Patents

Literature

46results about How to "Liquid flow is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

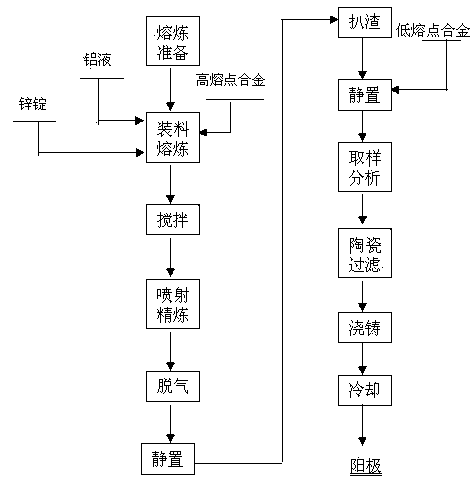

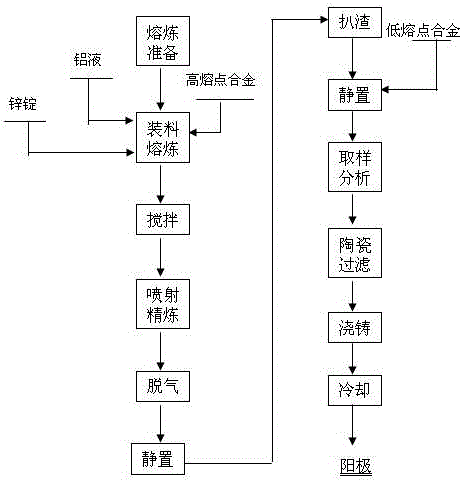

Casting method of aluminum alloy sacrificial anode

The invention belongs to the technical field of corrosion and prevention, and in particular relates to a casting method of an aluminum alloy sacrificial anode. The casting method comprises the following steps: adding basic electrolytic molten aluminum to a resistance furnace; then adding a zinc ingot to obtain molten aluminum alloy; performing jet refining on the molten aluminum alloy by adopting an argon located refining agent; charging argon to refined aluminum alloy melt to degas; drossing oxidizing scum on the surface of the aluminum alloy melt through a drossing tool; adding a low melting point metallic element to drossed aluminum alloy melt; electromagnetically agitating the melt after pressing the low melting point metal; carrying out ceramic filtering; pouring and casting the aluminum alloy melt to a preheated iron anode mould at an even casting speed under the temperature of 700 to 740 DEG C until the mould is full of the aluminum alloy melt; and moving the aluminum alloy melt out of the mould after cooling, solidifying and molding, so as to obtain the aluminum alloy sacrificial anode. The casting method has the characteristics of being short in smelting time, small in loss of iron scale, high in degassing and purifying performances, and low in smelting cost.

Owner:NORTHEASTERN UNIV +1

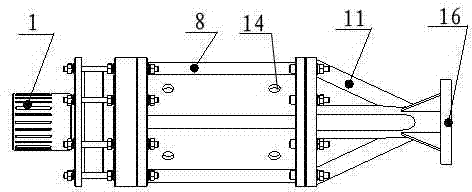

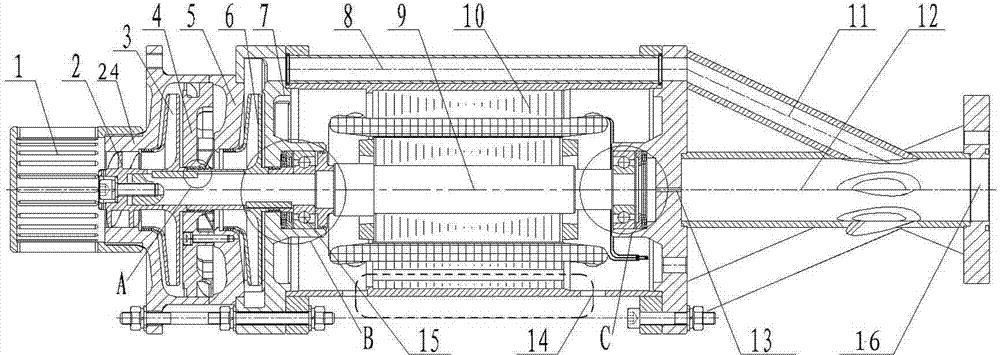

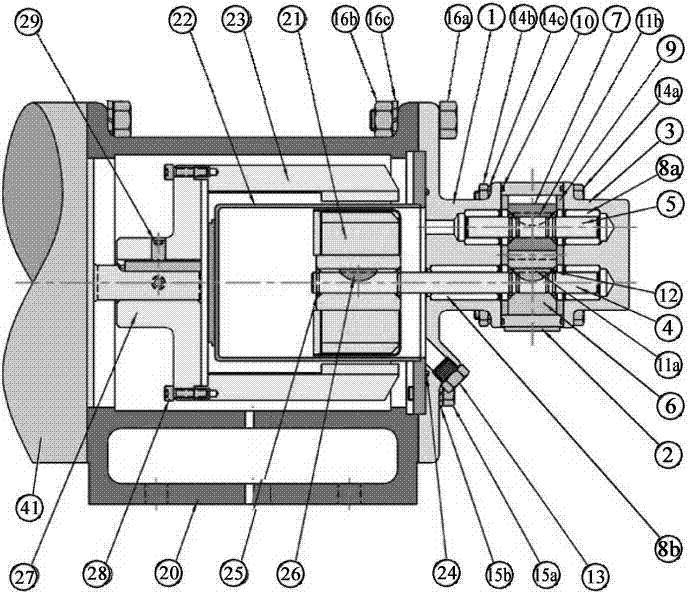

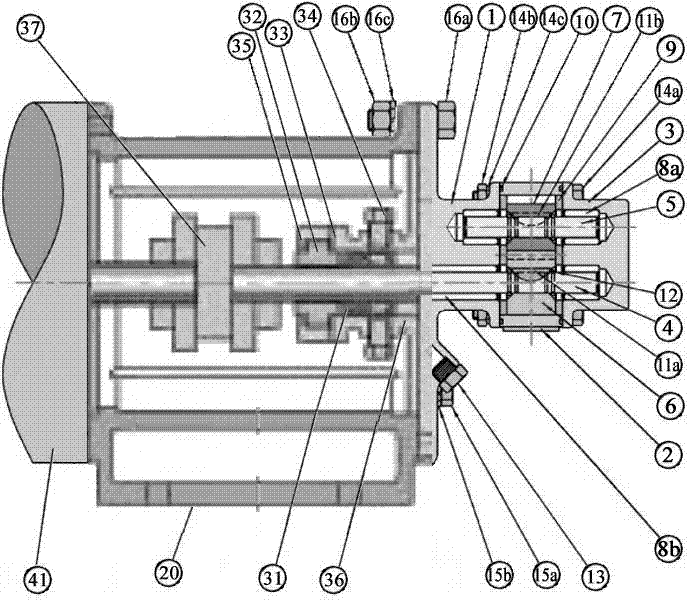

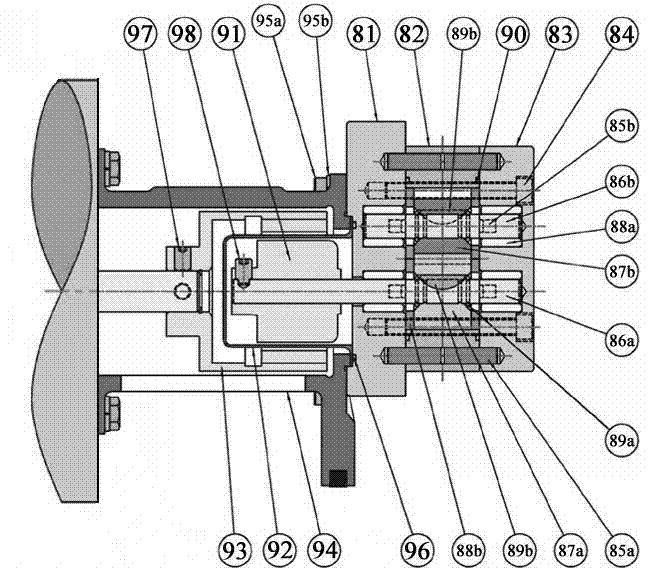

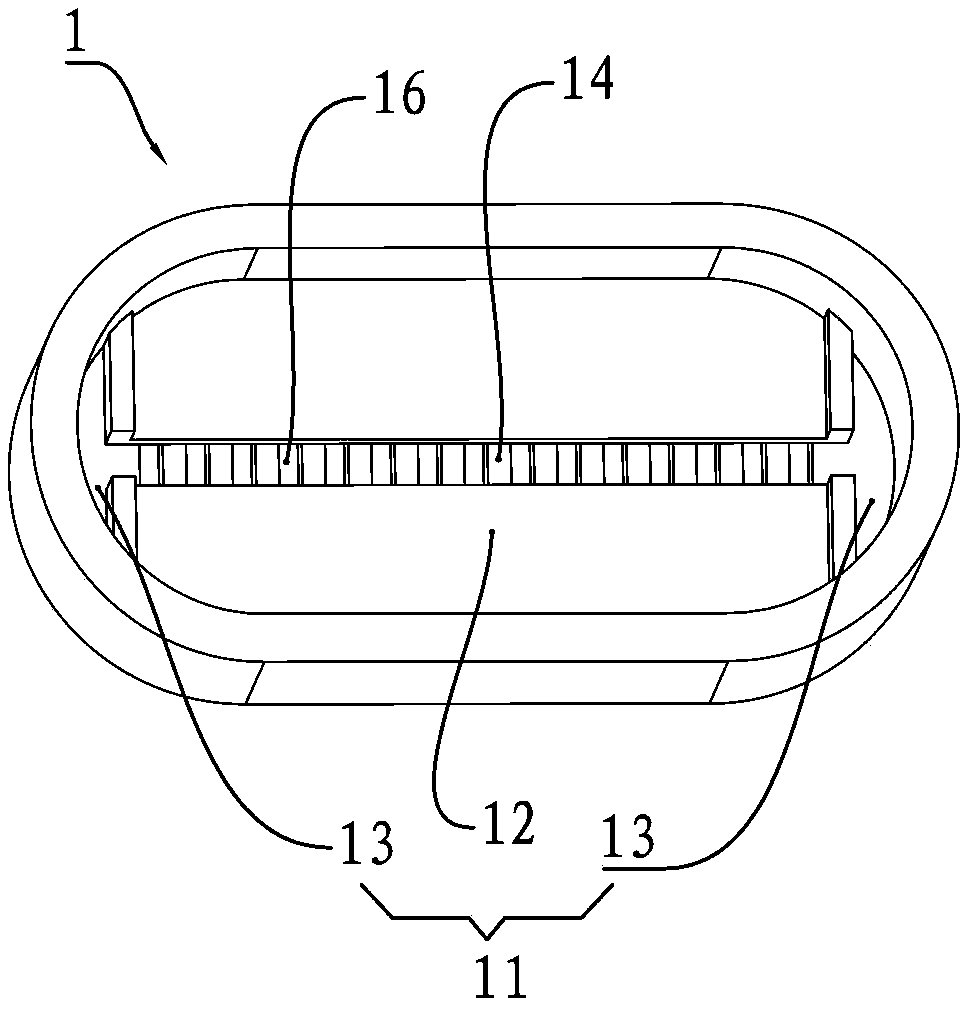

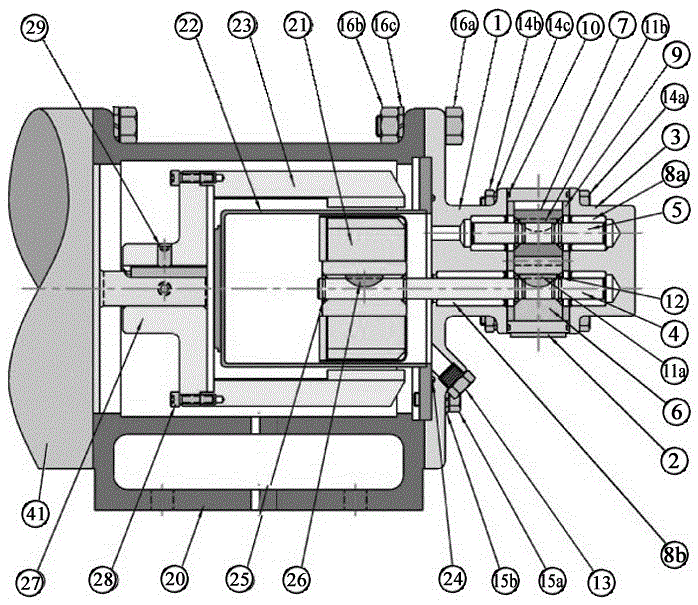

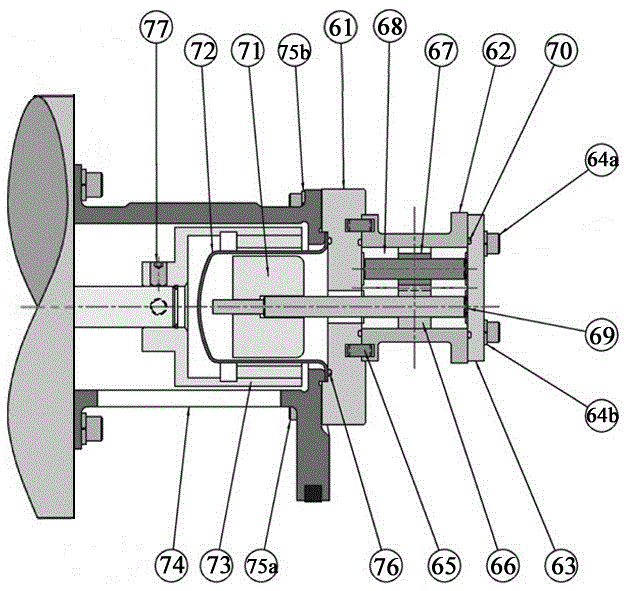

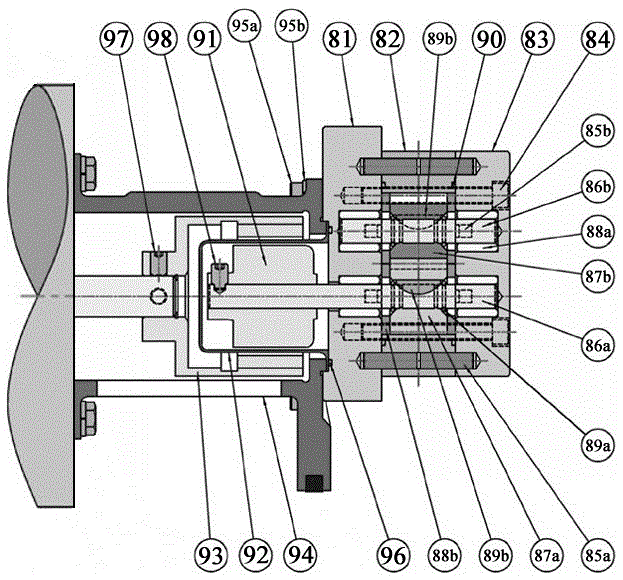

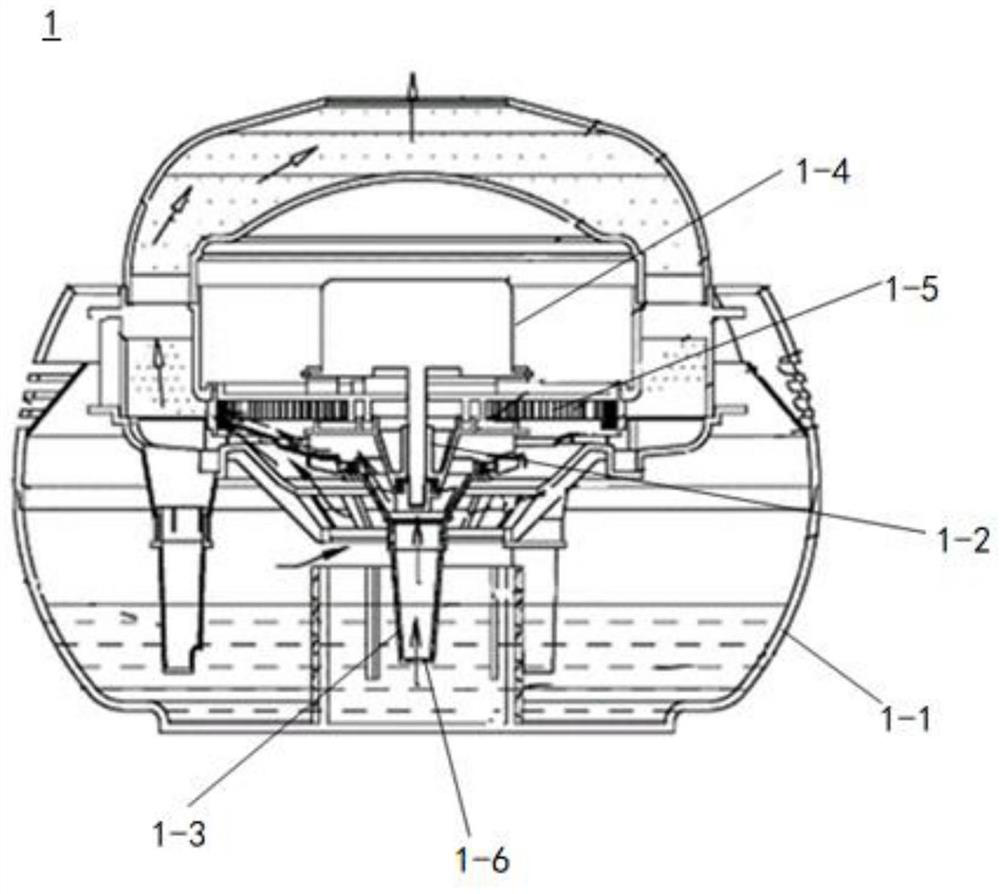

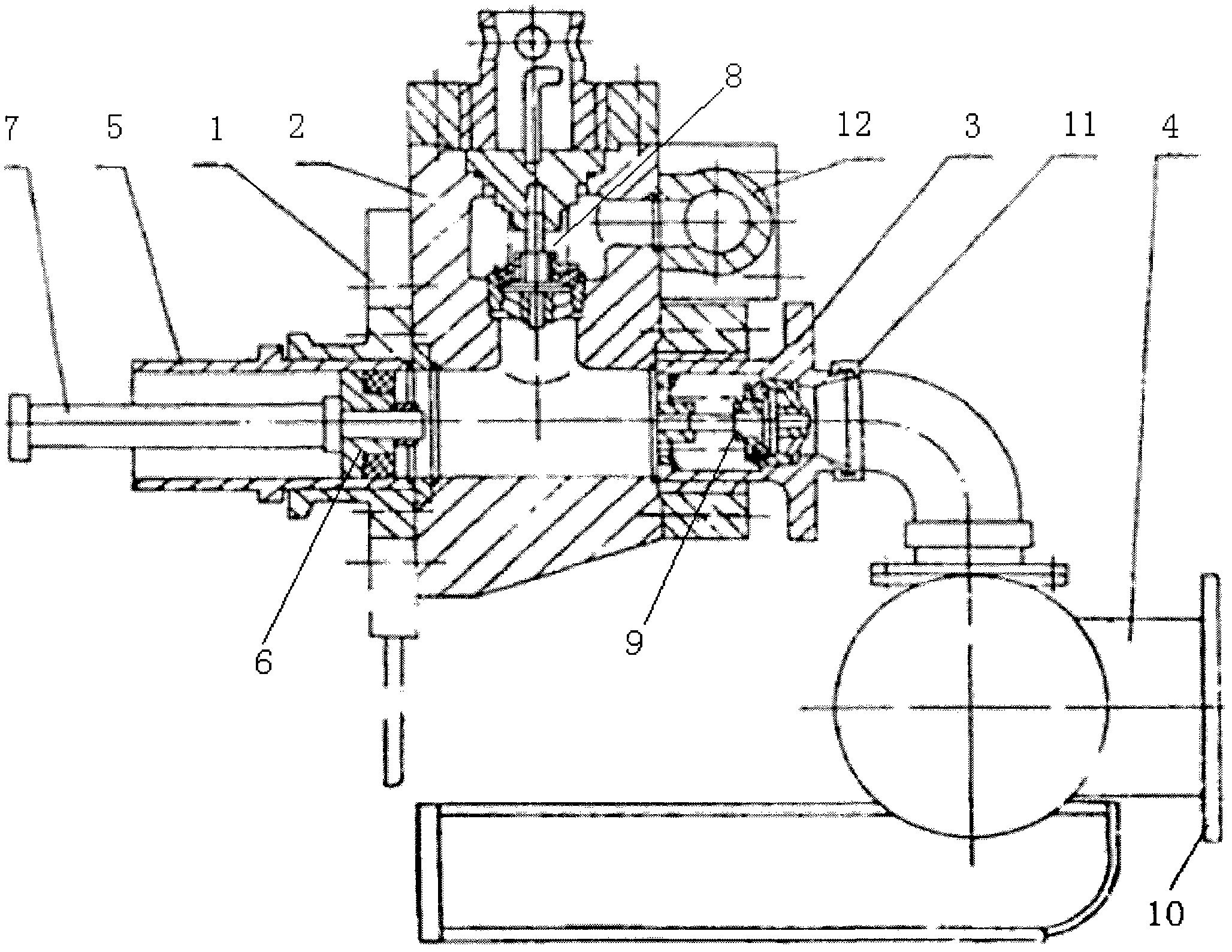

LNG immersed pump

The invention discloses an LNG immersed pump and belongs to the technical field of LNG. A stator and a rotor shaft are arranged in a motor cavity in the LNG immersed pump, and side wall channels are arranged in the side wall of a pump body; a motor upper cover is connected to the rear end of the pump body and provided with a plurality of liquid flowing channels communicated with the side wall channels, and the liquid flowing channels are arranged in an inclined mode and intersect with one another at a liquid outlet; a motor lower cover is connected to the front end of the pump body, liquid via holes communicated with the side wall channels are formed in the motor lower cover, a shell is connected to the motor lower cover to form a working cavity and provided with a first-stage flow guide disc to partition the working cavity into a front cavity and a rear cavity, a flow channel communicated with the front cavity and the rear cavity is arranged on the first-stage flow guide disc, a second-stage impeller is arranged in the rear cavity, a first impeller is arranged in the front cavity, a liquid inlet is formed in the front cavity in a connected mode, and an inducer is arranged in the liquid inlet; the rotor shaft penetrates through the motor lower cover and the working cavity and extends into the liquid inlet, and the first-stage impeller, the second-stage impeller and the inducer are all arranged on the rotor shaft in a sleeved mode. The LNG immersed pump is simple in structure and suitable for being popularized and used.

