Patents

Literature

445results about "Drip prevention valves" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

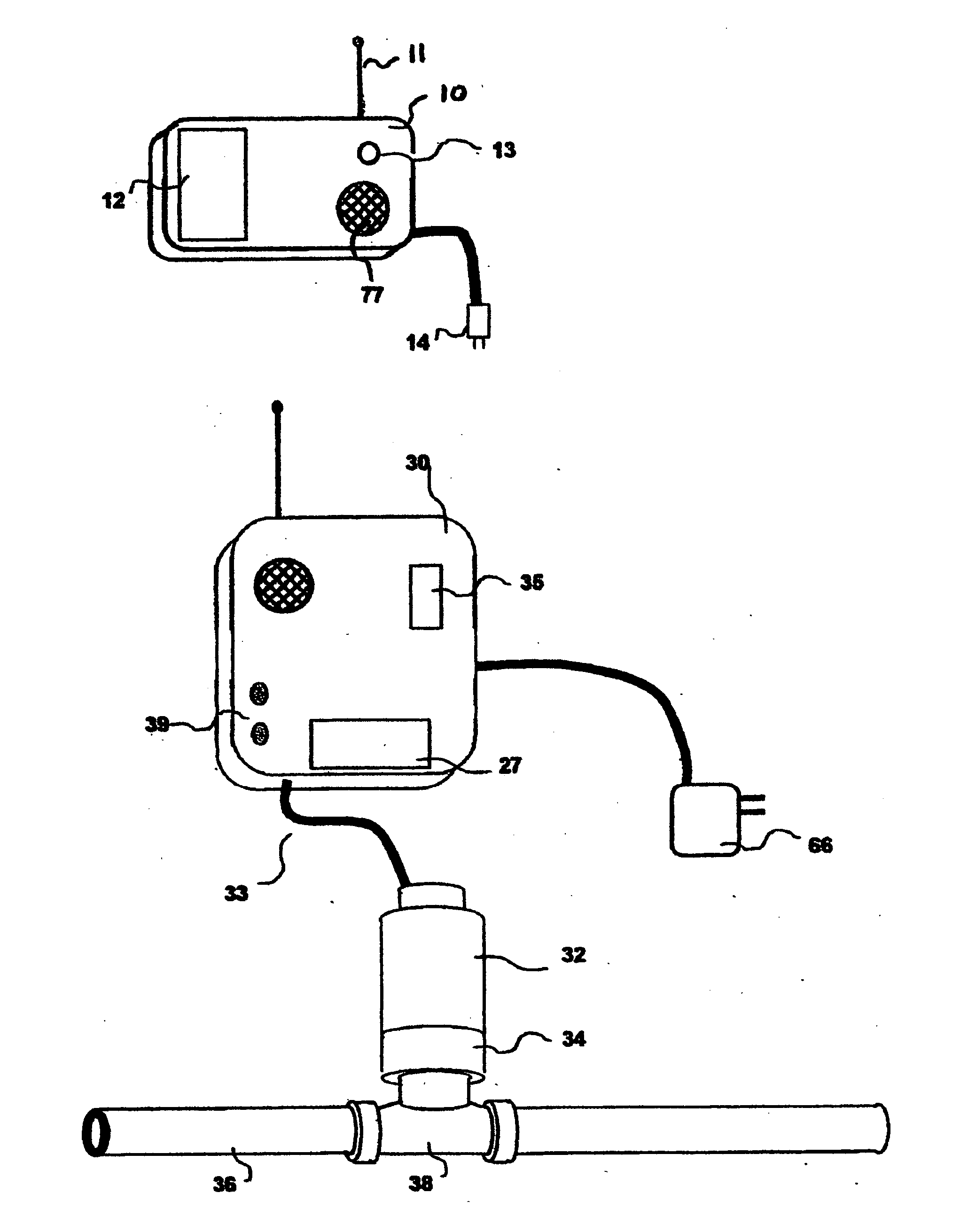

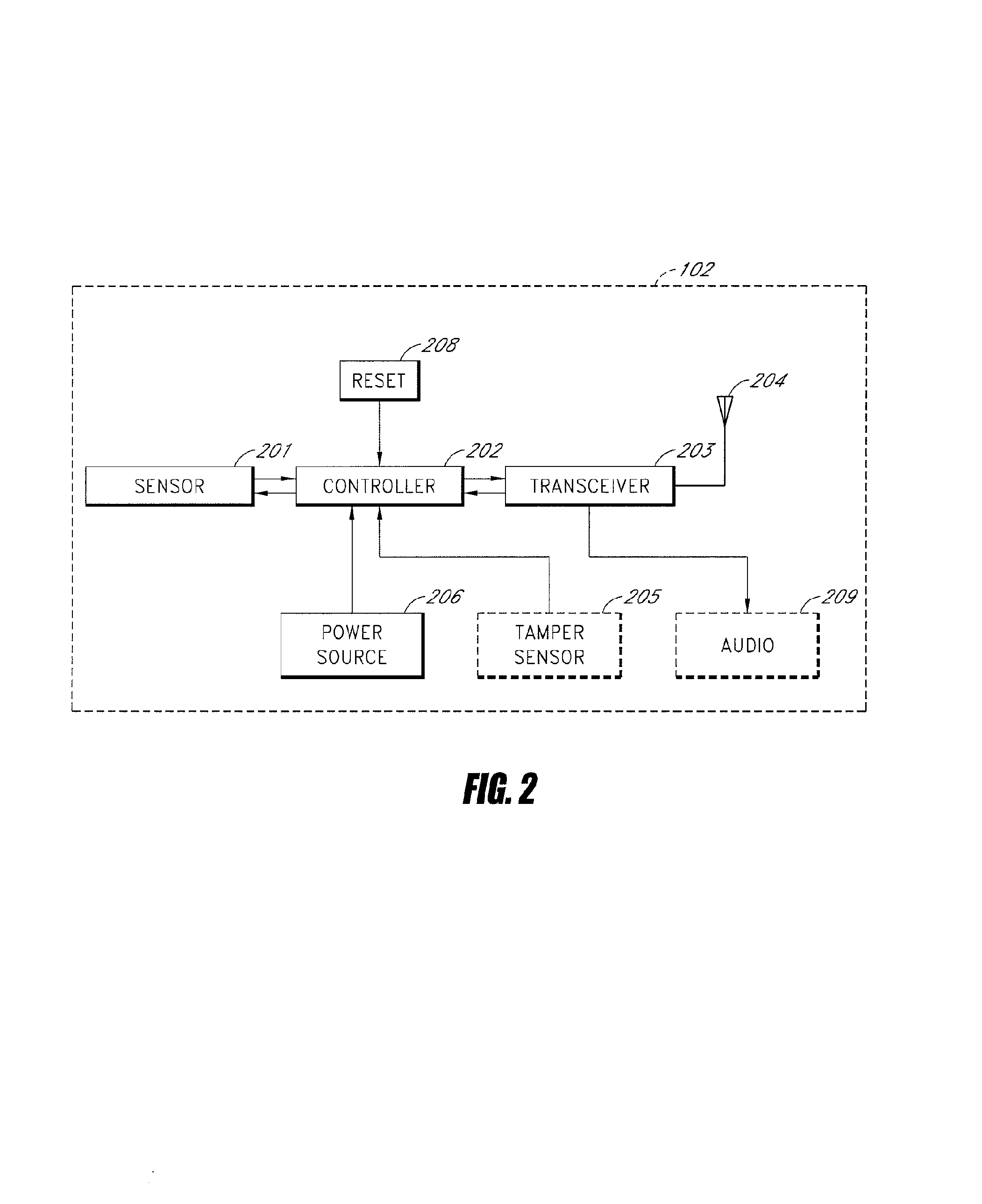

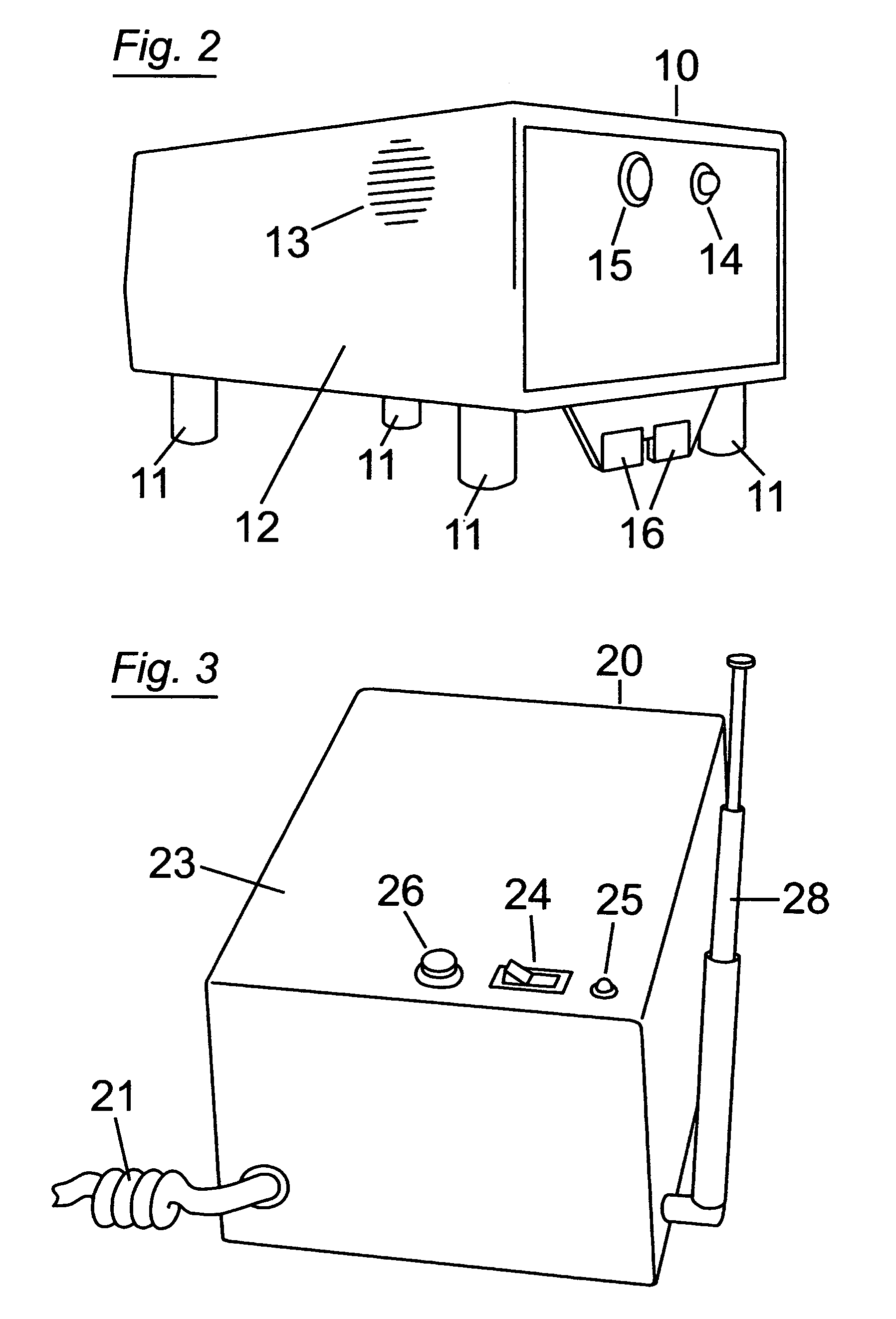

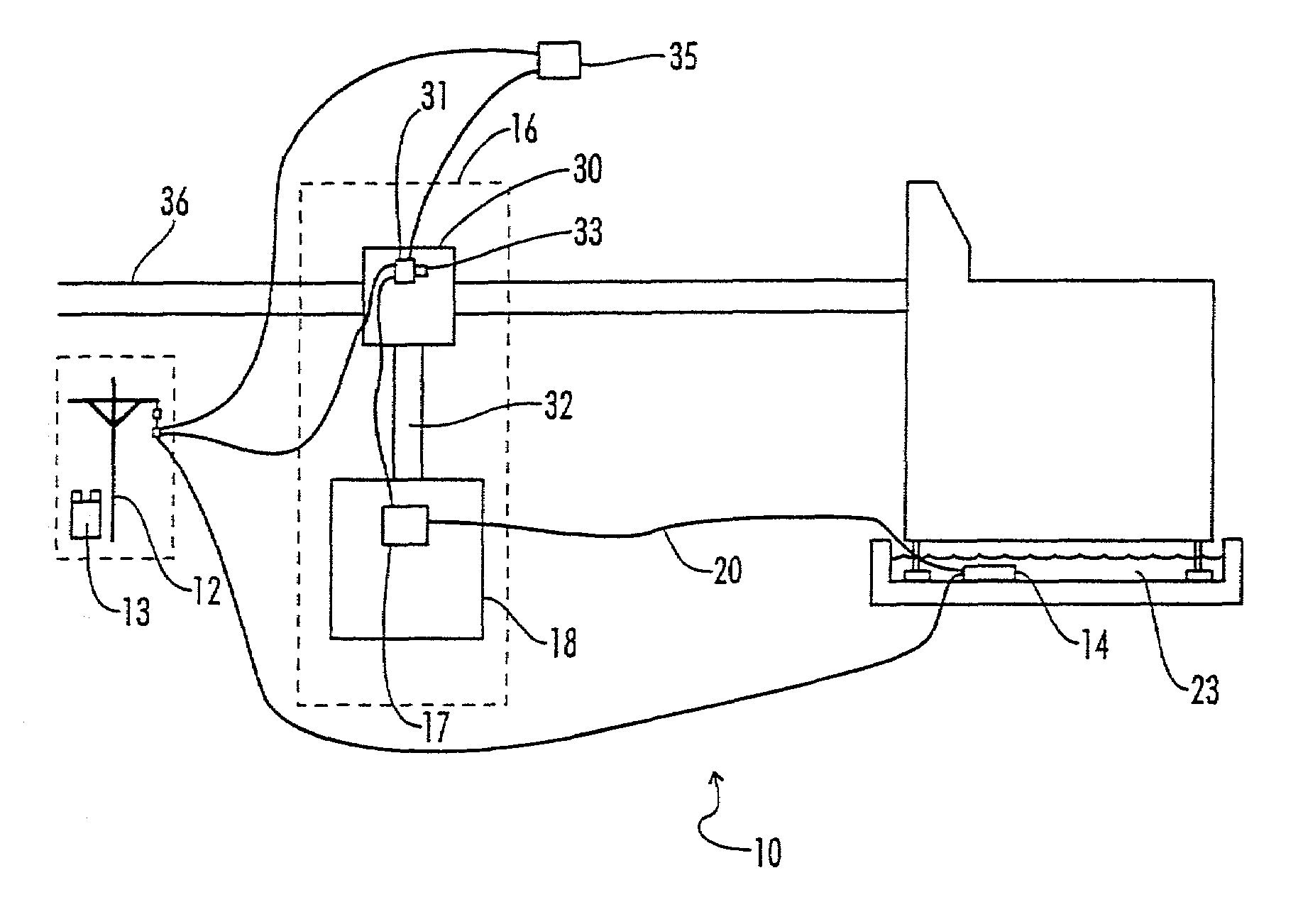

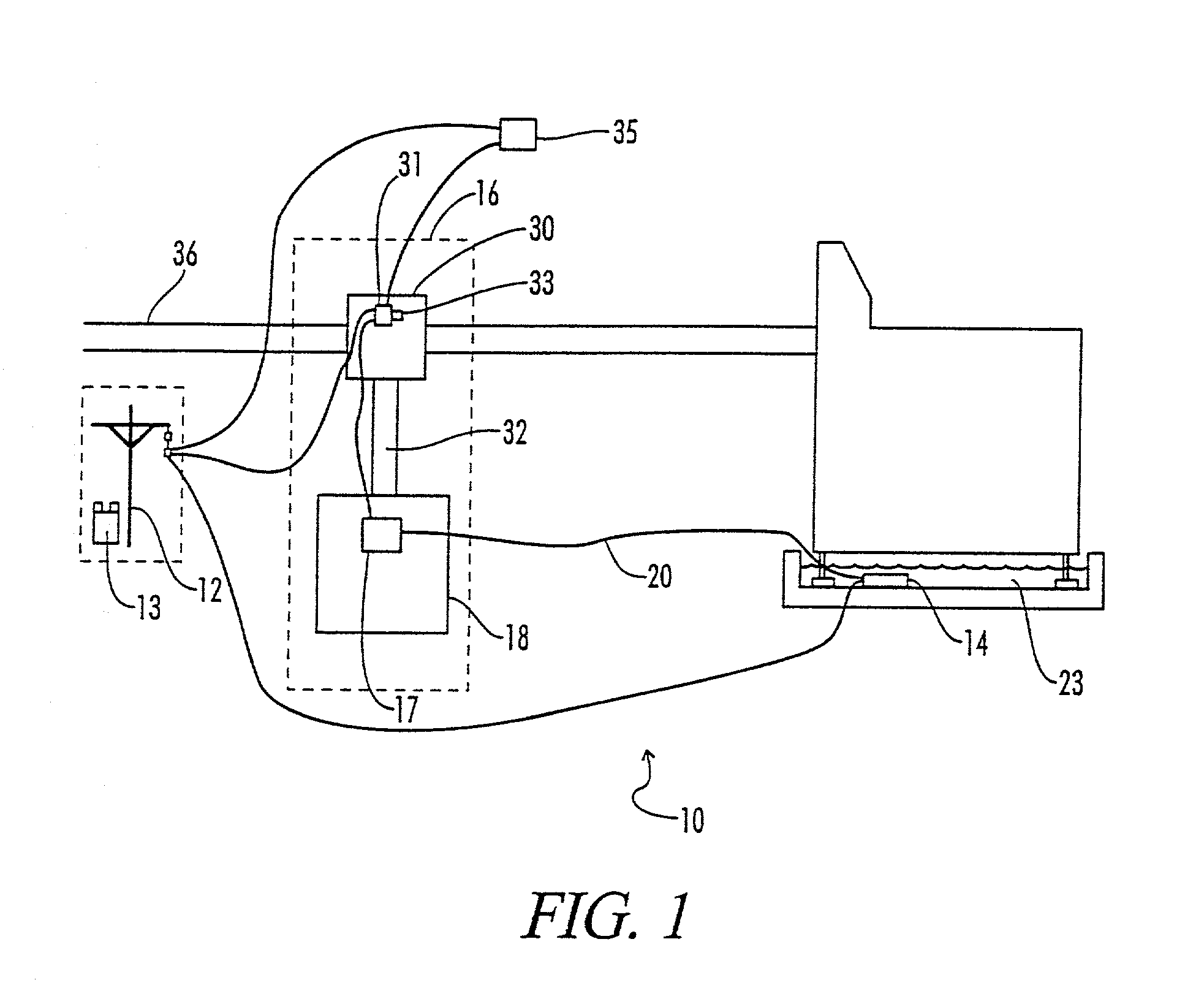

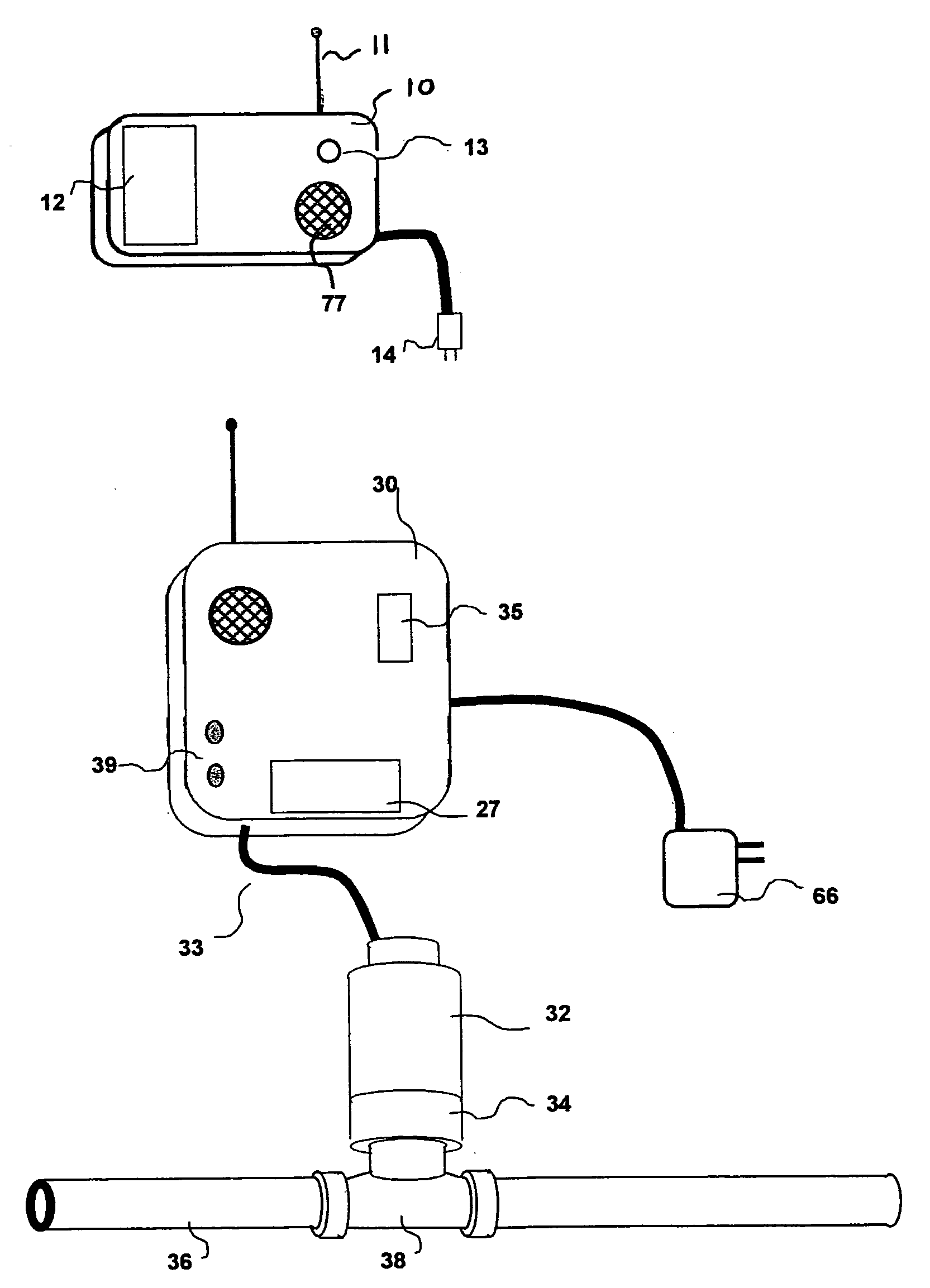

Secure wireless leak detection system

InactiveUS20070289635A1Easy to installReduce power consumptionDetection of fluid at leakage pointOperating means/releasing devices for valvesTransceiverMotor control

