A method for preparing a composite material for a positive electrode of a lithium sulfide battery

A lithium-sulfur battery and composite material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reducing active materials, affecting electronic conduction, and destroying the structure of positive electrode materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

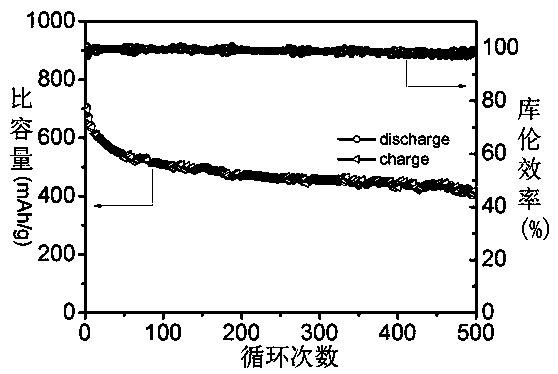

Examples

Embodiment 1

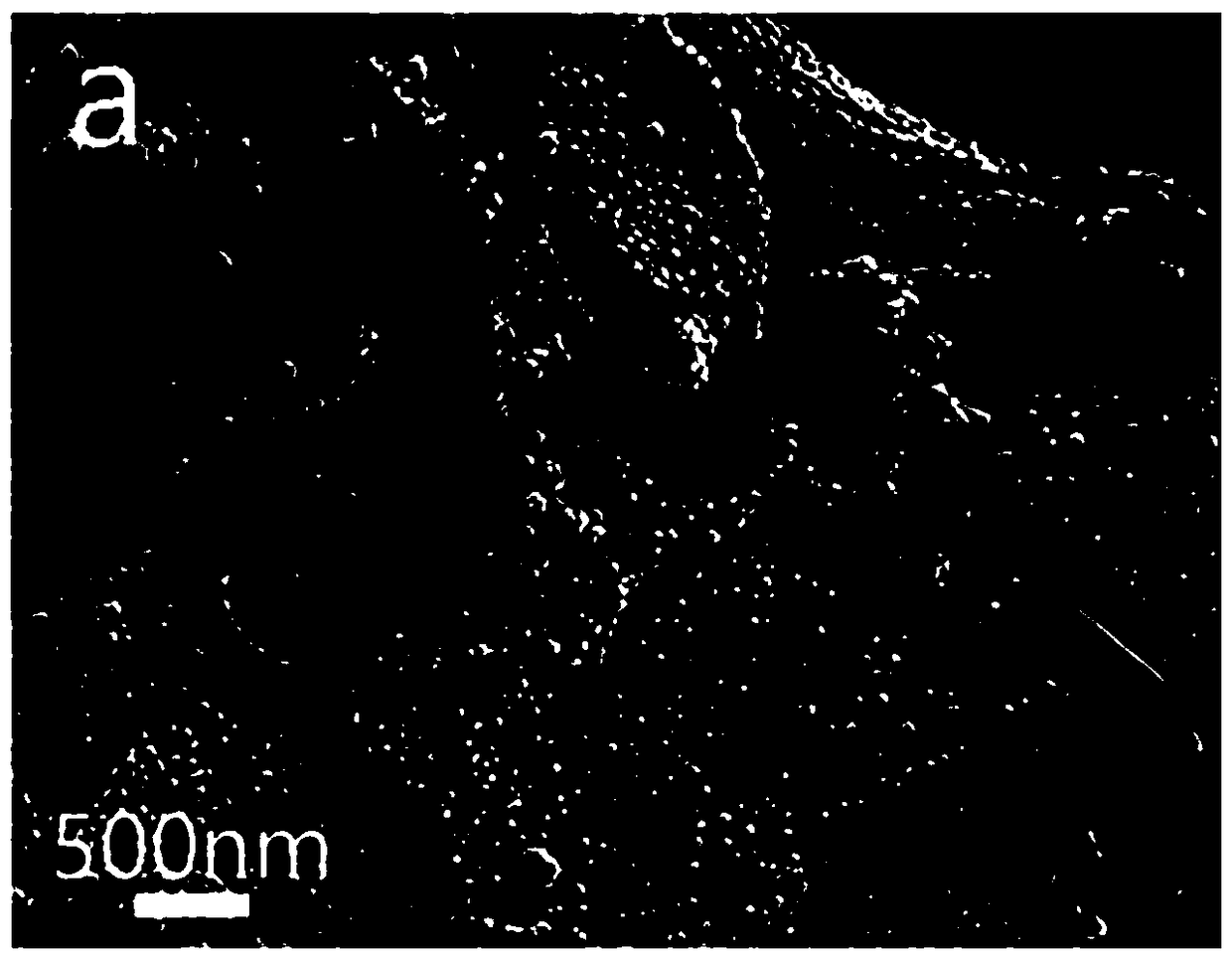

[0025] A kind of S@TiO 2 / MXene material, its preparation method comprises the following steps:

[0026] 1) Dissolve 300mg of resorcinol-formaldehyde resin pellets with a particle size of 350nm in 40ml of absolute ethanol, disperse ultrasonically for 15min, add hexadecyltrimethylammonium bromide (0.6mmol / l) and stir to modify the surface After stirring for 2 hours, centrifuge and wash with absolute ethanol, then dissolve the modified resorcinol-formaldehyde resin pellets in 40ml of absolute ethanol, and finally drop 0.3ml of butyl titanate slowly, stir for 12h, centrifuge After washing, dry at 60°C, put it into a muffle furnace for calcination at a constant temperature of 550°C for 3 hours, and obtain a white solid;

[0027] 2) Mix 20 mg of the white solid obtained in step 1) with 140 mg of sublimed sulfur, soak in 10 ml of carbon disulfide solution (3 mg / ml) for 3 minutes, stir for 3 hours until the carbon disulfide is completely volatilized, and then put it into a polytetra...