Owner:CHENGDU ANDERSON MEASUREMENT

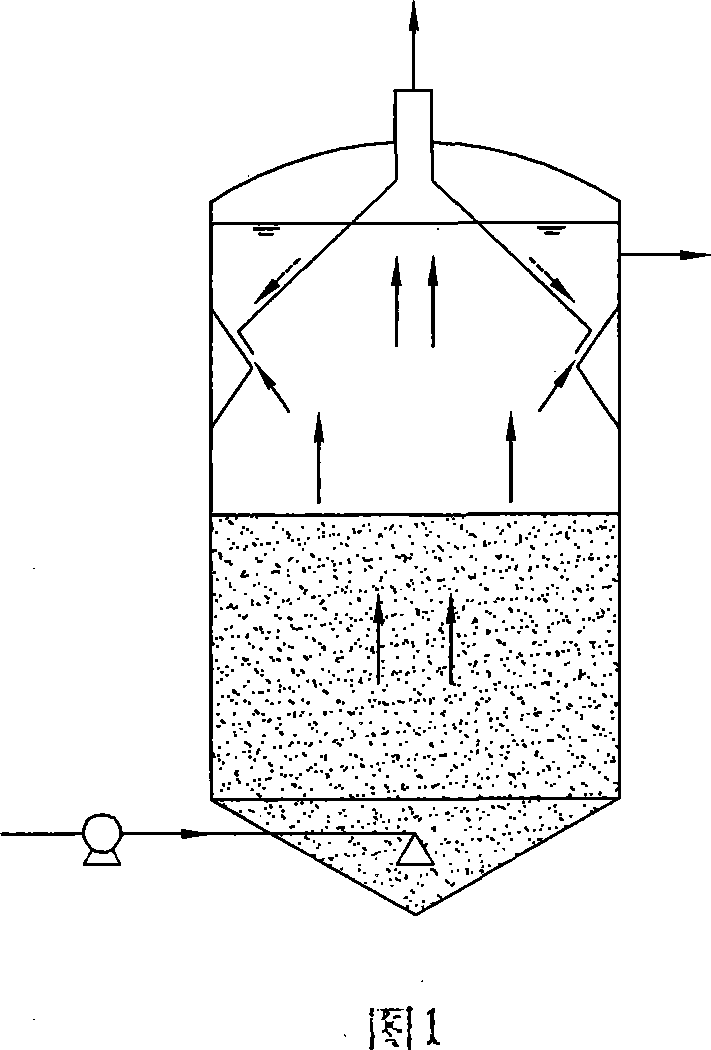

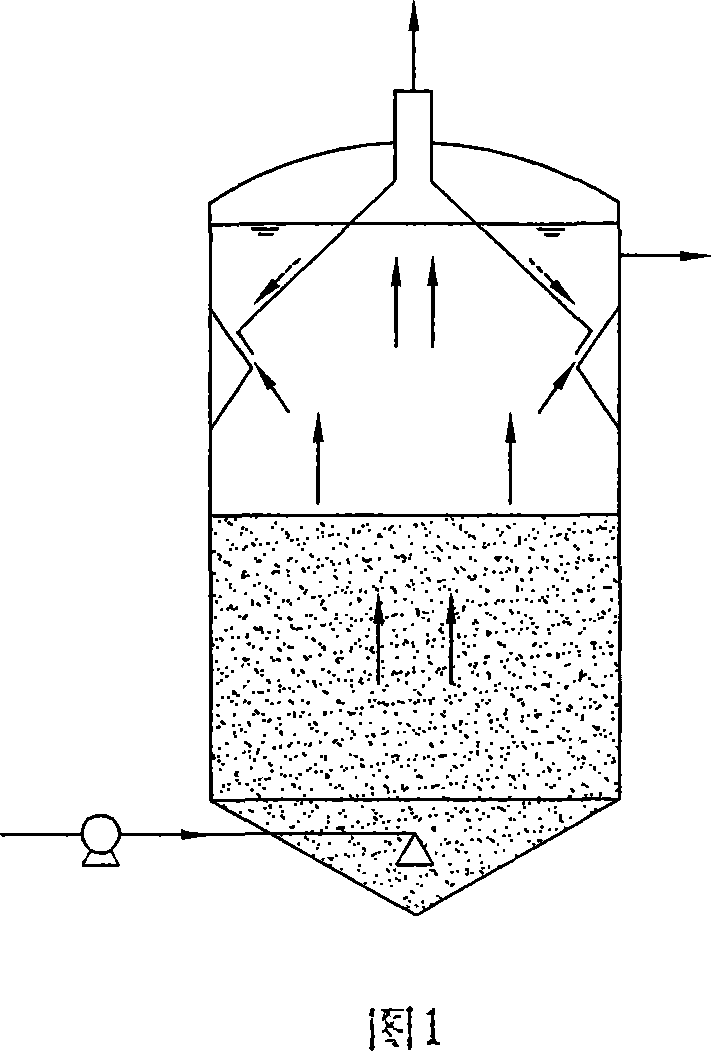

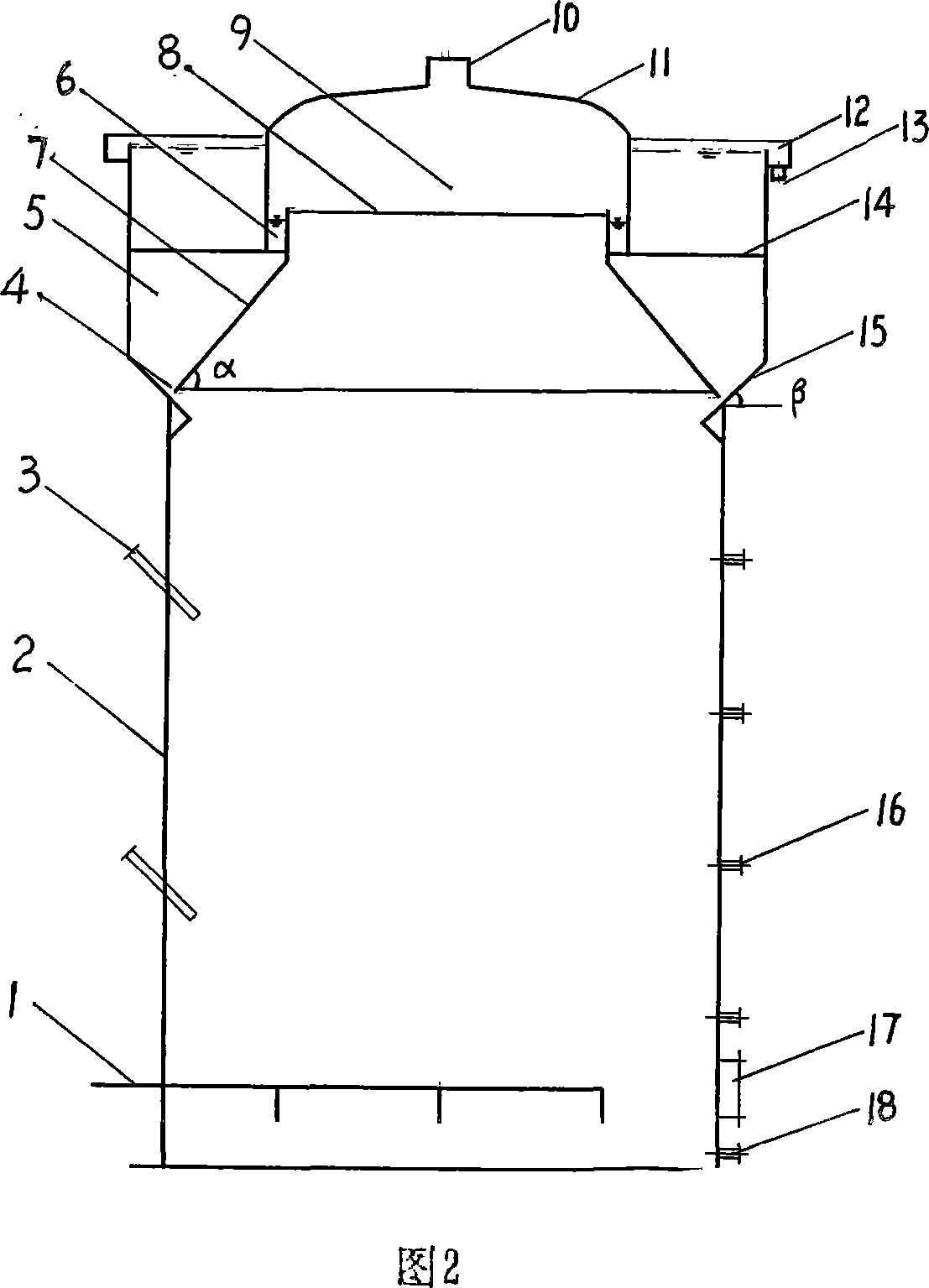

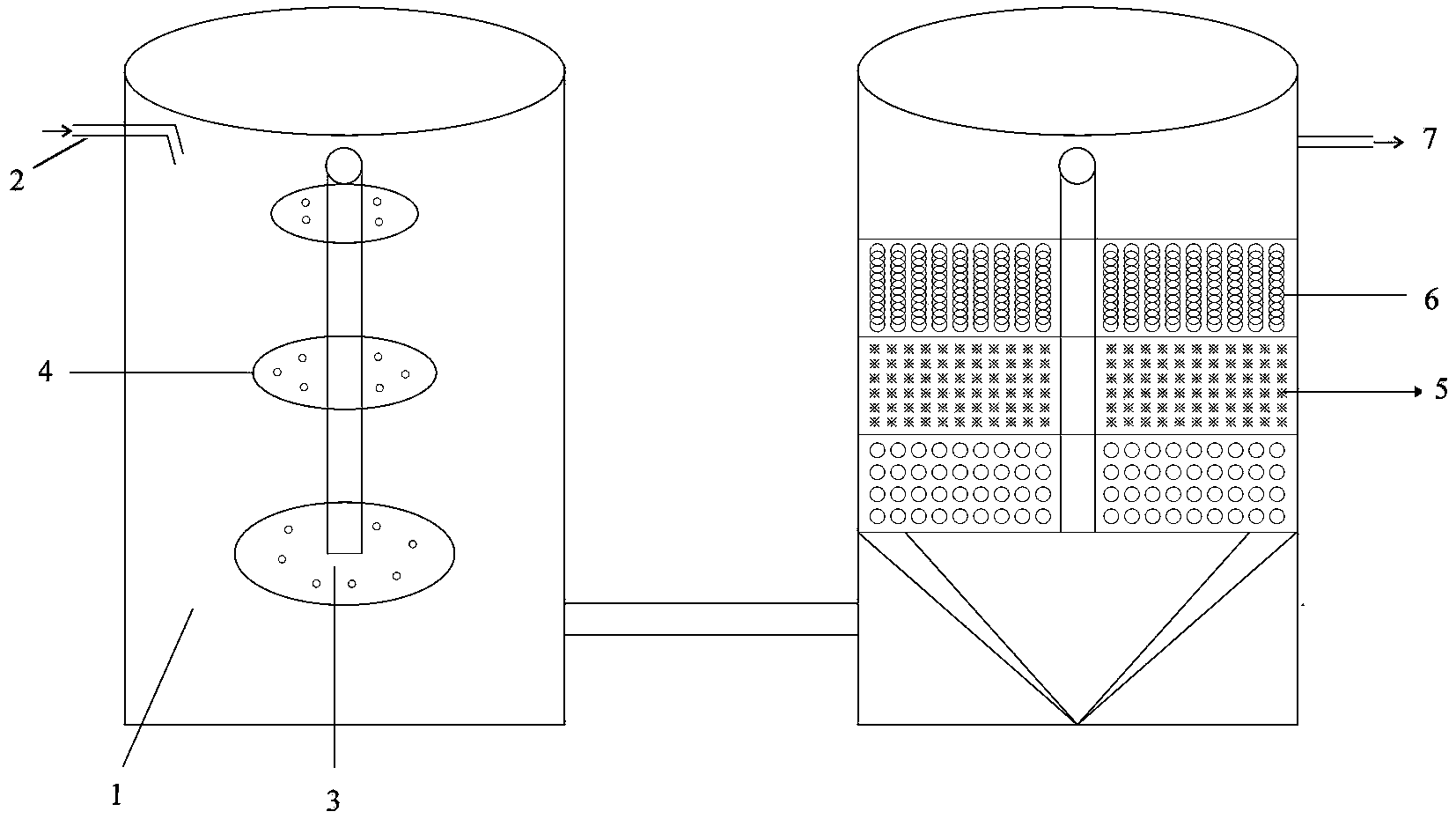

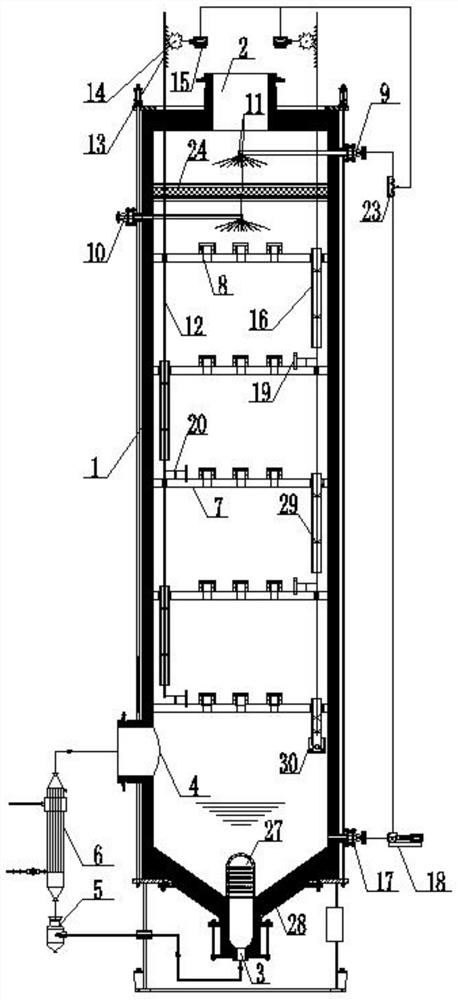

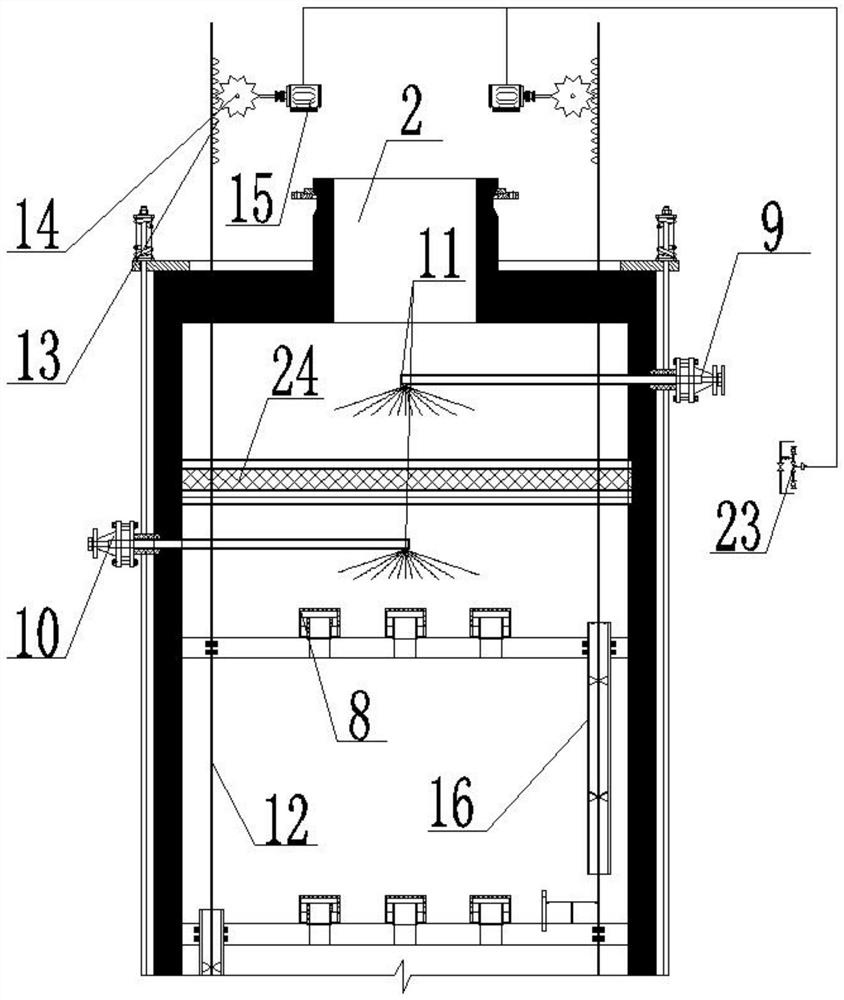

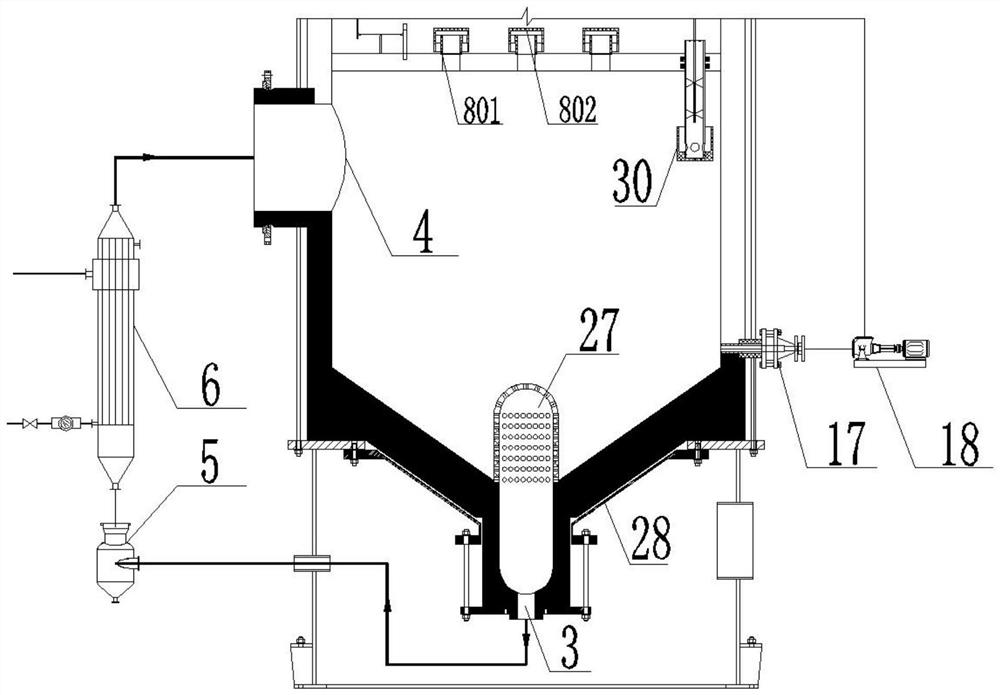

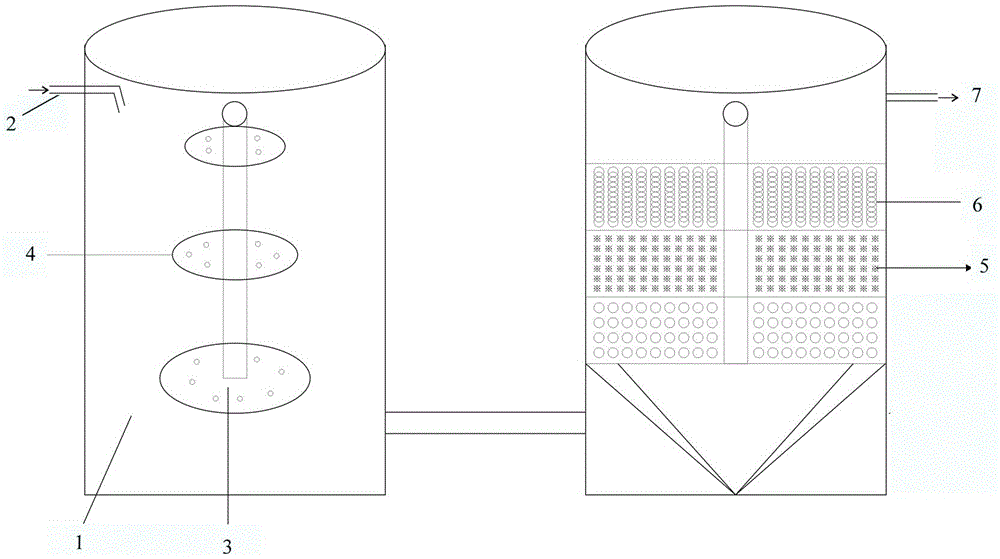

Upflow type anaerobic reactor

ActiveCN101054234AGood separation effectGood solid-liquid separation effectWaste based fuelTreatment with anaerobic digestion processesThree-phaseInlet flow

The invention relates to an up flow type anaerobic reactor, which comprises a barrel of the reactor, a water distributor pipe arranged on the lower end of the barrel, a three phase separator composed of a cone diversion drum arranged on the upper end of the barrel and a gas hood arranged on the upper end of the cone diversion drum, a circular passage arranged between the lower end of the gas hood wall and cone diversion drum wall, a circular passage arranged between the cone diversion drum and the upper wall of the barrel, a settling zone barrel arranged on the upper end of the reactor barrel, a drain trough arranged on top of the settling zone barrel, the combination of two circular passages can separate sludge with water, gas with water at different position, has good separating effect of gas, sludge, water, thereby avoiding the problem of return-sludge flow interfered by inlet flow because of mixed liquor ascent passage sharing one passage with return-sludge flow in a conventional three phase separator, the invention can keep liquid flow in settling zone steady, fluid state closing to laminar flow, has good solid-liquid separation effect.

