Complete pre-mixing type combustion system

A combustion system, pre-mixed technology, applied in the direction of combustion control, combustion equipment, lighting and heating equipment, etc., can solve the problems of poor flame stability, small adjustment range, large structure, etc., to achieve uniform velocity field, uniform and stable flow rate, The effect of simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below through examples.

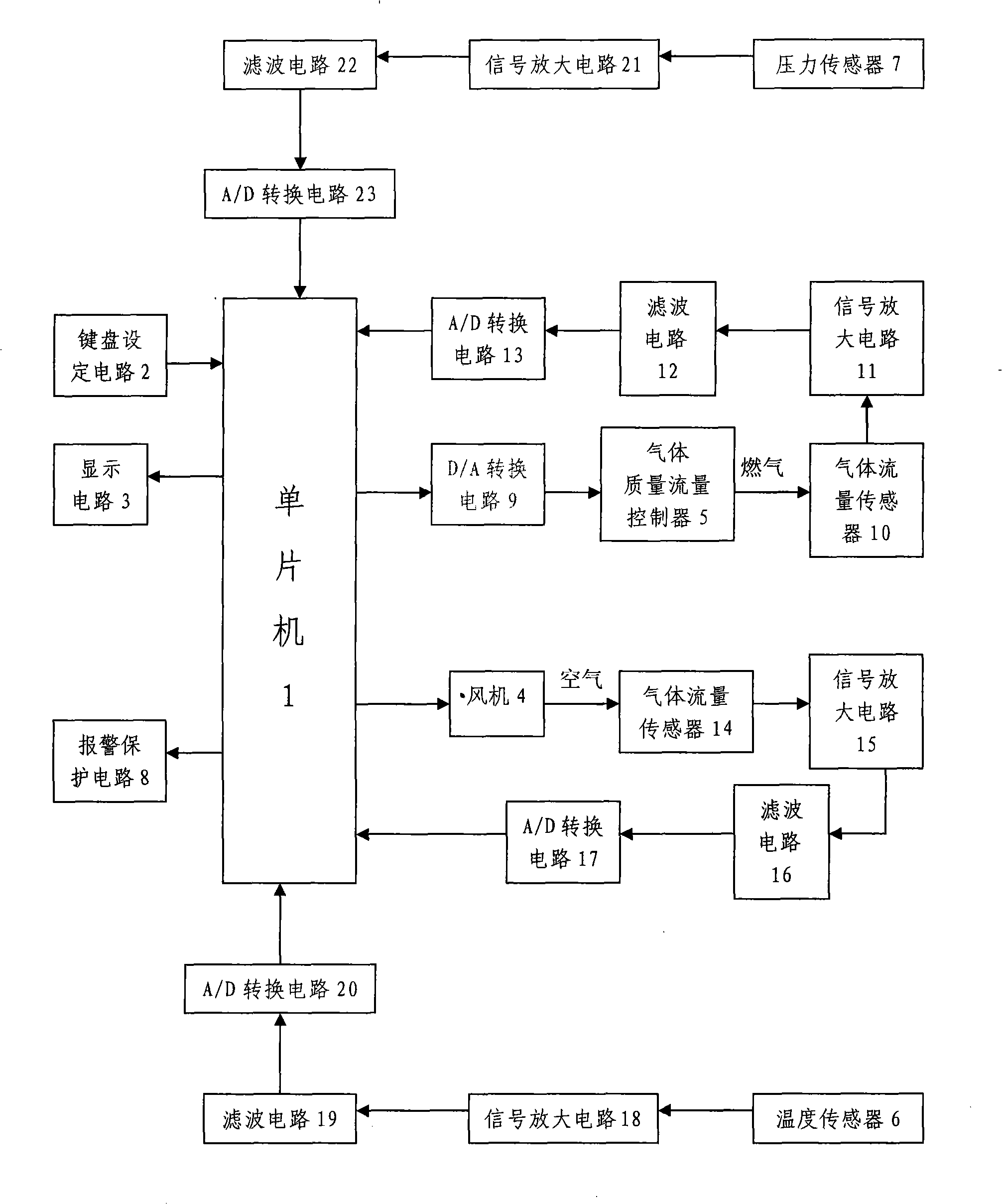

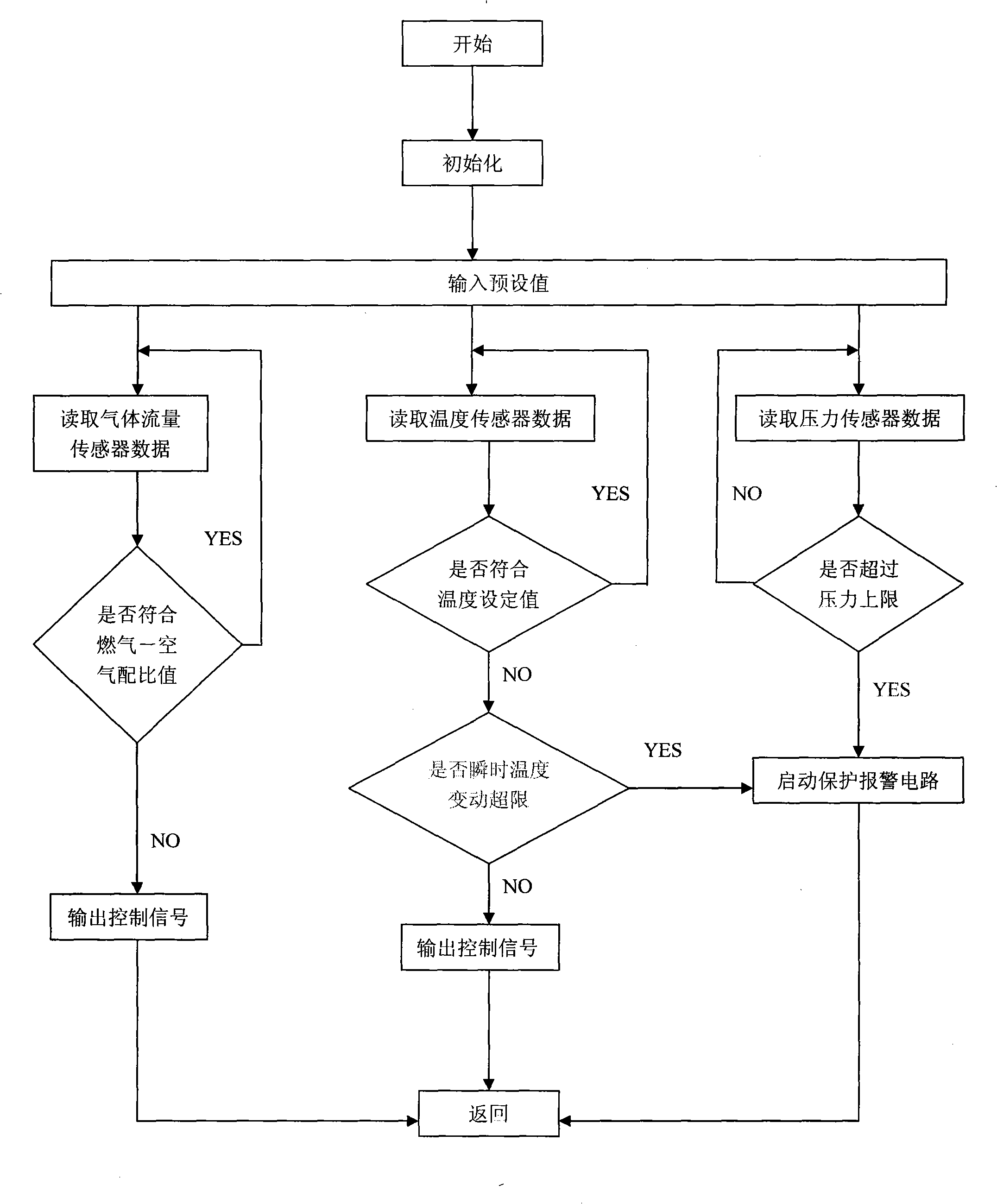

[0024] like figure 1 As shown, the complete premixed combustion system of the present invention includes a single-chip microcomputer 1, a keyboard setting circuit 2, a display circuit 3, a signal amplification circuit, a filter circuit, an A / D conversion circuit, a D / A conversion circuit, a gas flow sensor, a fan 4. Gas mass flow controller 5, temperature sensor 6, pressure sensor 7 and alarm protection circuit 8:

[0025] --Single-chip microcomputer 1 is connected with display circuit 2 and keyboard setting circuit 3 respectively;

[0026] --Single-chip microcomputer 1 is connected with D / A conversion circuit 9, gas mass flow controller 5, gas flow sensor 10, signal amplifier circuit 11, filter circuit 12, A / D conversion circuit 13 in sequence, the output of A / D conversion circuit 13 The terminal is connected to the microcontroller 1 for monitoring the gas flow rate;

[0027] --The single-ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com