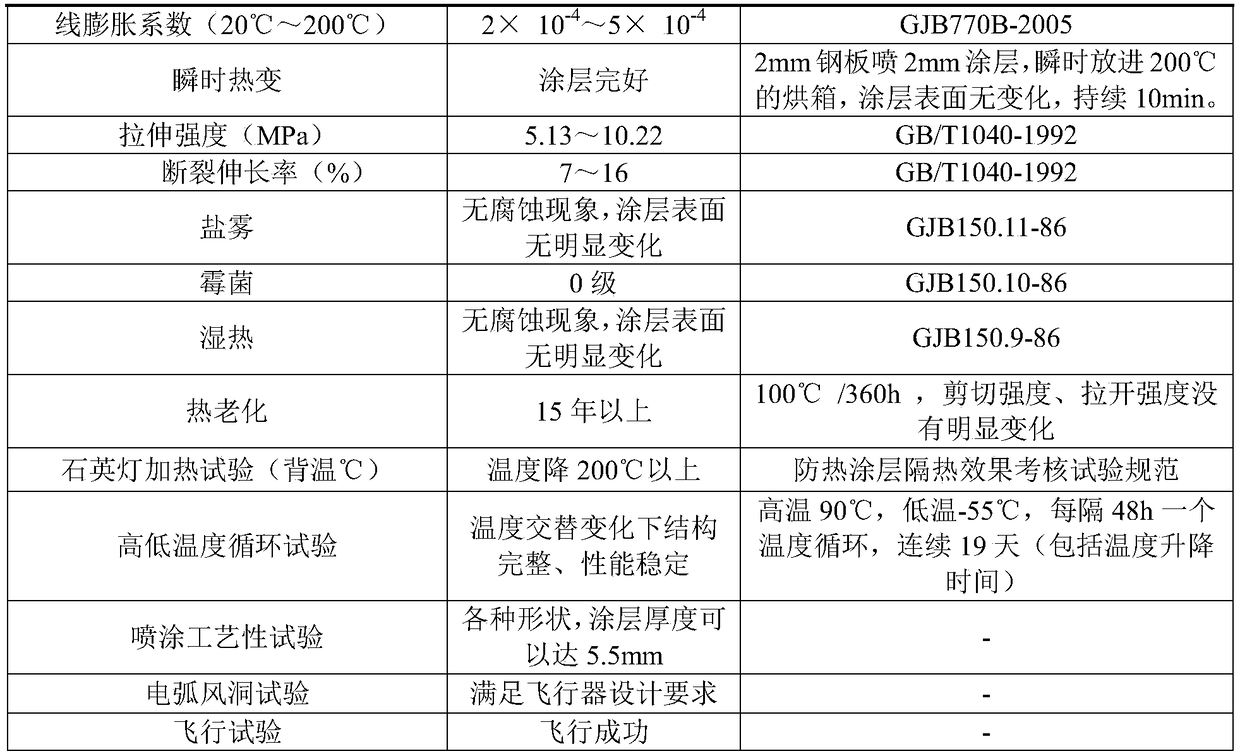

[0057] Implemented products: External heat protection of type I high Mach number aircraft, the coating thickness is required to be 0.45mm to 0.65mm, and the coating formula used is shown in Table 3.

[0058] Table 3 Low-density heat-resistant and heat-insulating coating formulation composition

[0059] serial number

Element

Proportion (parts by mass)

effect

1

100

film forming

2

650 low molecular weight polyamide

10

toughness curing agent

3

651 low molecular weight polyamide

4

toughness curing agent

4

2-Ethyl-4-methylimidazole

2

Hardener

5

Glass beads (1000 mesh)

6

insulation

6

Iron oxide (industrial)

3

heat proof

7

18

insulation

8

Amine polyphosphate (industrial)

6

flame retardant

9

Aluminum hydroxide (120 mesh)

8

flame retardant

10

Silica (120 mesh...

Embodiment 2

[0067] Implemented products: Type II new long-endurance aircraft external heat protection, coating thickness 4.5mm ~ 5.5mm, turning to 3.5mm ± 0.1mm, the coating formula used is shown in Table 5.

[0068] Table 5 Formulation of low-density heat-resistant and heat-insulating coating

[0069] serial number

components

Proportion (parts by mass)

effect

1

100

film forming

2

650 low molecular weight polyamide

20

toughness curing agent

3

651 low molecular weight polyamide

8

toughness curing agent

4

2-Ethyl-4-methylimidazole

4

Hardener

5

Glass beads (1000 mesh)

15

insulation

6

Iron oxide (industrial)

6

heat proof

7

25

insulation

8

Amine polyphosphate (industrial)

10

flame retardant

9

Aluminum hydroxide (120 mesh)

14

flame retardant

10

Silica (120 mesh)

...

Embodiment 3

[0077] The internal heat protection of Type III aircraft launch equipment, the coating thickness is 0.15mm-0.25mm, and the coating formula used is shown in Table 7.

[0078] Table 7 Formulation of low-density heat-resistant and heat-insulating coating

[0079] serial number

components

Proportion (parts by mass)

effect

1

ES-06 epoxy silicone resin

100

film forming

2

650 low molecular weight polyamide

15

toughness curing agent

3

651 low molecular weight polyamide

8

toughness curing agent

4

2-Ethyl-4-methylimidazole

3

Hardener

5

Glass beads (1000 mesh)

13

insulation

6

Iron oxide (industrial)

5

heat proof

7

Mica powder (200 mesh)

23

insulation

8

Amine polyphosphate (industrial)

8

flame retardant

9

Aluminum hydroxide (120 mesh)

12

flame retardant

10

Silica (120 mesh)

15

heat proof

11

Si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com