Owner:沃克福德环境科技(深圳)有限责任公司

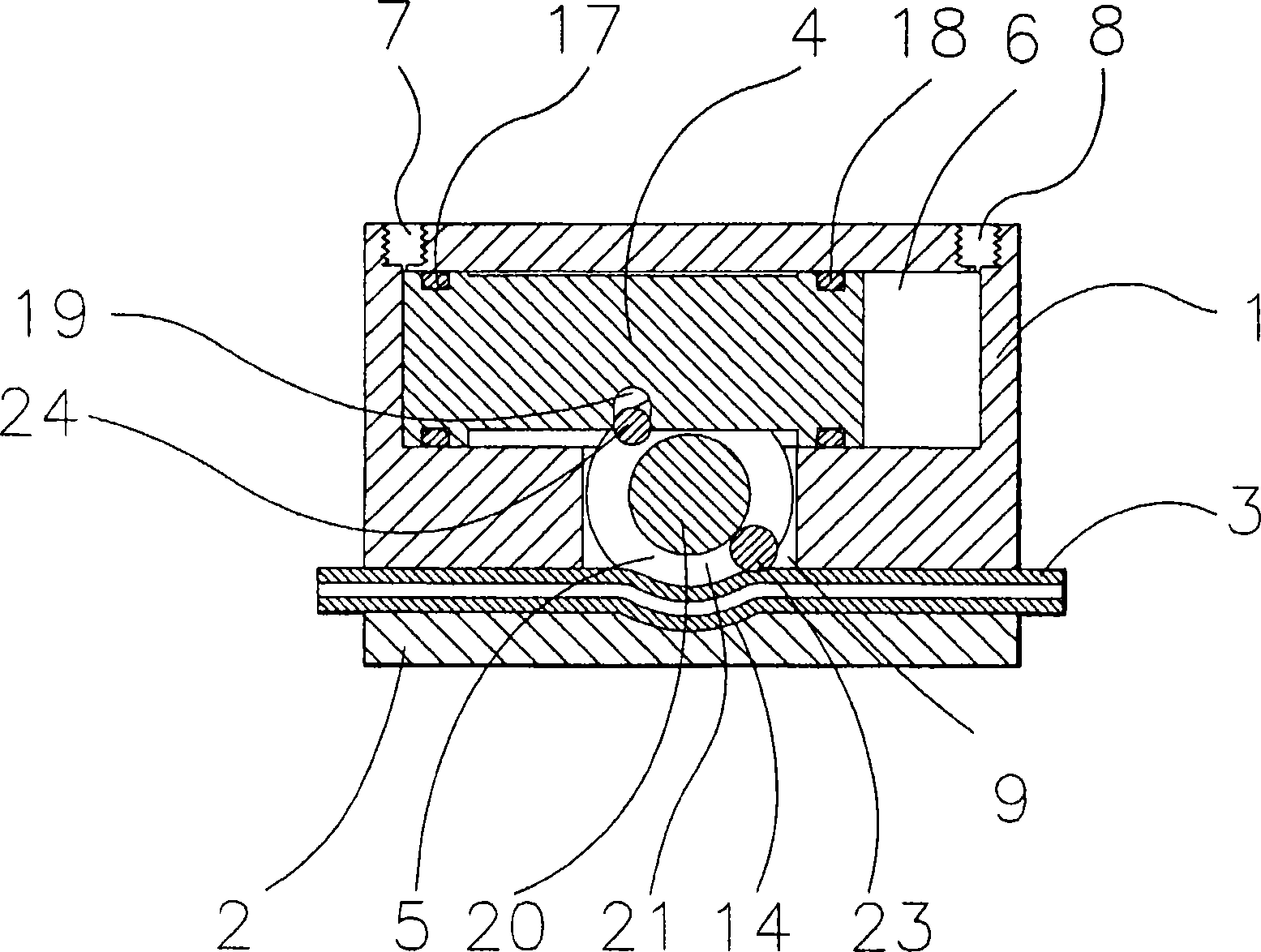

Valve

InactiveCN1894525ALiquid flow is stableReduce yield deteriorationDiaphragm valvesOperating means/releasing devices for valvesMechanical engineering

Owner:ASAHI YUKIZAI KOGYO CO LTD

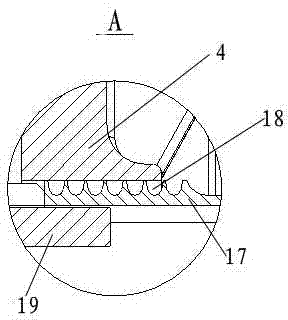

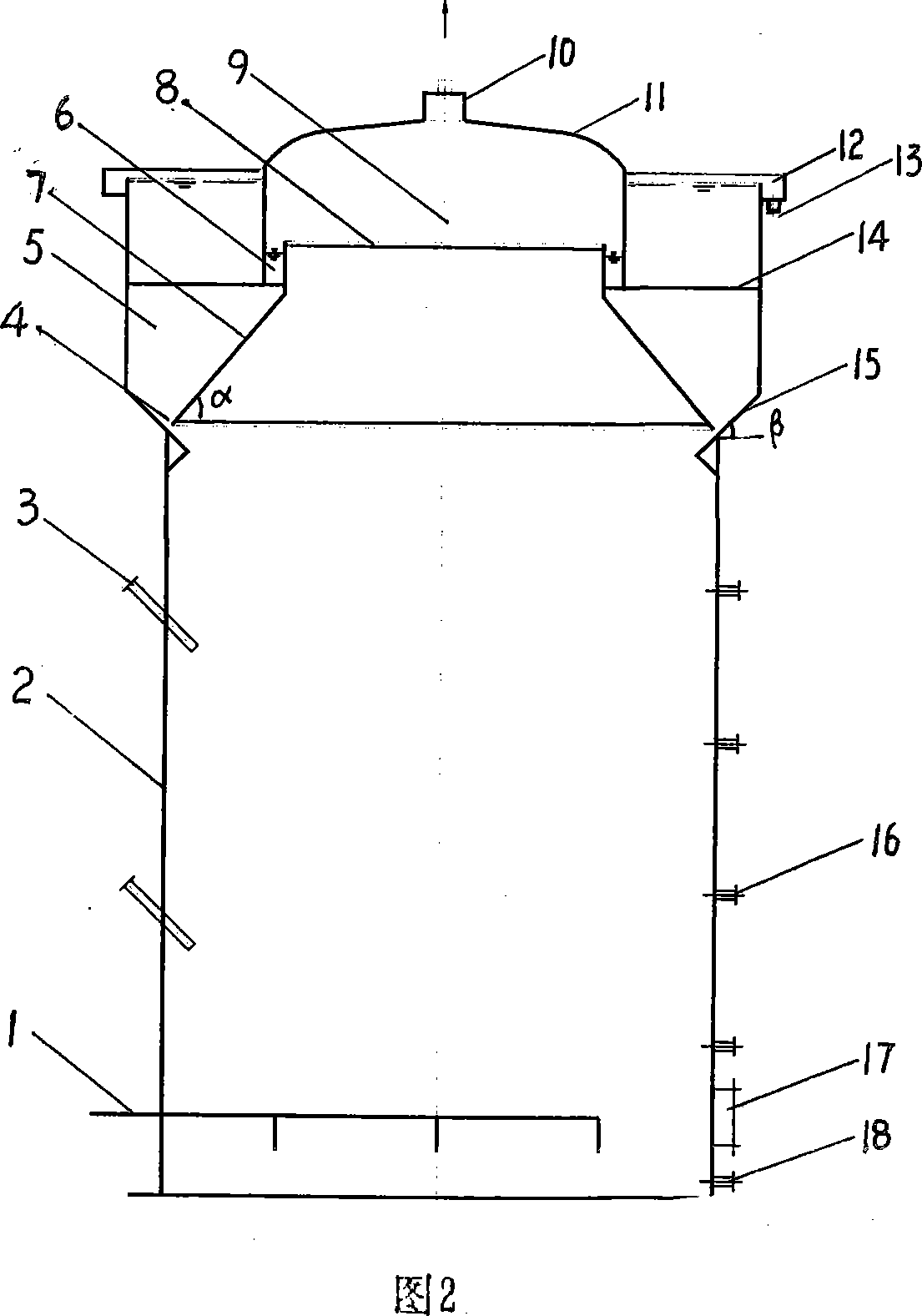

Three-phase separator for high efficiency anaerobic reactor

InactiveCN101054235AReduced release rateReduce entrainmentLiquid degasificationTreatment with anaerobic digestion processesWide mouthThree-phase

The invention relates to a three phase separator of an up flow type anaerobic reactor, which is composed of a cone diversion drum arranged on the upper end of a anaerobic reactor barrel, a gas hood arranged on the upper end of the cone diversion drum, a gas chamber is composed of the gas hood and a wide mouth of the cone diversion drum, a circular passage arranged between the lower end of the gas hood wall and the upper end of the cone diversion drum wall, a circular passage arranged between the lower end of the cone diversion drum wall and the upper wall of the anaerobic reactor barrel, a gas chamber with bigger volume and a bigger gas liquid separation interface is composed of a circular wide mouth on upper of the cone diversion drum and a cylinder gas hood, can reduce release rate of biogas and aqueous vapour entraining amount discharged from the reactor barrel, adopting the invention, gas in mixture liquor of gas, sludge and water can not enter into the settling zone barrel, gas can be separated and removed effectively to avoid gas leaking to the settling zone barrel to interfere solid-liquid separation effect.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

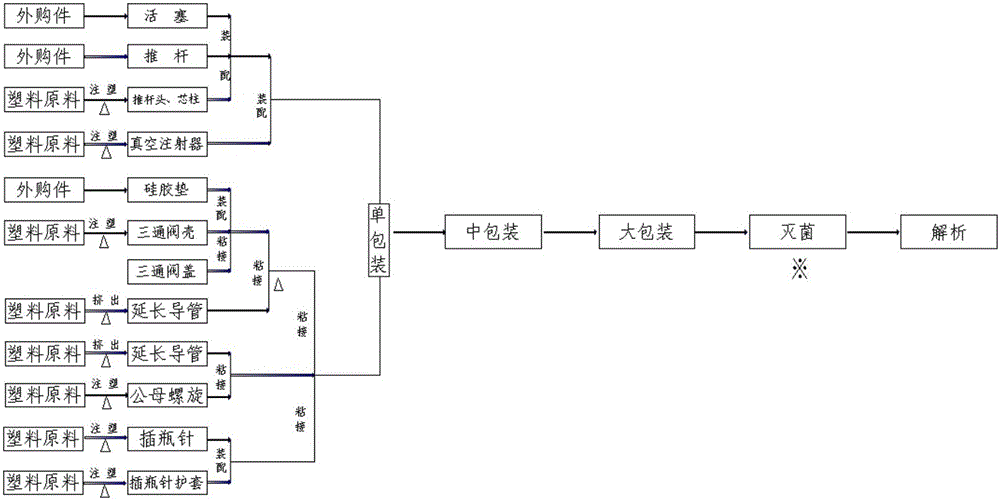

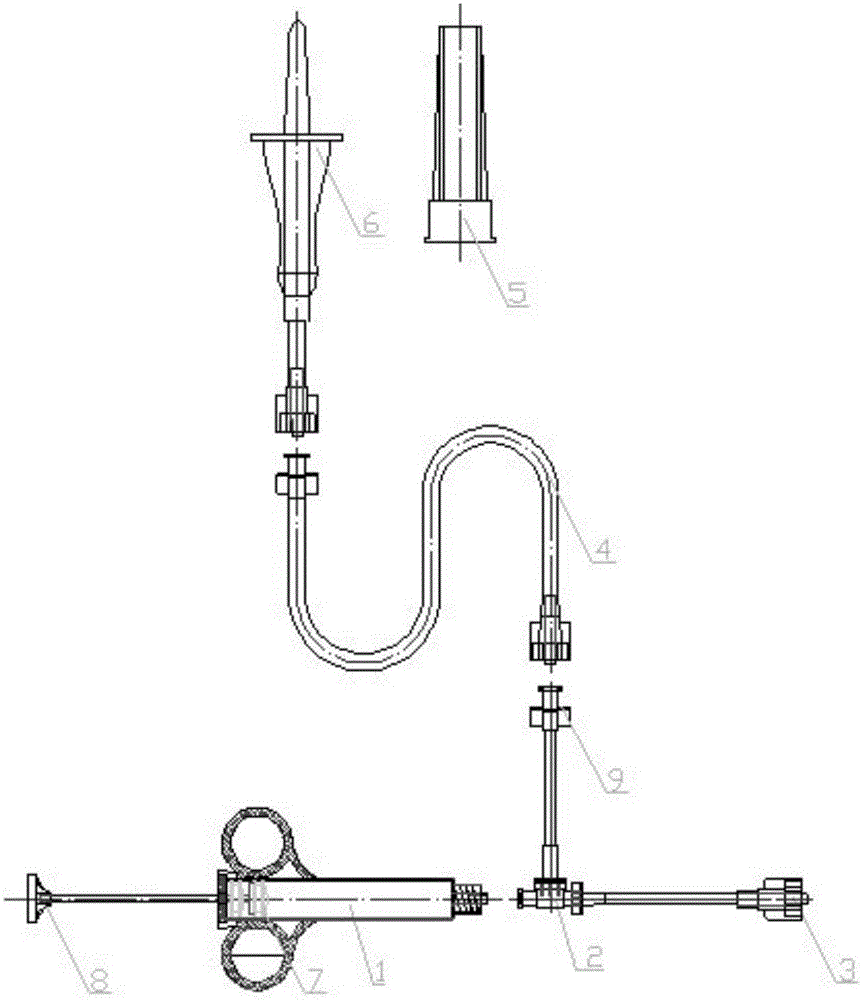

Lumen flusher

The invention discloses a lumen flusher. The lumen flusher comprises a bottle splicing needle and a liquid outlet unit, wherein the bottle splicing needle comprises a needle head for splicing a flushing liquid bottle, a needle base which is connected at the tail end of the needle head and an output tube which is arranged at the tail end of the needle base; the needle head and the needle base are cavity structures; the cavities are connected with the output tube in a penetration mode; a liquid outlet joint is arranged at the tail end of the output tube; the liquid outlet unit is connected with the liquid outlet joint in a matched mode through a liquid inlet joint arranged at an end opening of the liquid outlet unit; the liquid flows into the liquid outlet unit through the bottle splicing needle; the liquid outlet unit is further provided with a liquid outlet for the liquid to flow out. According to the scheme adopted by the invention, the flusher is stable in flow; the liquid outlet flow can be controlled by virtue of frequency of pressing a pushing rod; the liquid outlet flow is great when the pushing rod is quickly pressed, and the liquid outlet flow is small when the pushing rod is slowly pushed. The flusher disclosed by the invention is stable in liquid flow; and the liquid outlet flow can be controlled by virtue of frequency of pressing the pushing rod; the liquid outlet flow is great when the pushing rod is quickly pressed, and the liquid outlet flow is small when the pushing rod is slowly pushed.

Owner:DINGYI MEDICAL EQUIP KUNSHAN

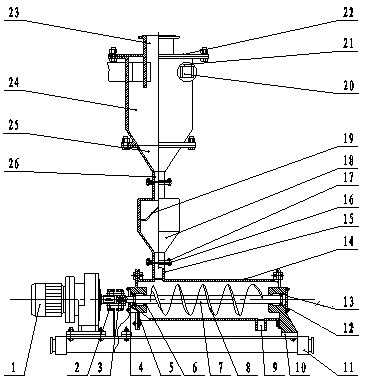

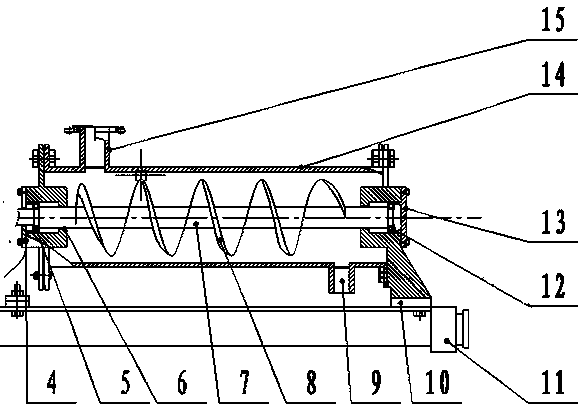

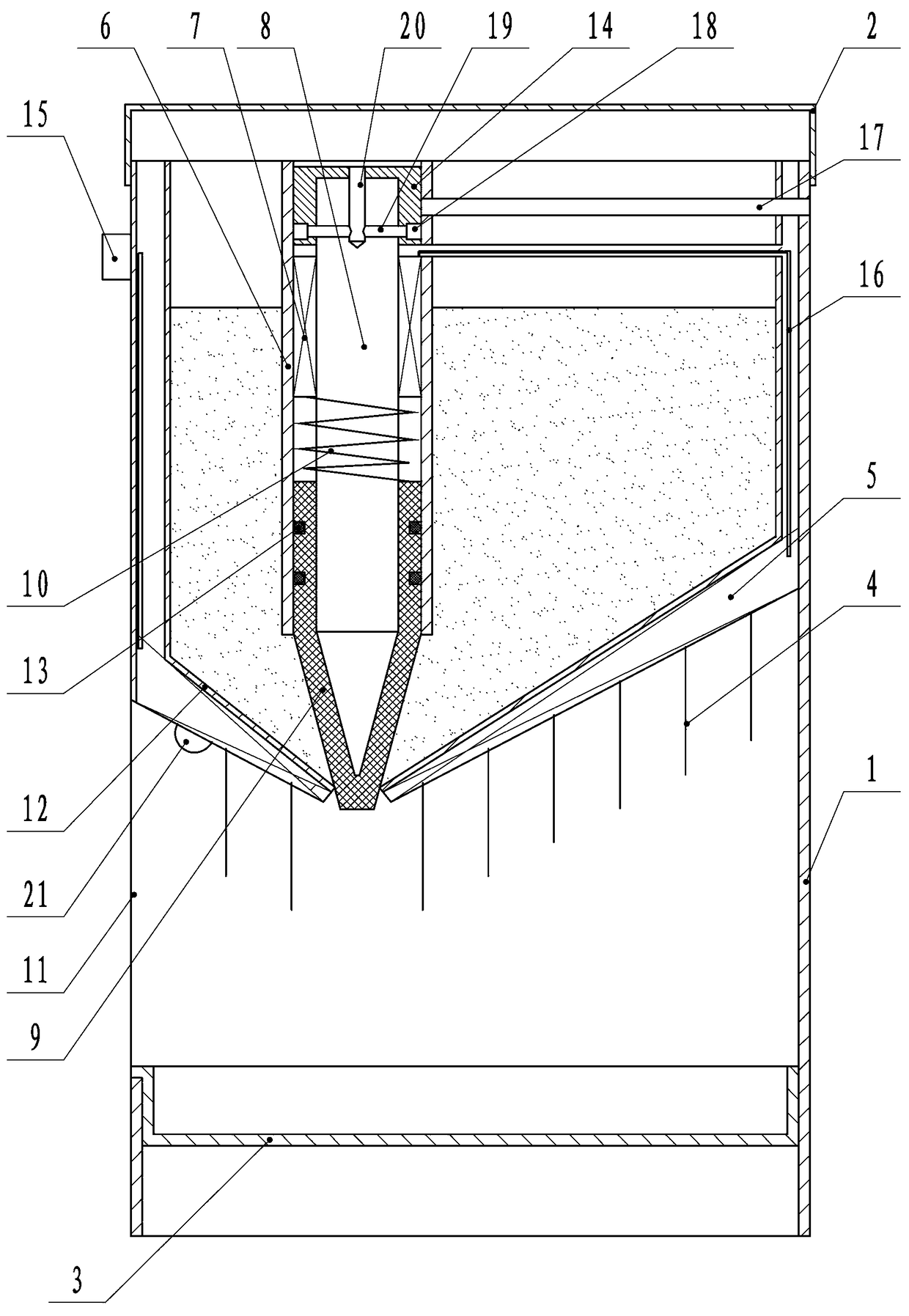

Impurity test bed

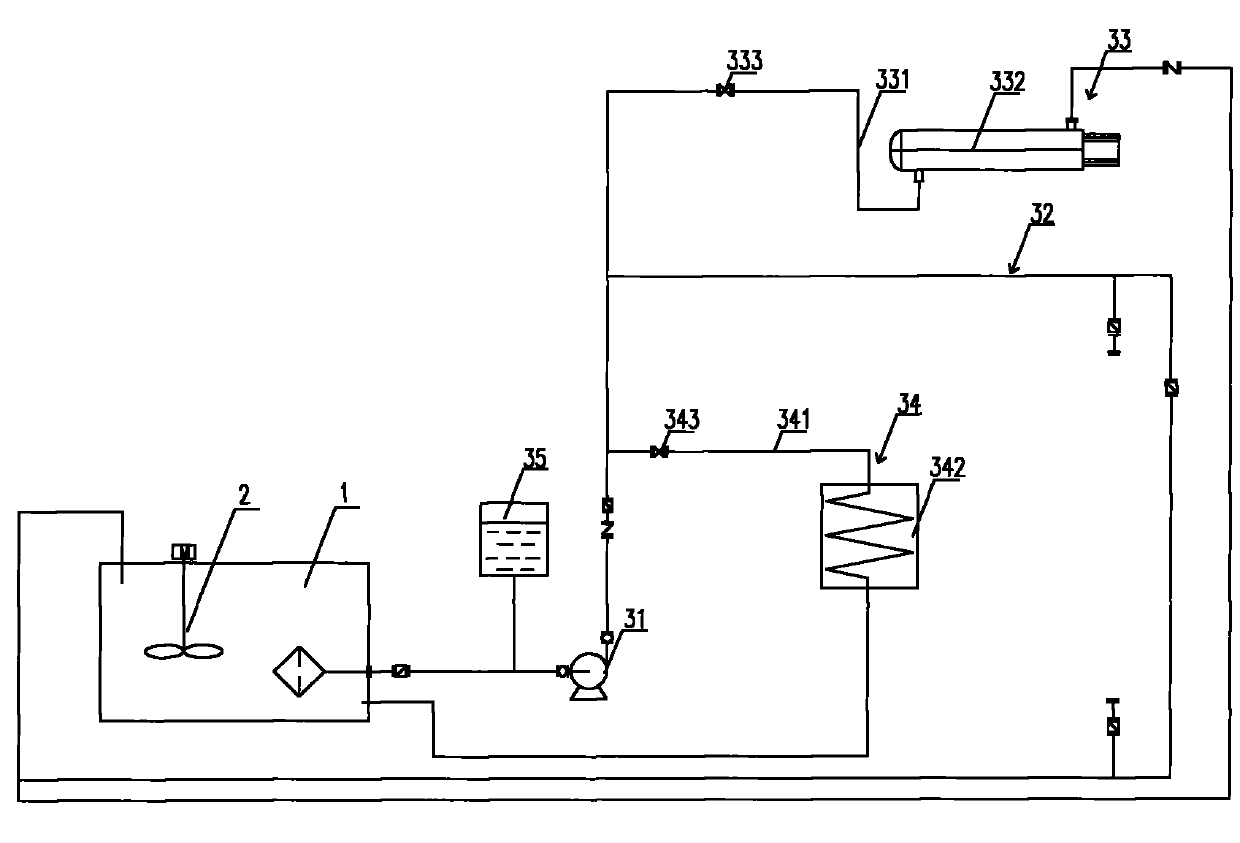

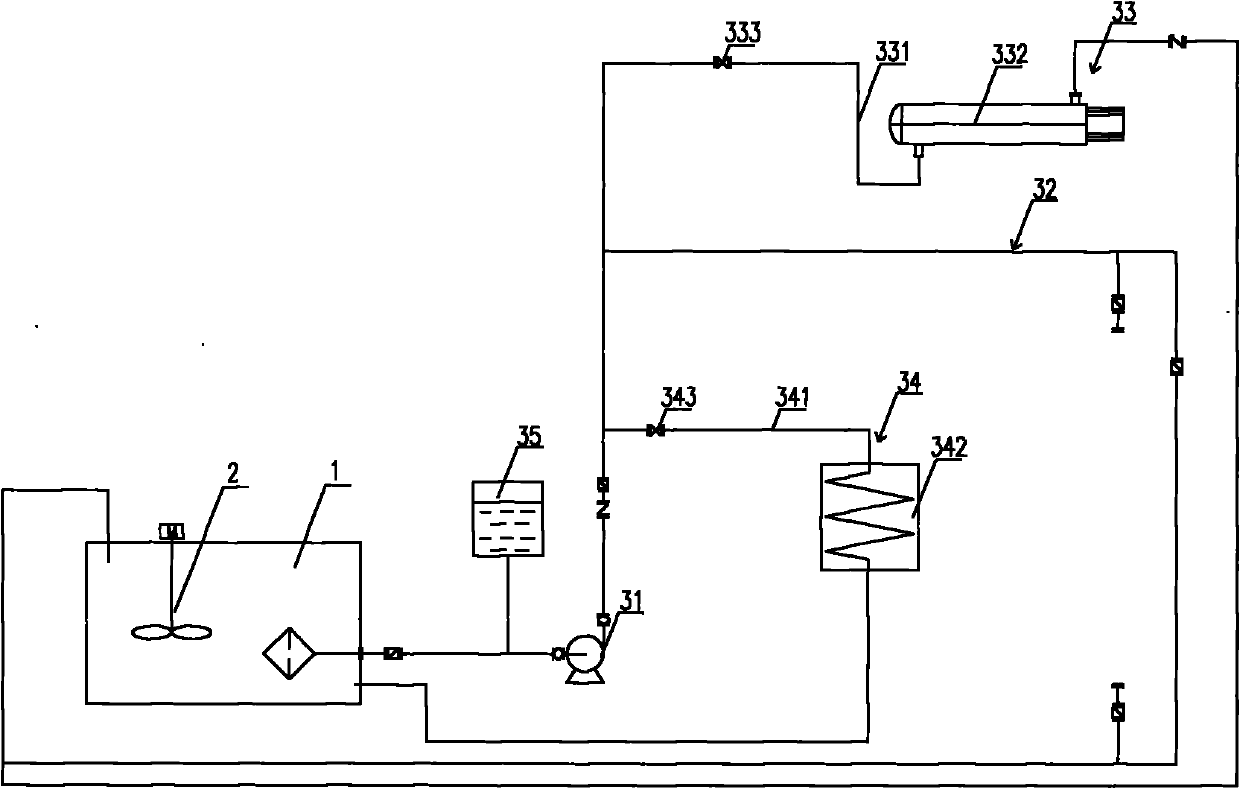

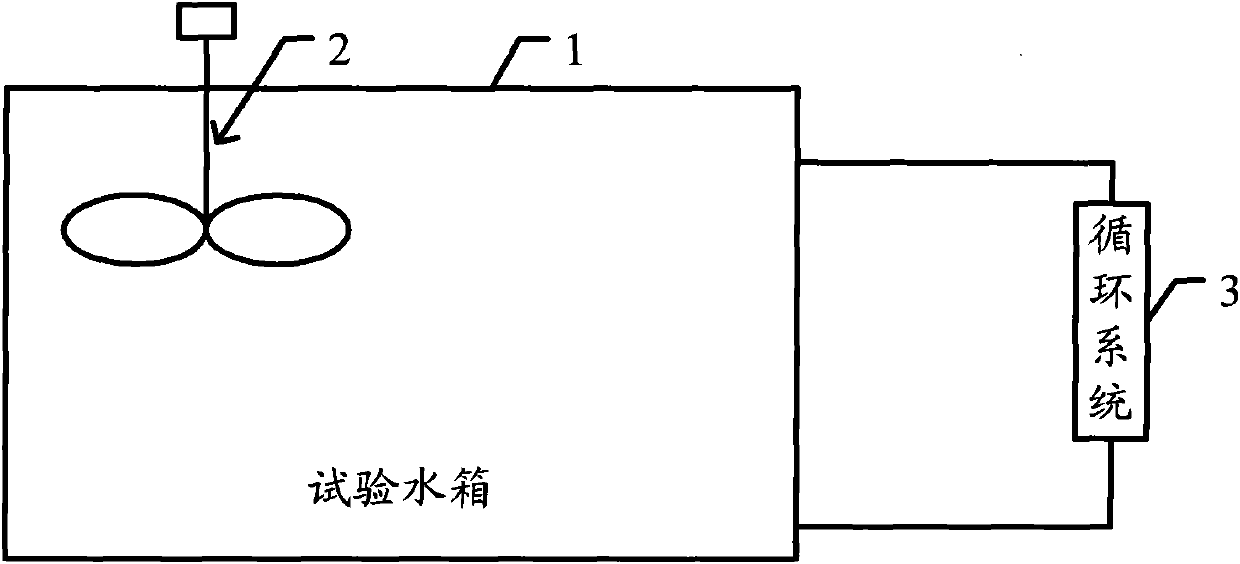

ActiveCN101949777AEasy to observeStable temperatureStructural/machines measurementNuclear powerEnvironmental engineering