Supervised wireless leak detection system, having a leak detection sensor unit, capable of transmitting a uniquely coded signal in response to a detected leak, a supervised wireless valve control transceiver unit having a receiver, capable of receiving said uniquely coded signal, and a transmitter for feeding the uniquely coded signal within the system, a valve shut-off mechanism in communication with said valve control transceiver unit said valve shut-off mechanism having a motor attached to a valve, said motor creating a rotation pulse used to close and open said valve, and a processor having an electronic circuitry containing sensor(s), detecting said motor rotation pulse count during a motorized valve closure or open process. Said processor functions in a setup process to memorize (learn) said motor rotation pulse count, required, to close and or to open the valve. Wherein said processor upon receipt of said uniquely coded signal in response to a detected leak, applies power to the motor to close the valve, the motor controlled to stop turning the valve in response to a processor received motor rotation pulse count number, substantially equal to a previously stored number needed to close or open said valve. A digital, voice, or SMS text message phone dialer is add to dispatch the detected leak signals, and notify monitoring personnel supervised system operation, end provide user access to turn on or off a valve(s) from a remote location(s).

Owner:RUGGIERI MONICA L +1

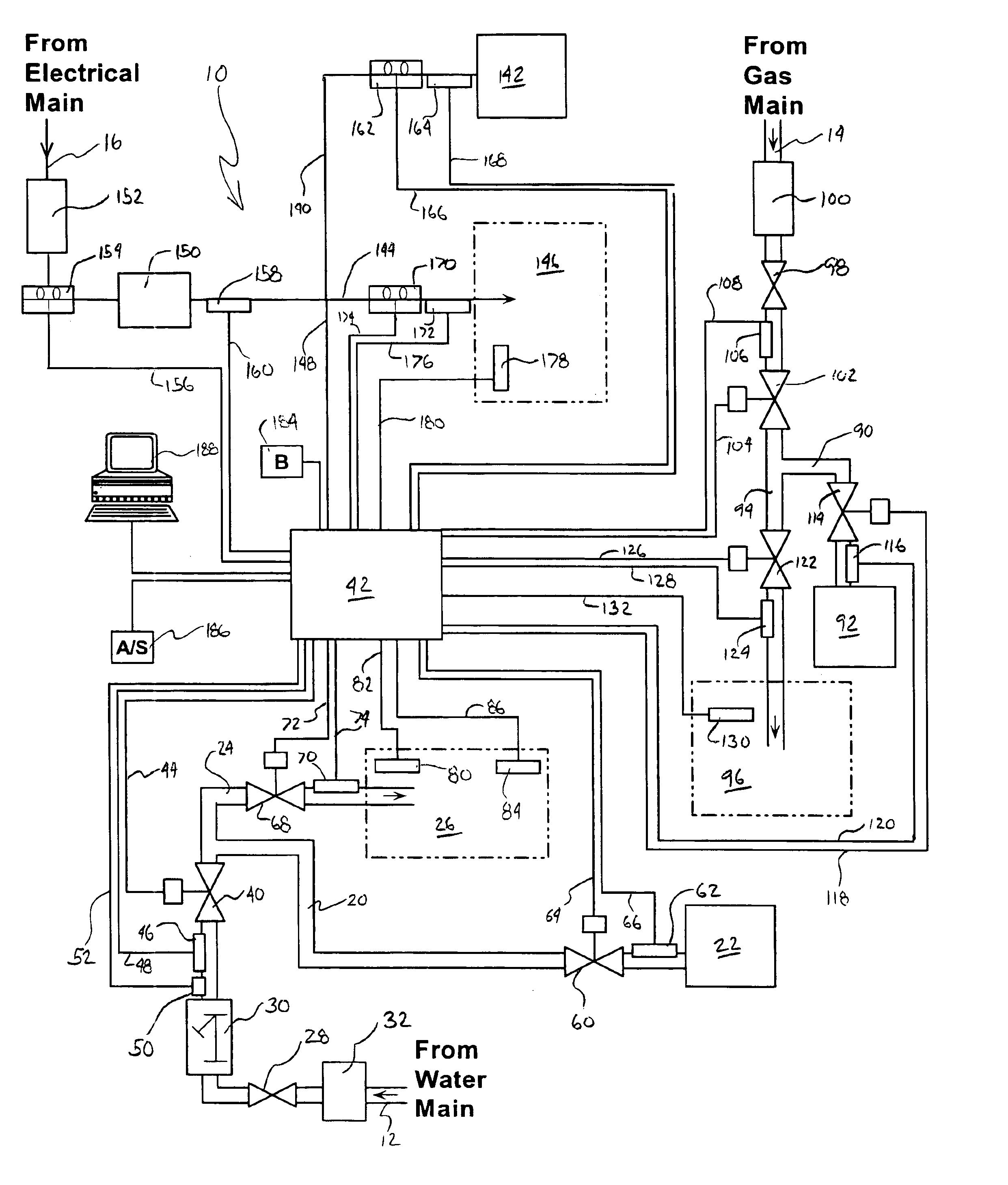

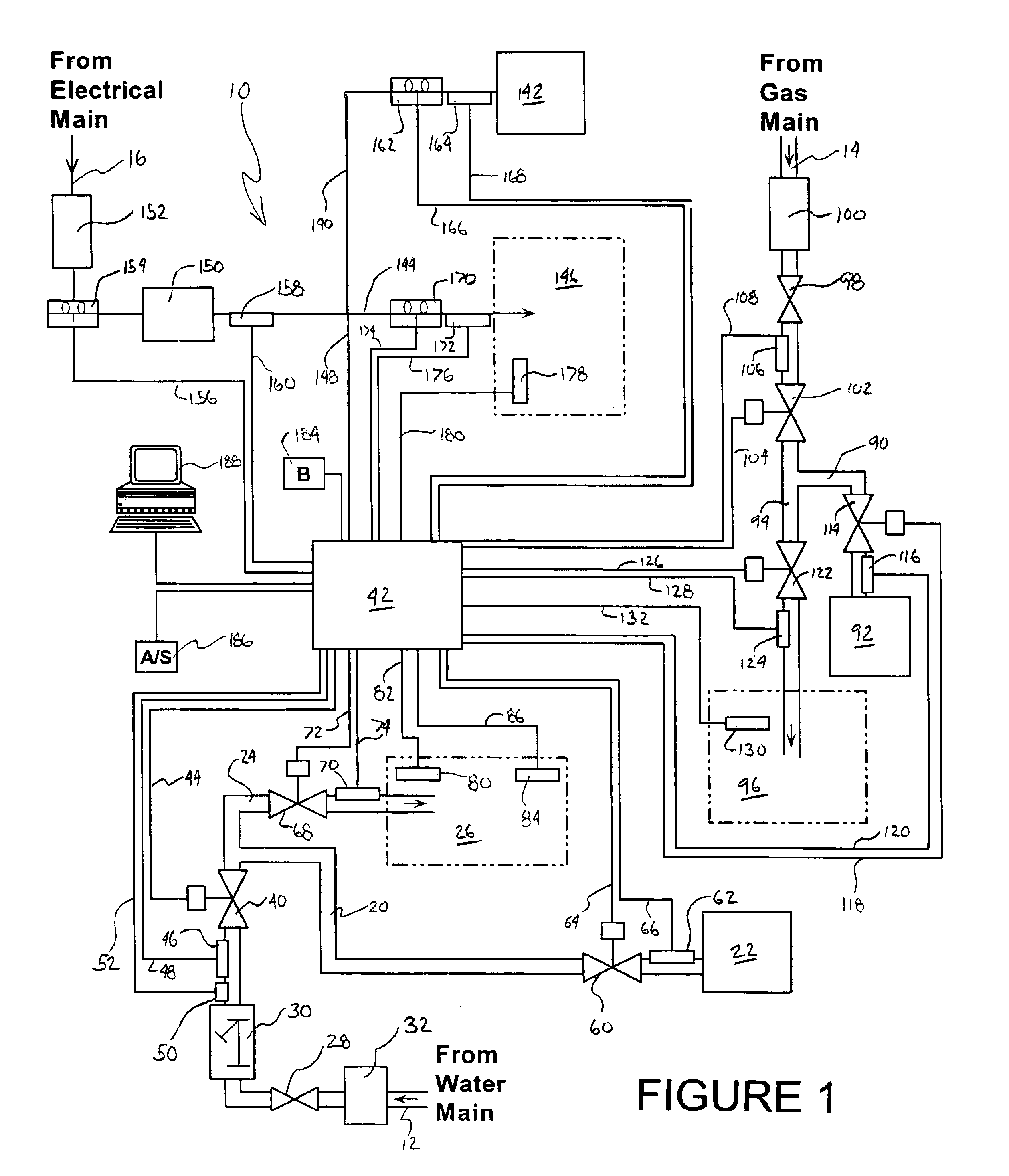

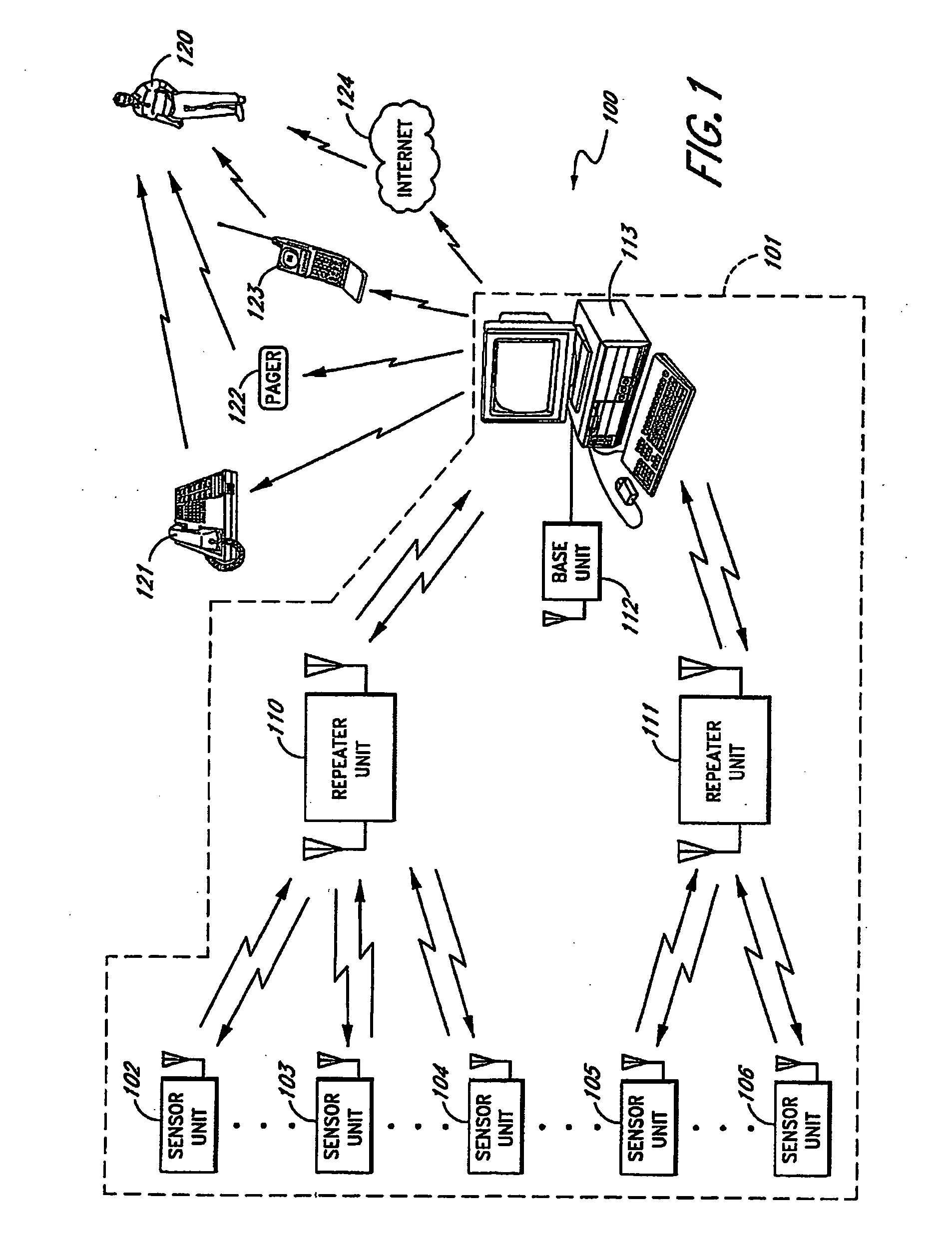

System and method for monitoring and controlling utility systems

A system for monitoring and controlling one or more utility systems includes a utility system main supply line for supplying a utility to at least one of a structure, an area and a building and a controlled shut-off device on the utility system main supply line. The controlled shut-off device is bias toward an open position and is movable toward a closed position upon receipt of an actuation signal wherein the utility is prevented from passing by the controlled shut-off device. A main utility sensor is on the utility system main supply line and a motion sensor that detects occupancy is in the building. A processor communicates with the controlled shut-off device, the main utility sensor and the motion sensor. The processor sends the actuation signal to the controlled shut-off device to move the controlled shut-off device toward the closed position when input from the main utility sensor and the motion sensor indicates occurrence of an abnormal event.

