Manufacturing method of producing high-purity cathode foil by virtue of electrochemical corrosion

A manufacturing method and high-purity technology, applied in capacitor electrodes, circuits, capacitors, etc., can solve problems such as low production efficiency and complicated process, and achieve the effects of simplified production process, reduced process flow, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

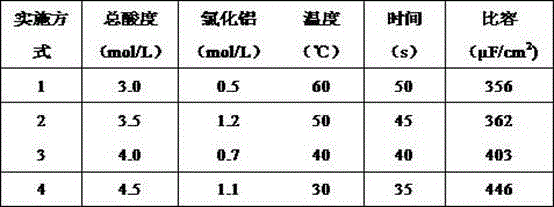

Embodiment 1

[0017] The pure aluminum-based aluminum foil (up to 99.8%) is pretreated (primary corrosion overflow solution) at a temperature of 20°C, and the action time: 90s. In a 60°C corrosion solution with 0.5mol / L aluminum chloride, the applied current density is 0.15A / cm 2 Under the conditions of primary corrosion for 10s, followed by surface chemical corrosion treatment, the temperature is 30°C, the action time is 80s, and then put into the 60°C corrosion solution with a total acidity of 3.0mol / L and an aluminum chloride of 0.5mol / L, and apply Current density: first level 0.02A / cm 2 , Level 2 0.05A / cm 2 , Level 3 0.08A / cm 2 , level 4 0.11A / cm 2 , level 5 0.13A / cm 2 , Level 6 0.18A / cm 2 , carry out staged corrosion for 50s, and finally process the treatment temperature is 60 ℃, the action time is 50s and post-treatment temperature is 70 ℃, the action time is 40s.

Embodiment 2

[0019] The pure aluminum-based aluminum foil (up to 99.8%) is pretreated (primary corrosion overflow liquid) at a temperature of 30°C, and the action time: 80s. In a 50°C corrosion solution with 0.8mol / L aluminum chloride, the applied current density is 0.18A / cm 2 Under the conditions of primary corrosion for 10s, followed by surface chemical corrosion treatment, the temperature is 40°C, the action time is 70s, and then put into the 50°C corrosion solution with a total acidity of 3.5mol / L and an aluminum chloride of 1.2mol / L, and apply Current density: first level 0.04A / cm 2 , Level 2 0.07A / cm 2 , Level 3 0.09A / cm 2 , level 4 0.11A / cm 2 , level 5 0.15A / cm 2 , Level 6 0.18A / cm 2 , carry out staged corrosion for 45s, the final in-process treatment temperature is 50°C, and the action time is 60s; the post-treatment temperature is 60°C, and the action time is 50s.

Embodiment 3

[0021] The pure aluminum-based aluminum foil (up to 99.8%) is pretreated (primary corrosion overflow solution) at a temperature of 40°C, and the action time: 70s. In a 40°C corrosion solution with 1.0mol / L aluminum chloride, the applied current density is 0.20A / cm 2 Under the condition of primary corrosion for 10s, followed by surface chemical corrosion treatment, the temperature is 50°C, the action time is 60s, and then it is put into a 40°C corrosion solution with a total acidity of 4.0mol / L and an aluminum chloride of 0.7mol / L. Current density: first level 0.05A / cm 2 , Level 2 0.07A / cm 2 , Level 3 0.09A / cm 2 , level 4 0.12A / cm 2, level 5 0.15A / cm 2 , Level 6 0.20A / cm 2 , carry out staged corrosion for 40s, and finally process the treatment temperature is 40 ℃, the action time is 70s and post-treatment temperature is 50 ℃, the action time is 60s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com