The embodiment of the invention discloses an impurity test bed, comprising a test water tank, a stirrer and a circulatory system, wherein the stirrer is arranged at the bottom of the test water tank; the circulatory system is communicated with the test water tank; the test water tank is used for containing liquid containing impurities and allowing a device to be tested to be soaked in the liquid containing impurities; the stirrer is used for stirring the liquid containing impurities which is contained in the test water tank to keep the liquid to be turbid; and the circulatory system is used for driving the liquid in the test water tank to pass the device to be tested continuously. The impurity test bed disclosed in the embodiment of the invention has stable performance, smaller fluctuation of test situations and high measurement accuracy, thus being suitable for serving as nuclear power equipment.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +1

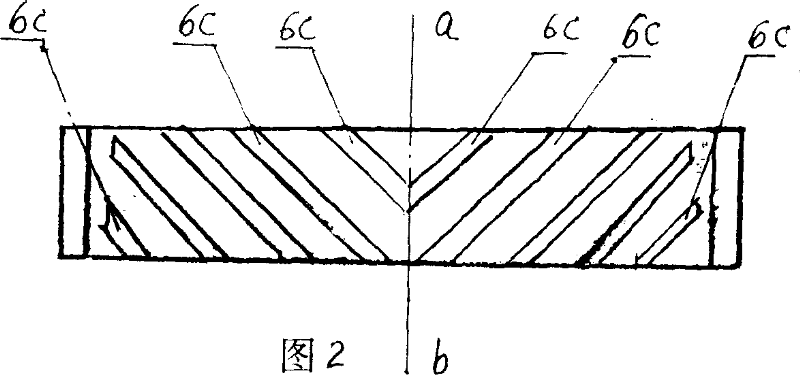

Manufacturing method of solar battery packaging glass and kiln furnace used for manufacture

The invention discloses a preparing method of solar battery packing glass, which comprises the following steps: choosing raw material; processing; disposing; allocating raw material; mixing; adding into furnace; melting; modeling and annealing; controlling content of quartz sand middle iron at 0-25ppm; setting height of weir at 715-780mm; forming 45degree cut angle of corundum brick in the flower curtain wall and wall broad centre line; assembling feeler unit connecting with controlling system in the furnace; making light transmittance ratio of glass higher than 92%. It possess merits of high white content, high fineness, high strength and long durability, which can satisfied needs of solar battery packing glass.

Owner:李静

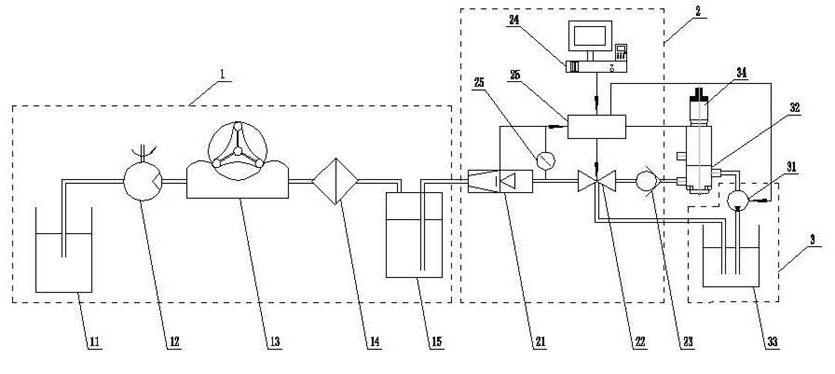

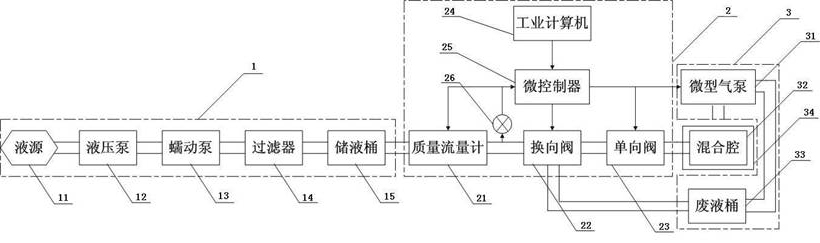

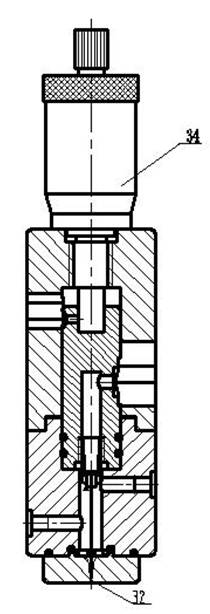

Liquid control system for double-fluid injector

ActiveCN102151627AImprove continuityImproved pressure stabilityLiquid surface applicatorsLiquid spraying apparatusPeristaltic pumpHydraulic pump

The invention relates to a liquid control system for double-fluid injection, which comprises a liquid source device, a liquid control device, a return suction device and a double-fluid injector, wherein the liquid source device, the liquid control device, the double-fluid injector and the return suction device are connected by hoses in turn, and liquid supply and recovery of the double-fluid injector are realized. In a liquid source device, a hydraulic pump is adopted to convey liquid to the system, and a peristaltic pump is used to reduce impulse. In the liquid control device, a liquid electromagnetic valve is adopted to supply continuous or impulse liquid flow to downstream equipment, a liquid one-way valve is arranged in the path of liquid before entering a mixing chamber to prevent liquid backflow caused by overhigh pressure in the mixing chamber, a return suction opening is formed on the other side of the mixing chamber, and a micro air pump is used to suck liquid before the system stops working to avoid trailing, wire drawing and other phenomena. The system can be used in ink injection, glue injection and welding processes and other processes, particularly a double-fluid injection spot gluing process.

Owner:SHANGHAI UNIV

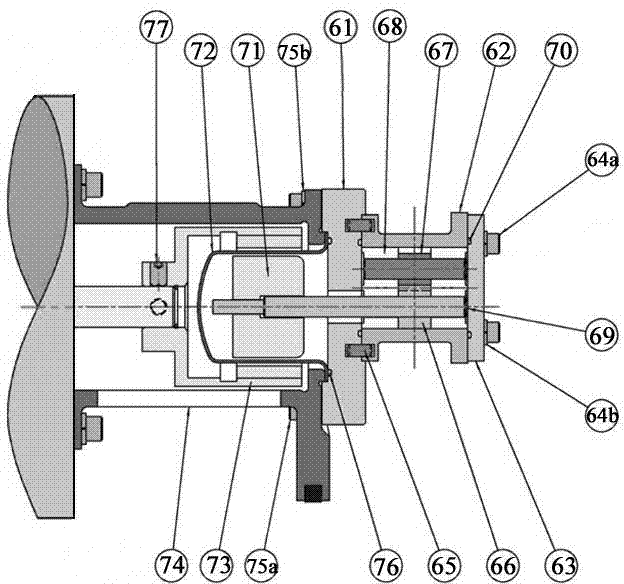

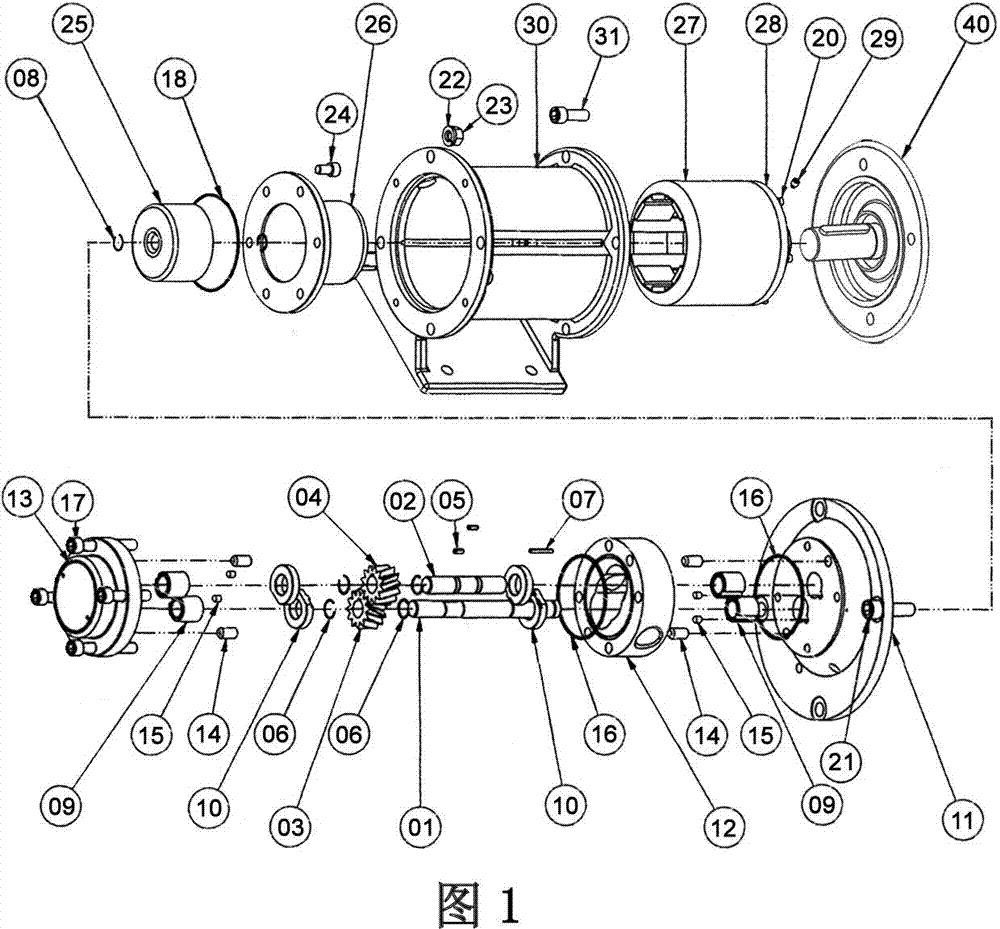

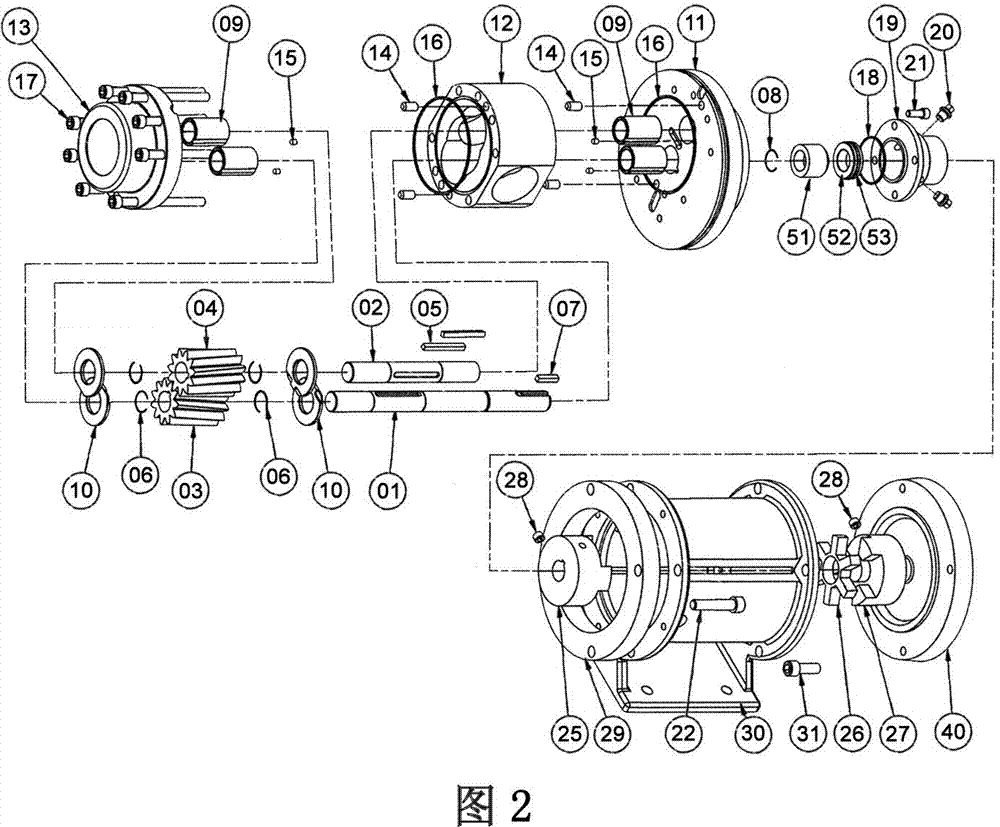

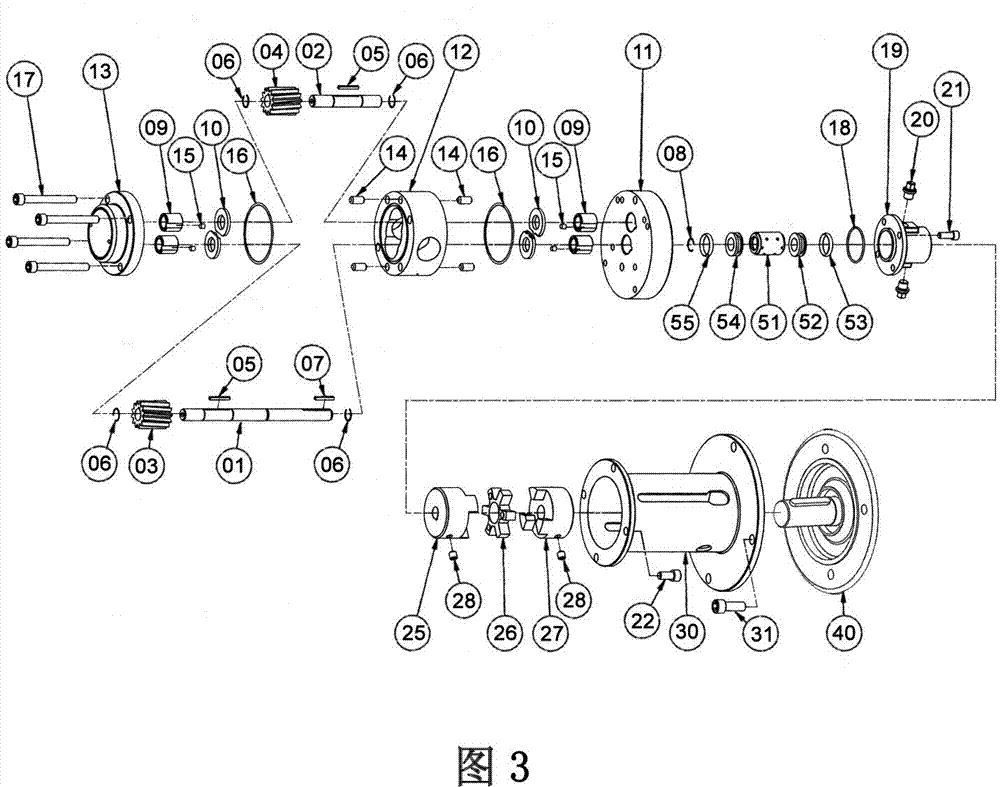

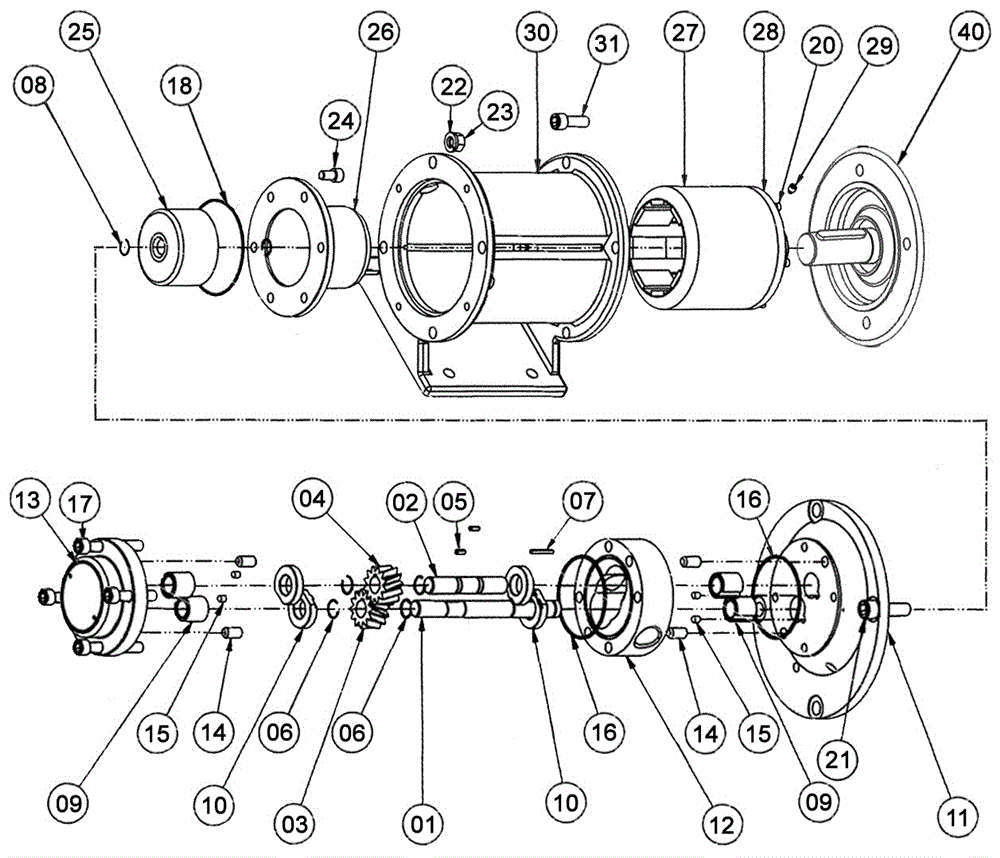

Novel magnetic gear pump

ActiveCN104214089AEfficient deliveryImprove the accuracy of useRotary piston pumpsRotary/oscillating piston combinationsMagnetic tension forceGear pump

The invention relates to a pump, in particular to a novel magnetic gear pump used for conveying various chemical mediums, or oil, or water, or poisonous and harmful, or flammable and explosive liquid and having the advantages of corrosion resistance, acid and alkali resistance, high-temperature resistance, high-pressure resistance, magnetic driving, zero leakage and zero pulsation. The magnetic gear pump, provided by the invention, solves the defects in the prior art through innovation of design structure, improvement of processing technology and reasonable selection of metal and nonmetal combination materials, so that the pump can satisfy the working conditions of high temperature, high pressure and various viscosities, and can efficiently convey various demanding chemical mediums having the characteristics of poison, harm, easy volatilization, easy corrosion and easy crystallization; the magnetic driving is adopted to connect the driving of the pump and a motor, so that zero leakage and zero pulsation are truly realized, the difficulty of shaft seal leakage in the prior art is solved, the radial load caused by misalignment is eliminated, the overload protection effect is achieved, and the wide application to various industries as petroleum, chemical engineering, pharmacy, foods, tobaccos, papermaking and laboratories is achieved.

Owner:何祥军

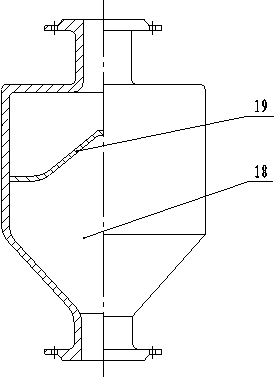

Three-inlet spiral slag pushing type hydraulic cyclone

InactiveCN103586145AEliminate dead zone for short circuitReduce usageReversed direction vortexCycloneSlag

The invention relates to a three-inlet spiral slag pushing type hydraulic cyclone, which comprises a settlement pot, an anti-backflow device, an inlet, an inlet pipe, a cover plate, an overflow pipe, a cylindrical body, a cone, an underflow pipe, a valve and a spiral slag pusher. The inlet design of the hydraulic cyclone is a three-inlet structure, the inlet employs three narrow and long gradually changed rectangular inlet pipes with three same cross section shapes, three inlets are symmetrically arranged with an angle presenting 120 DEC, the long edge of the rectangle is parallel to axis of the hydraulic cyclone, wherein one long edge is tangent with the inner surface of the cylindrical body, separation efficiency can be improved by the structure; the settlement pot is connected at the underflow port, the anti-backflow device is added in the settlement pot for preventing phenomenon of liquid leakage; a cylindrical hopper is connected at the lower part of the settlement pot, a spiral is arranged in the cylindrical hopper, and a speed regulation motor is used for uninterruptedly rotating the spiral for discharging solid slag though a spiral shaft outside the cylindrical hopper. According to the invention, slag deposited at the underflow port can be discharged in an automatic, stable and adjustable mode.

