Three-inlet spiral slag pushing type hydraulic cyclone

A technology of hydrocyclone and slag pusher type, which is applied in the direction of swirling devices and devices whose axial direction can be reversed, etc., which can solve the problems of clogging the vortex center, offset, and reduction of separation efficiency, so as to prevent leakage liquid phenomenon, feed liquid flow is stable, and the effect of reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

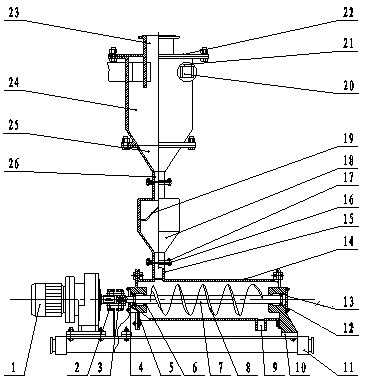

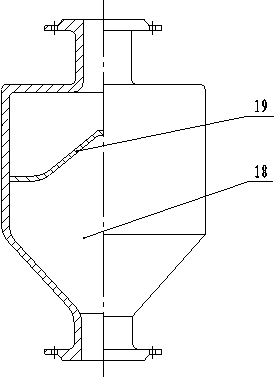

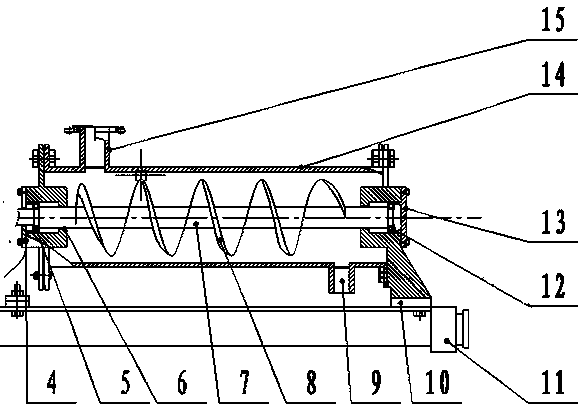

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a three-inlet spiral slag pushing type hydrocyclone of the present invention is mainly composed of a settling tank 18, an anti-reflux device 19, an inlet 20, a feed pipe 21, a cover plate 22, an overflow pipe 23, a cylinder body 24, Cone 25, underflow pipe 26, valve 27 and screw slag pushing mechanism, said spiral slag pushing mechanism consists of speed regulating motor 1, coupling 2, key 3, first bearing end cover 4, tapered roller bearing 5, Washer 6, screw shaft 7, screw 8, slag outlet of trough 9, bearing seat 10, base 11, self-aligning bearing 12, second bearing end cover 13, trough 14, slag inlet 15 of trough, flange 16 , Flange soft gasket 17 constitutes.

[0017] The inlet 20 of the hydrocyclone is designed as a three-inlet structure, and the inlet 20 adopts three narro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com