Valve

A technology of valves and valve bodies, applied in valve details, diaphragm valves, valve devices, etc., can solve problems such as liquid leakage, deterioration of yield, and inconsistent time, so as to achieve stable liquid flow, reduce deterioration of yield, and make it difficult for bubbles to stay Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described below with reference to the drawings, but it goes without saying that the present invention is not limited to the embodiments.

[0031] For the first embodiment of the present invention in Figure 1 to Figure 7 Indicated.

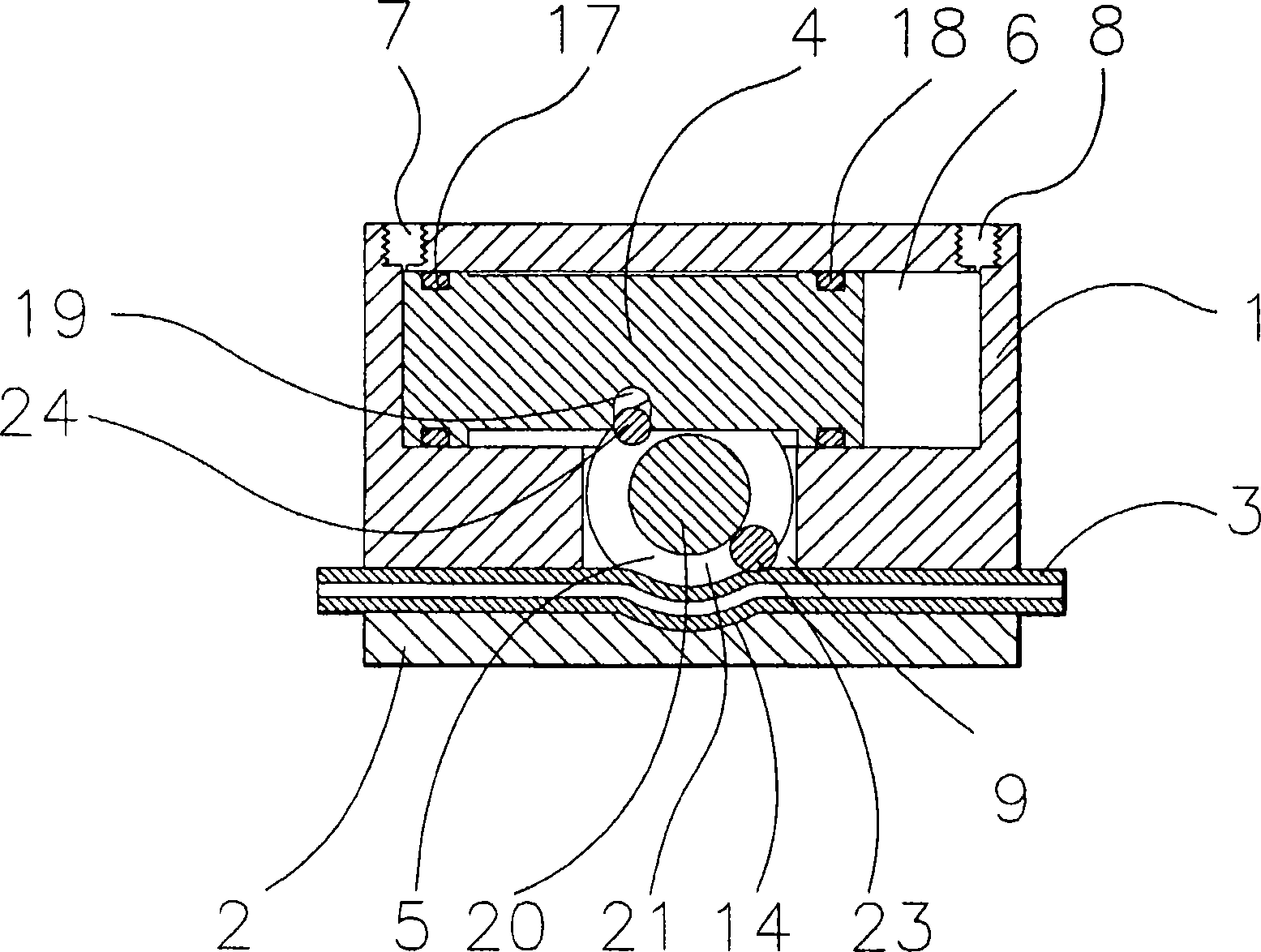

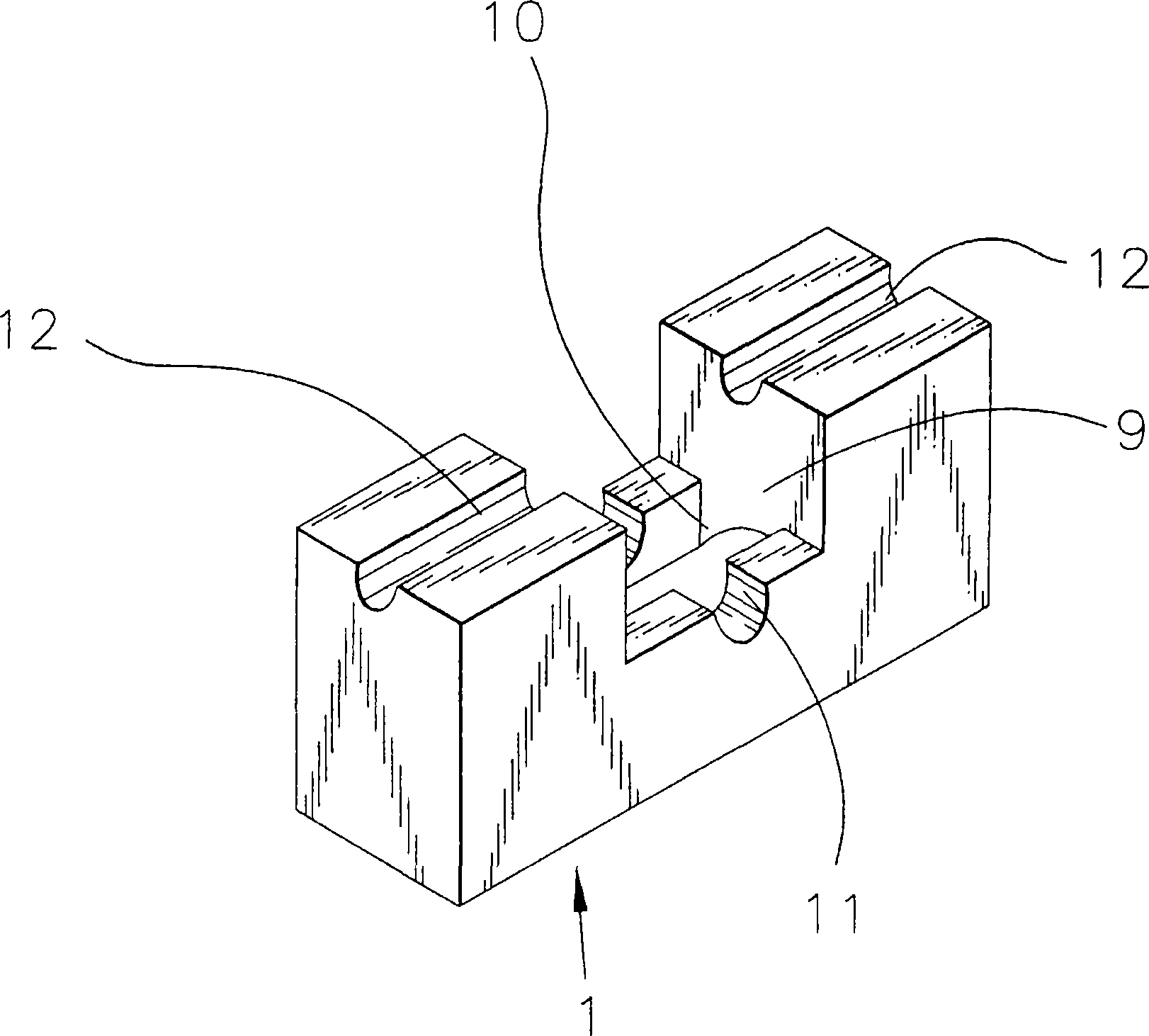

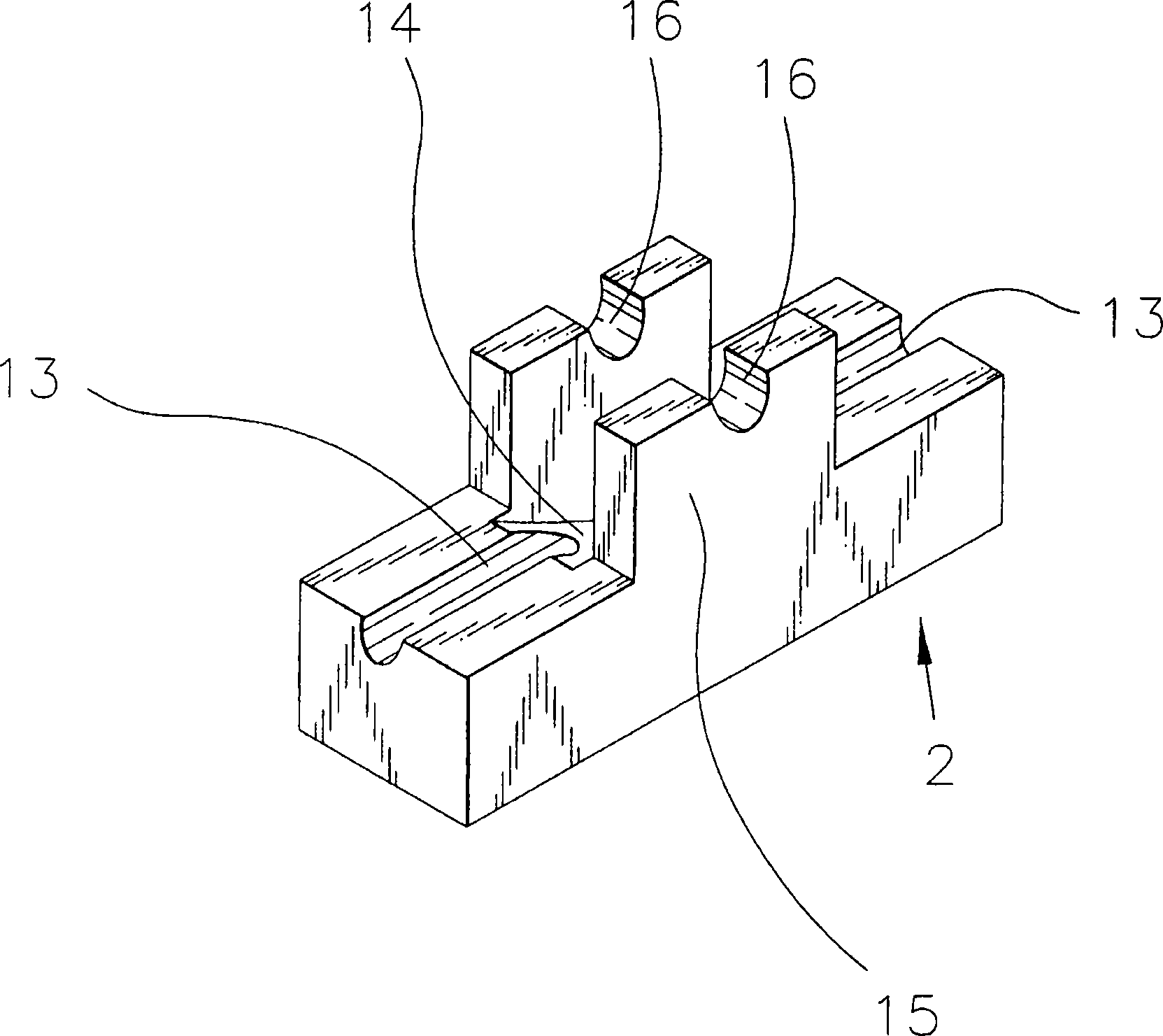

[0032] exist figure 1 Among them, the reference numeral "1" refers to the upper side valve box. The upper side valve box 1 has a cylinder chamber 6 and a pair of working fluid supply ports 7, 8 communicating with the cylinder chamber 6 inside. A concave portion 9 having a rectangular cross section is formed in the central portion. A rectangular opening 10 communicating with the cylinder chamber 6 is formed on the upper surface of the recess 9, and a groove-shaped bearing portion having a semicircular cross section is formed on both outer sides of the upper surface of the recess 9 in a direction perpendicular to the axial direction. 11. In addition, on the bottom surface of the upper side valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com