Owner:SOUTHWEST PETROLEUM UNIV

Domestic sewage filtering device

InactiveCN104163542AReduce impactLiquid flow is stableMultistage water/sewage treatmentEngineeringFilter material

The invention discloses a domestic sewage filter device, which comprises two parts of a separation device and a filtering device; the separation device is a cylinder, an upper side face of the cylinder is provided with a water inlet, a support column is arranged in the middle of the cylinder, the support column is provided with movable separation disintegrators, a lower side face of the cylinder is provided with a water outlet; the filtering device is a cylinder, the lower side face of the cylinder is provided with a water inlet, the water inlet of the cylinder of the filtering device is connected with the water outlet of the cylinder of the separation device, an upper side face of the cylinder of the separation device is provided with a water outlet, multi layers of filter materials are arranged from bottom to top in the cylinder of the separation device, the lower filter material is arranged on a filter plate, the filter plate is supported by a column or other substances, and an exhaust pipe is arranged in the middle of the filter materials. The domestic sewage filter device adopts the technical scheme, compared with the prior art, the domestic sewage filter device has the advantages of full sewage degradation, fast purification, simple structure, and up-to-standard sewage discharge.

Owner:苗育卓 +1

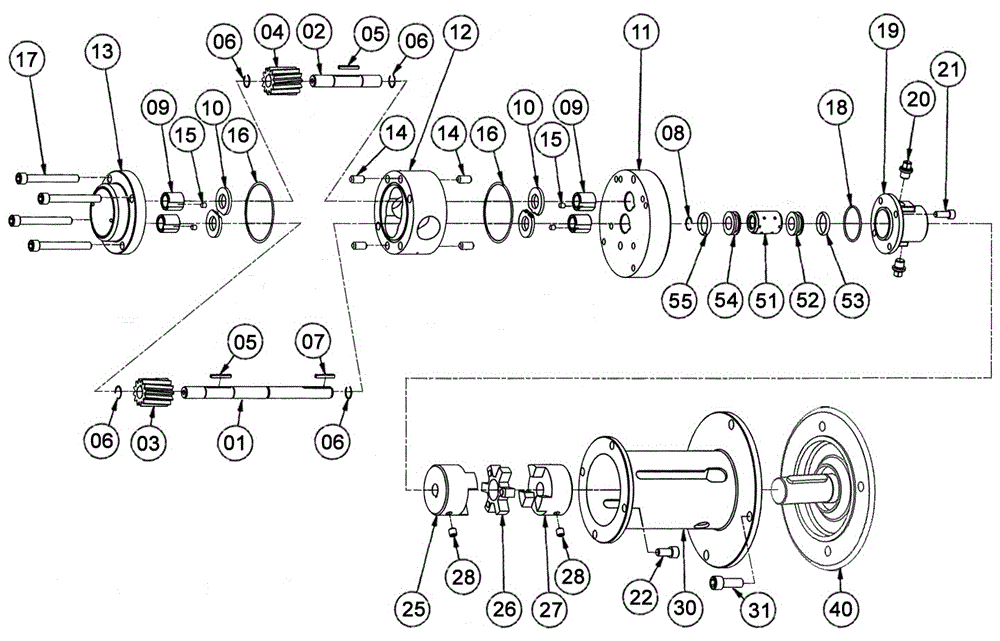

Novel flavoring feeding pump

InactiveCN104214087AImprove the accuracy of useCompletely sealedRotary piston pumpsRotary piston liquid enginesEngineeringHigh pressure

The invention relates to the technical field of pumps, in particular to a novel flavoring feeding pump. The novel flavoring feeding pump comprises a pump body, a base, a joint drive, internal parts and the like. According to the novel flavoring feeding pump, a design structure is innovated; the processing technology is improved; metal and non-metal combination materials are reasonably selected; and therefore the shortage of the traditional technology is overcome. It is ensured that the pump can meet working conditions with high temperature, high pressure and various kinds of viscosity, and flavoring feeding chemical media and various harsh chemical media can be efficiently conveyed. A short shaft of a self-centering structure and the magnetic or mechanical sealing mode are adopted to enable the pump to be connected with the drive of a motor; the zero-leakage non-pulse aim is truly achieved; the problem that a traditional pump is prone to leaking is solved; radial loads caused by non centering are omitted; the overload protection effect is achieved; and application of cut tobacco mixing flavoring, cut stem flavoring, cut stem feeding, leaf feeding, cut leaf feeding and moisture regaining of the tobacco industry and application of conveying, metering, circulating, injecting, lifting and the like of flavoring feeding of industries such as food, pharmacy and chemical engineering can be met.

Owner:何祥军

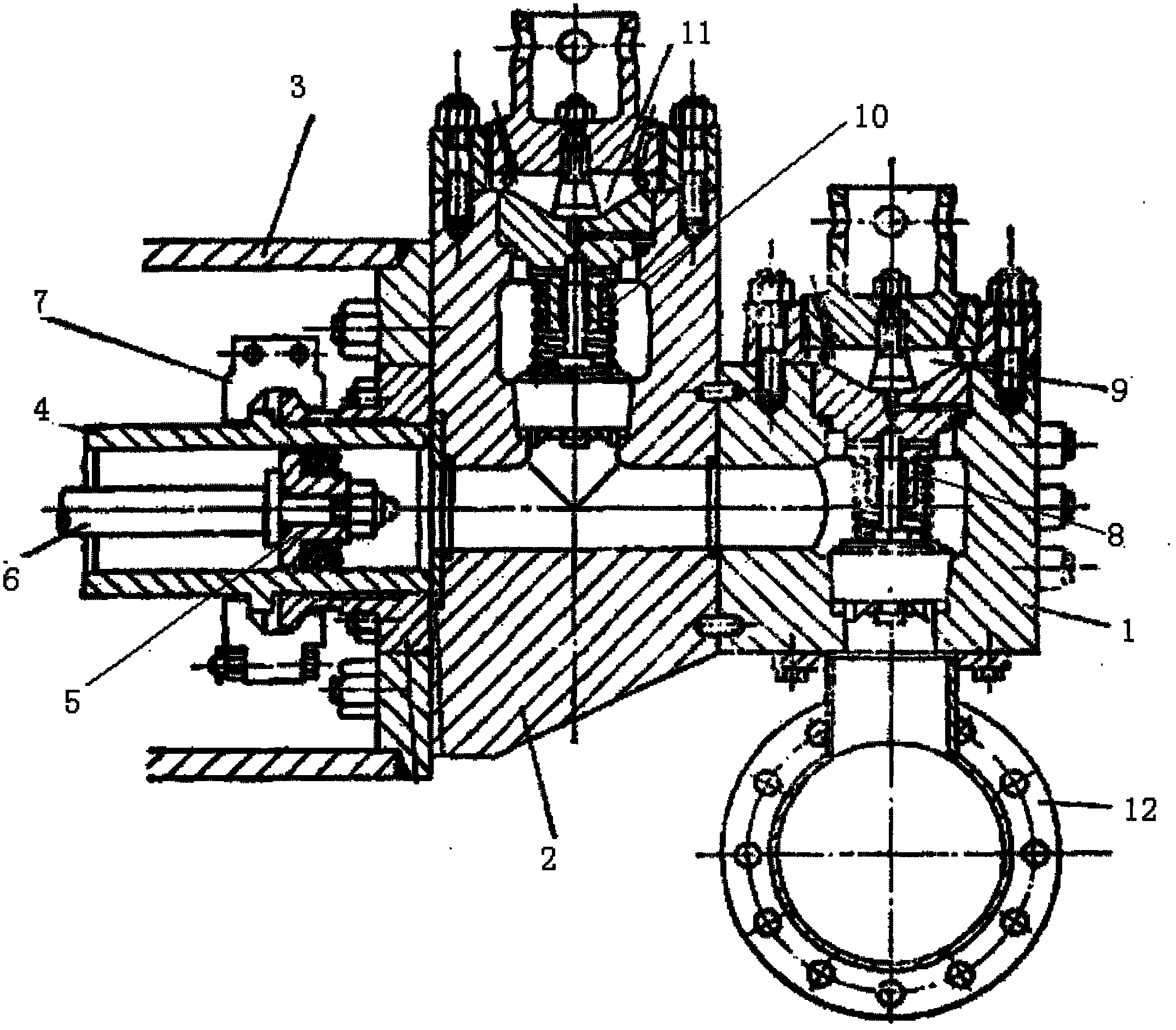

Pressurization method of well drilling pump applied to petroleum industry

InactiveCN103104469ALiquid flow is stableReduce vibrationPositive displacement pump componentsLiquid fuel engine componentsWell drillingEngineering

The invention discloses a pressurization method of a welling drilling pump applied to a petroleum industry. The pressurization method comprises: (a) firstly, a suction valve (8) and a discharging valve (10) are started, and a piston device is started; (b) liquid is sucked into a suction valve box (1) from a suction flange (12) and enters into a discharging valve box (2) through the suction valve (8); (c) then, a piston (6) in the piston device conducts back-and-forth motion, and therefore, the liquid entering into the discharging valve box (2) is pressurized; (d) pressurized liquid is finally discharged through the discharging valve (10). The pressurization method can enable liquid flow to be stable, reduces vibration and pressure fluctuation, and the suction valve can be independently dismantled so as to facilitate maintaining.

Owner:谢月

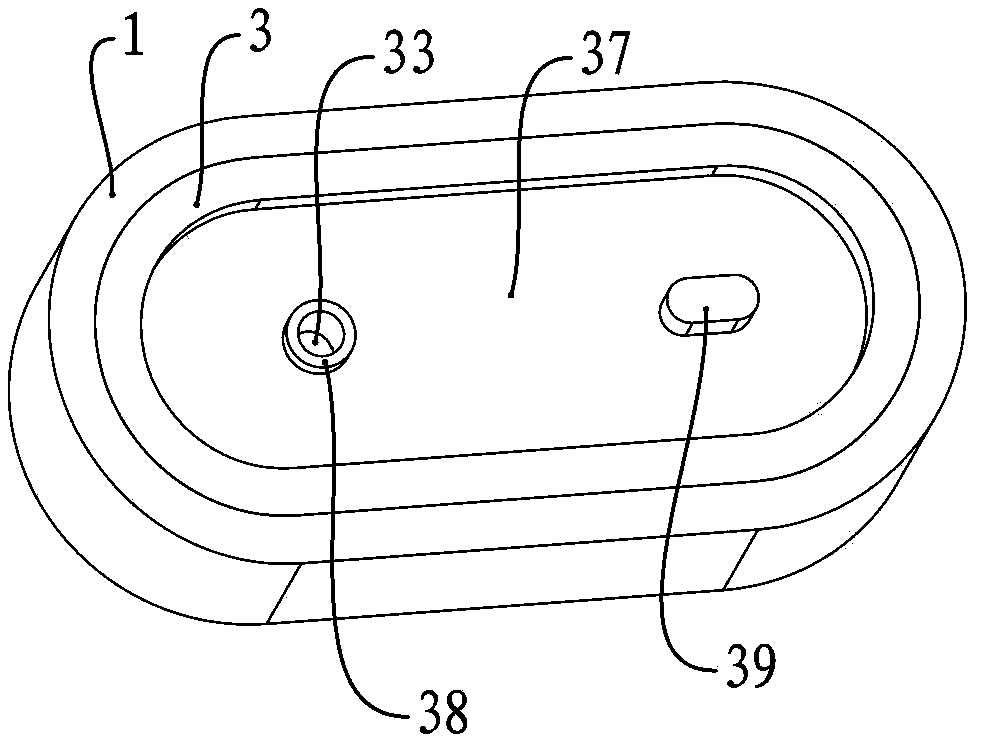

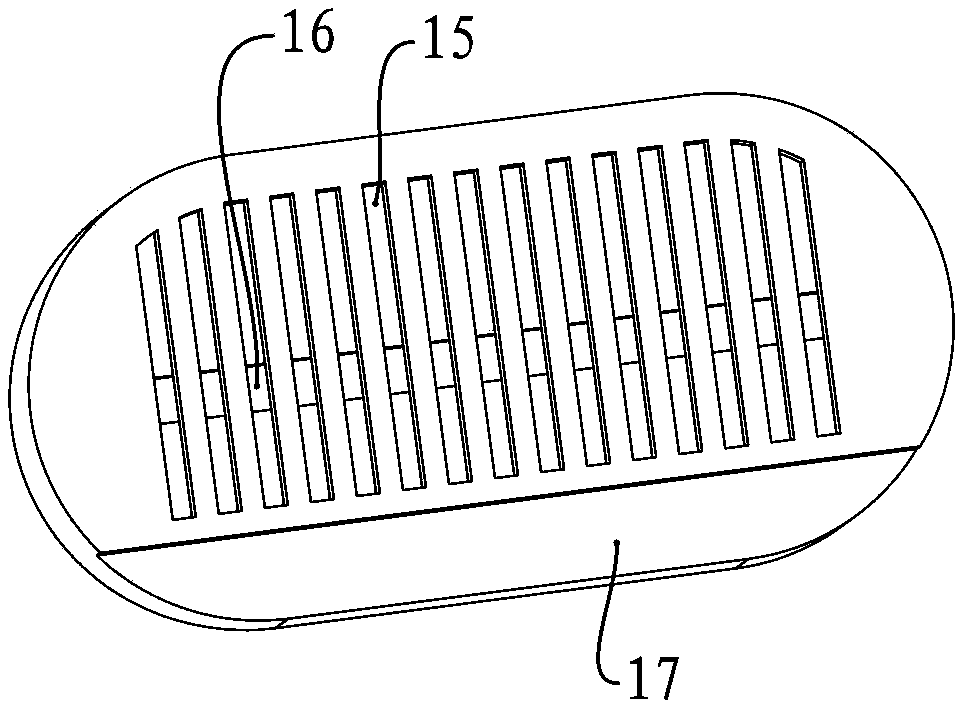

Pressure compensation type emitter and drip irrigation belt/tube

ActiveCN104174518AExtended service lifeStable pressure compensation functionWatering devicesSpray nozzlesDrip irrigationEngineering

The invention relates to the technical field of drip irrigation, in particular to a pressure compensation type emitter. The pressure compensation type emitter comprises an emitter base with a water inlet hole and an emitter upper cover with a water outlet hole; the upper side of the emitter base is provided with an accommodating cavity; the emitter upper cover is arranged in the accommodating cavity; a clamping groove is formed in the accommodating cavity; a rubber sheet is arranged in the clamping groove; the rubber sheet is positioned between the emitter base and the emitter upper cover; liquid enters the inside of the pressure compensation type emitter through the water inlet hole; the rubber sheet is positioned between the emitter base and the emitter upper cover and the rubber sheet separates the emitter base from the emitter upper cover, and thus, when the liquid enters the inside of the pressure compensation type emitter, the liquid pressure acts on the rubber sheet, the rubber sheet squeezes the emitter upper cover with the water outlet hole and the water passing sectional area is changed, so that flow of the liquid passing through the water outlet hole is enabled to be stabilized in a regulated range. Therefore, the pressure compensation type emitter can be applied to products such as an emitter.

Owner:SHENZHEN BATIAN ECOTYPIC ENG

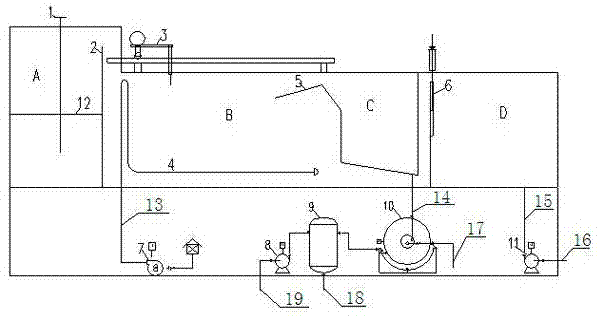

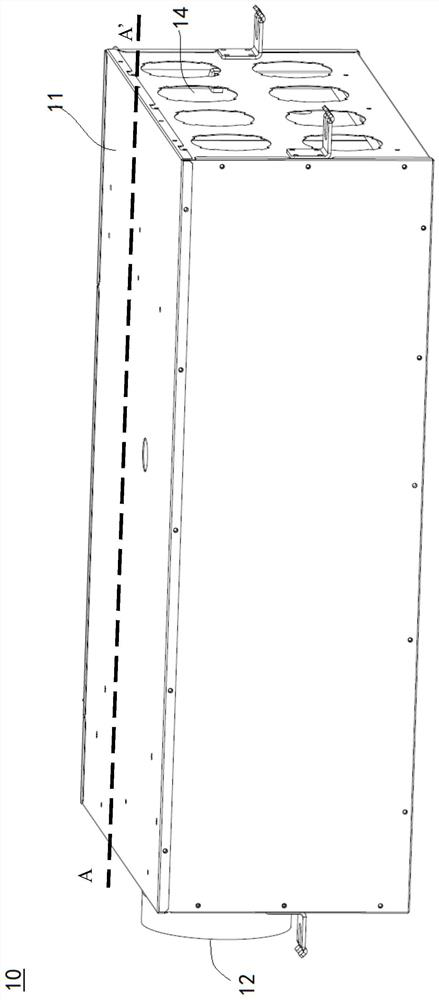

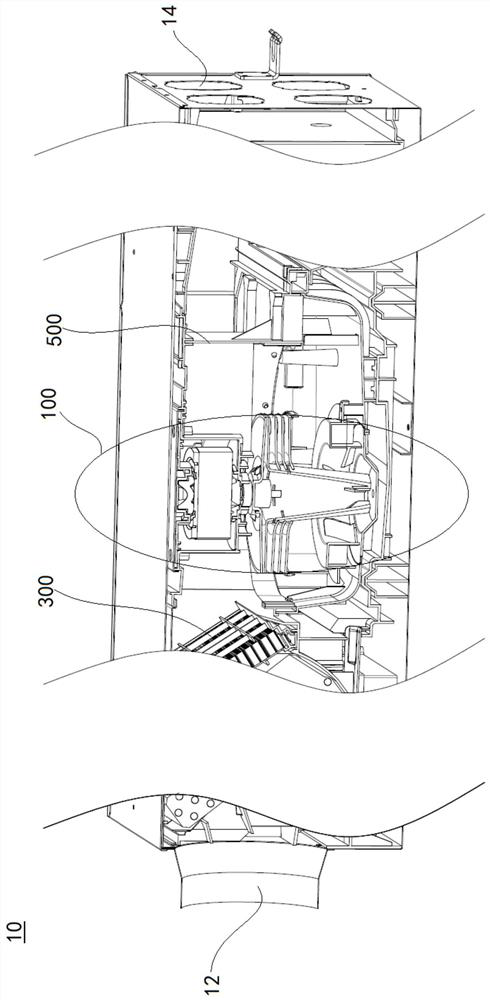

Natural gas wet desulphurization and regeneration integrated apparatus

A natural gas wet desulphurization and regeneration integrated apparatus comprises a regeneration separating reactor and a filter circulating skid, and is designed in a two layer manner, the regeneration separating reactor is at the upper layer, the filter circulating skid is at the lower layer, and the regeneration separating reactor and the filter circulating skid are separated by a skidding rack; the regeneration separating reactor comprises an injection chamber A, a separation chamber B, a sulfur foam chamber C and a lean solution chamber D which are arranged from left to right, the injection chamber A is communicated with the separation chamber B, and the separation chamber B is communicated with the sulfur foam chamber C through an overflow plate, and is communicated with the lean solution chamber D through a flashboard; an injection device is arranged at the central portion of the injection chamber A from top to bottom, and the upper top of the separation chamber B is horizontally provided with a sludge scraper; and the filter circulating skid comprises a blower connected with the separation chamber B through a gas distribution tube, a rotary drum filter connected with the bottom of sulfur foam through a sulfur foam outlet tube, a separator connected with a liquid outlet of the rotary drum filter, a vacuum pump connected with the separator, and a lean solution pump connected with the bottom of the lean solution chamber D.

Owner:CHINA PETROCHEMICAL CORP +2

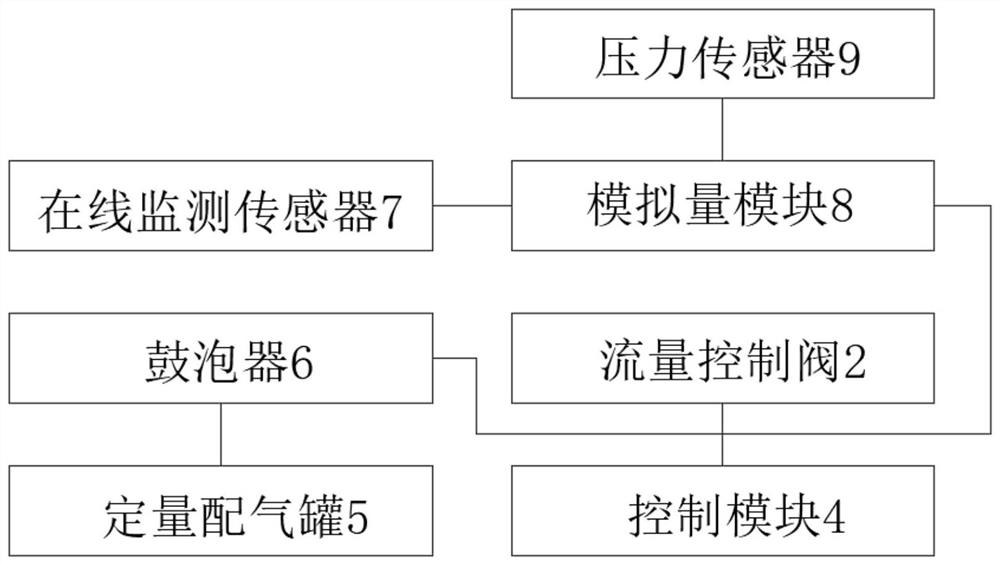

Improved glass kiln bubbling system

InactiveCN114507000AImprove homogenizationLiquid flow is stableGlass furnace apparatusThermodynamicsProcess engineering

The invention relates to an improved glass kiln bubbling system which comprises a gas ejector pipe and a control module, the gas ejector pipe is fixedly connected with the interior of a quantitative gas distribution tank through a bubbler, the control module is electrically connected with the bubbler, and the control module is further electrically connected with an online monitoring sensor. The on-line monitoring sensor is arranged in the glass melting furnace to measure the real-time temperature and viscosity of molten glass; the bubbler can perform intermittent pulse operation according to a preset natural period frequency, bubbles are intermittently conveyed into molten glass, and through mutual cooperation of the online monitoring sensor and the analog quantity module, the bubble diameter and the bubble frequency of the bubbles can be adjusted according to the temperature and viscosity fluctuation of the high-temperature molten glass, so that the molten glass flow is stable, and the stability of the molten glass is improved. The homogenization degree is high, and the quality of the produced product is better.