Owner:UHLER KENNETH J

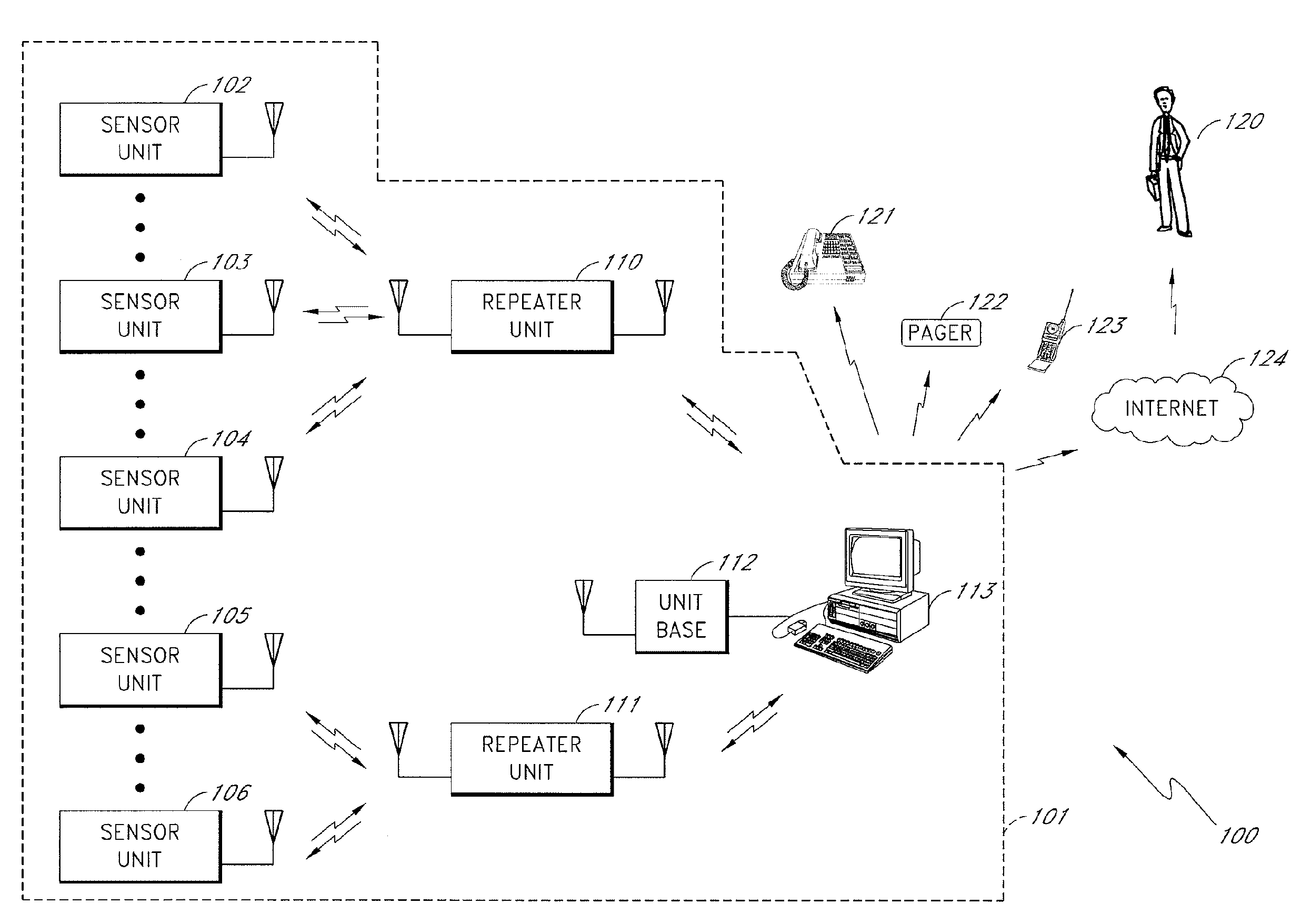

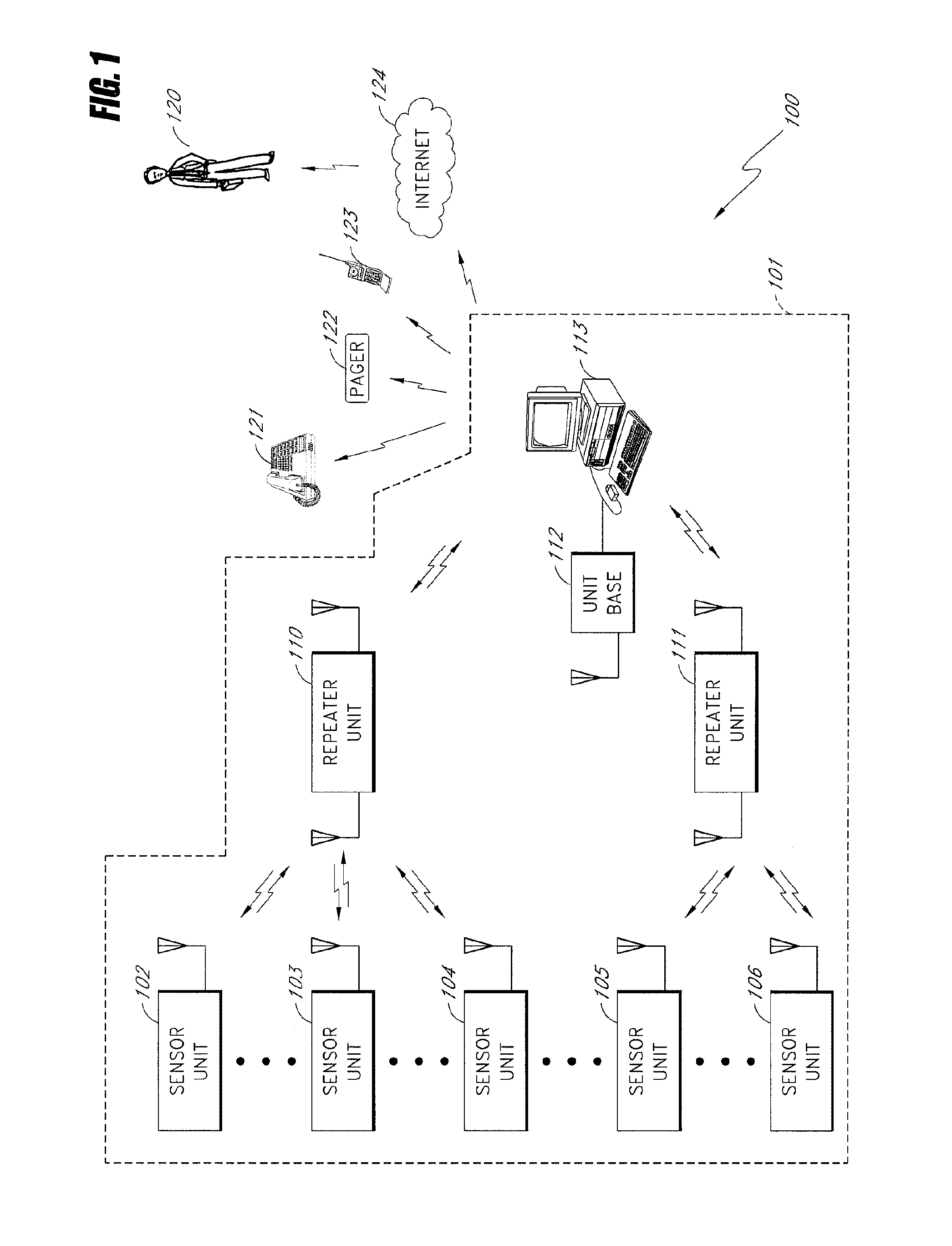

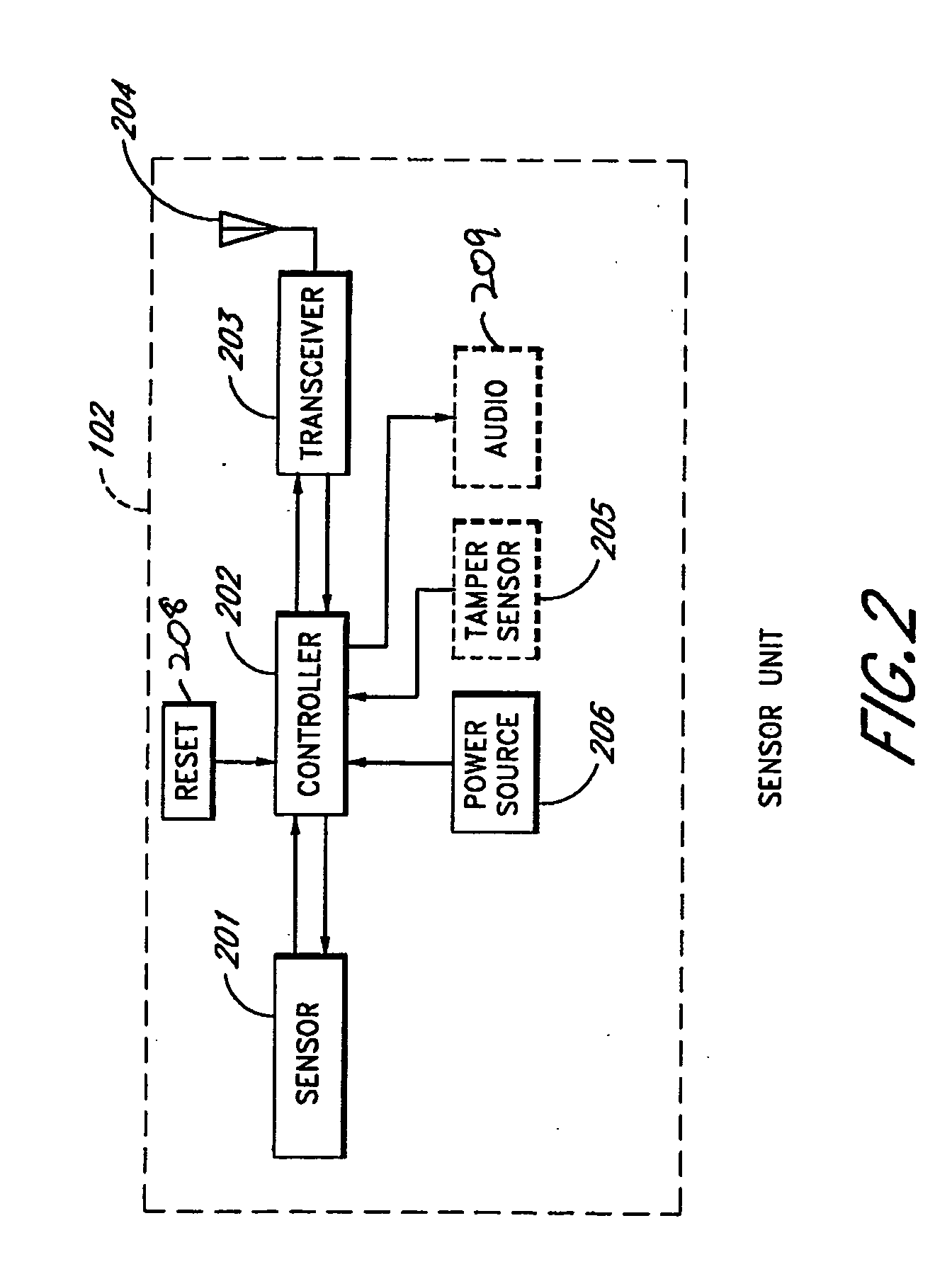

Method and apparatus for detecting water leaks

A system for detecting water leaks is described. In one embodiment, the system includes a plurality of sensors, selected from a moisture sensor, a water level sensor, and / or a water temperature sensor. A processor collects moisture readings from the sensors. In one embodiment, the processor reports a possible water leak when a moisture sensor detects moisture above a moisture threshold value. In one embodiment, the processor report a water leak when the water level reading exceeds a water threshold value and / or when the temperature reading exceeds a temperature threshold value.

Owner:GOOGLE LLC

Method and apparatus for detecting water leaks

ActiveUS20050275547A1Low costIncrease rangeOther washing machinesPipeline systemsEngineeringWater leak

A system for detecting water leaks is described. In one embodiment, the system includes a plurality of sensors, selected from a moisture sensor, a water level sensor, and / or a water temperature sensor. A processor collects moisture readings from the sensors. In one embodiment, the processor reports a possible water leak when a moisture sensor detects moisture above a moisture threshold value. In one embodiment, the processor report a water leak when the water level reading exceeds a water threshold value and / or when the temperature reading exceeds a temperature threshold value.

Owner:GOOGLE LLC

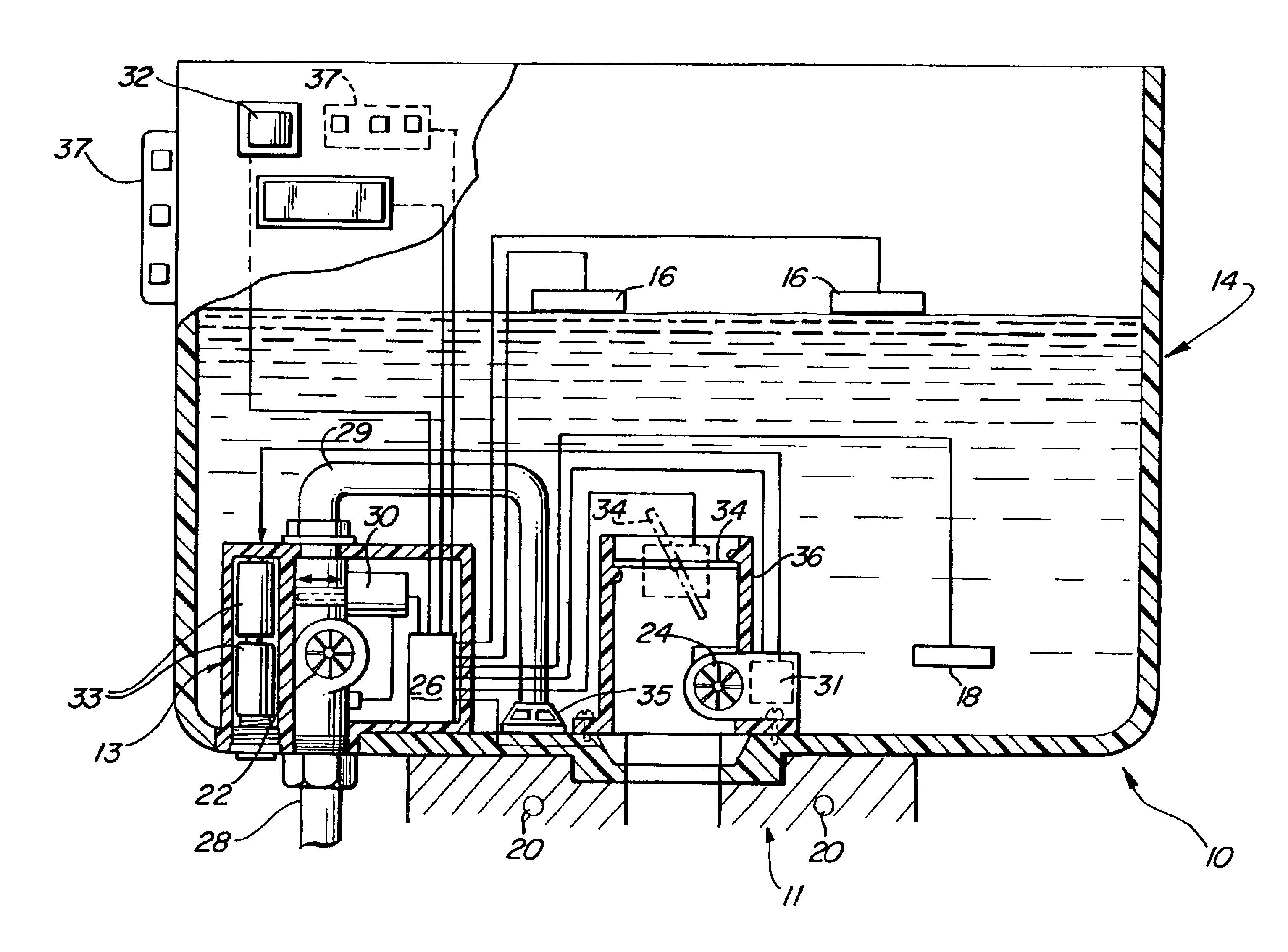

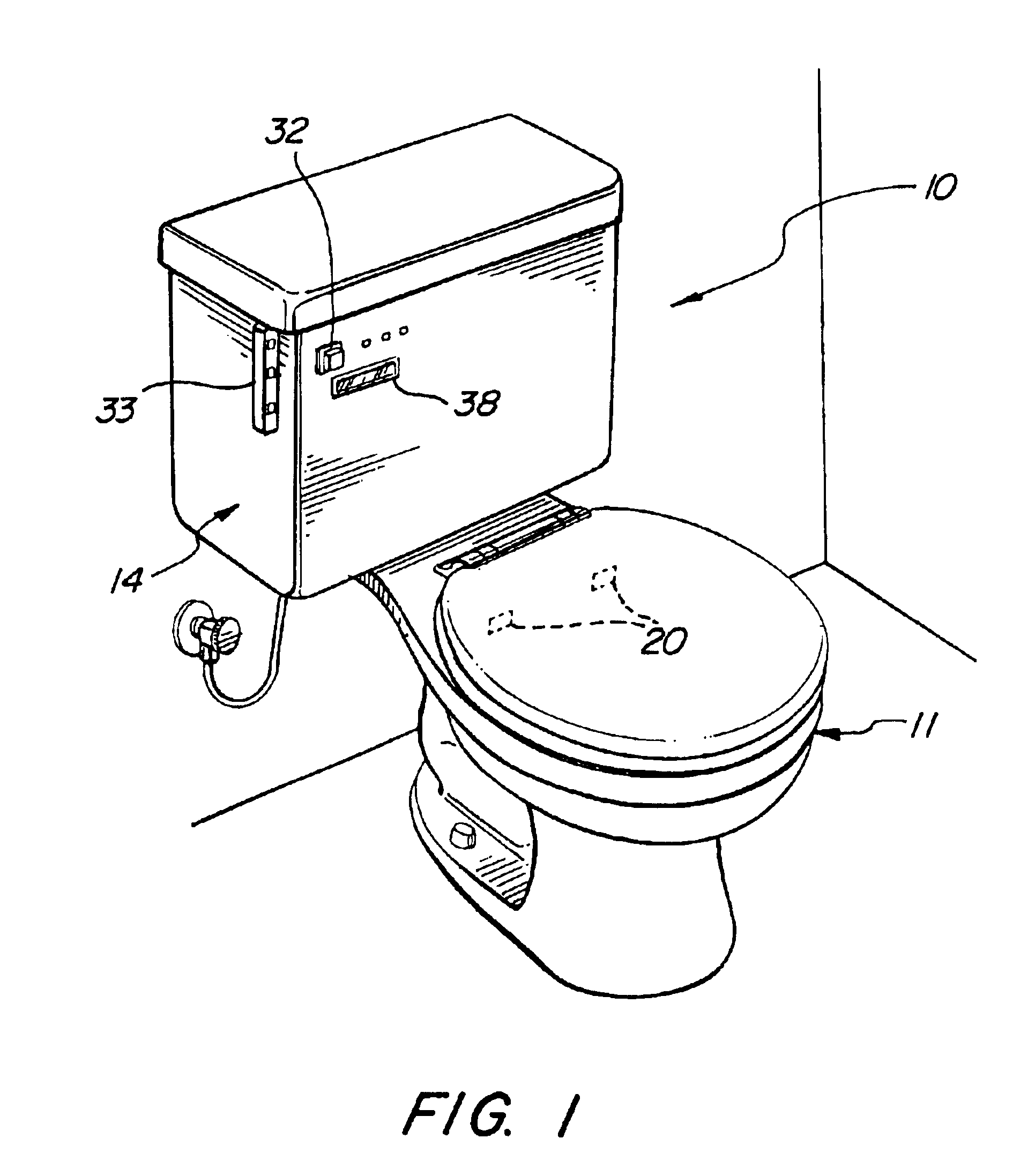

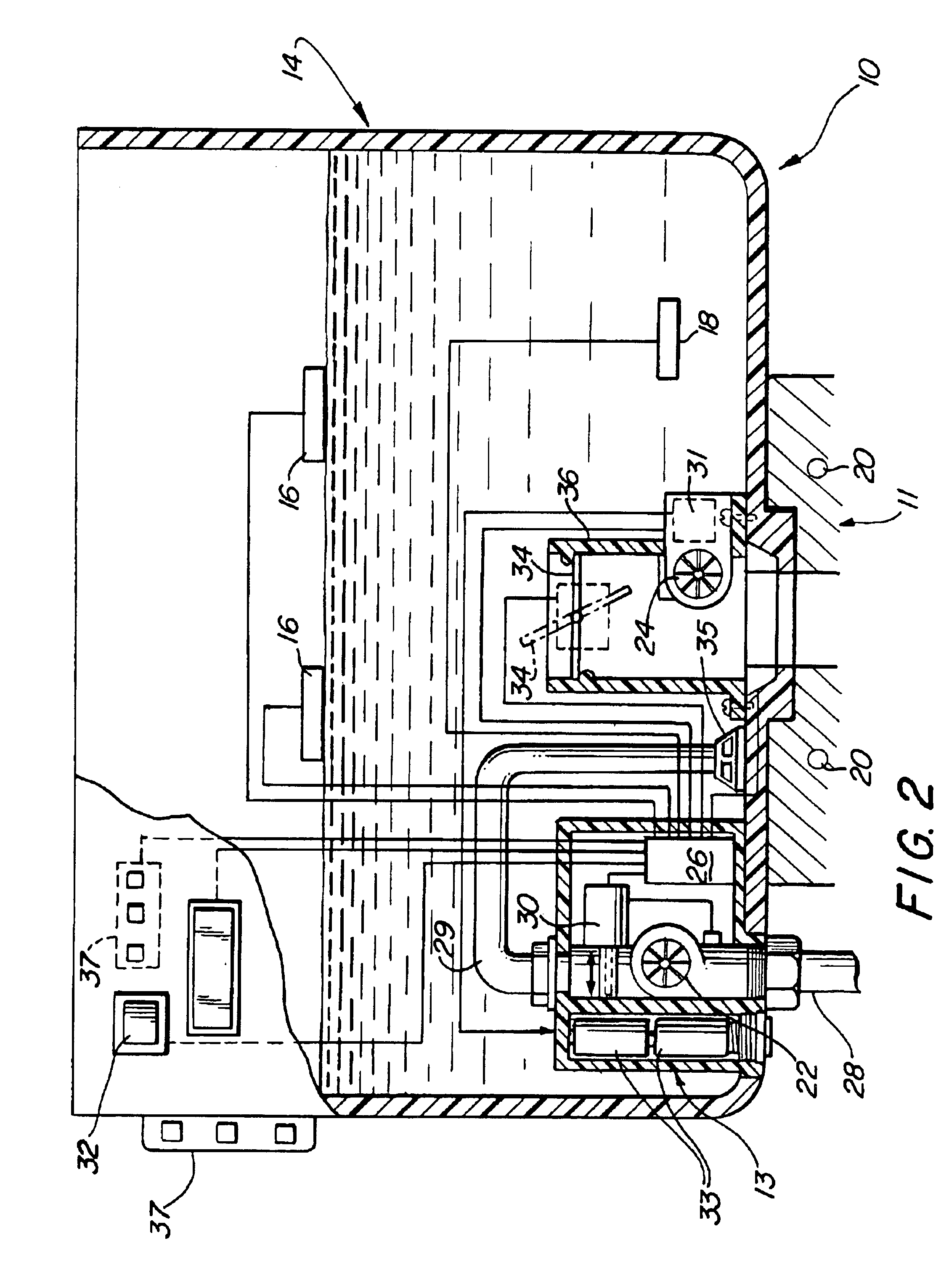

Toilet control system

InactiveUS6877170B1Detection and prevention of leakDetection and prevention of and overflowWater closetsLevel controlControl systemWater flow

A toilet water measuring and flow control system, including leak and overflow detection and prevention elements. The system has inlet and outlet flow sensors operably connected to inlet and outlet control valves and to water level sensors to measure and control water flow to and from the toilet. Water level sensors held in a toilet tank are connected to the system to control the volume of water fed to the toilet tank and passing through the outlet. The toilet tank may be provided with a movable reservoir to more accurately control the amount of water held in the tank and exiting the tank upon flushing.