Embodiment 2

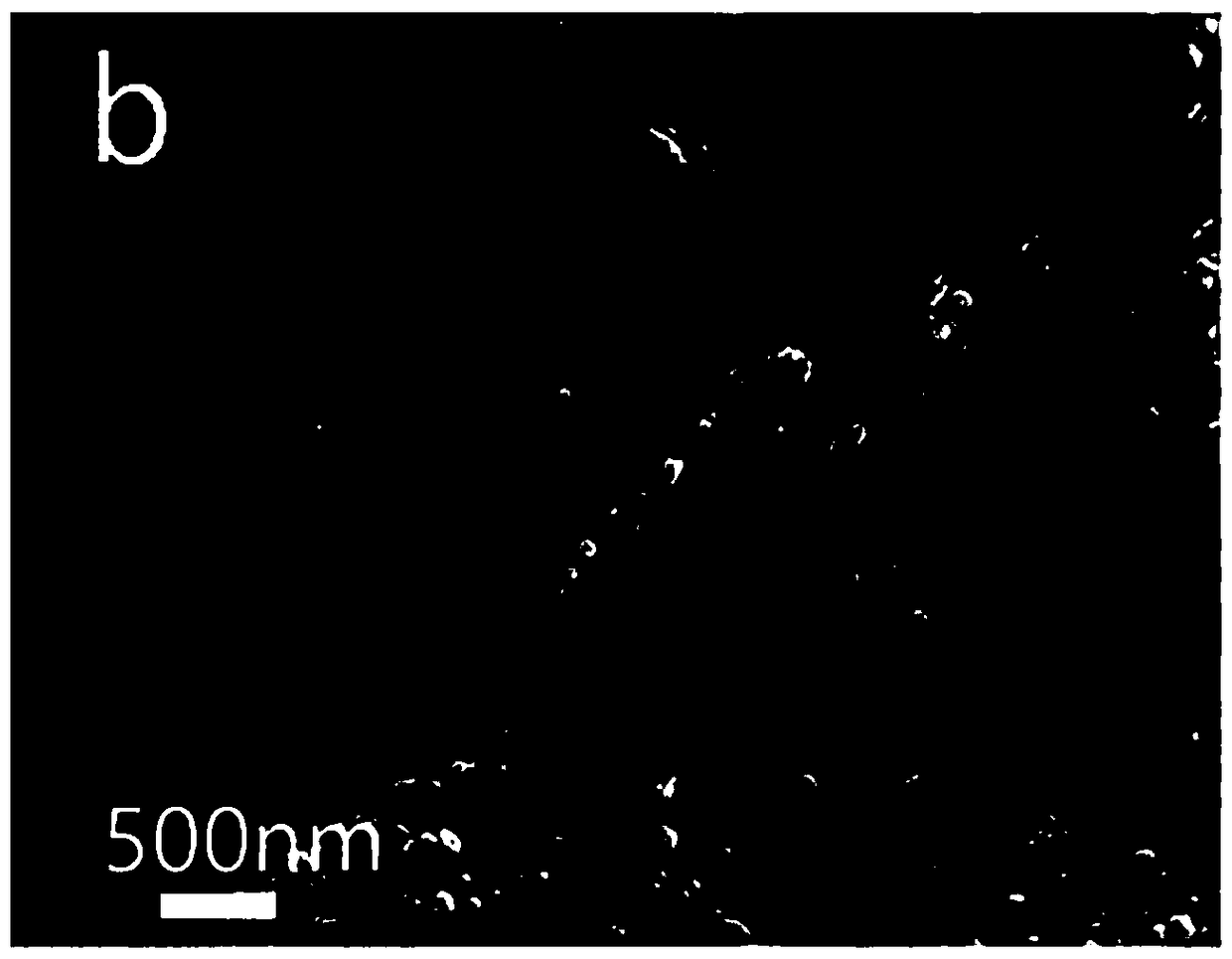

[0033]1) Dissolve 300mg of resorcinol-formaldehyde resin pellets with a particle size of 500nm in 40ml of absolute ethanol, disperse ultrasonically for 15min, add cetyltrimethylammonium bromide (0.6mmol / l) and stir to modify the surface After stirring for 2 hours, centrifuge and wash with absolute ethanol, then dissolve the modified resorcinol-formaldehyde resin pellets in 40ml of absolute ethanol, and finally slowly drop in 0.4ml of butyl titanate, stir for 12h, centrifuge After washing, dry at 60°C, put it into a muffle furnace for calcination at a constant temperature of 550°C for 3 hours, and obtain a white solid;

[0034] 2) Mix 20 mg of the white solid obtained in step 1) with 140 mg of sublimed sulfur, soak in 10 ml of carbon disulfide solution (3 mg / ml) for 3 minutes, stir for 3 hours until the carbon disulfide is completely volatilized, and then put it into a polytetrafluoroethylene reactor under an argon atmosphere Sealed in the middle, heated for melting reaction (r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com