Owner:SHANDONG PHARMA GLASS

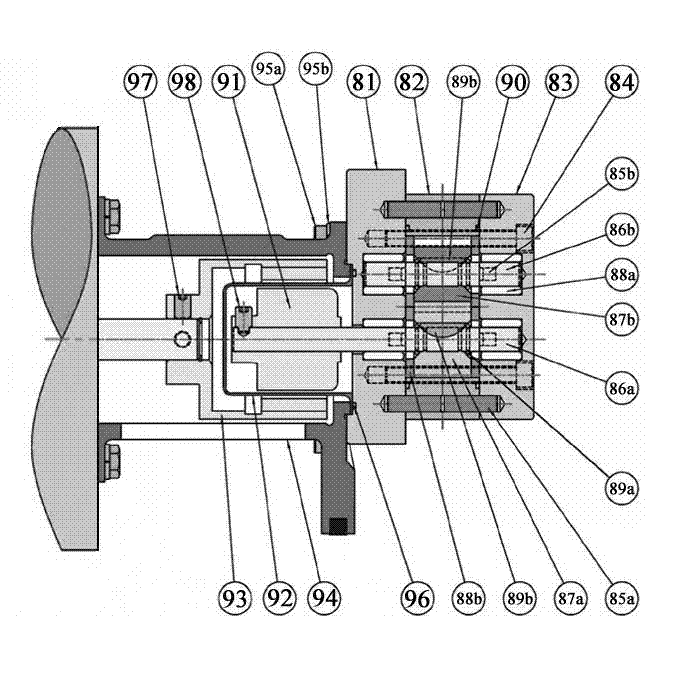

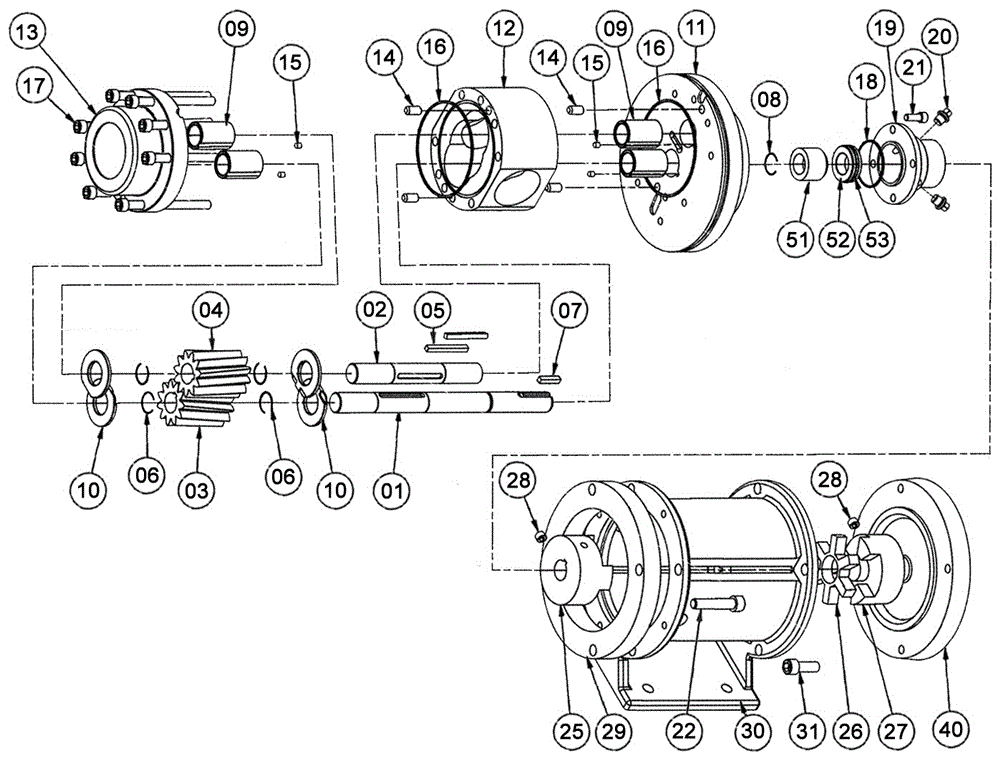

Novel high-pressure chemical industry gear pump

ActiveCN104500389AGuaranteed working lifeSmooth pumping operationRotary piston pumpsRotary/oscillating piston combinationsChemical industryMagnetic tension force

The invention relates to a pump and particularly relates to a novel high-pressure chemical industry gear pump which is used for conveying various chemical media, corrosive and dangerous chemicals, or oil or water or toxic and harmful liquids or inflammable and detonable liquids and has high pressure resistance, high temperature resistance, corrosion resistance, acid and alkali resistance and abrasion resistance. According to the novel high-pressure chemical industry gear pump, a pair of unique helical gears capable of resisting high-pressure pumping and a wear-resisting plate with a pressure relief groove are designed and adopted; by virtue of innovatively designing the structure, improving the processing process, reasonably selecting metal and nonmetal combined materials, and adopting short-axis coupling and magnetic driving mode of a self-alignment structure or a mechanical seal mode of a coupling with an elastomer to connect driving between the pump and a motor, working conditions with high pressure, high pressure difference and various viscosity are met, various harsh chemical media are efficiently delivered, the defect or blank of the prior is overcome, zero leakage and no pulse are really realized, the leakage problem of an existing shaft seal is solved, and extensive application in various industries such as petroleum and chemical industry is met.

Owner:何祥军

A new type of magnetic gear pump

ActiveCN104214089BEfficient deliveryImprove the accuracy of useRotary piston pumpsRotary/oscillating piston combinationsMagnetic tension forceGear pump

A new type of magnetic gear pump, the invention relates to a pump, in particular to a pump for conveying various chemical media or oil or water or toxic, harmful or flammable and explosive liquids, with corrosion resistance, acid and alkali resistance, high temperature and high pressure resistance, A new type of magnetic gear pump with zero leakage and no pulsation with magnetic drive. The magnetic gear pump provided by the present invention solves the deficiencies of the current technology by innovatively designing the structure, improving the processing technology and rationally selecting metal and non-metal composite materials, thereby ensuring that the pump can meet the working conditions of high temperature, high pressure and various viscosities. Harmful, volatile, easy to corrode, easy to crystallize and various harsh chemical media for efficient transportation; and the design uses magnetic drive to connect the drive of the pump and the motor, which truly achieves zero leakage and no pulsation, and solves the problem of existing shaft seal leakage , eliminates the radial load caused by misalignment, plays an overload protection role, and meets a wide range of applications in various industries such as petroleum, chemical, pharmaceutical, food, tobacco, paper and laboratories.

Owner:何祥军

Melting and casting method of aluminum alloy sacrificial anode

Owner:NORTHEASTERN UNIV LIAONING +1

Graphite bubble-cap tower for purifying wet-process phosphoric acid by solvent extraction method

InactiveCN112426747ARealize the function of automatic sewage discharge and dischargeDo not destroy the logistics statusVortex flow apparatusLiquid solutions solvent extractionO-Phosphoric AcidGraphite

The graphite bubble-cap tower comprises a graphite tower body, multiple layers of tower plates are horizontally arranged in the graphite tower body from top to bottom, a downcomer is movably and vertically arranged on the edge of each layer of tower plate in a penetrating mode, and a distance exists between the top end of each downcomer and the surface of the corresponding tower plate; a upper downcomer and a lower downcomer are arranged on the left side and the right side of a upper-layer tower plate and a lower-layer tower plate in a staggered mode, the edges of the left side and the right side in the graphite tower body are each provided with a connecting shaft, the top ends of the connecting shafts extend out of the top of the graphite tower body, and racks are arranged at the extending ends of the connecting shafts and meshed with gears which are connected with servo motors. The connecting shafts extend downwards to penetrate into the downcomers on the same side and are fixedly connected with the downcomers, a lower overflow weir is arranged on the side, close to the downcomers on the upper portion, of each layer of tower plate, and the lower overflow weirs are connected withthe adjacent connecting shafts through lower overflow weir opening devices. According to the equipment, the functions of tower plate pollution discharge, emptying and automatic cleaning are achieved in a non-stop state, and it can be guaranteed that the bubble-cap tower operates without stopping throughout the year.

Owner:GUIZHOU LANXIN GRAPHITE MECHANICAL & ELECTRICAL EQUIP MFG

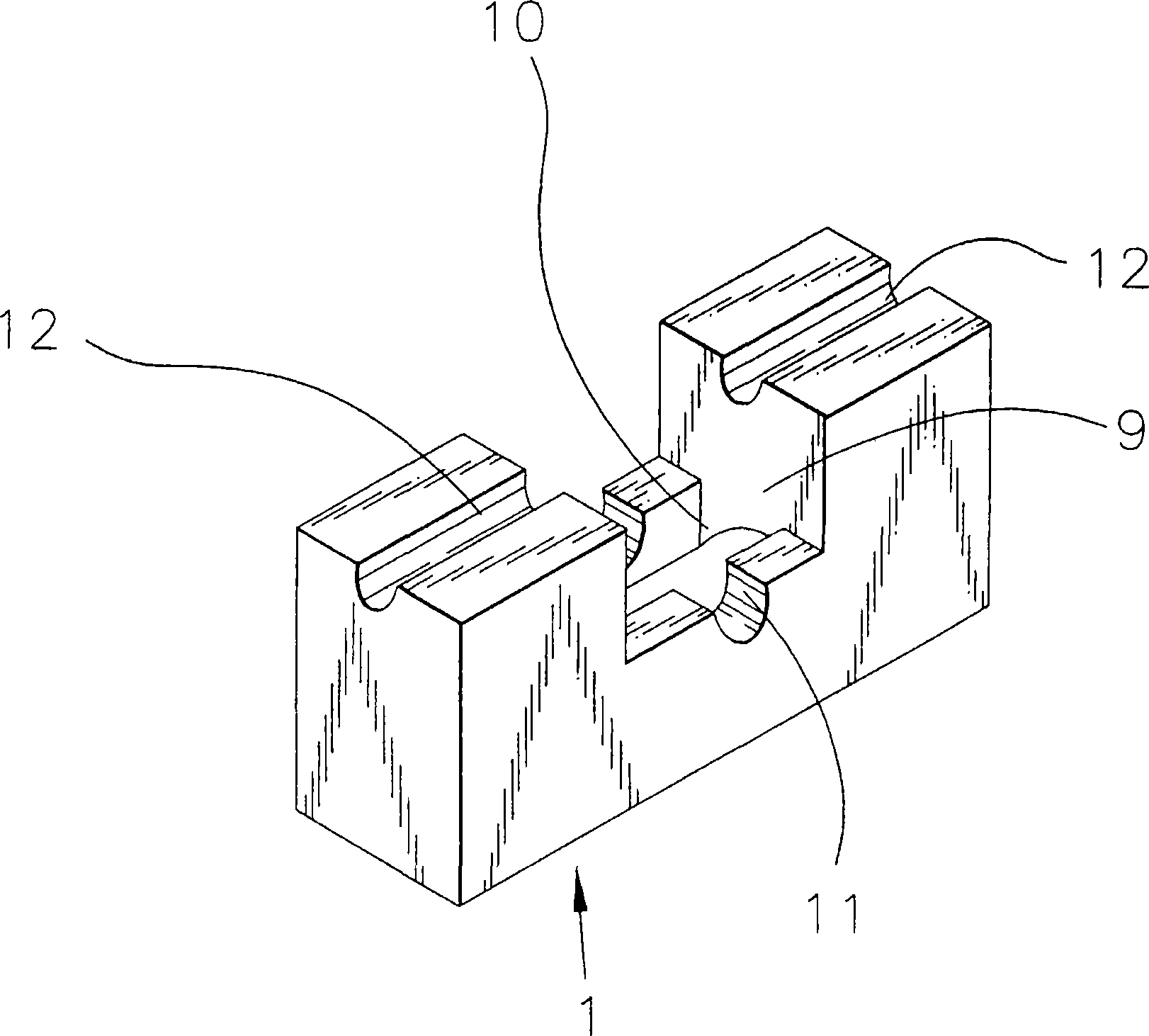

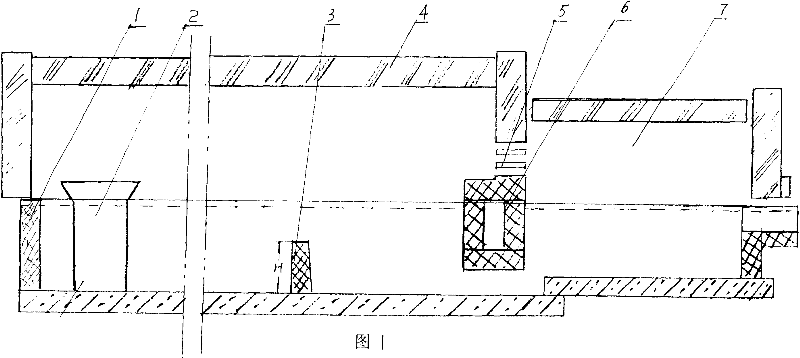

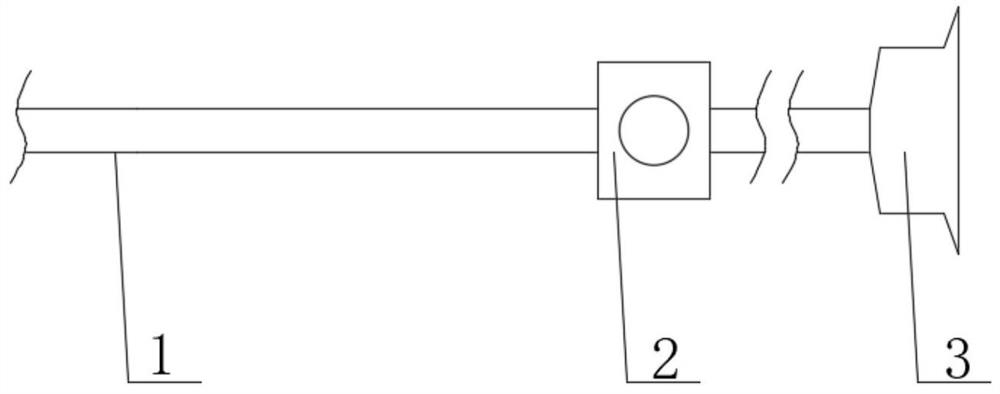

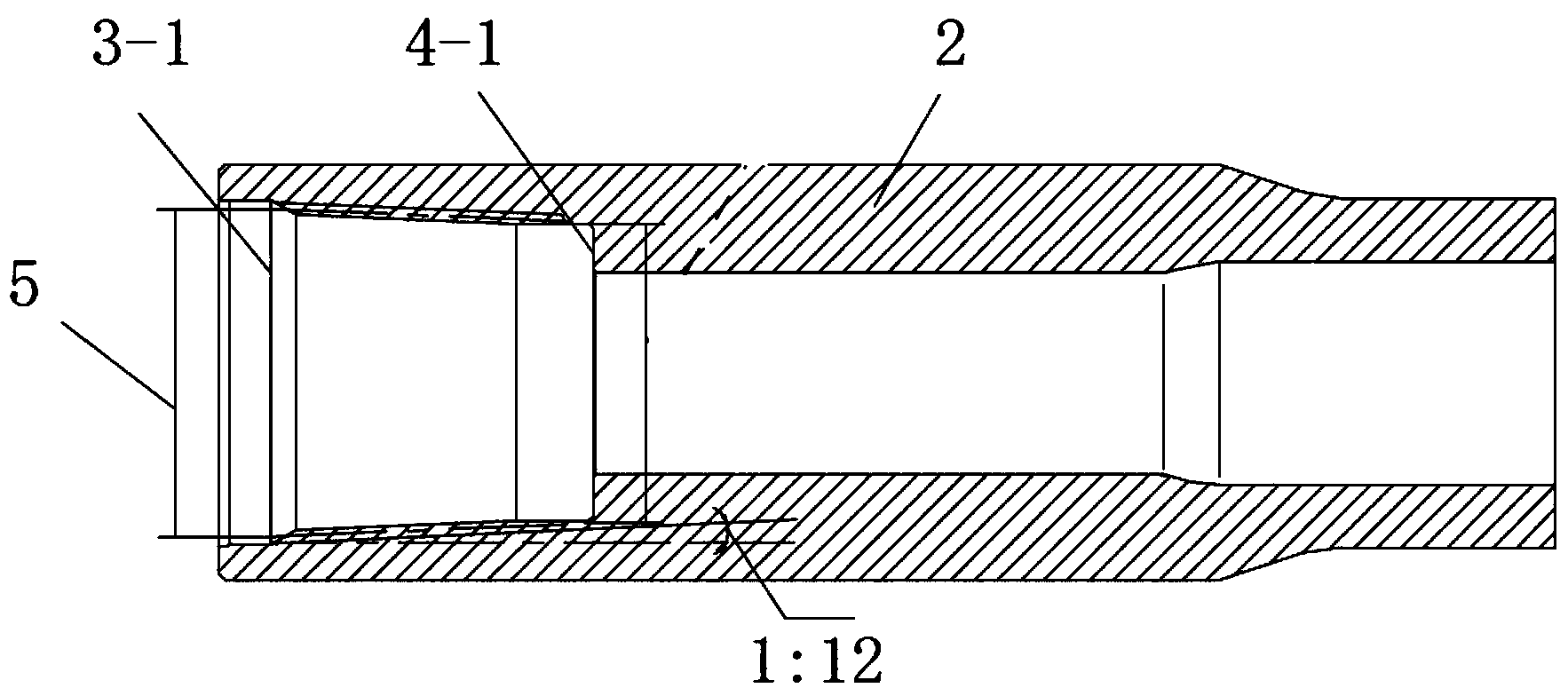

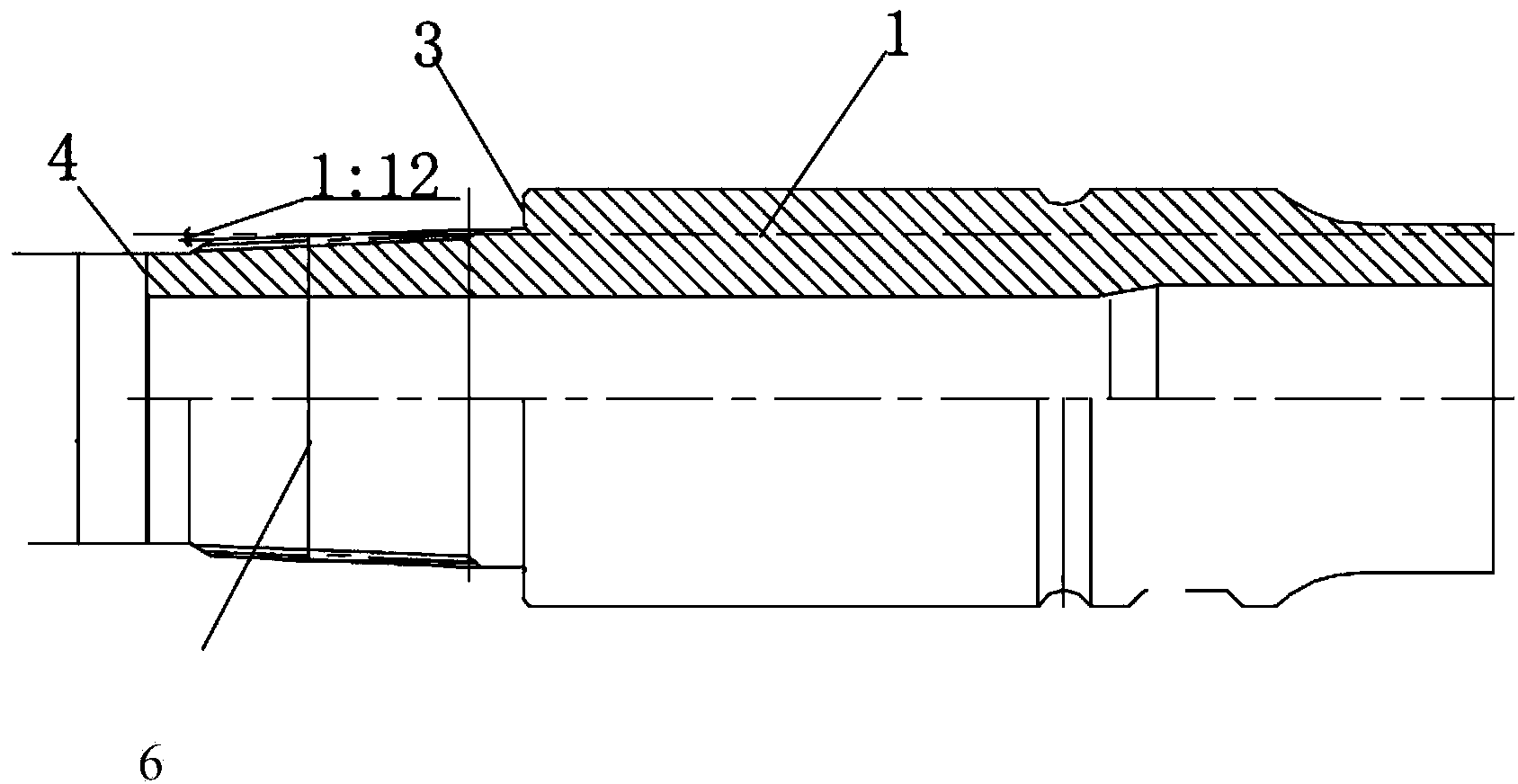

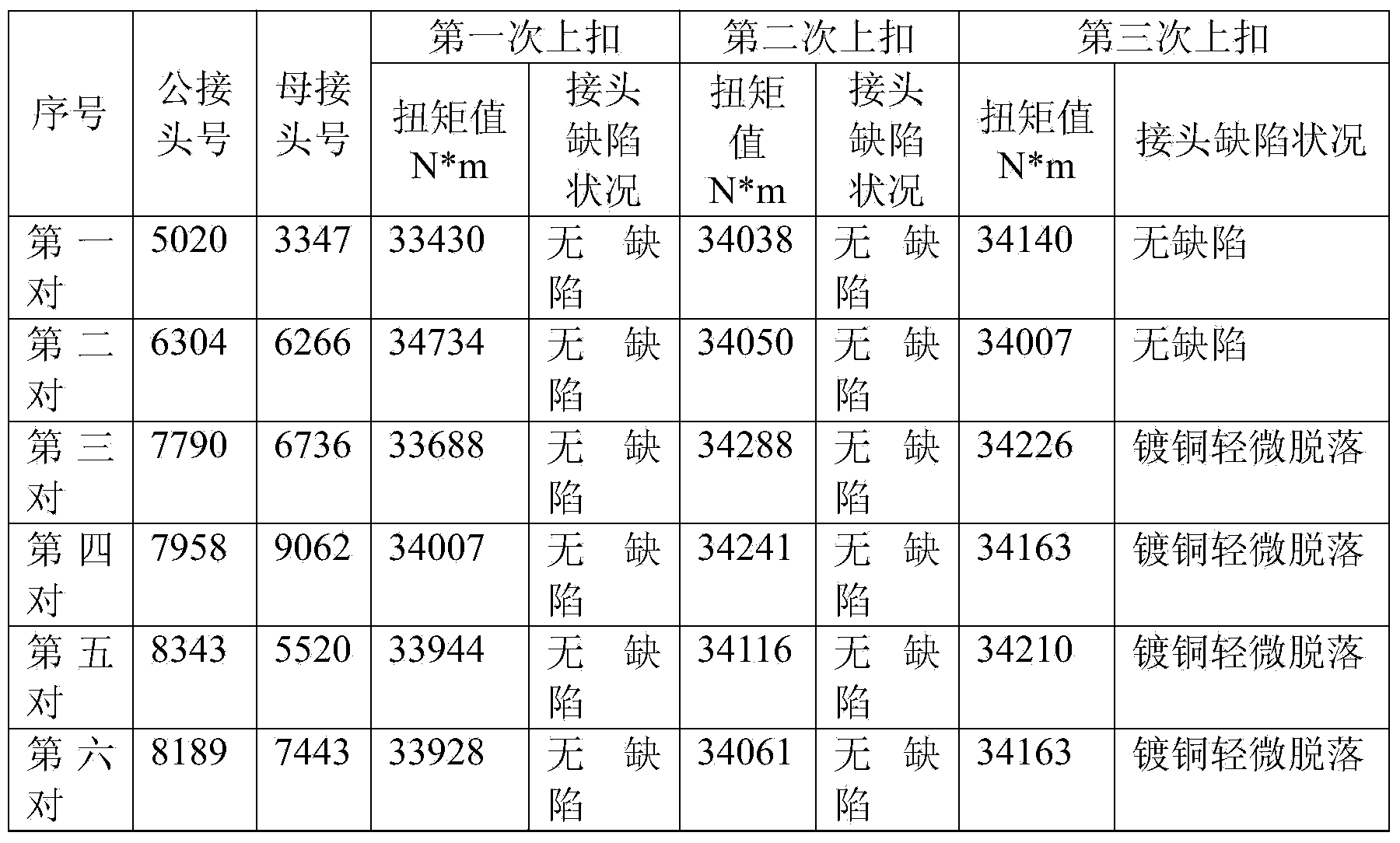

Drill pipe joint

InactiveCN104295246AIncreased salvageabilityImprove hydraulic performanceDrilling rodsDrilling casingsStress concentrationEngineering

The invention discloses a drill pipe joint. The drill pipe joint comprises a male joint and a female joint, and the male joint is connected with the female joint through a male joint thread and a female joint thread in a matched mode. The two sides of the male joint thread are provided with a main male joint shoulder and an auxiliary male joint shoulder respectively, and the two sides of the female joint thread are provided with a main female joint shoulder and an auxiliary female joint shoulder respectively. The thread positions of the male joint and the female joint connected in the matched mode are conical in the axial direction, the conicity of each thread position is 1:12, the outer diameter phi of the large end of the male joint is 127+ / -5 mm, and the pitch diameter phi of the base surface of the male joint and the pitch diameter phi of the base surface of the female joint are 100+ / -1 mm. The conicity of the thread positions of the male joint and the female joint connected in the matched mode is improved, the thread positions have higher binding force, rigidity is enhanced, and torsion resistance can be improved by more than 60% under the circumstance that the wall thicknesses are the same; stress concentration of the connection position is lowered, and fatigue resistance is improved.