Owner:NICCOLE FAMILY TRUST

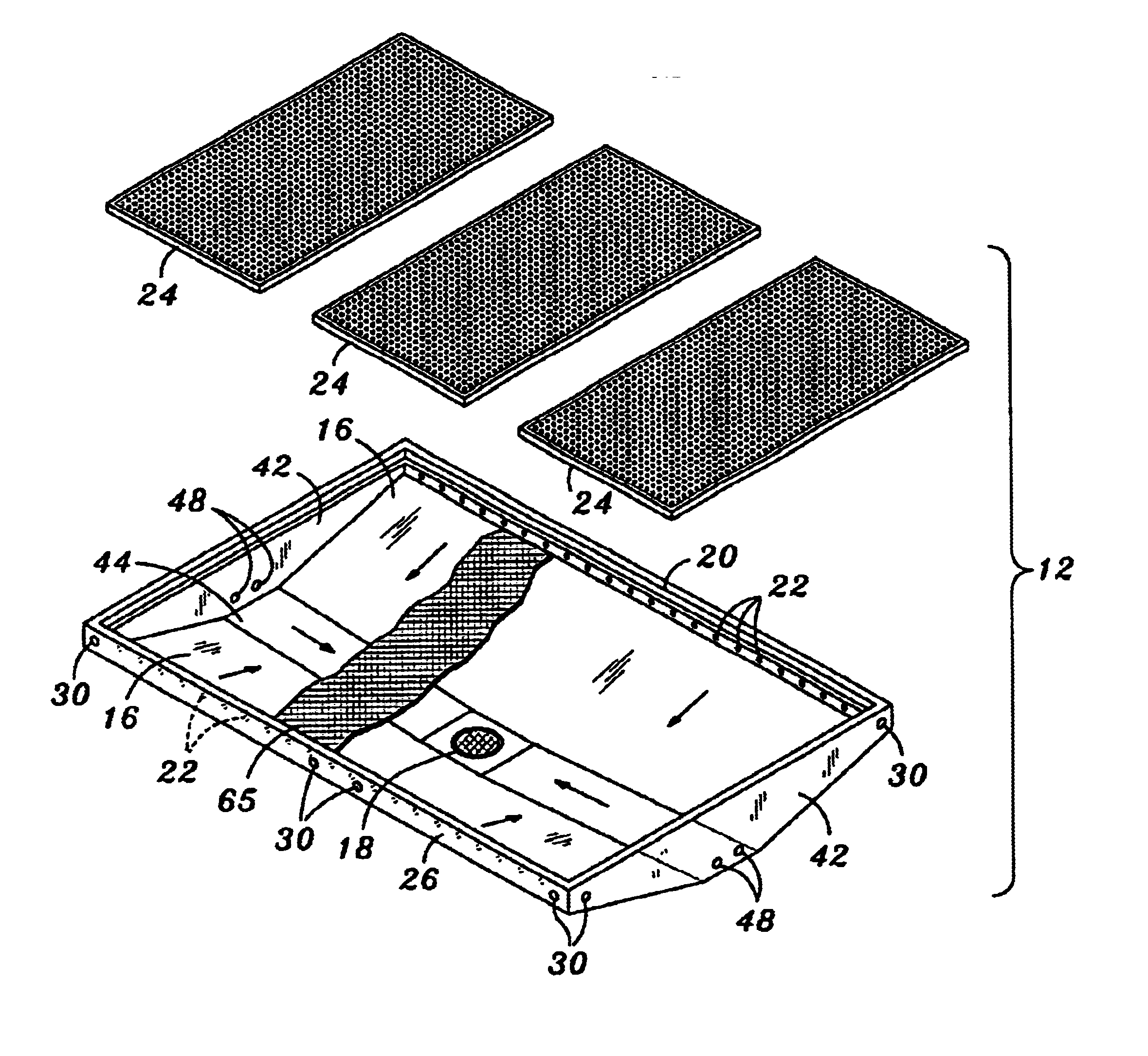

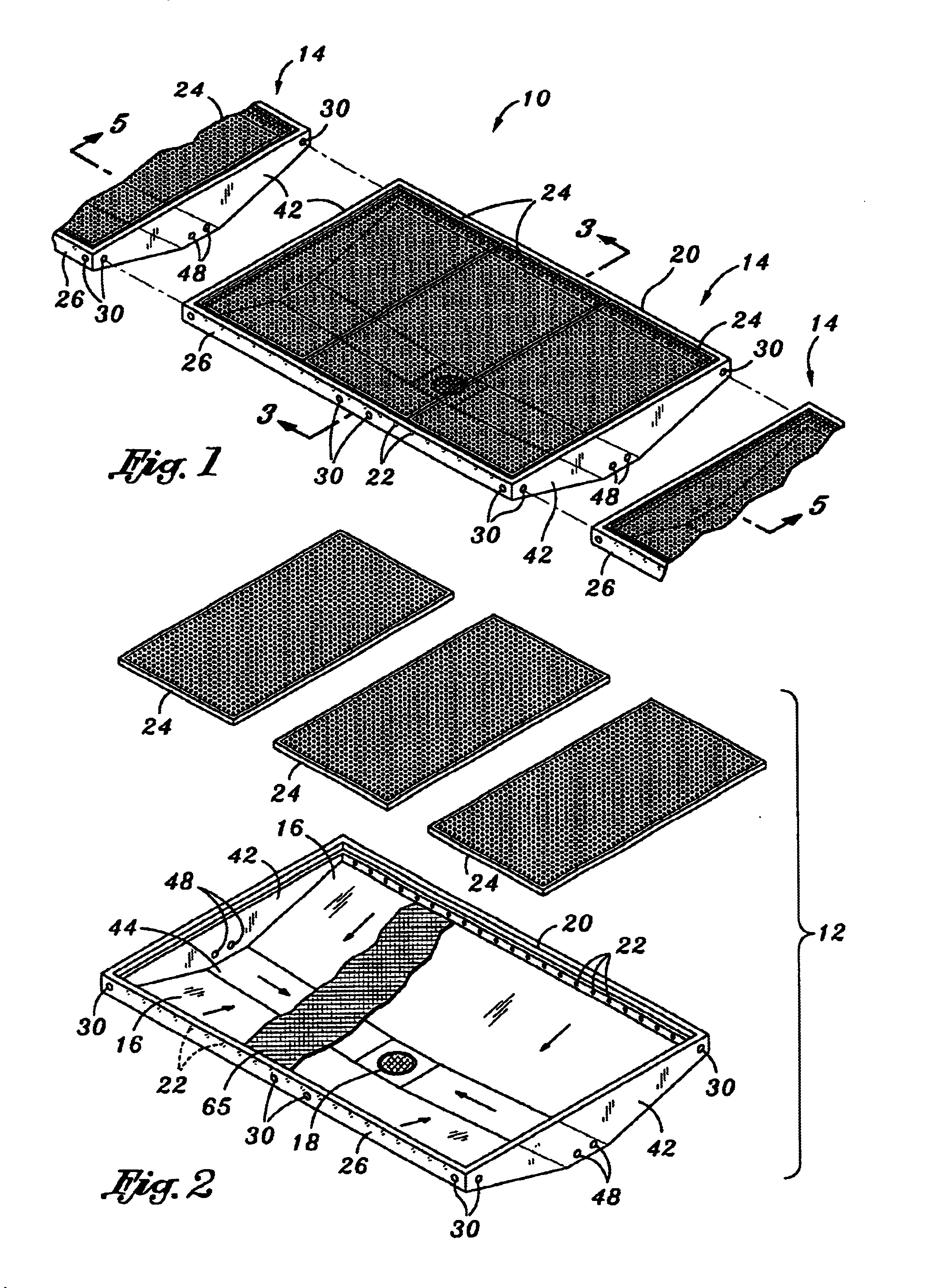

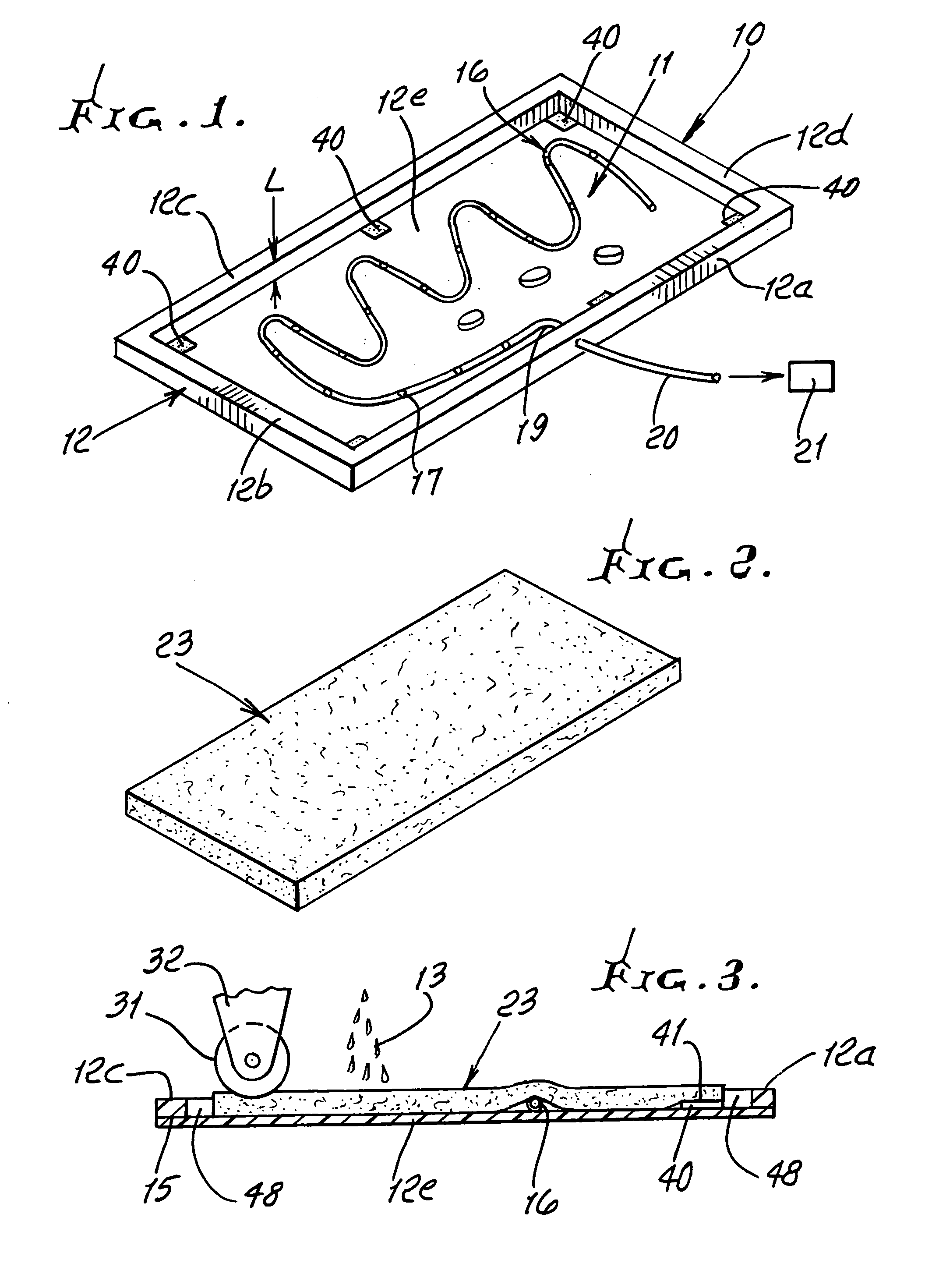

Self-cleaning flooring system

A self-cleaning flooring system for catching waste products has at least one module comprising a drain pan and a floor grid. The drain pan has a ramp and a central drain outlet. The ramp extends around the drain pan defining a drain pan periphery. The ramp slopes downward from the drain pan periphery towards the drain outlet. The drain pan periphery has a plurality of discharge ports spaced therealong for discharge of flushing fluid onto the ramp such that the waste products are washed down the ramp towards the drain outlet. The floor grid extends across the drain pan and is mounted upon the drain pan periphery for supporting personnel standing thereon while permitting waste products to pass therethrough. The module is interconnectable to horizontally adjacent modules to form the flooring system.

