Shed material of composite insulator

A composite insulator and shed technology, applied in the field of composite insulator shed materials, can solve the problems of packaging, transportation, installation, operation and maintenance difficulties, long composite insulator structure height, uneven potential distribution, etc. performance, improve hydrophobicity, easy to cure and form the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

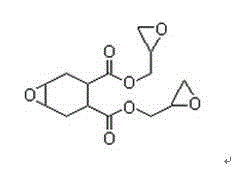

[0024] Example 1 1. First mix 50 grams of nitrile rubber with 300 grams of bisphenol A epoxy resin to obtain 350 grams of flexible epoxy resin, weigh 700 grams of bisglycidyl hexahydrophthalate and the flexible epoxy resin 300 grams get 1000 grams of A component; Acrylonitrile content is 16wt% in the nitrile rubber;

[0025] 2. Weigh 1,000 grams of methyl hexahydrophthalic anhydride as a curing agent and 30 grams of 2,4,6-tris(dimethylaminomethyl)phenol as an accelerator to obtain 1,030 grams of component B;

[0026] 3. Take by weighing 3500 grams of silicon dioxide as a filler, 30 grams of 4-dihydroxybenzophenone as an ultraviolet absorber, 15 grams of magnesium stearate as a stabilizer, and 20 grams of magnesium hydroxide as a flame retardant. gram, 10 grams of γ-glycidyl ether oxypropyltrimethoxysilane as coupling agent, get 3575 grams of C component; This silicon dioxide comprises the particle of 38 microns of 5wt%<particle diameter≤48 microns, 80wt% 23 microns < particle...

Embodiment 2

[0028] Example 2 1. First, mix 54 grams of carboxy-terminated nitrile rubber with 300 grams of bisphenol A diglycidyl ether to obtain 354 grams of flexible epoxy resin, and weigh 4,5-epoxycyclohexane-1,2- 2 800 grams of diglycidyl diformate and 200 grams of flexible epoxy resin get 1000 grams of A component; Acrylonitrile content is 12wt% in the carboxyl-terminated nitrile rubber;

[0029] 2. Weigh 1100 grams of methyl hexahydrophthalic anhydride as a curing agent and 45 grams of dimethylaniline as an accelerator to obtain 1145 grams of component B;

[0030] 3. Take by weighing 2000 grams of silicon dioxide as a filler, 10 grams of 4-dihydroxybenzophenone as an ultraviolet absorber, 5 grams of zinc stearate as a stabilizer, and 15 grams of aluminum hydroxide as a flame retardant. gram, 10 grams of gamma-methacryloxypropyltrimethoxysilane as coupling agent, get 2040 grams of C component; All the other are with embodiment 1

[0031] 4. When pouring the insulator shed mold; mix ...

Embodiment 3

[0033] 1. First mix 30 grams of carboxyl-terminated nitrile rubber with 200 grams of bisphenol A diglycidyl ether to prepare 230 grams of flexible epoxy resin, and weigh 4,5-epoxycyclohexane-1,2-2 dicarboxylic acid 850 grams of diglycidyl ester and 150 grams of flexible epoxy resin get 1000 grams of A component; Acrylonitrile content is 21wt% in the carboxyl-terminated nitrile rubber,

[0034]2. Weigh 1150 grams of methyl hexahydrophthalic anhydride as a curing agent and 50 grams of dimethylaniline as an accelerator to obtain 1200 grams of component B;

[0035] 3. Take by weighing 3000 grams of aluminum hydroxide as a filler, 24 grams of 4-dihydroxybenzophenone as an ultraviolet absorber, 16 grams of zinc stearate as a stabilizer, and 10 grams of magnesium hydroxide as a flame retardant. gram, 10 grams of β-(3,4-epoxycyclohexylethyl) trimethoxysilane as coupling agent, get 3060 grams of C component; All the other are with embodiment 1

[0036] 4. When pouring the insulator um...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com