Owner:TIANJIN DEHUA GASOLINEEUM EQUIP MFG

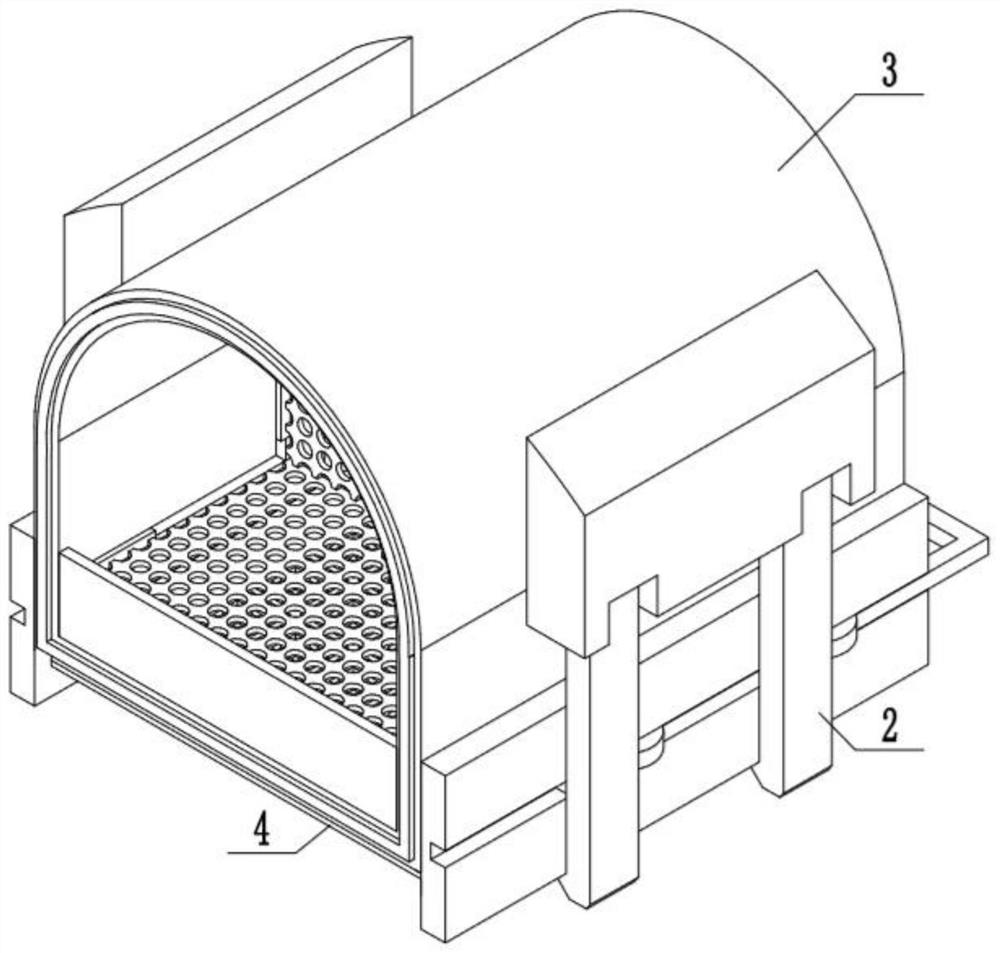

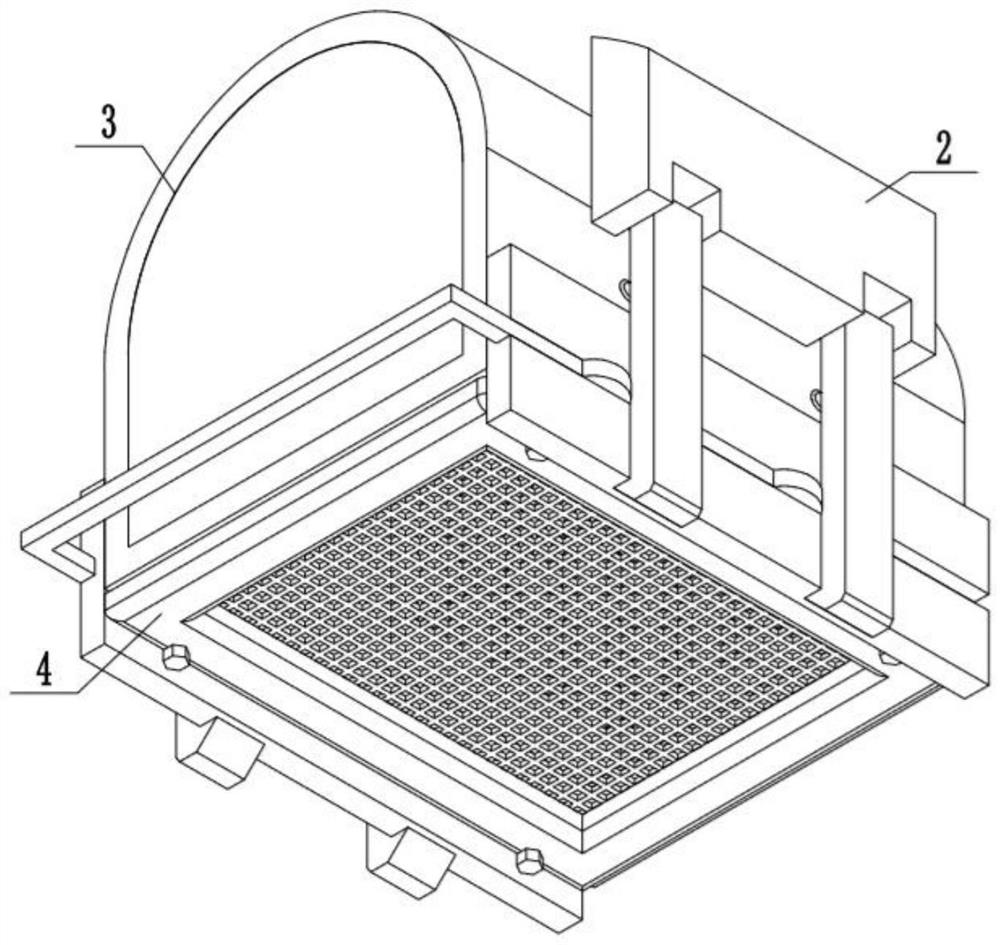

Liquid breaking unit and air treatment device comprising same

PendingCN114060987AStable speedLiquid level stabilityLighting and heating apparatusNoise suppressionWater storageAir treatment

The invention provides a liquid breaking unit and an air treatment device comprising the same. The liquid breaking unit comprises a water storage part, wherein a liquid storage space is formed by a bottom surface of the water storage part and side surfaces of the water storage part; a breaking part which comprises a water suction pipe, wherein the lower end of the water suction pipe is inserted into the liquid in the liquid storage space, and the water suction pipe sucks the liquid through rotation and micronizes the liquid; and a driving part which is connected with the breaking part and drives the water suction pipe to rotate, wherein a water retaining part which is separated from the water suction pipe is arranged near the lower end of the water suction pipe in a sleeving manner, and the water retaining part comprises a water retaining surface which is formed into a closed surface facing the water suction pipe and surrounding the water suction pipe, and water retaining ribs protruding from the water retaining surface to the water suction pipe and inclind downwards in the rotating direction of the water suction pipe. According to the liquid breaking unit, the stable humidification amount can be guaranteed, and noise caused by the unstable rotating speed of the motor can be reduced.

Owner:PANASONIC ECOLOGY SYSTEMS GUANGDONG CO LTD

Filler for separator equipment

InactiveCN113877300AFunction of relaxationRealize the function of taking outLoose filtering material filtersGravity filtersEngineeringMechanical engineering