Owner:DTS ENTERPRISES INC

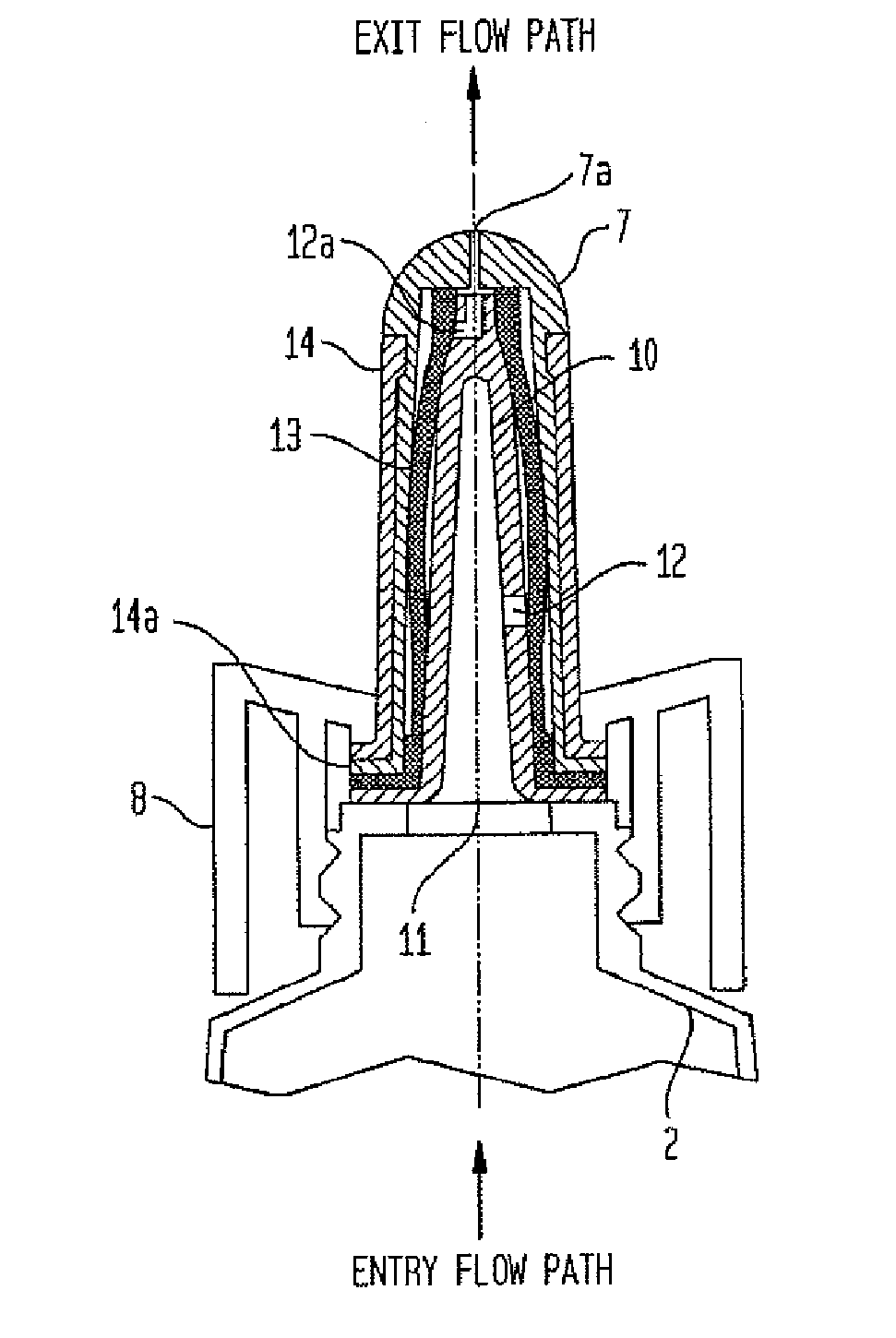

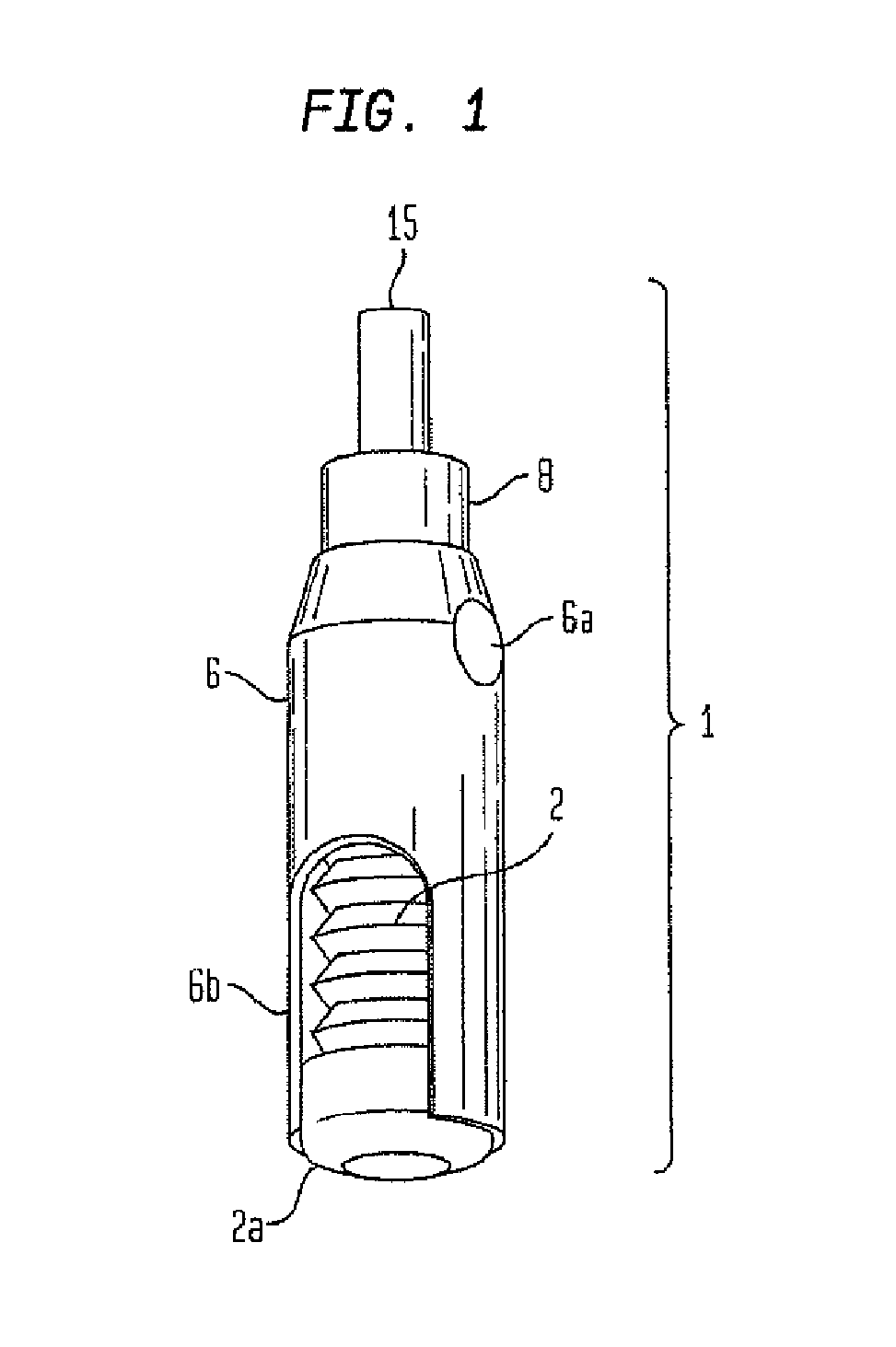

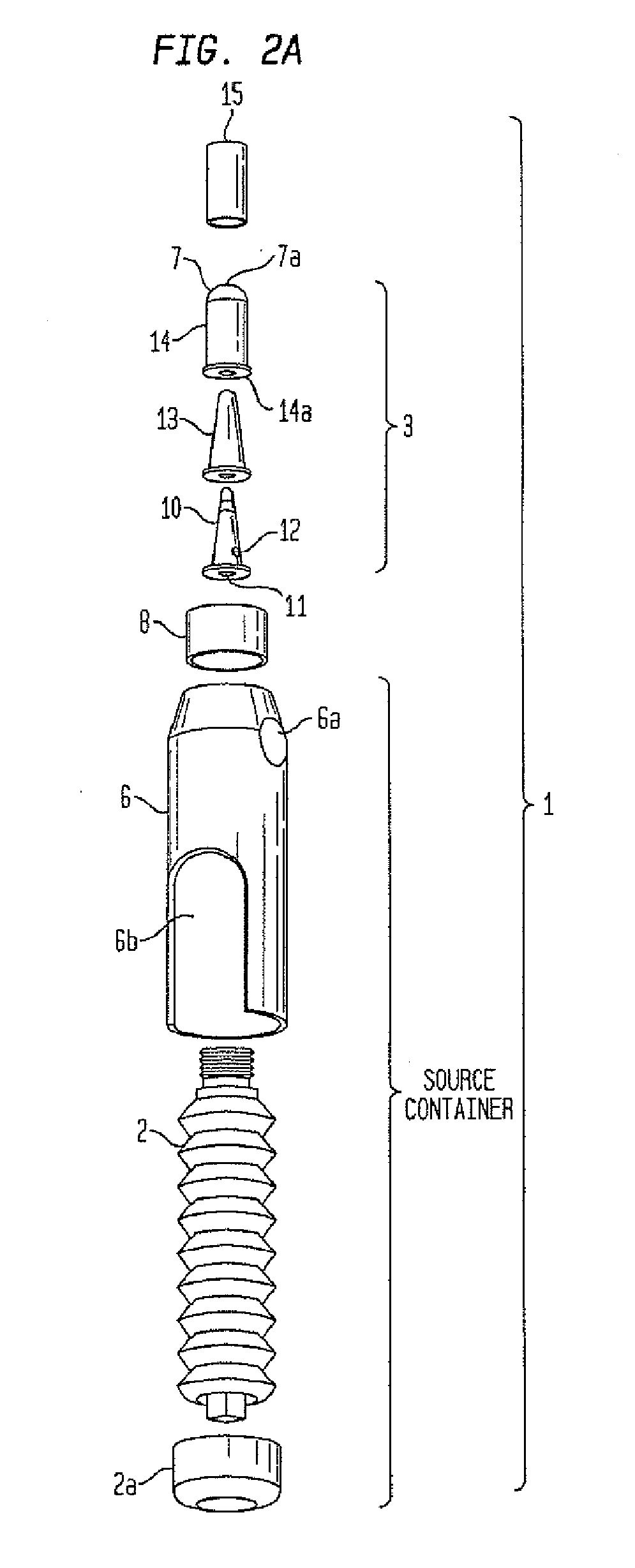

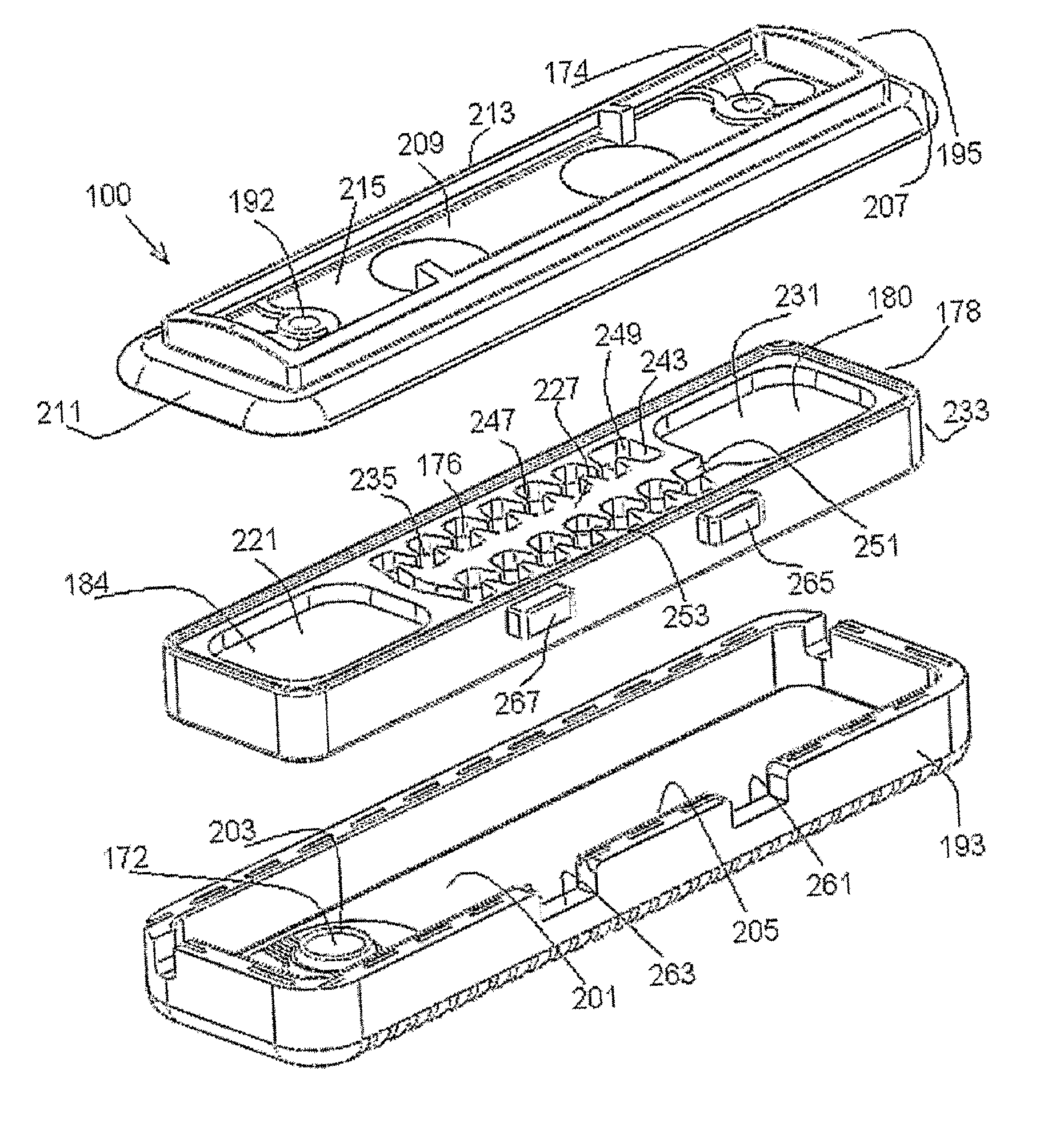

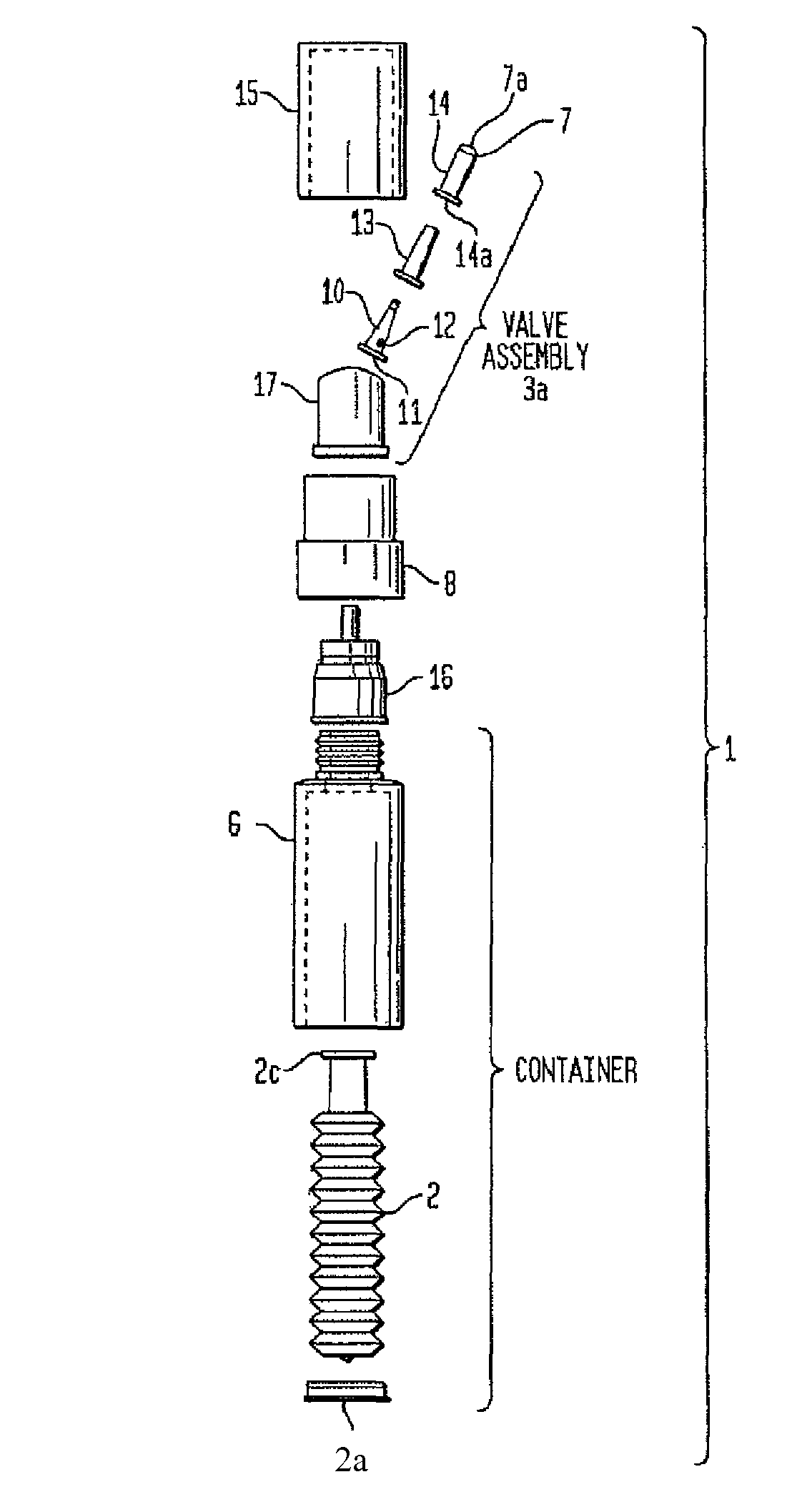

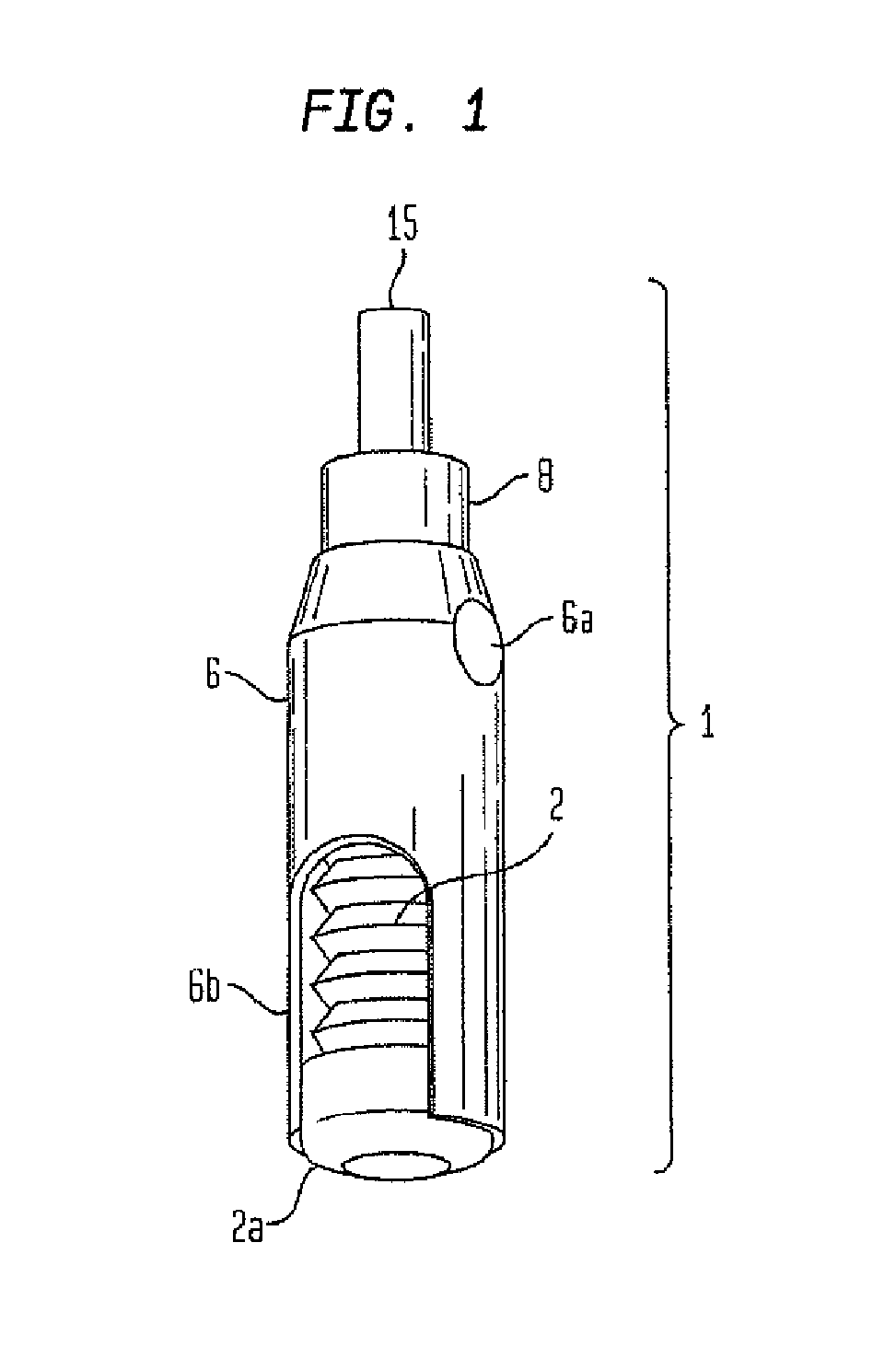

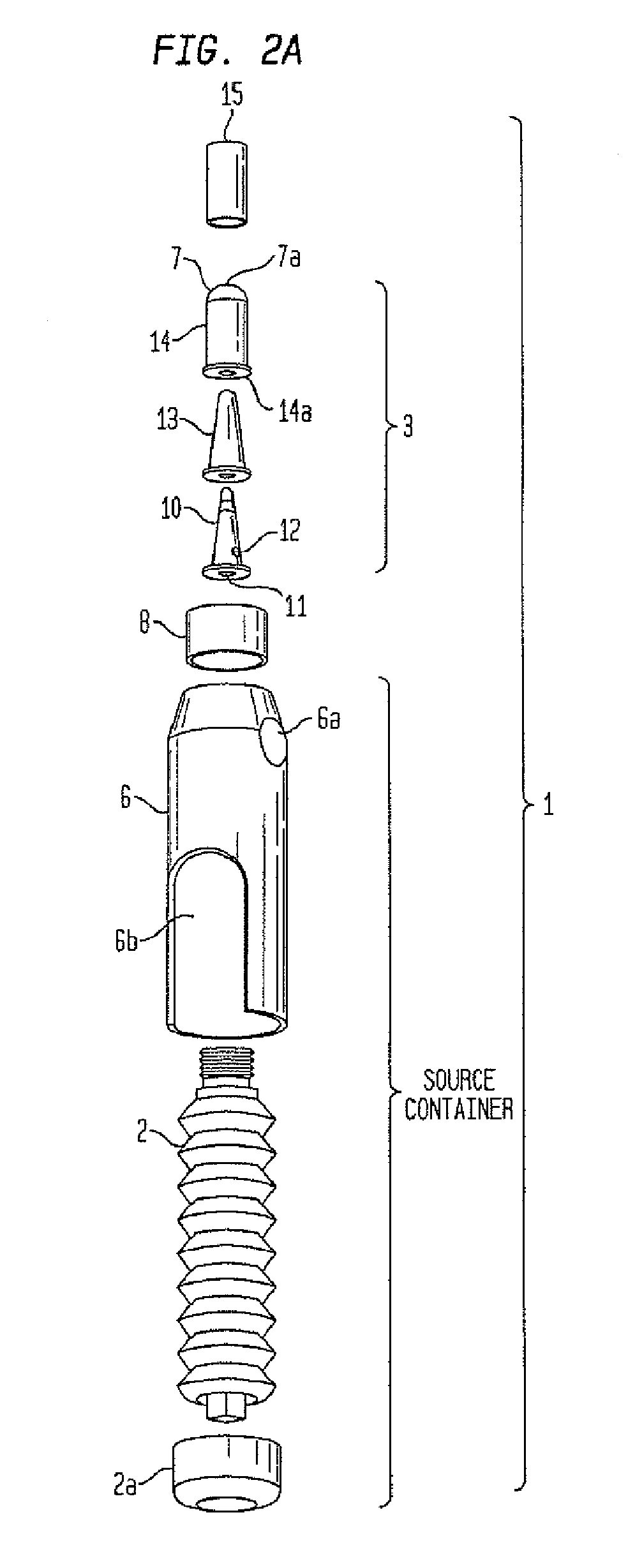

Metered Drop Push Button Dispenser System

InactiveUS20090236374A1Prevent backflowLess elasticPackage recyclingCheck valvesPreservative freeEngineering

A reusable continuously sealing metered dosing one-way valve assembly and delivery system flows a premeasured amount of a sterile flowable substance from a source which is coupled to an actuator assembly to an outlet orifice and prevents any backflow of contaminants through the continuously sealing one way valve assembly when the flowable substance ceases to flow. The valve assembly includes an elastomeric membrane which aids in preventing any backflow of contaminants when dispensing of the flowable substance is stopped. Multiple dosing of preservative-free flowable substance is provided.

