Negative electrode active material, method for producing the negative electrode active material, and lithium ion secondary battery using the negative electrode active material

A technology of negative electrode active material and manufacturing method, applied in secondary batteries, lithium storage batteries, non-aqueous electrolyte storage batteries, etc., can solve problems such as high discharge capacity, and achieve the effect of high discharge capacity and increased discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

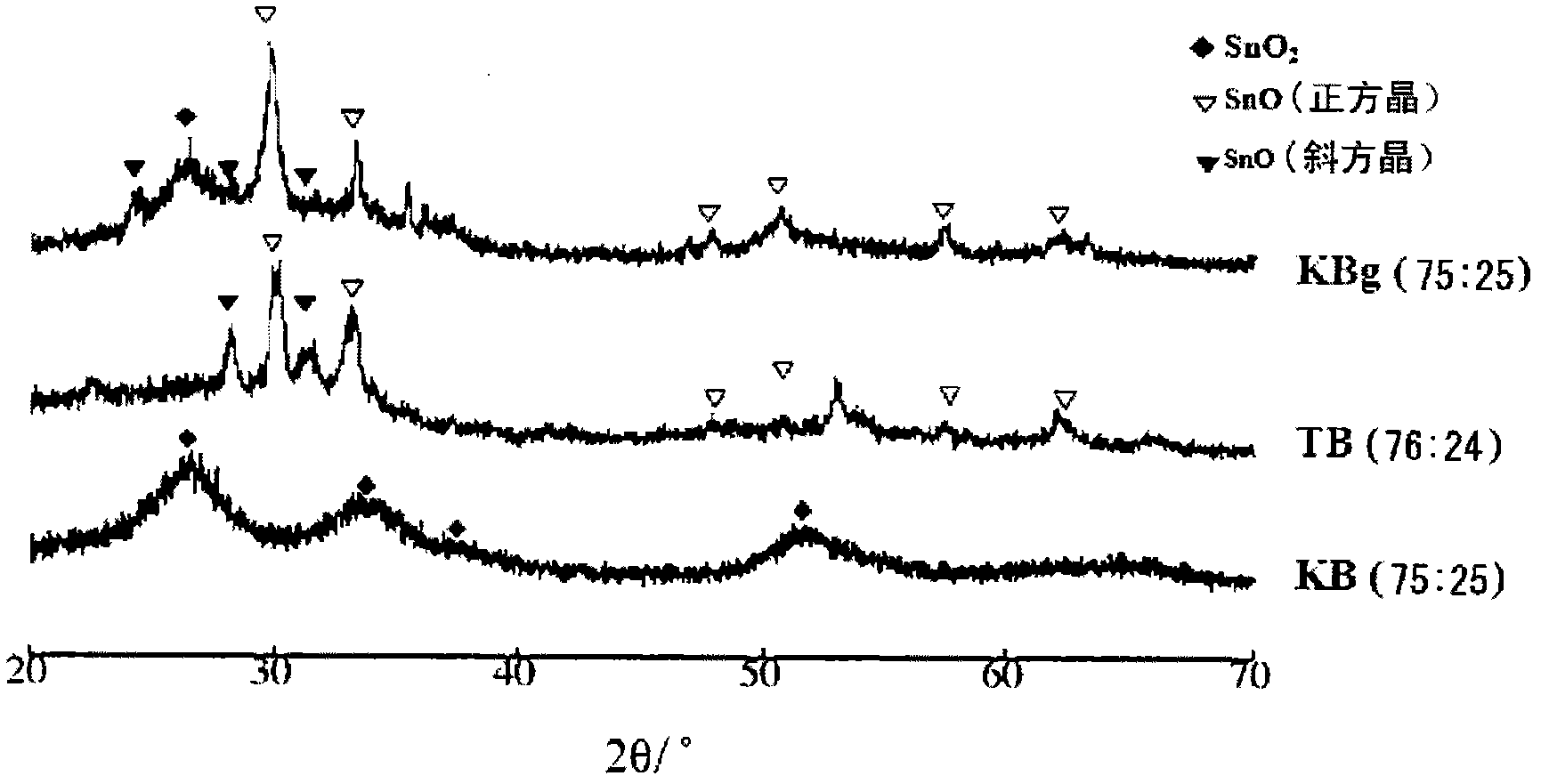

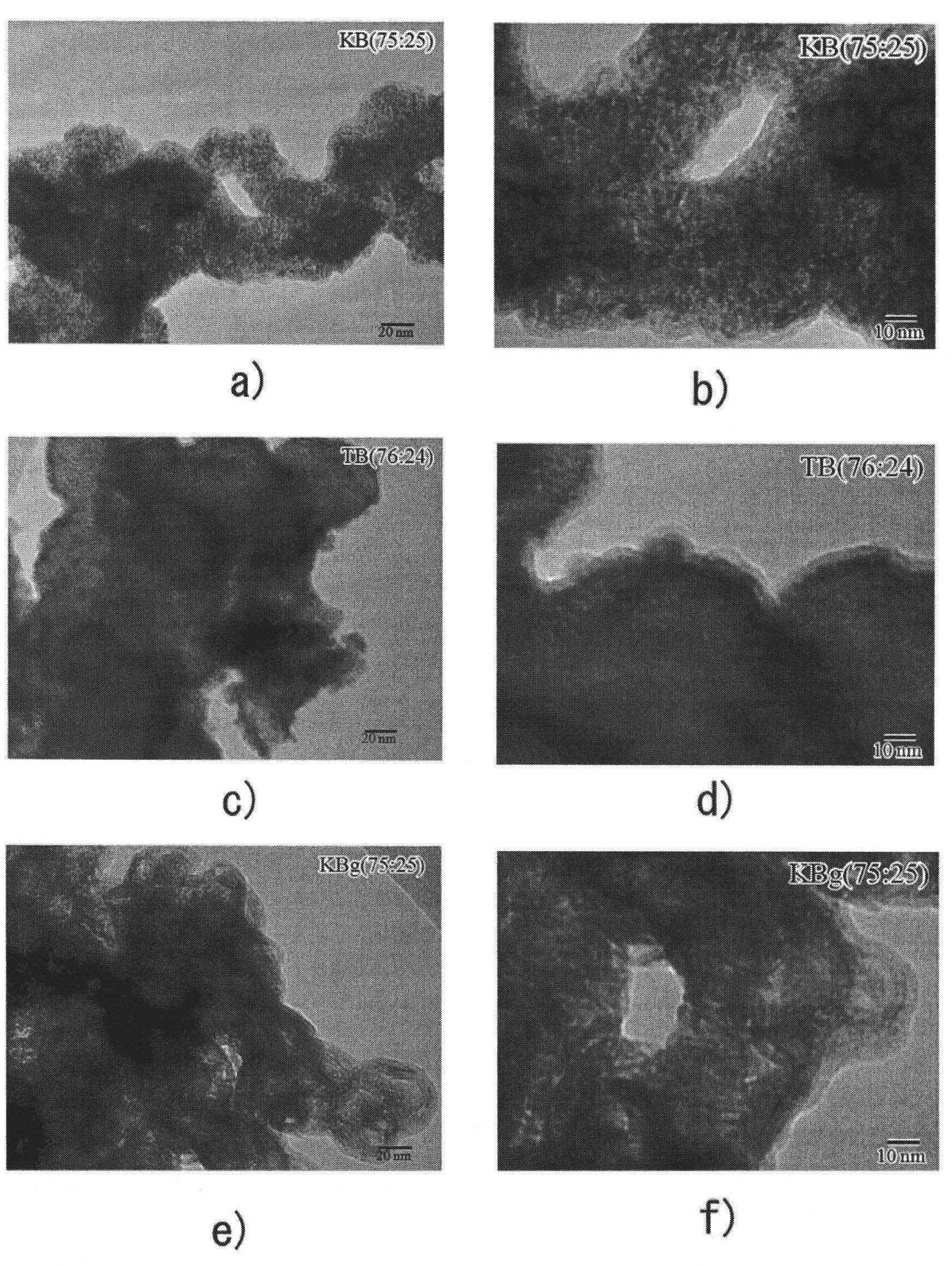

[0094] To (Japanese) Unexamined Patent Publication No. 2007-160151 figure 1 Into the inner cylinder of the reactor shown in , which is composed of an outer cylinder and an inner cylinder, a through hole is provided on the side of the inner cylinder, and a weir plate is arranged at the opening of the outer cylinder, and 1.9 g of SnCl 2 2H 2 O was dissolved in 30 ml of water and 1.3 g of Ketjen Black (trade name Ketjen Black EC600J, manufactured by Ketjen Black International Co., Ltd., primary particle size 34 nm, pore size 4 nm) to apply 70000 kgms to the reaction solution. -2The centrifugal force makes the inner cylinder rotate for 300 seconds, so that the SnCl 2 2H 2 O and Ketjen Black are dispersed. Once the inner cylinder stops rotating, add 16.8ml of 1M NaOH aqueous solution to the inner cylinder, and then apply 70000kgms to the reaction solution -2 The centrifugal force makes the inner cylinder rotate for 120 seconds. During this period, a film is formed on the inner...

Embodiment 2

[0097] The procedure of Example 1 was repeated except that 0.54 g of KB (trade name Ketjen Black EC600J, manufactured by Ketjen Black International Co., Ltd., primary particle diameter 34 nm, pore diameter 4 nm) was used.

