Melting and casting method of aluminum alloy sacrificial anode

A sacrificial anode, aluminum alloy melt technology, applied in the field of corrosion and protection, can solve the problems of reduced current efficiency, poor removal of oxide inclusions, general degassing effect, etc., to avoid the influence of anode performance and shorten melting time , the effect of shortening the melting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

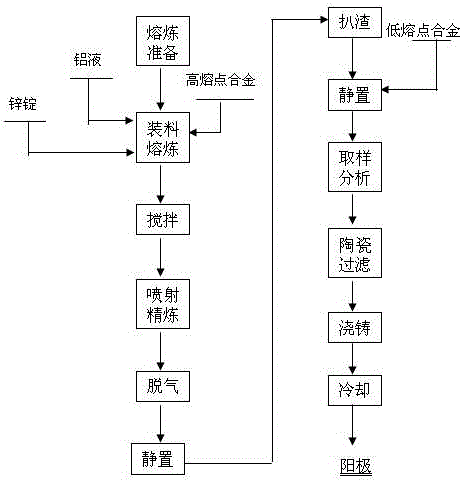

Method used

Image

Examples

Embodiment 1

[0028] (1) Turn on the power of the resistance furnace, preheat and raise the temperature to 750°C, add electrolytic primary aluminum liquid to the resistance furnace, then add aluminum-silicon alloy and zinc ingot to form aluminum alloy liquid, add 0.3% of the weight of the aluminum alloy liquid to cover agent to evenly cover the surface of the molten aluminum without leaking the molten aluminum;

[0029] (2) Argon loading composition is 39% NaCl+50%KCl+4.4%CaF 2 +6.6%Na 3 AlF 6 The refining agent is spray-refined on the aluminum alloy liquid, the refining temperature is 720°C, the amount of refining agent accounts for 0.6% of the total charge, and the refining time is 20 minutes to obtain a refined aluminum alloy melt;

[0030] (3) After refining, pass argon gas into the aluminum alloy melt for degassing. The degassing time is 7 minutes. The degassed aluminum alloy melt is allowed to stand for 20 minutes, and then use a slag removal tool to remove the surface of the alumin...

Embodiment 2

[0040] (1) Turn on the power of the resistance furnace, preheat and raise the temperature to 800°C, add electrolytic primary aluminum liquid to the resistance furnace, then add aluminum-titanium alloy and zinc ingot to form aluminum alloy liquid, and add 0.5% of the weight of the aluminum alloy liquid to cover agent to evenly cover the surface of the molten aluminum without leaking the molten aluminum;

[0041] (2) Argon loading composition is 39% NaCl+50%KCl+4.4%CaF 2 +6.6%Na 3 AlF 6 The refining agent is spray-refined on the aluminum alloy liquid, the refining temperature is 740°C, the amount of refining agent accounts for 0.3% of the total charge, and the refining time is 30 minutes to obtain a refined aluminum alloy melt;

[0042] (3) After refining, pass argon gas into the aluminum alloy melt for degassing. The degassing time is 15 minutes. After degassing, the aluminum alloy melt is left to stand for 5 minutes, and then use a slag removal tool to remove the surface of ...

Embodiment 3

[0052] (1) Turn on the power of the resistance furnace, preheat and raise the temperature to 900°C, add electrolytic primary aluminum liquid into the resistance furnace, then add zinc ingots to form an aluminum alloy liquid, add a covering agent accounting for 0.8% of the weight of the aluminum alloy liquid, and cover the aluminum The surface of the liquid is evenly covered, and the aluminum liquid does not leak out;

[0053] (2) Argon loading composition is 39% NaCl+50%KCl+4.4%CaF 2 +6.6%Na 3 AlF 6 The refining agent is spray-refined on the aluminum alloy liquid, the refining temperature is 780°C, the amount of refining agent accounts for 0.5% of the total charge, and the refining time is 5 minutes to obtain a refined aluminum alloy melt;

[0054] (3) After refining, pass argon gas into the aluminum alloy melt for degassing. The degassing time is 10 minutes. The degassed aluminum alloy melt is left to stand for 10 minutes, and then use a slag removal tool to remove the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com