Owner:RESEAL INT

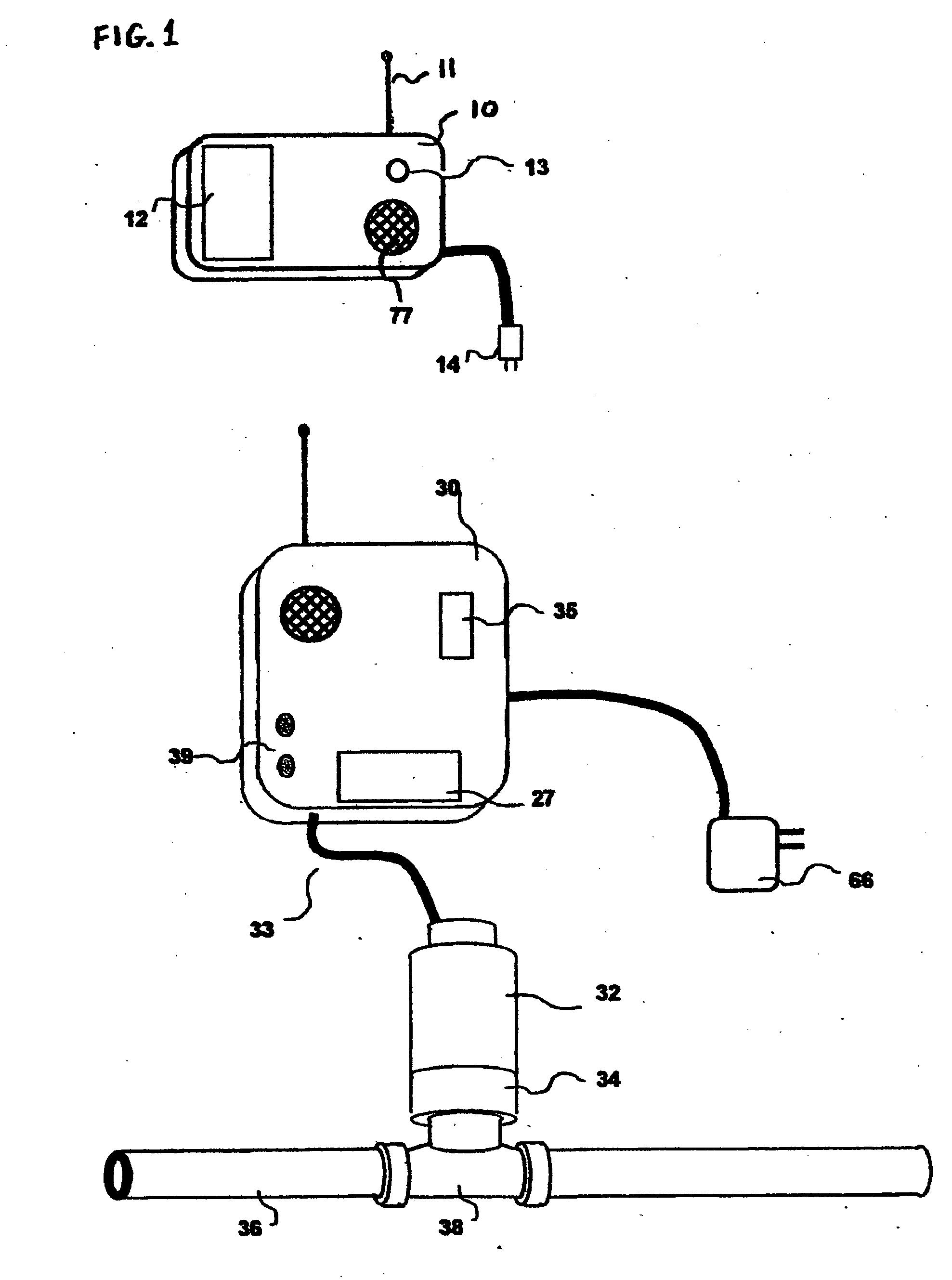

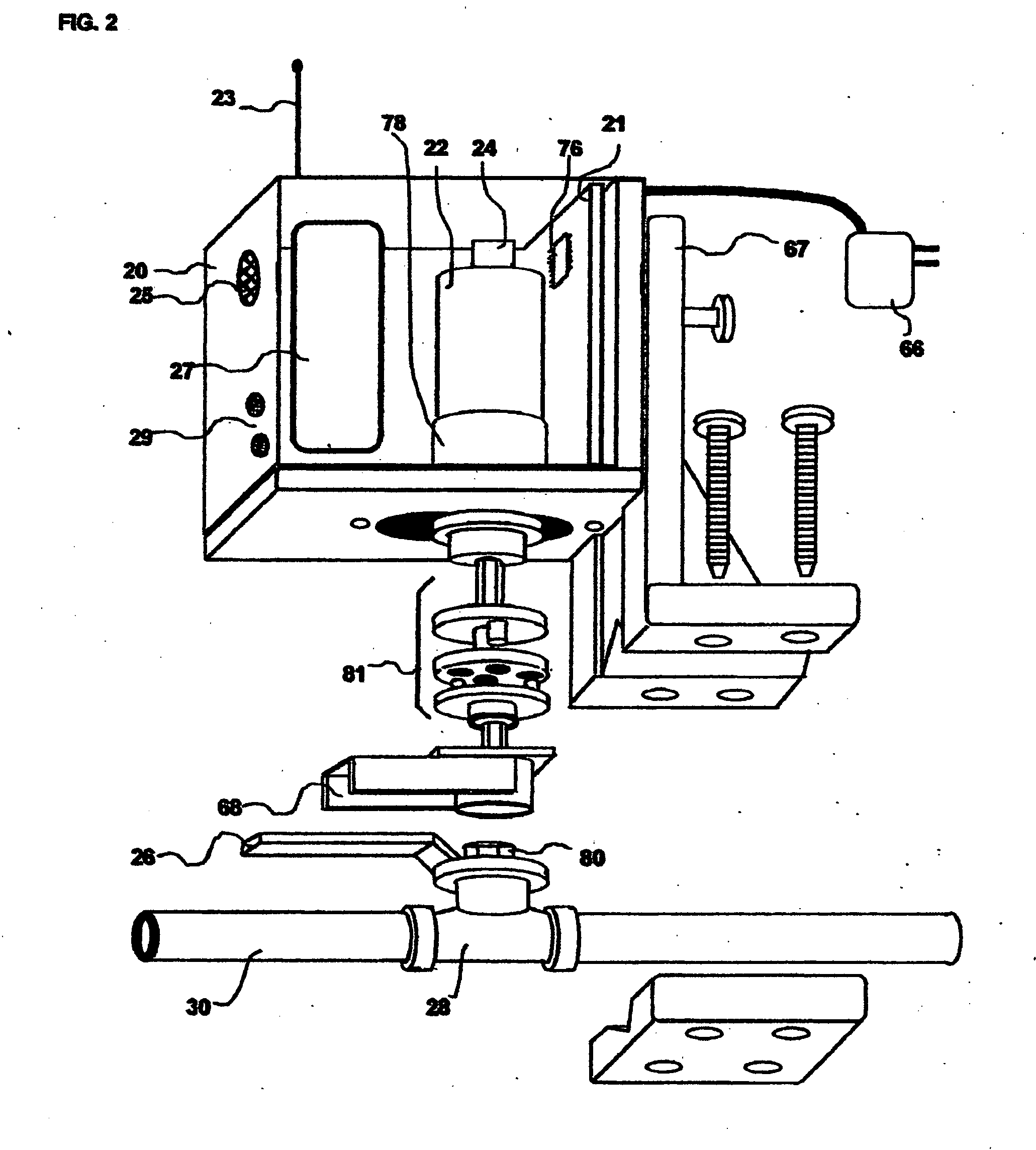

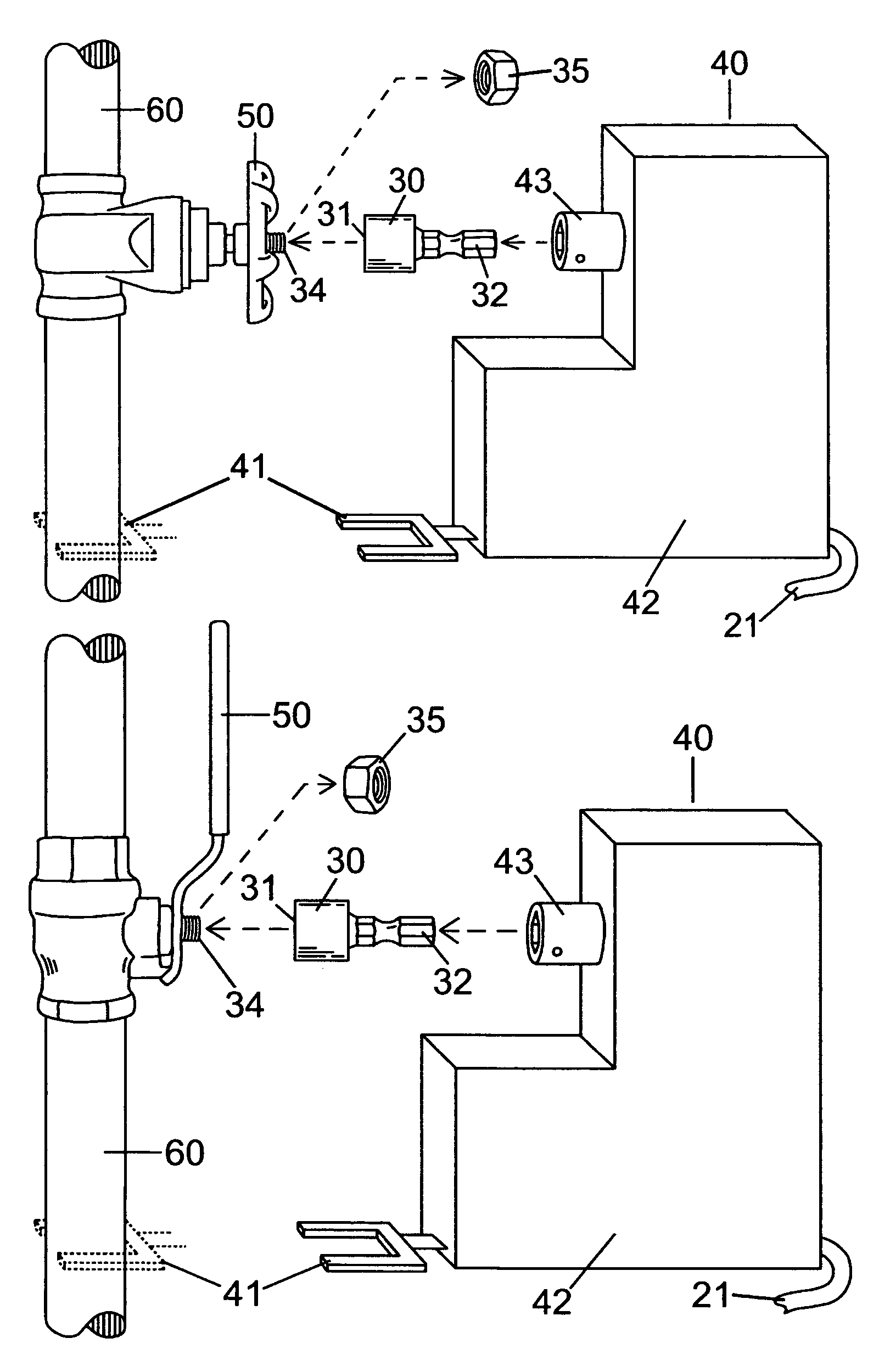

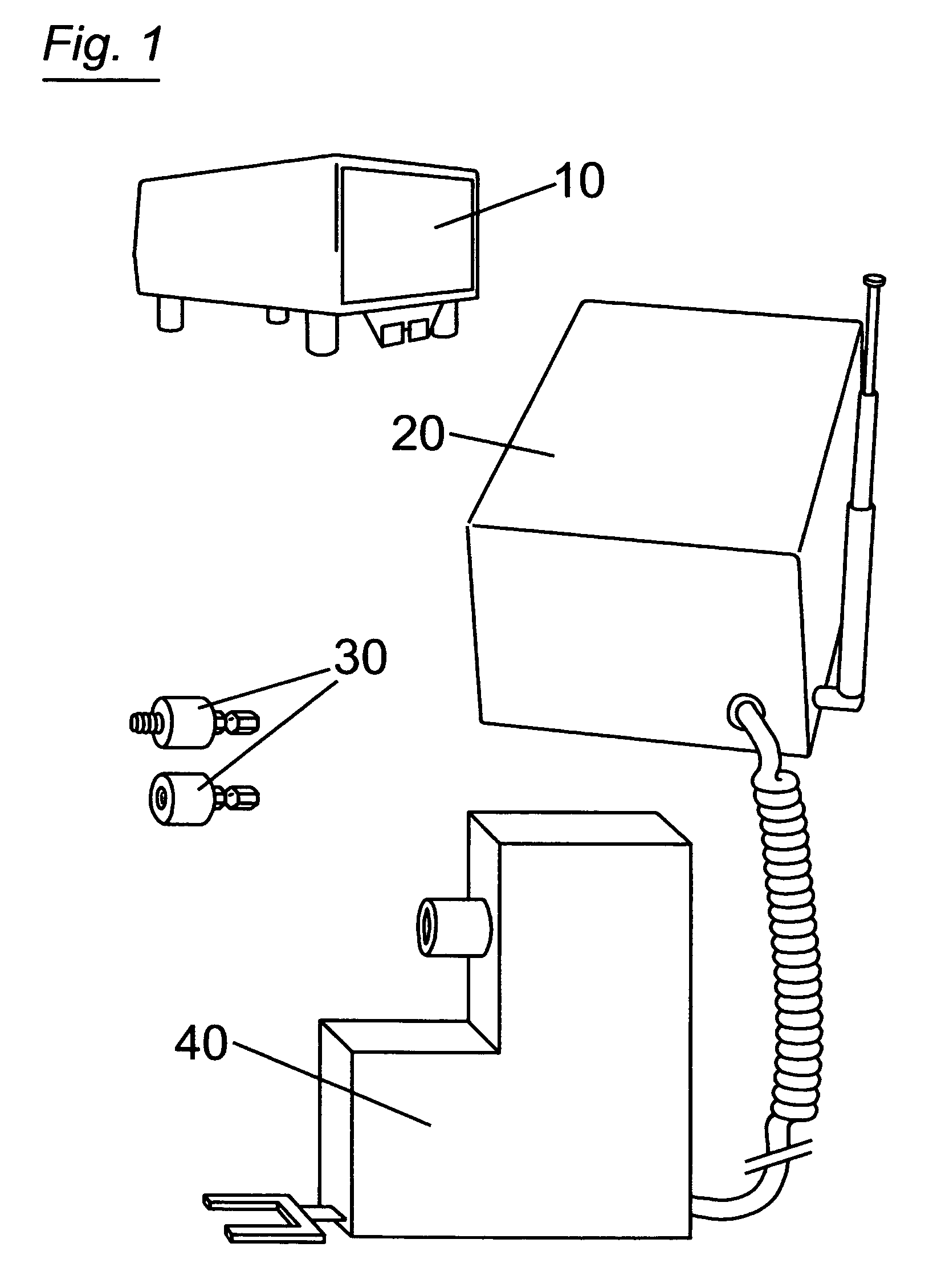

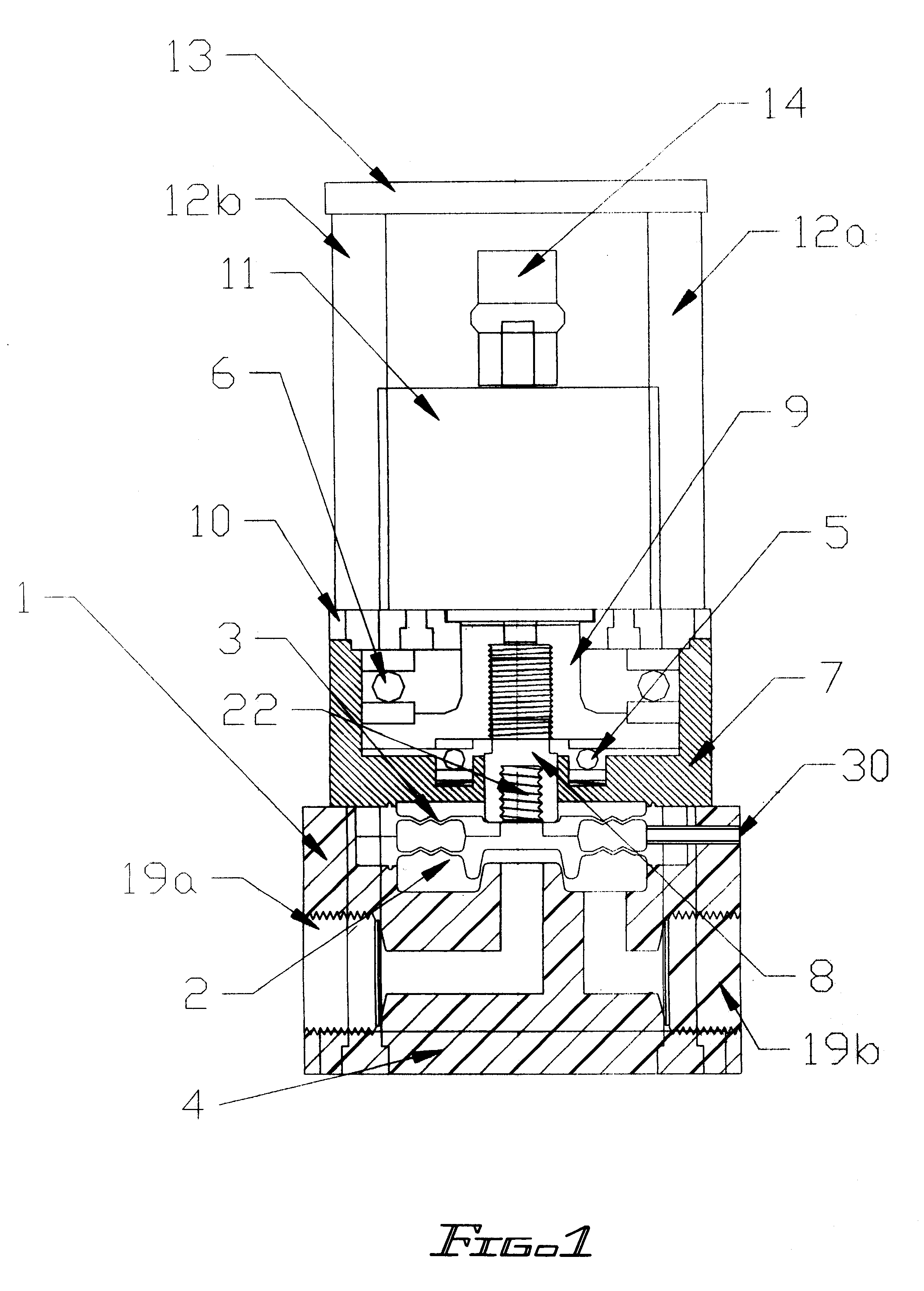

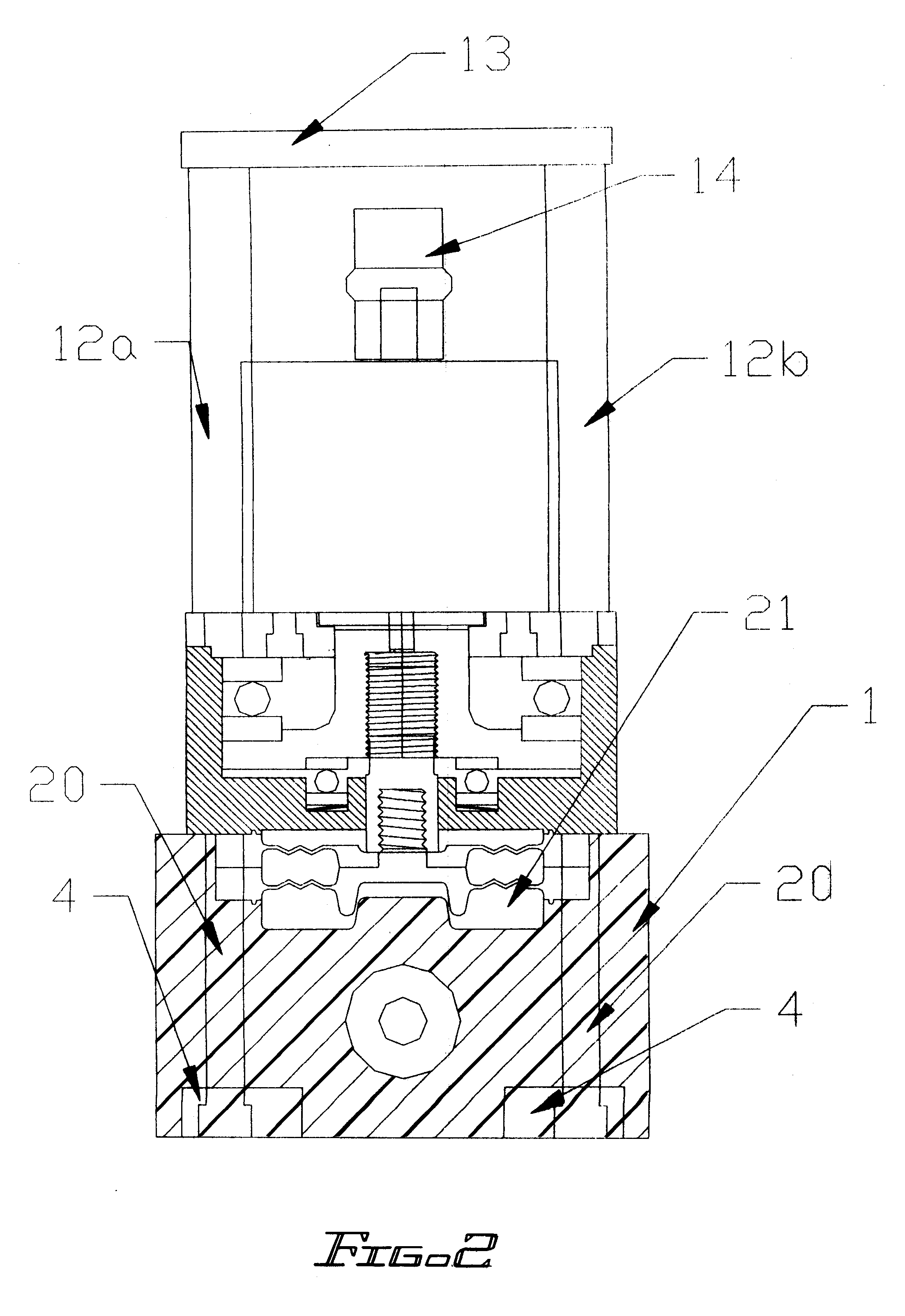

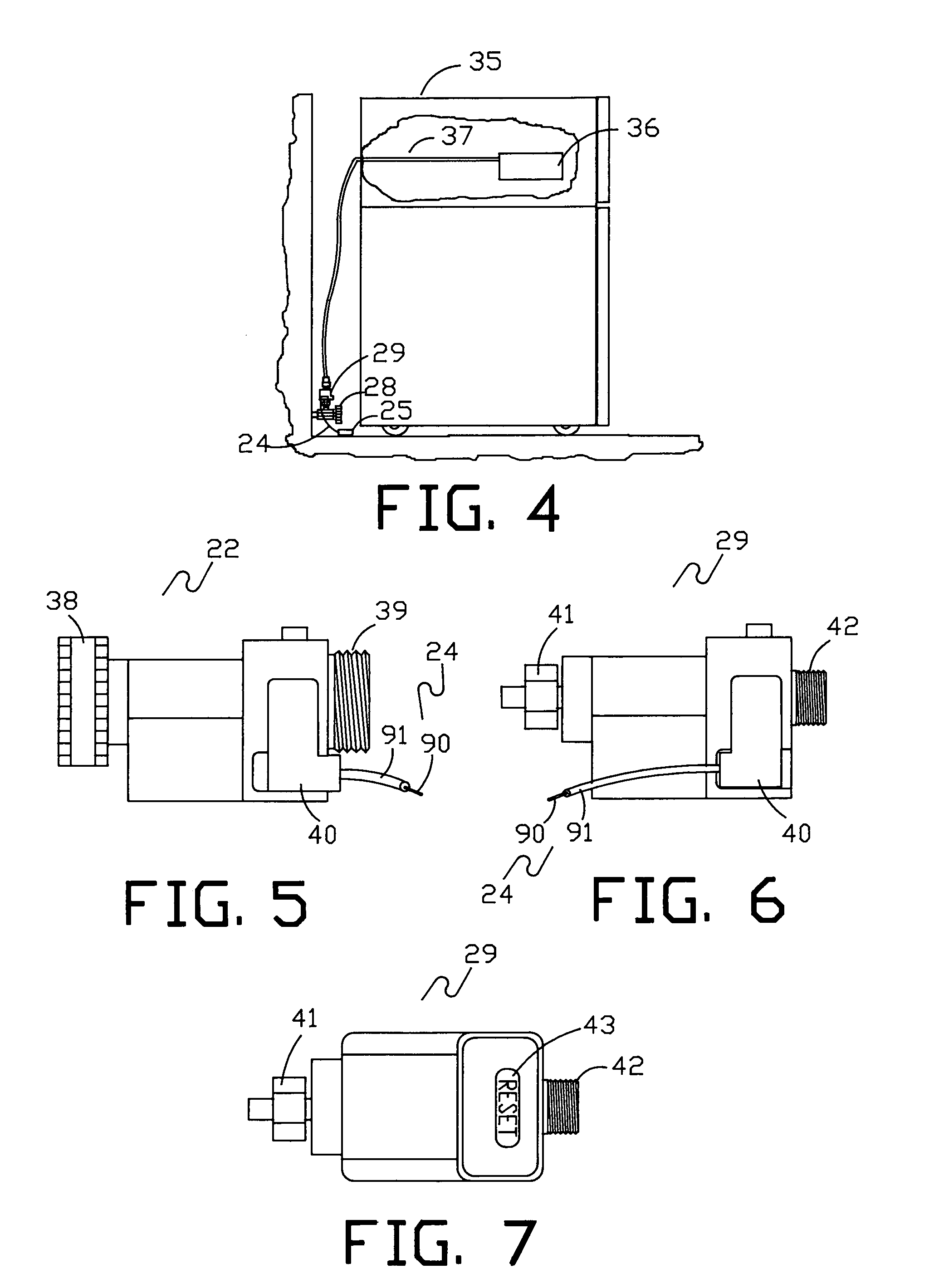

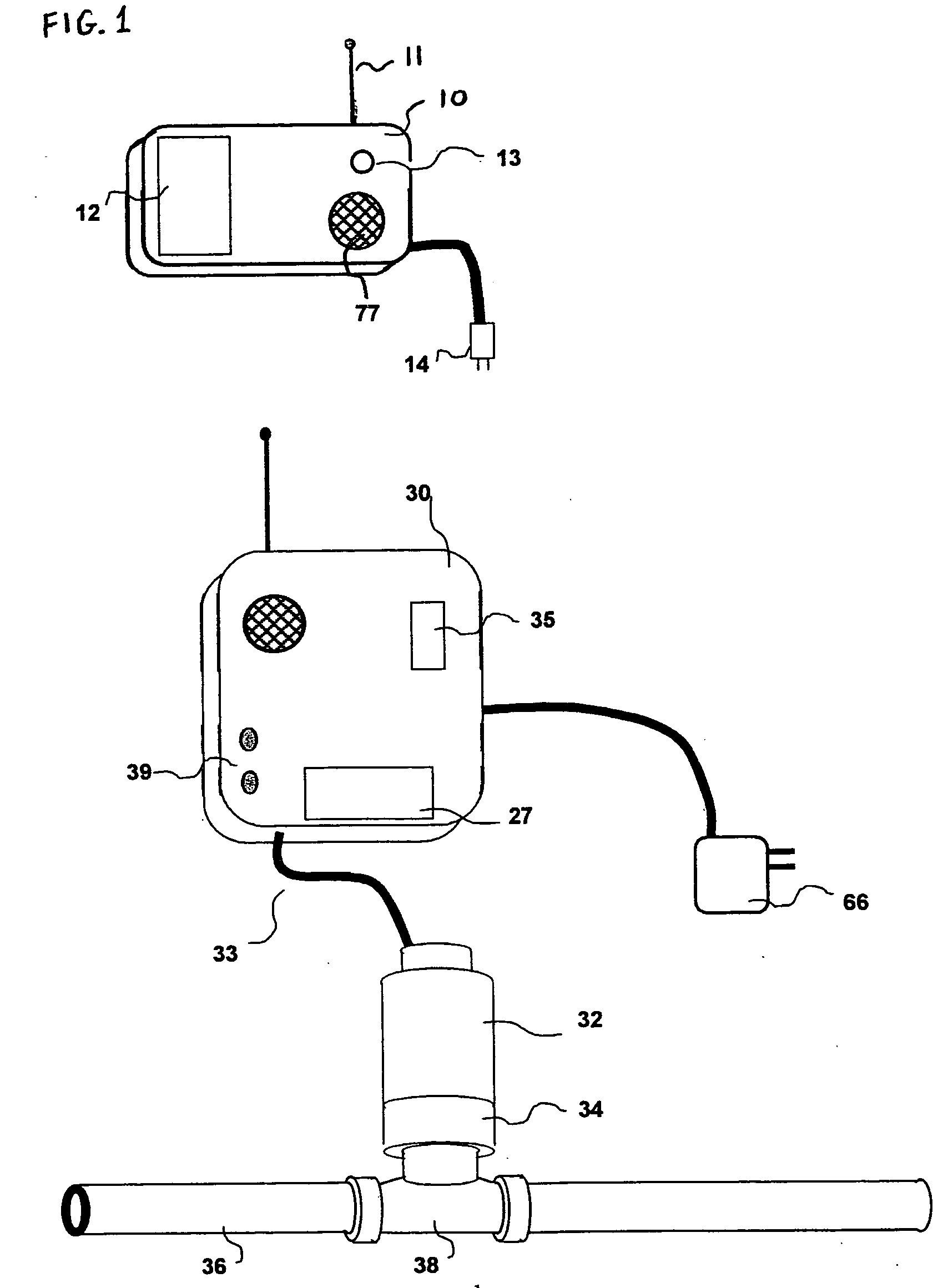

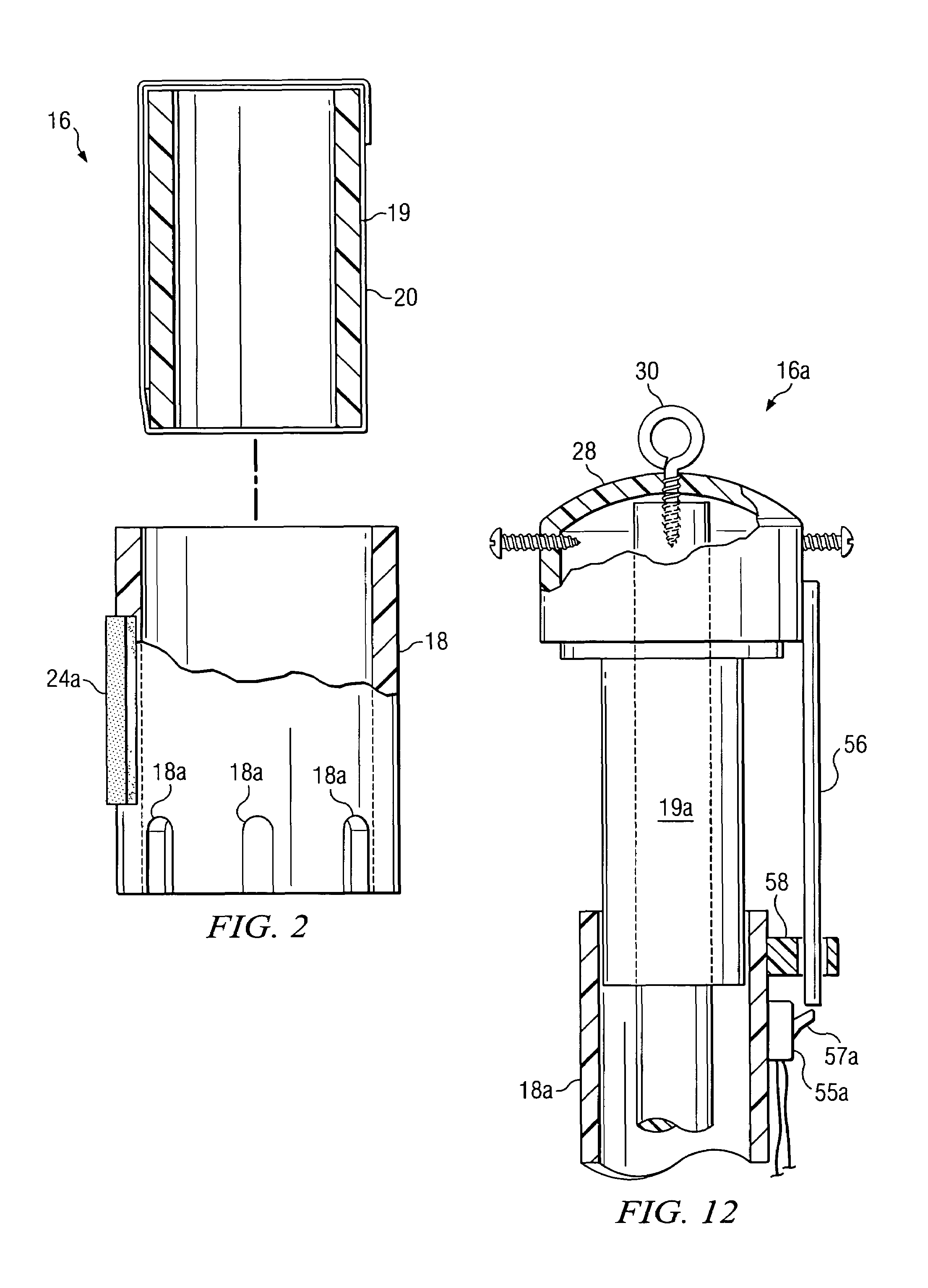

Valve shut off device

ActiveUS7066192B1Quickly easily securesEasy to installOperating means/releasing devices for valvesServomotor componentsEngineeringVALVE PORT

The invention is a valve shut off device that is easy to install and remove. The valve shut off device has at least one sensor, a receiver a set of interchangeable adapters, and a motor unit. The motor unit is attached to a valve handle by an adapter, and the sensor can communicate to activate the motor. When the sensor detects a leaking substance, the motor unit is activated and turns the valve handle to the “off” position. The adapters allow easy installation and removal of the valve shut off device. Additionally, the adapters accommodate a variety of valves making the system universal. Among other things, the valve shut off device allows a property owner to be absent from his or her property without the risk of a leak causing extensive damage.

Owner:DELANEY BRIAN +1

Anti-pumping dispense valve

Anti-pumping dispense valves, constructed according to principles of this invention, comprise a fluid transport housing having a fluid inlet passage extending into the housing, a fluid outlet passage extending out of the housing, and a fluid transport chamber disposed within the housing. The fluid transport chamber includes an valve seat. An actuator housing is