Vertical pipeline pump uniform in inlet flow field velocity distribution

A velocity distribution, vertical pipeline technology, applied to the components of pumping devices for elastic fluids, non-variable-capacity pumps, pumps, etc., can solve the problem of large hydraulic loss, large difference in velocity gradient, and uneven velocity distribution. problems, to achieve the effect of stabilizing the liquid flow, improving the uniformity of the flow, and improving the flow conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

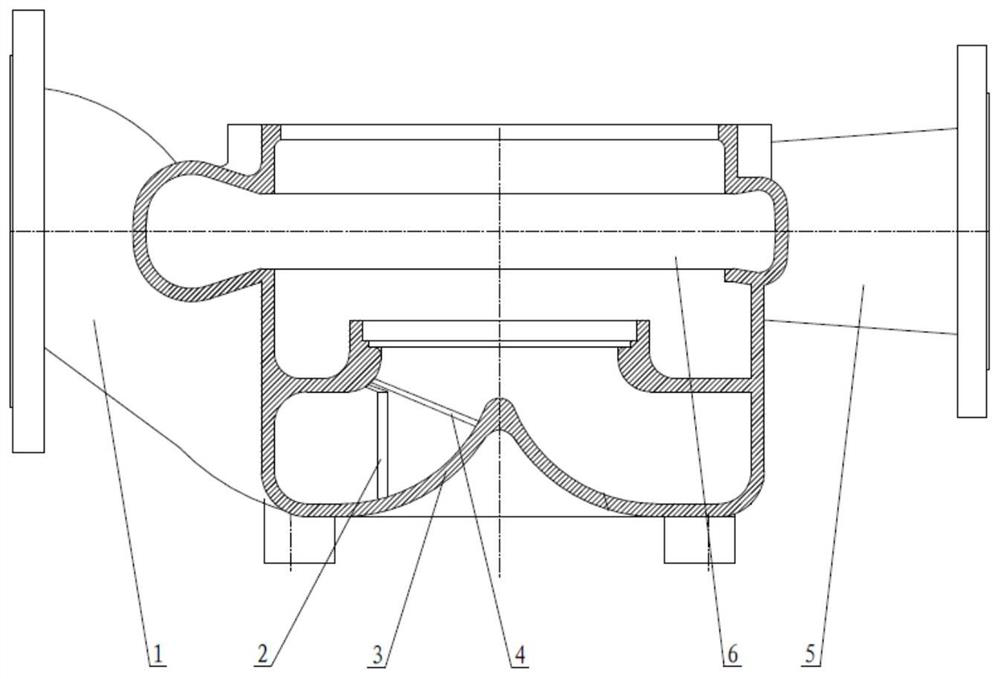

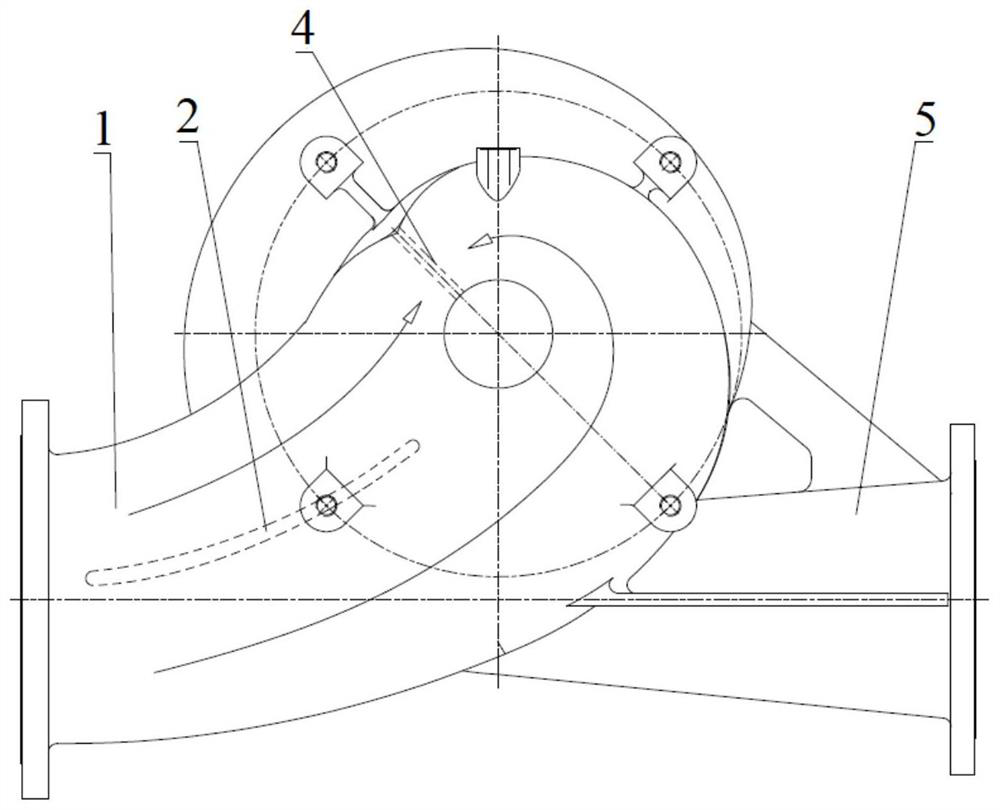

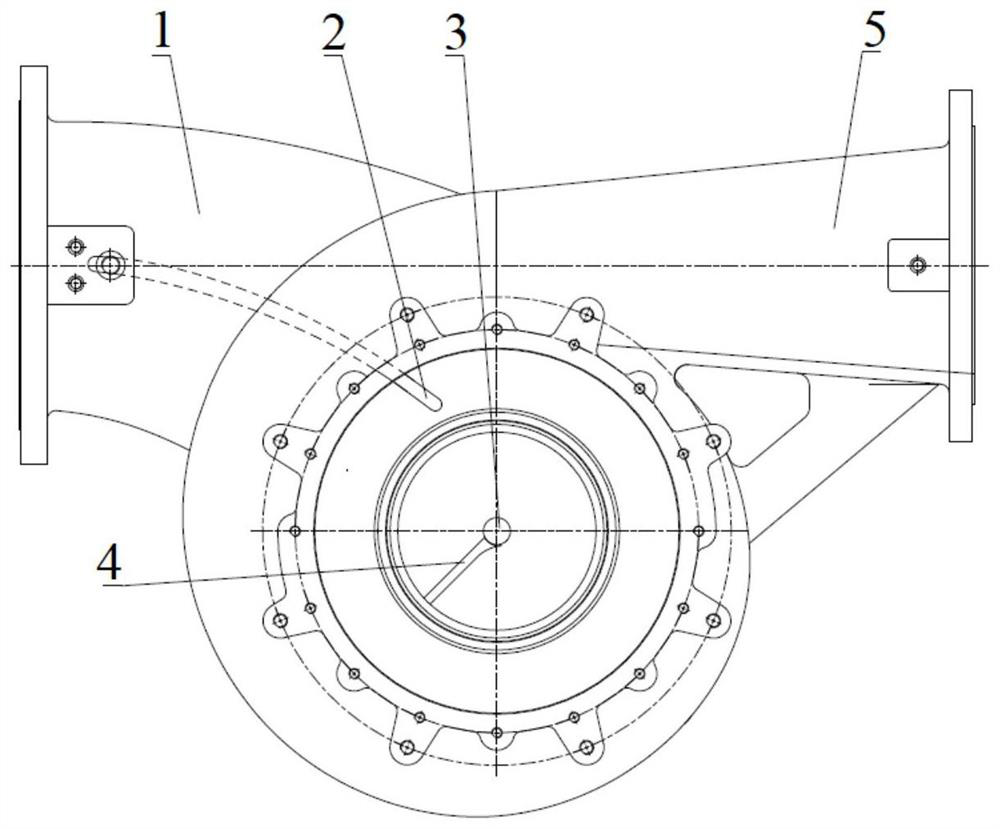

[0021] Such as Figure 1-3 As shown, a vertical pipeline pump with a uniform inlet flow field velocity distribution of the present invention includes a water absorption chamber cavity 6, a water inlet pipe 1 communicating with the lower end of the water absorption chamber cavity 6, and a water absorption chamber. The water outlet pipe 5 connected to the upper side wall of the cavity 6; the connection line between the inlet center of the water inlet pipe 1 and the outlet center of the water outlet pipe 5 is perpendicular to the axis of the water absorption chamber cavity 6; the inlet and outlet of the water inlet pipe 1 The inlets of the pipelines 5 are connected with the cavity 6 of the water absorption chamber in a spiral channel;

[0022] The bottom of the water inlet pipe 1 is provided with a diversion cone 3 structure extending toward the water inlet of the water absorption chamber cavity 6, and the axis of the diversion cone 3 coincides with the axis of the water absorpti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circumferential angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com