Silicon carbon anode material for lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve problems such as loss of active materials, deterioration of cycle performance, low delithiation potential, etc., achieve high efficiency for the first time, improve ion and Electron transfer rate, effect of high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

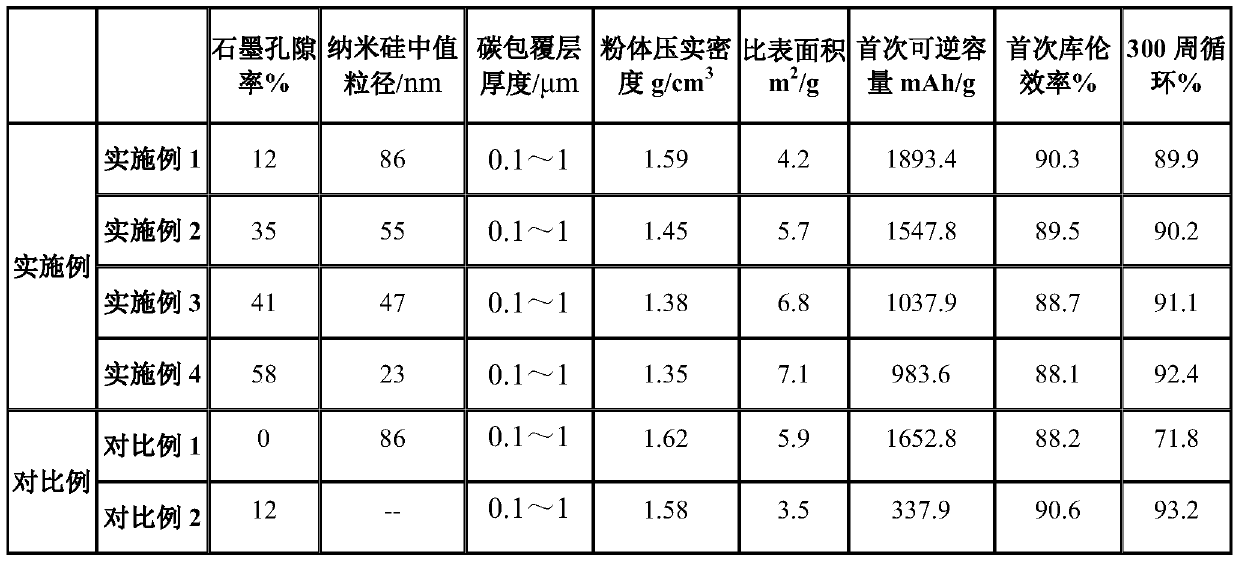

Examples

Embodiment 1

[0043] A method for preparing a silicon-carbon negative electrode material for a lithium-ion battery, comprising the steps of:

[0044] (1) Add artificial graphite and rubidium hydroxide into the reaction kettle according to the mass ratio of 1:0.1. After the solution is stirred evenly, start to heat up to 100°C and keep it warm for 10 hours. During the heating period, stir slowly until the solution is completely dried to obtain porous graphite;

[0045] (2) Add the porous graphite obtained in step (1) into the CVD furnace liner, feed nitrogen to get rid of the air in the CVD furnace until the oxygen content is lower than 100ppm, and then raise the temperature to 700 at a heating rate of 1°C / min. ℃, and then pass through silane for vapor deposition for 5 hours, the silane gas flow rate is 1L / min, so that the nano-silicon particles are uniformly deposited in the pores of the graphite, and the precursor of the negative electrode material is obtained;

[0046] (3) Put the negati...

Embodiment 2

[0048] A method for preparing a silicon-carbon negative electrode material for a lithium-ion battery, comprising the steps of:

[0049] (1) Add artificial graphite and potassium hydroxide into the reaction kettle according to the mass ratio of 1:0.5. After the solution is stirred evenly, start to heat up to 250°C and keep it warm for 5 hours. During the heating period, stir slowly until the solution is completely dried to obtain porous graphite;

[0050] (2) The porous graphite obtained in the step (1) is added into the CVD furnace liner, and helium gas is introduced to get rid of the air in the CVD furnace until the oxygen content is lower than 100ppm, and then at a heating rate of 3°C / min, the temperature is raised to 800°C, then feed dichlorodihydrogen silicon for vapor phase deposition for 3 hours, the gas flow rate of dichloro dihydrogen silicon is 3L / min, so that nano-silicon particles are uniformly deposited in the pores of graphite, and the precursor of the negative el...

Embodiment 3

[0053] A method for preparing a silicon-carbon negative electrode material for a lithium-ion battery, comprising the steps of:

[0054](1) Add artificial graphite and sodium hydroxide into the reaction kettle according to the mass ratio of 1:1. After the solution is stirred evenly, start to heat up to 400°C, keep it warm for 1h, and stir slowly during heating until the solution is completely dried to obtain porous graphite;

[0055] (2) The porous graphite obtained in the step (1) is added into the CVD furnace liner, and argon gas is introduced to get rid of the air in the CVD furnace until the oxygen content is lower than 100ppm, and then at a heating rate of 3° C. / min, the temperature is raised to 800°C, then pass through trichlorosilane for vapor deposition for 1 hour, the gas flow rate of trichlorosilane is 5L / min, so that nano-silicon particles are uniformly deposited in the pores of graphite, and the precursor of the negative electrode material is obtained;

[0056] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com