attached to the fluid transport housing and includes an actuator chamber that is in contact with the fluid transport chambers. A diaphragm / poppet assembly is disposed within the fluid transport chamber and comprises a poppet positioned downstream of the seat for placement against the seat to stop fluid flow through the first fluid transport chamber. An actuator is disposed within the actuator chamber for moving the diaphragm / poppet assembly. Dispense valves of this invention operate to provide a slight vacuum within the fluid flow passageway in the valve to retain or pull back into the valve any nondispensed liquid, thereby eliminating and / or greatly reducing the possibility product contamination via unwanted excess liquid dispensement or dried residual liquid dispensement.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS CORP

Rotary valve with internal leak control system

Rotary valve comprising (a) a rotor having a rotor face rotatable about an axis perpendicular to the rotor face, a plurality of openings, and at least one passage connecting at least one pair of the plurality of openings; (b) a stator having a stator face in sealing contact with the rotor face to form a planar rotary valve seal with an outer periphery, a plurality of openings in the stator face that are connected to respective passages through the stator, and wherein at least one of the passages through the stator is a stator vacuum passage directly connected to a vacuum pump; (c) a sealed valve chamber having an interior volume contiguous with the outer periphery of the rotary valve seal, which chamber is sealed from the atmosphere surrounding the rotary valve; and (d) a vacuum vent passage connected to the sealed valve chamber.