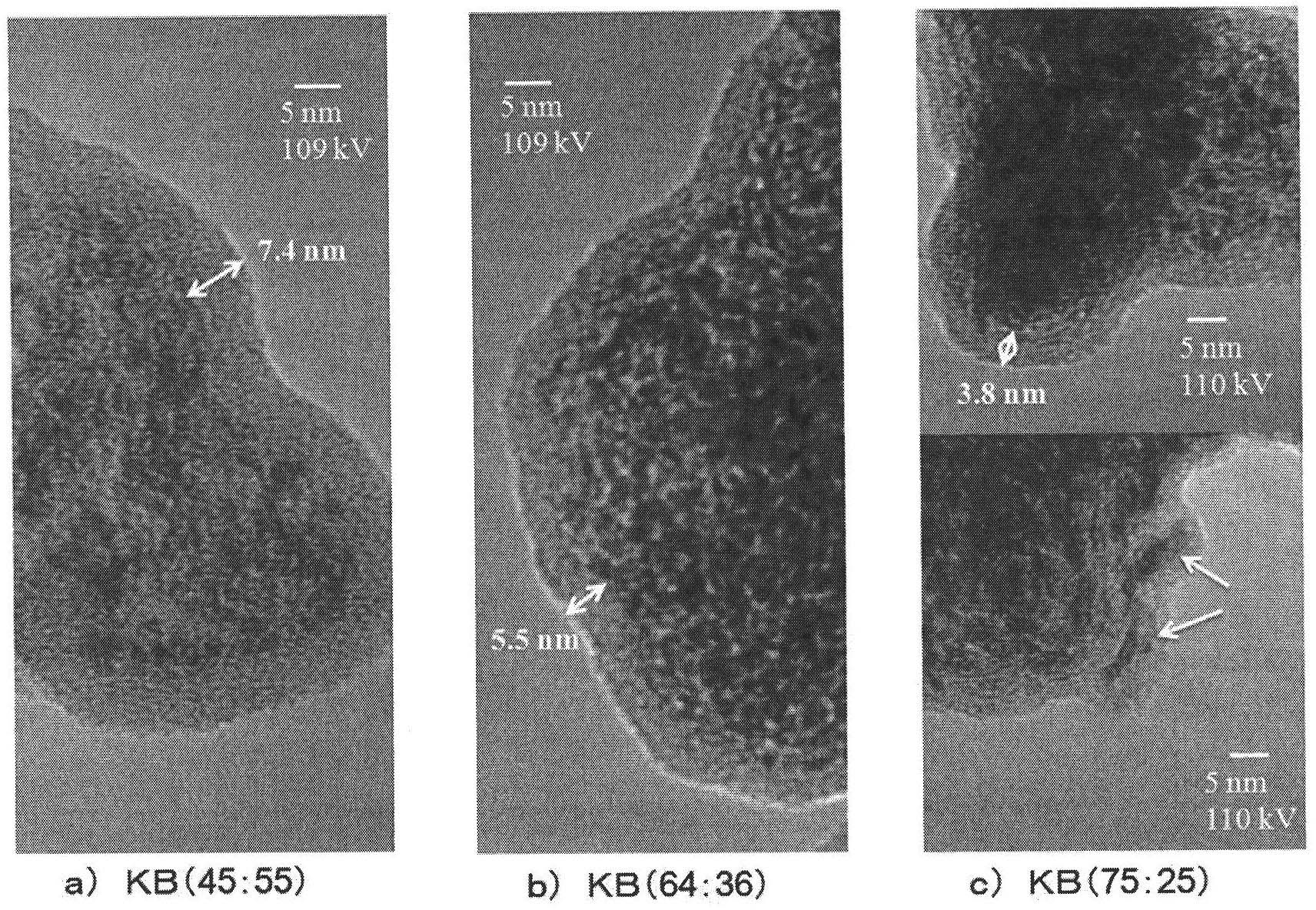

[0098] In KB carrying the obtained tin oxide particles, it was confirmed that tin dioxide was produced. In addition, the composition ratio of tin dioxide and KB is SnO in terms of mass ratio 2 : KB=64: 36, the feed amount (SnO 2 :KB=70:30) are roughly the same value. Furthermore, it was confirmed from the TEM photograph that the particle size of the tin dioxide particles was 1 to 2 nm, and that 95% by mass of the primary particles existed in a non-aggregated state.

Embodiment 3

[0100] The procedure of Example 1 was repeated except that 0.33 g of KB (trade name Ketjen Black EC600J, manufactured by Ketjen Black International, primary particle diameter 34 nm, pore diameter 4 nm) was used.

[0101] In KB carrying the obtained tin oxide particles, it was confirmed that tin dioxide was produced. In addition, the composition ratio of tin dioxide and KB, in terms of mass ratio, is SnO 2 : KB=75: 25, the feed amount (SnO 2 :KB=80:20) are roughly the same value. Furthermore, it was confirmed from the TEM photograph that the particle size of the tin dioxide particles was 1 to 2 nm, and that 85% by mass of the primary particles existed in a non-aggregated state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com