Owner:TIANJIN TIANYI CHEM TECH DEV CO LTD

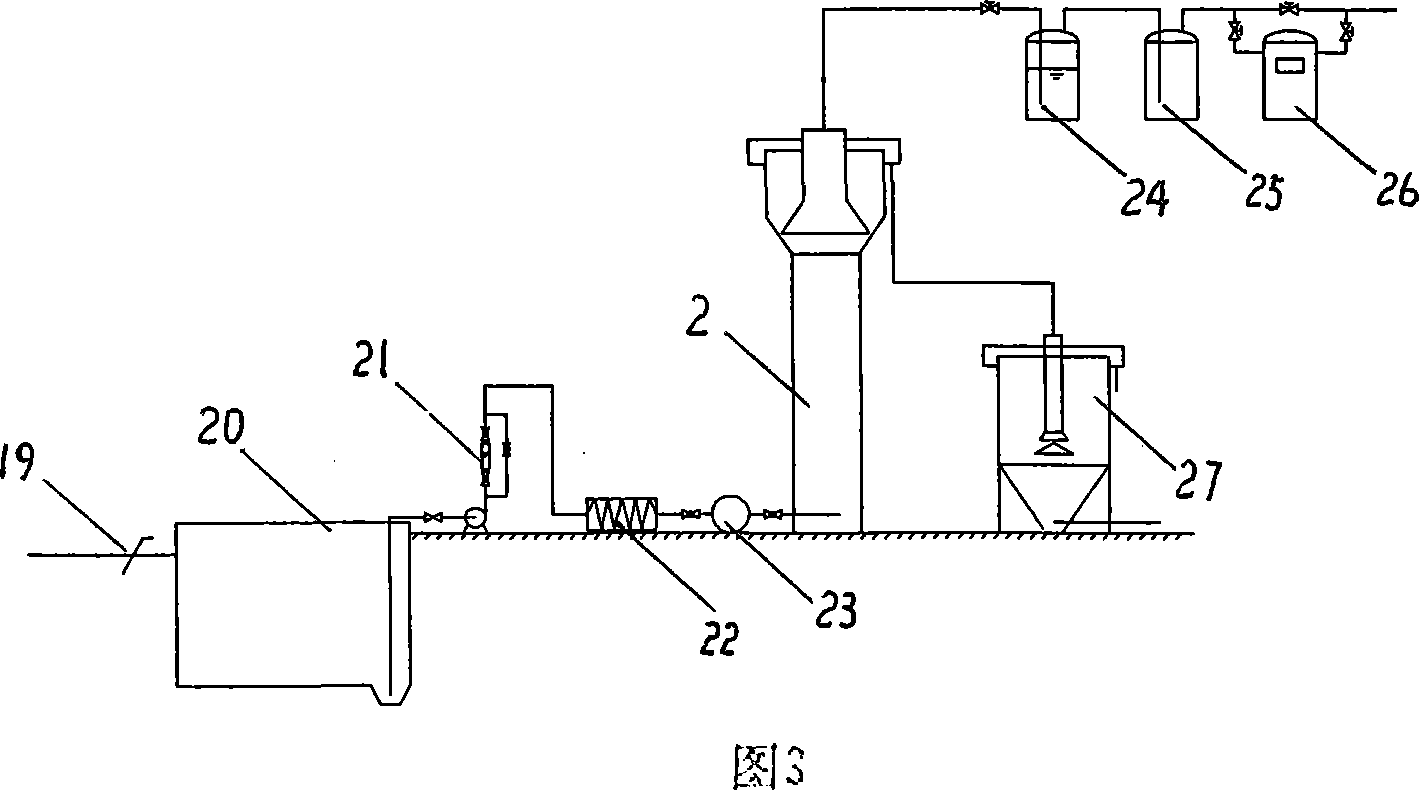

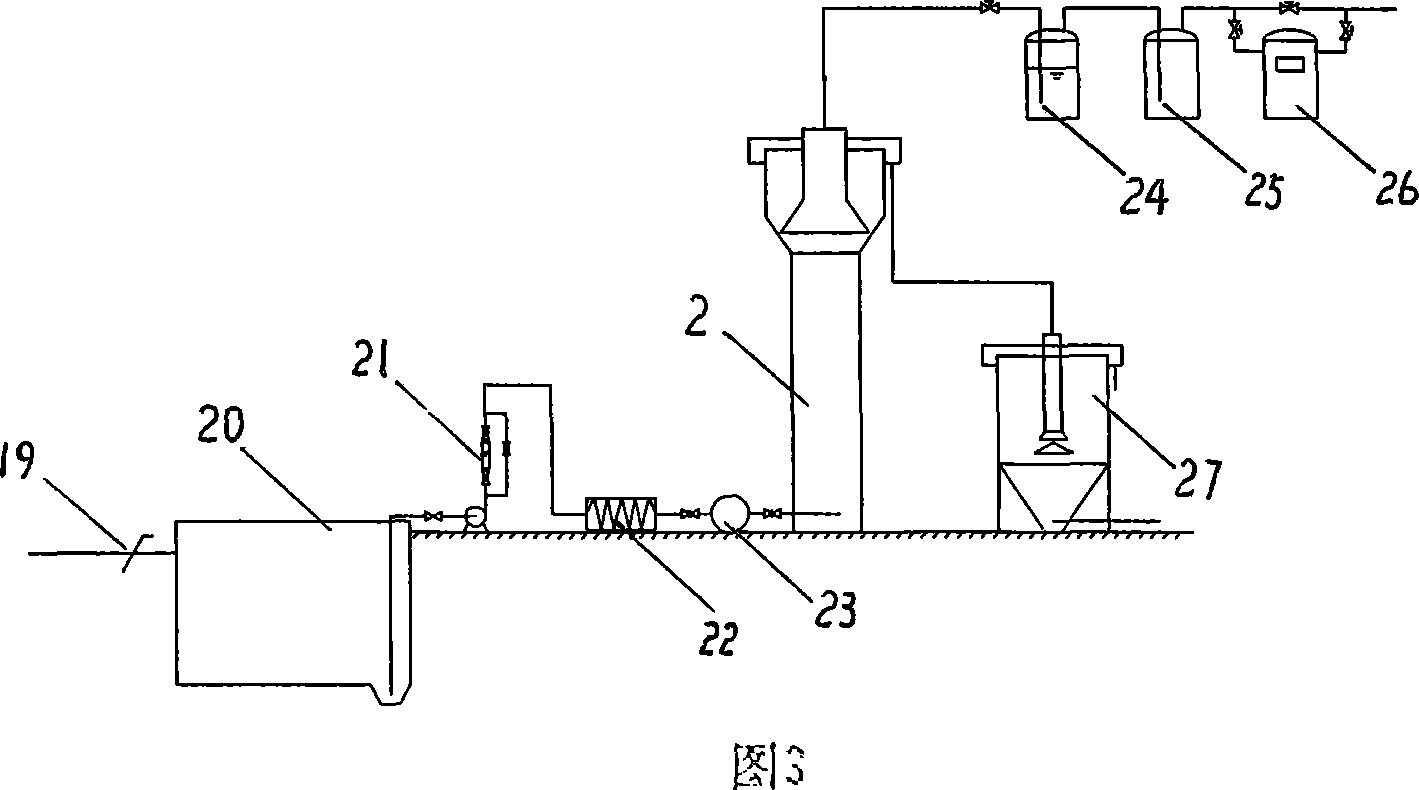

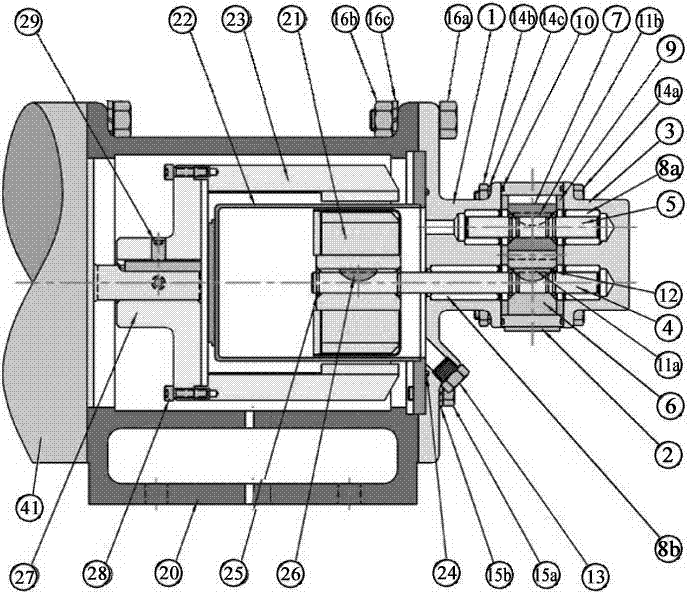

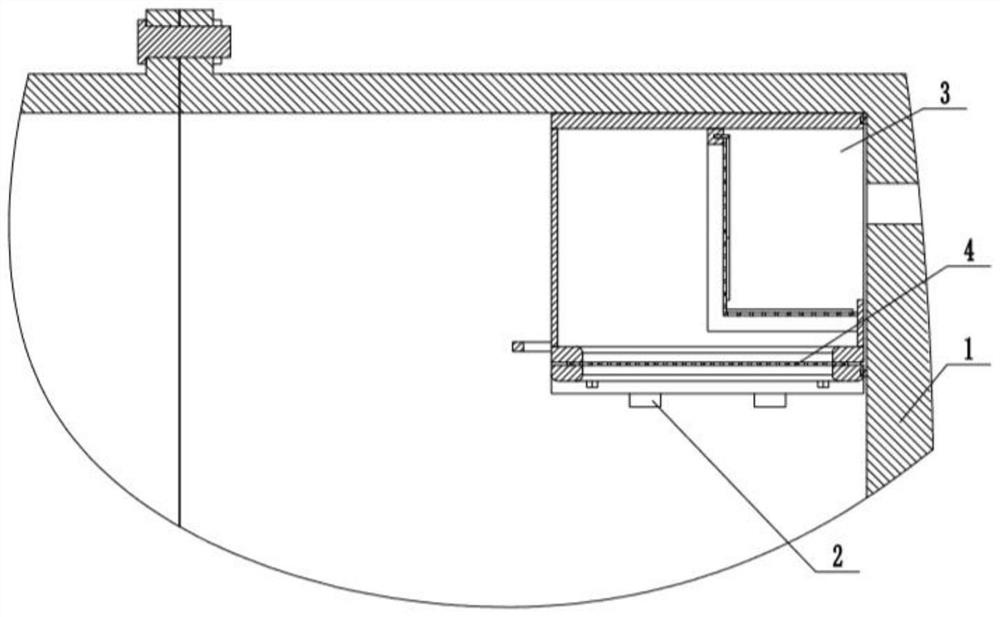

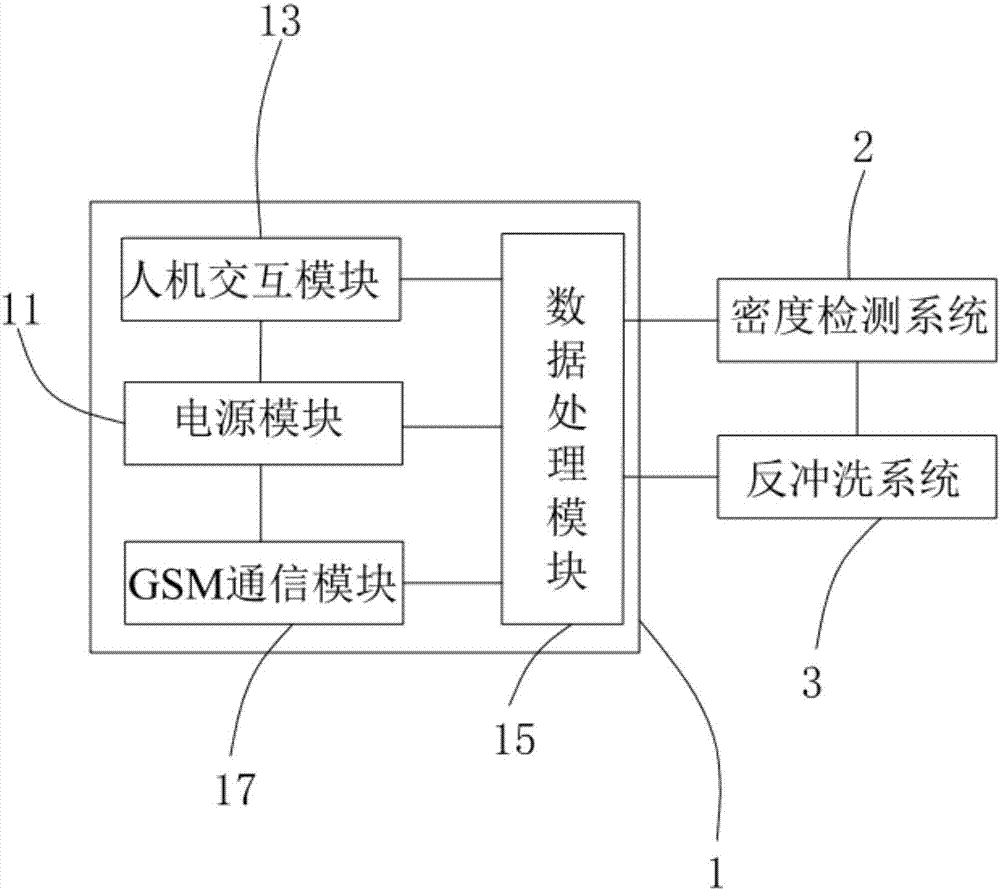

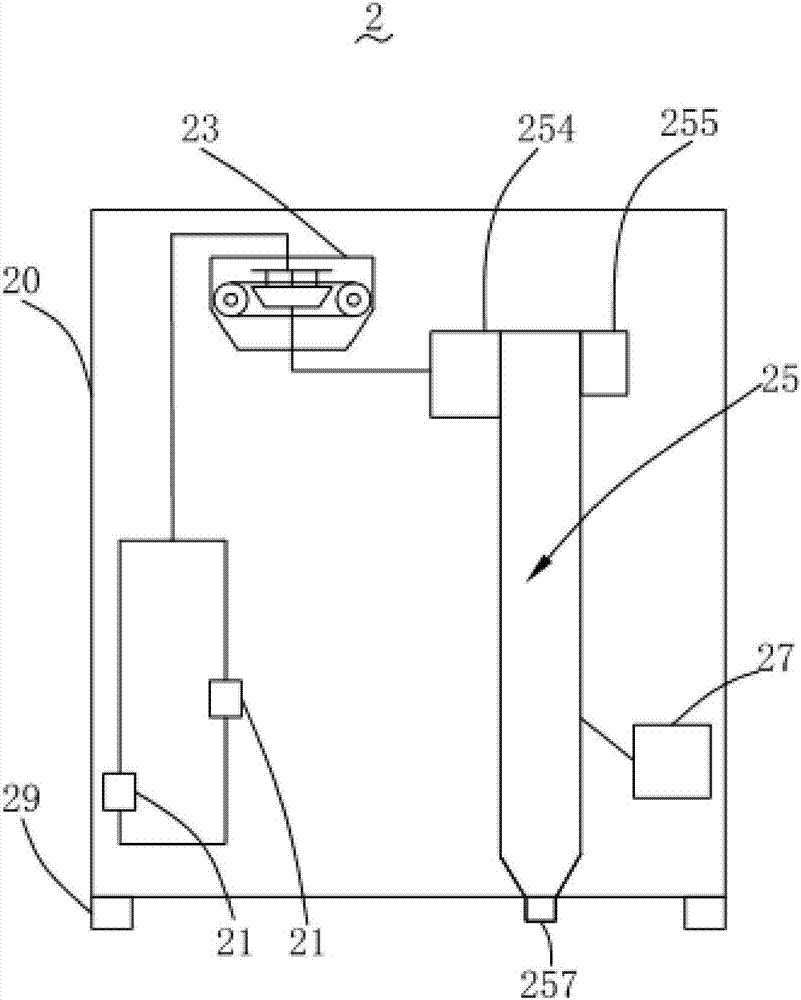

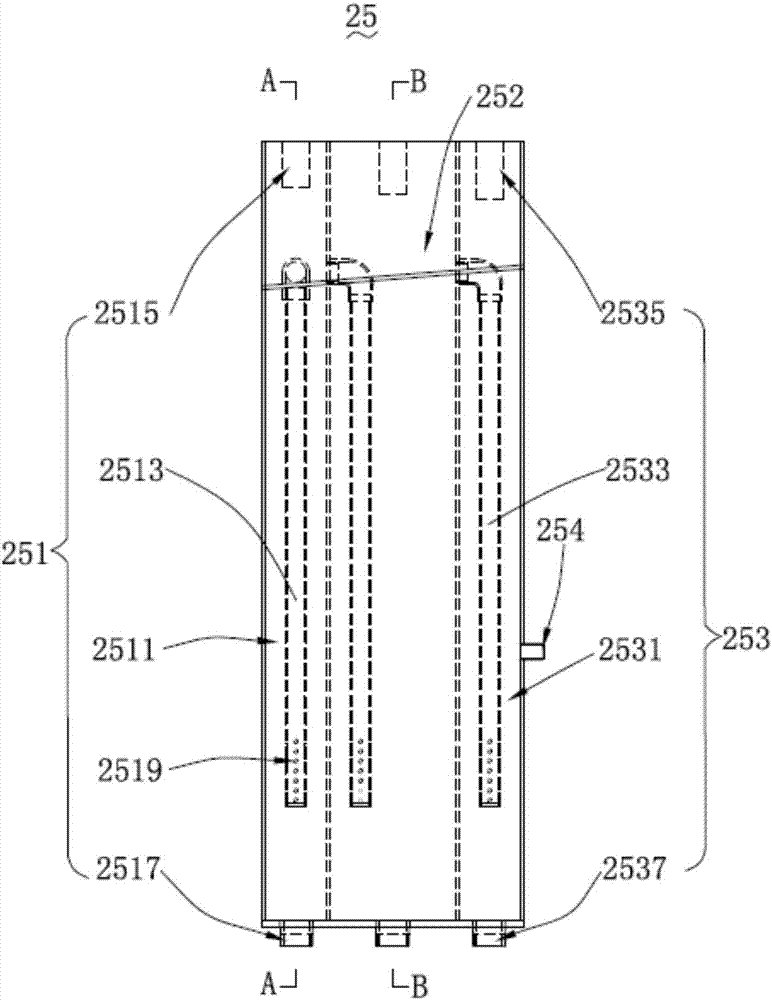

Digital intelligent liquid densitometer, and density detecting method thereof

InactiveCN107101910ALiquid flow is stableShorten detection timeSpecific gravity using flow propertiesLiquid densityControl system

The invention discloses a digital intelligent liquid densitometer. The digital intelligent liquid densitometer comprises a PLC control system (1) and a density detecting system (2); the PLC control system (1) is used for controlling the density detecting system (2) to detect liquid density; the density detecting system (2) comprises a sampling pump (21), a primary automatic filter (23), a multistage sedimentation device (25), and a density detecting device (27) which are connected successively; the multistage sedimentation device (25) comprises at least two sedimentation units, wherein the volumes of the two sedimentation units are different, so that the flow speeds of a liquid to be detected through the two sedimentation units are different. The digital intelligent liquid densitometer is capable of realizing filtering sedimentation of impurities in the liquid to be detected, on one hand, influences caused by foam and crystals in the liquid to be detected are reduced, and on the other hand, static settlement is not needed, detection time is shortened, on-line real-time detection is realized, and influences on production caused by data delay are avoided.

Owner:QINGHAI SALT LAKE IND

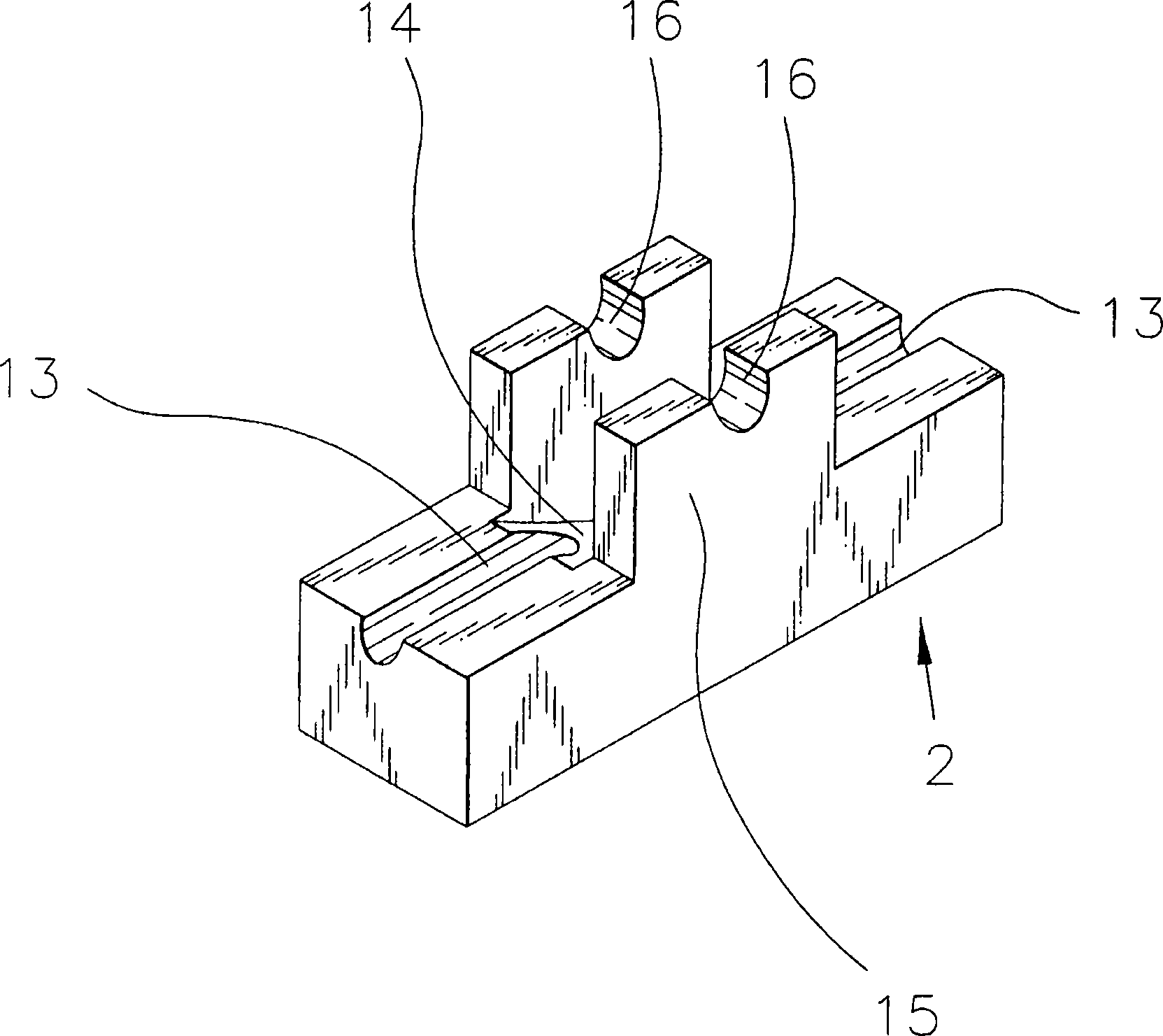

Drilling pump with T-type pump head

InactiveCN103104447AReduce volatilityReduce vibrationPositive displacement pump componentsFlexible member pumpsSlurryPump head

The invention discloses a drilling pump with a T-type pump head, and the drilling pump with the T-type pump head is substantially formed by a shell body (1), a discharge liquor cylinder (2) arranged on the shell body (1), a discharging pipe (12) connected and communicated with the discharge liquor cylinder (2), a liquid suction cylinder (3) connected and communicated with the discharge liquor cylinder (2), and a suction pipe (4) connected and communicated with the liquid suction cylinder (3). A piston device communicated with the discharge liquor cylinder (2) is arranged inside the shell body (1). The drilling pump with the T-type pump head is in a compact structure and cancels a suction chamber, the volume and the quality of the drilling pump with the T-type pump head are reduced by 25% - 30%. The drilling pump with the T-type pump head is easy to process and manufacture, convenient to flaw detect and inspect, and can ensure the quality of the pump head products. Slurry is sucked in a horizontal mode, the clearance volume in the pump head cylinder is small, the suction efficiency and the volumetric efficiency of the drilling pump are improved; liquid flow is smooth, the pressure fluctuation and vibration is reduced, and the drilling pump impact load is also reduced. The change of a suction valve is very convenient and time-saving, and the workload of dismounting and changing is little.

Owner:谢月

Domestic sewage filter device

InactiveCN104163542BReduce impactLiquid flow is stableMultistage water/sewage treatmentEngineeringExhaust pipe

The invention discloses a filter material device for domestic sewage, which comprises two parts: a separating device and a filtering device; the separating device is a cylinder with a water inlet on the upper side of the cylinder and a support in the middle of the cylinder Column, on the supporting column, there is a movable separation pulverizer, and a water outlet is provided on the lower side of the cylinder; the filter device is a cylinder, and a water inlet is provided on the lower side of the cylinder, and the water inlet is connected with the separation device The water outlet on the upper cylinder is connected, and the water outlet is provided on the upper side of the cylinder, and there are multiple layers of filter material in the cylinder from bottom to top. Or other supports, and an exhaust pipe is arranged in the middle of the filter material. Because the present invention adopts the above-mentioned technical scheme, compared with the prior art, the present invention has the advantages of sufficient sewage degradation, fast purification, simple structure, and can meet the sewage discharge standard.

Owner:苗育卓 +1

An intelligent domestic liquid seasoning box

An intelligent domestic liquid seasoning box comprises a cylinder, the cylinder is a cylindrical cylinder with an upper end opening at the bottom, the upper end surface of the cylinder is provided with a sealing cover, and an opening hole is arranged in the middle of the front side of the cylinder body; a liquid receiving pan is arranged on the lower side of the opening hole, a funnel-shaped partition layer is arranged in the upper cylinder of the opening hole; a plurality of infrared sensing probe receivers arranged from the outside to the inside are arranged on the lower layer of the spacer.A micro-core board processor is also arranged on the lower layer of the spacer layer; a magnet valve coil, an electromagnet core, a protective sleeve, a compression spring, a sealing ring and a sealing sleeve are arrange in that valve seat, and a maximum flow adjusting knob is also arranged on the upper side of the front end of the barrel body, so that the liquid key is extended into the upper side of the barrel body to realize the intelligent use of the liquid seasoning, and the original manual tedious operation is saved.

Owner:林坚

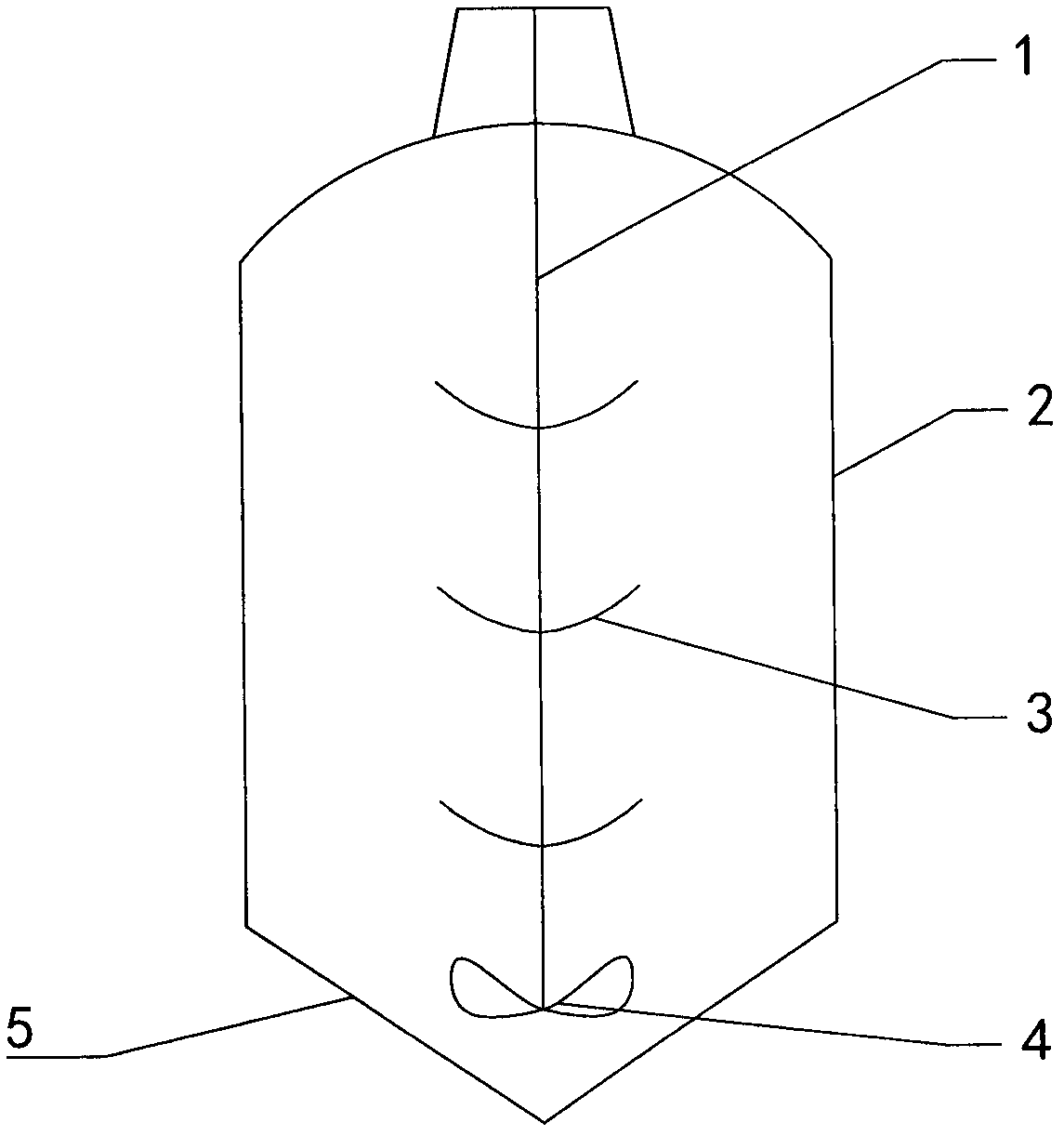

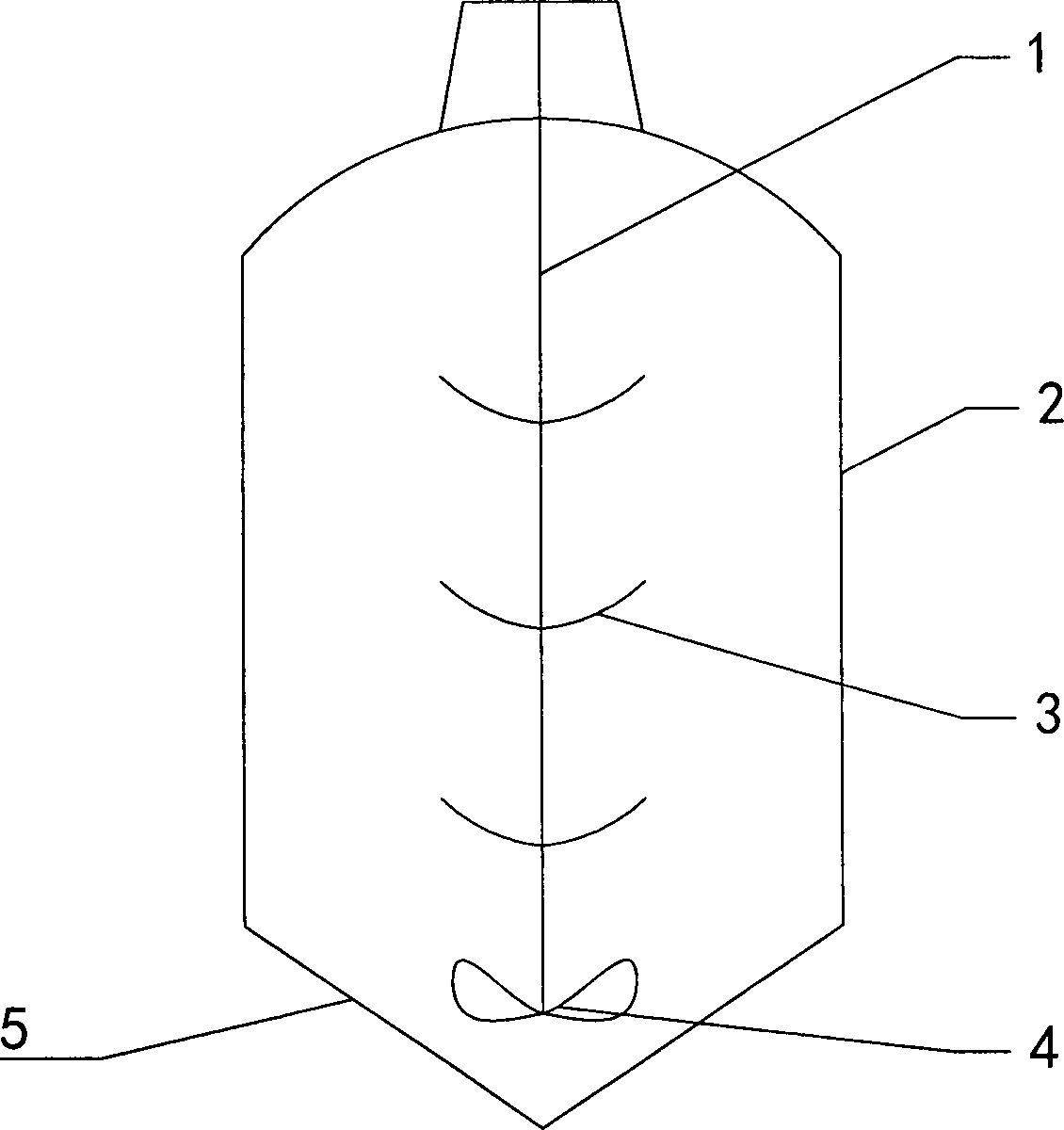

Crystallizing tank

InactiveCN102600633AFully crystallizedLiquid flow is stableCrystallization separationImpellerEngineering

The invention relates to a crystallizing tank, which is specially used for producing a cephalosporin sodium raw material drug. The crystallizing tank comprises a conical shell and the shell is internally provided with an agitating shaft; the crystallizing tank is characterized in that an impeller type agitating paddle is arranged at the lower part of the agitating shaft; and the impeller type agitating paddle is arranged at a conical shell part of the shell; and the agitating shaft is further provided with a plurality of anchor-shaped agitating paddles. The crystallizing tank disclosed by the invention has the advantages of stable liquid flow, no turbulent flow, no dead angles and good crystallizing effect.

Owner:ZIBO WANCHANG TONGTAI PHARMA

A new type of high pressure chemical gear pump

ActiveCN104500389BGuaranteed working lifeSmooth pumping operationRotary piston pumpsRotary/oscillating piston combinationsChemical industryMagnetic tension force

The invention relates to a pump and particularly relates to a novel high-pressure chemical industry gear pump which is used for conveying various chemical media, corrosive and dangerous chemicals, or oil or water or toxic and harmful liquids or inflammable and detonable liquids and has high pressure resistance, high temperature resistance, corrosion resistance, acid and alkali resistance and abrasion resistance. According to the novel high-pressure chemical industry gear pump, a pair of unique helical gears capable of resisting high-pressure pumping and a wear-resisting plate with a pressure relief groove are designed and adopted; by virtue of innovatively designing the structure, improving the processing process, reasonably selecting metal and nonmetal combined materials, and adopting short-axis coupling and magnetic driving mode of a self-alignment structure or a mechanical seal mode of a coupling with an elastomer to connect driving between the pump and a motor, working conditions with high pressure, high pressure difference and various viscosity are met, various harsh chemical media are efficiently delivered, the defect or blank of the prior is overcome, zero leakage and no pulse are really realized, the leakage problem of an existing shaft seal is solved, and extensive application in various industries such as petroleum and chemical industry is met.

Owner:何祥军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com