Owner:AIR PROD & CHEM INC

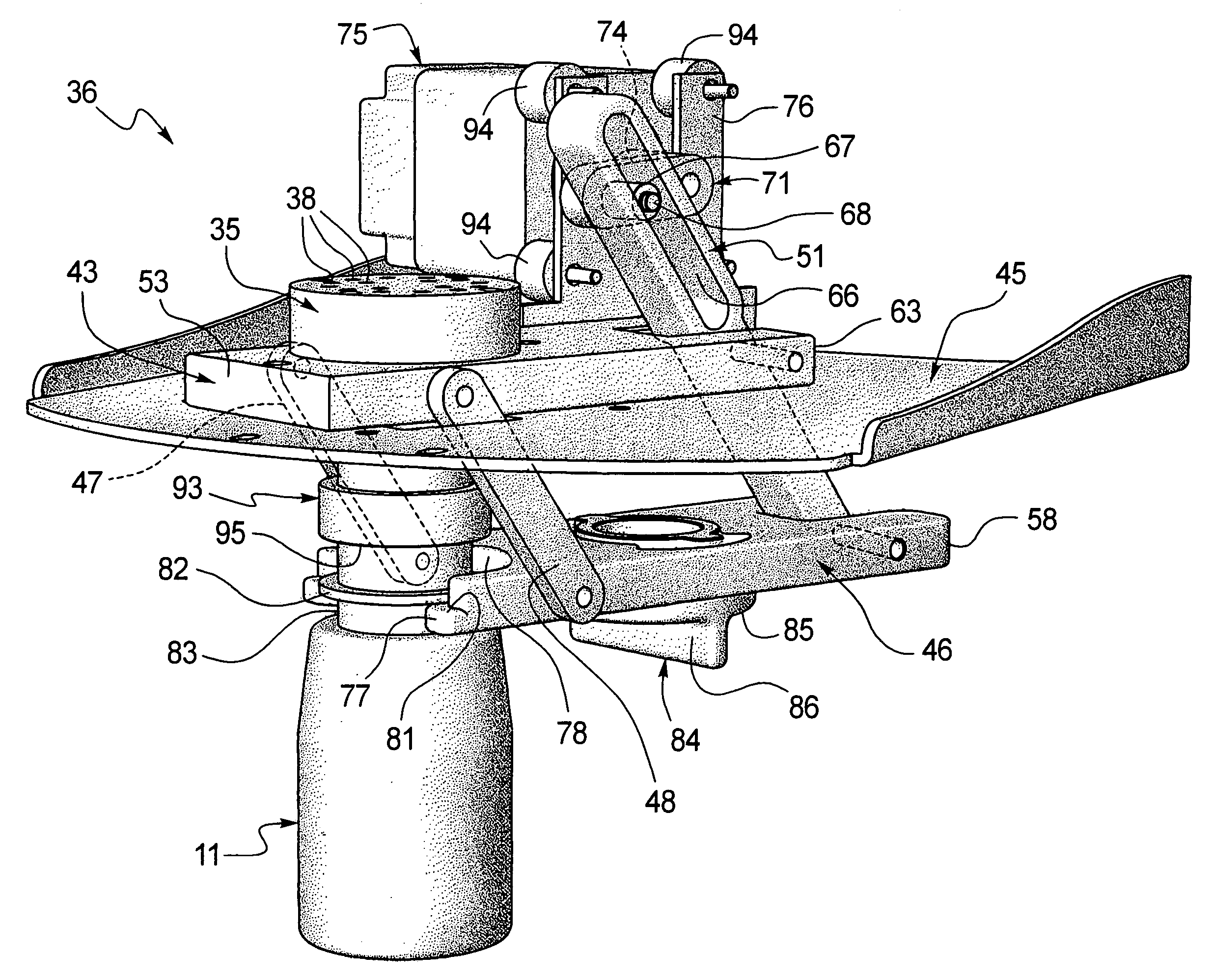

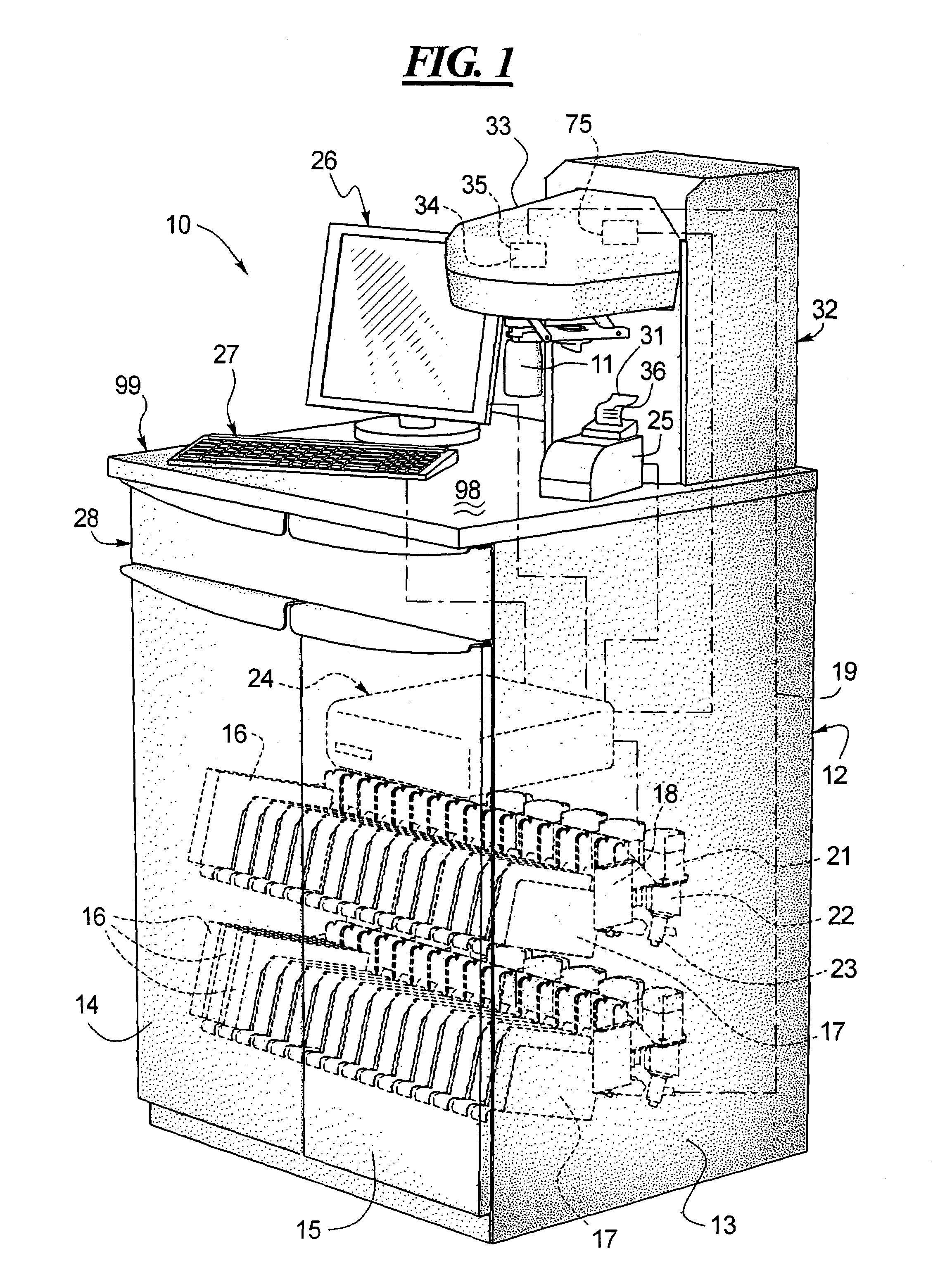

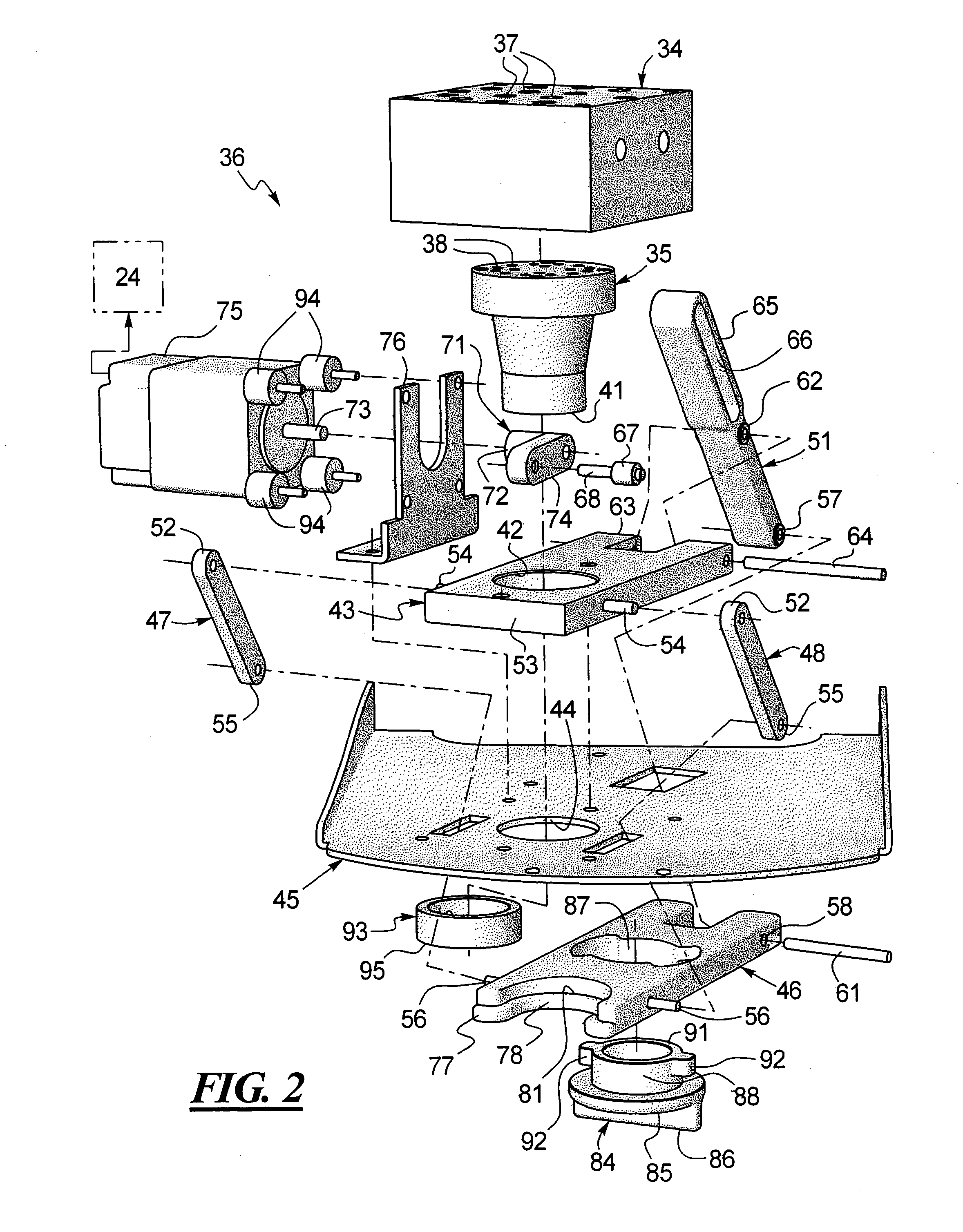

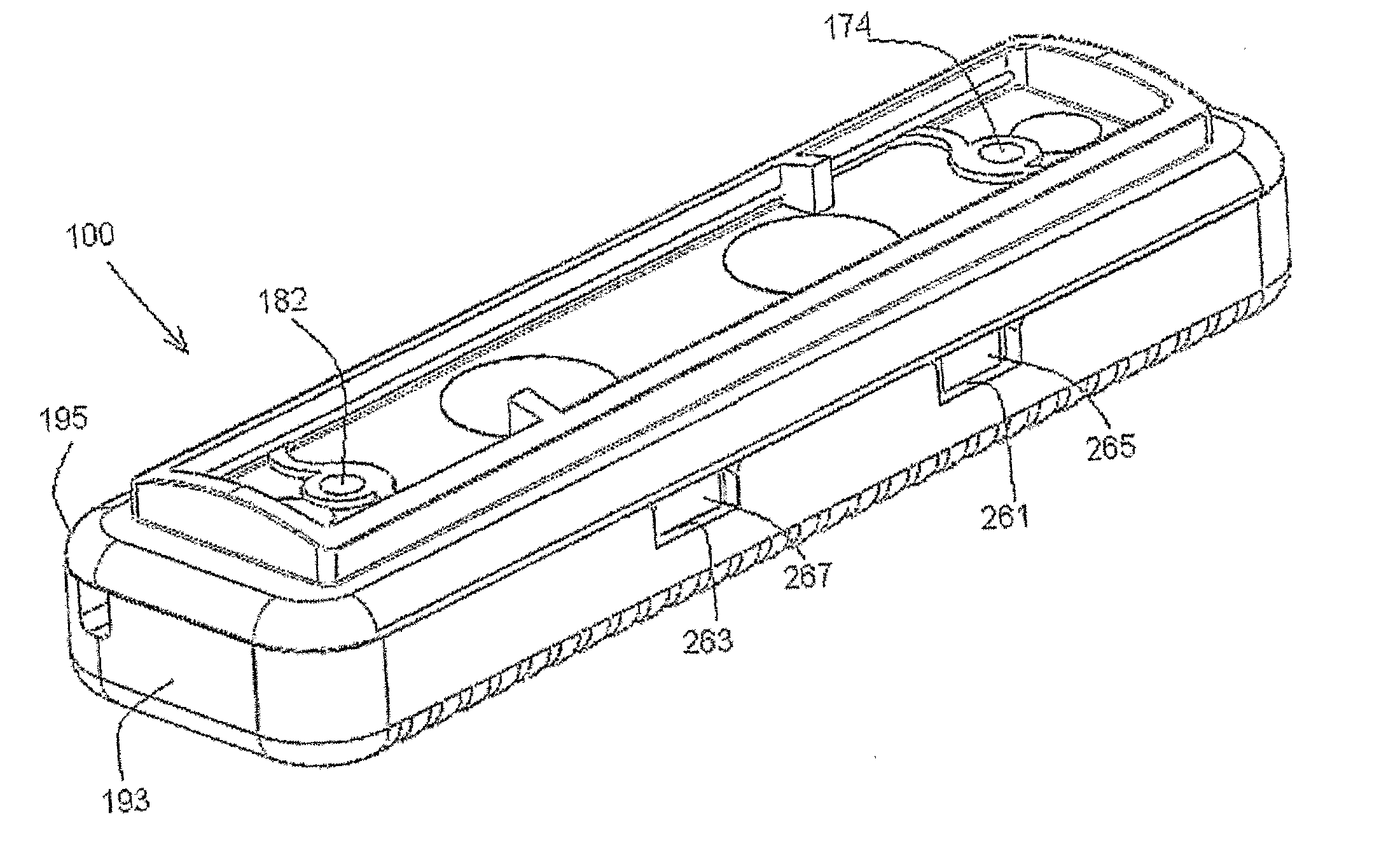

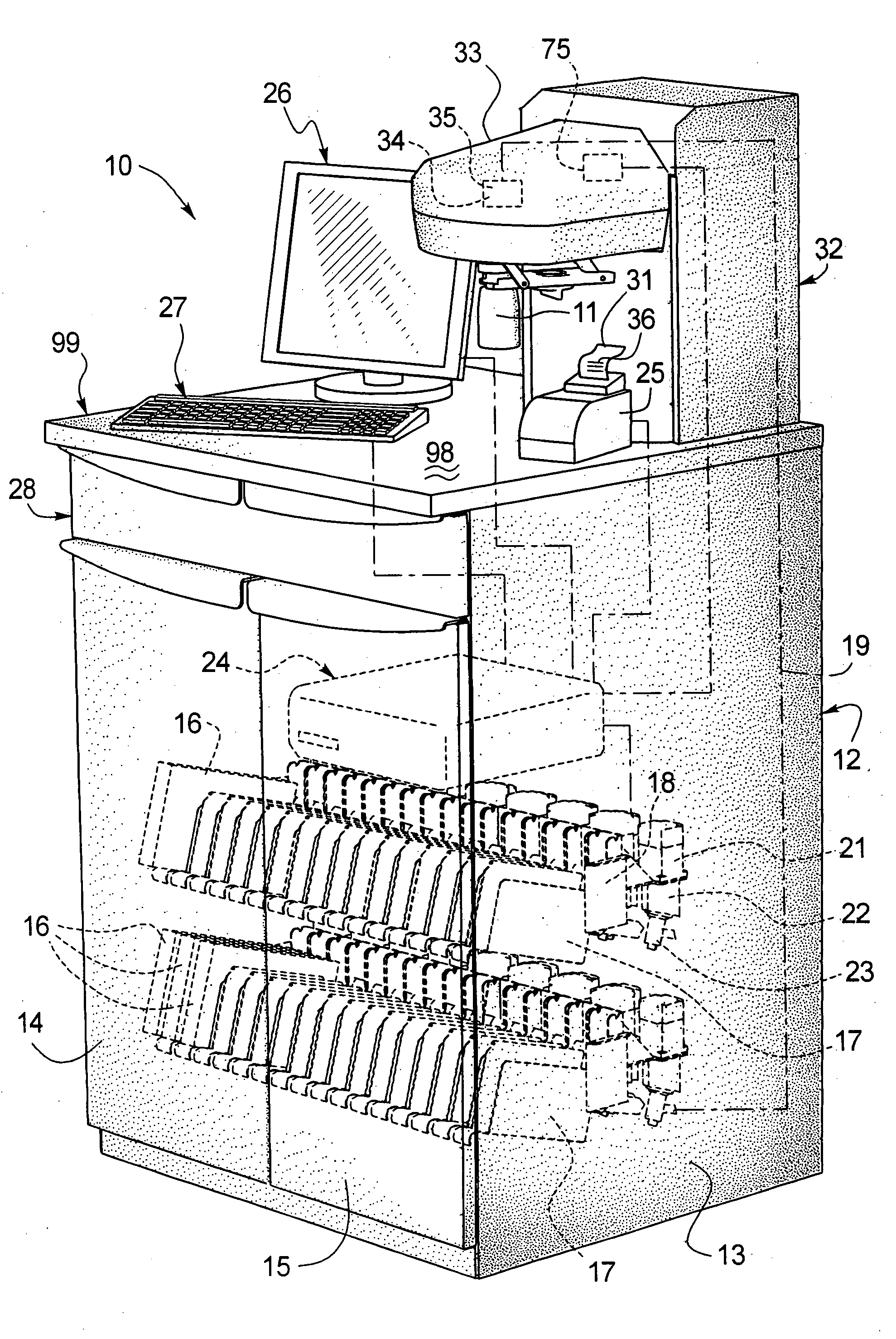

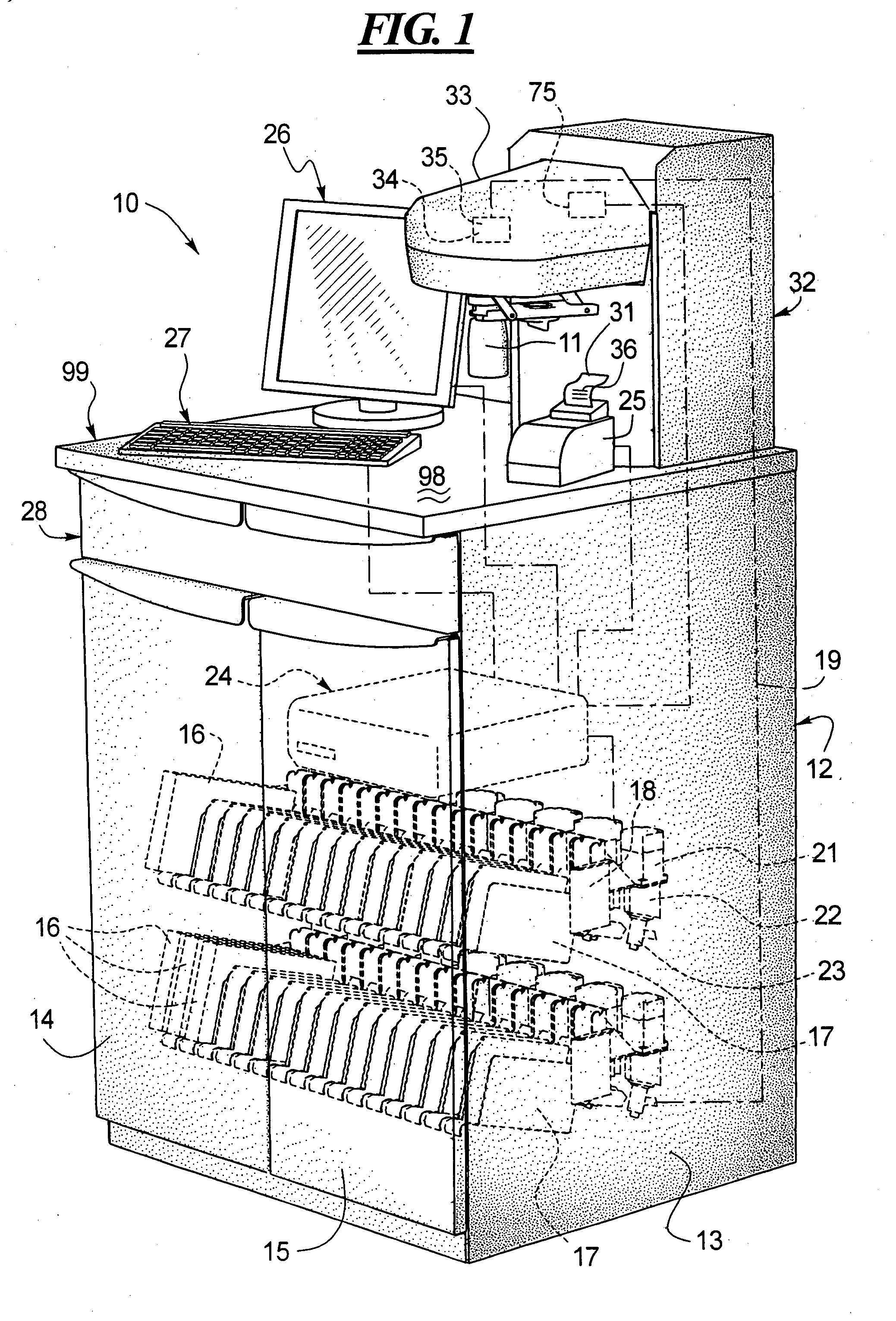

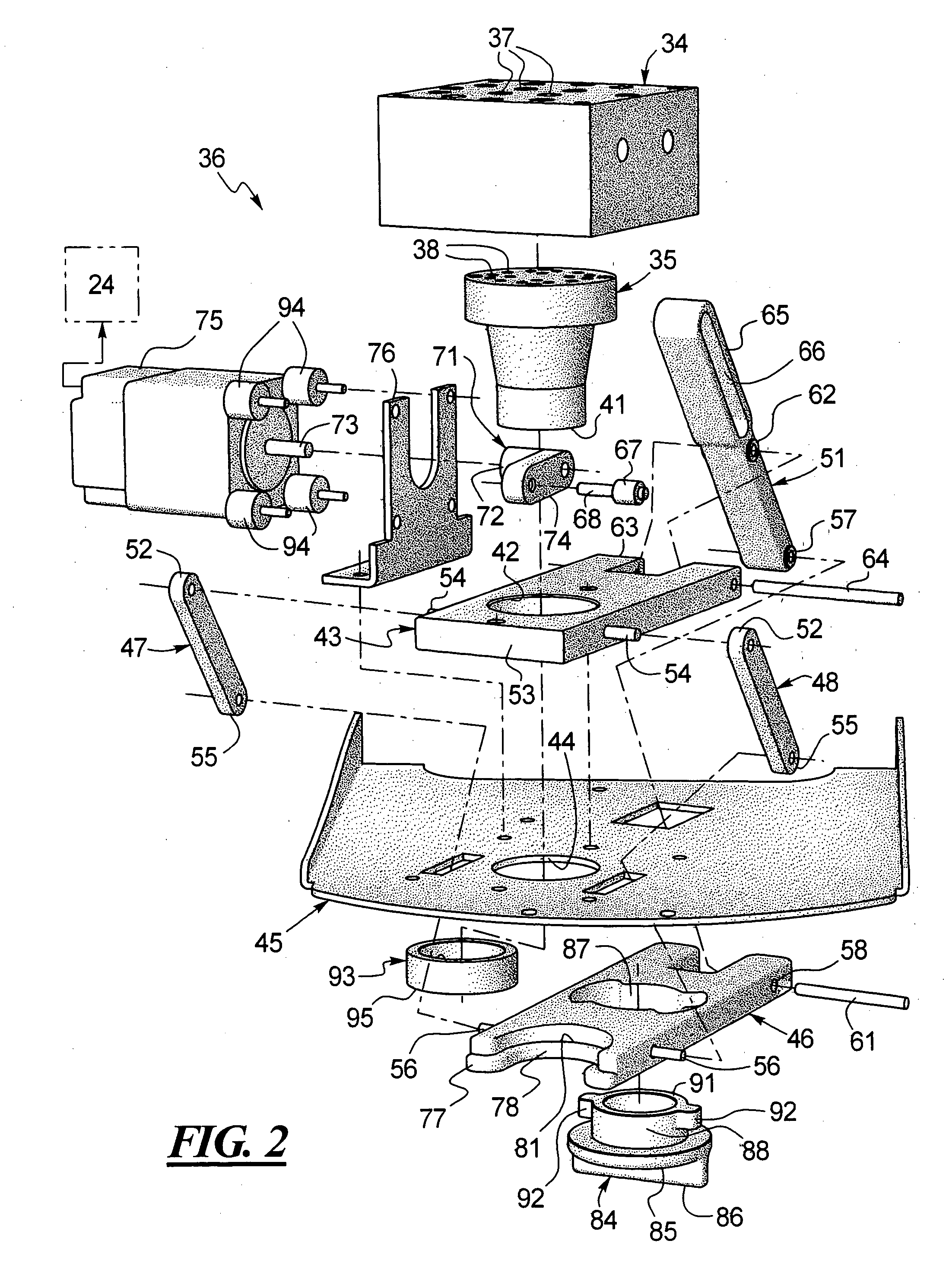

Apparatus for dispensing paint and stain samples and methods of dispensing paint and stain samples

ActiveUS7228879B2Eliminate needReduce and eliminate possibilityClosuresBarrels/casks fillingEngineeringNozzle

An improved fluid dispenser specially adapted to provide sample-size amounts of a fluid mixture is shown and described. An automated closure and seal system is provided for the manifold that moves, on command from a controller, from a closed or sealed position thereby limiting exposure of the manifold and fluid outlet nozzles from the ambient atmosphere, to a dispense system where a sample-size container is held up against and engaging a lower end of the manifold for a sealing element disposed on a lower portion of the manifold. When the dispense is complete, the system automatically moves back toward a closed position where the filled container is held open and ready to be removed by a technician before it is capped and labeled.

Owner:FLUID MANAGEMENT LLC

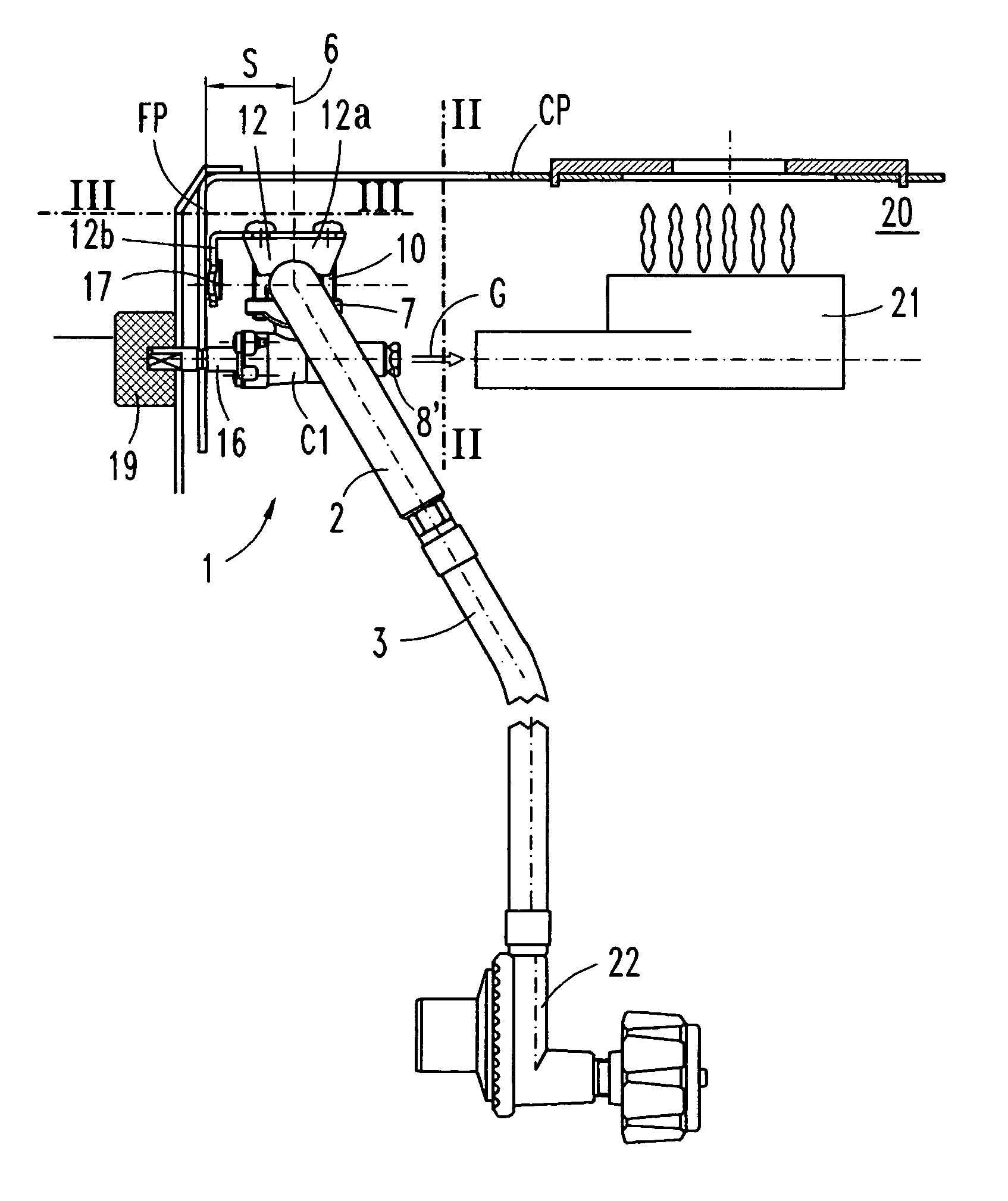

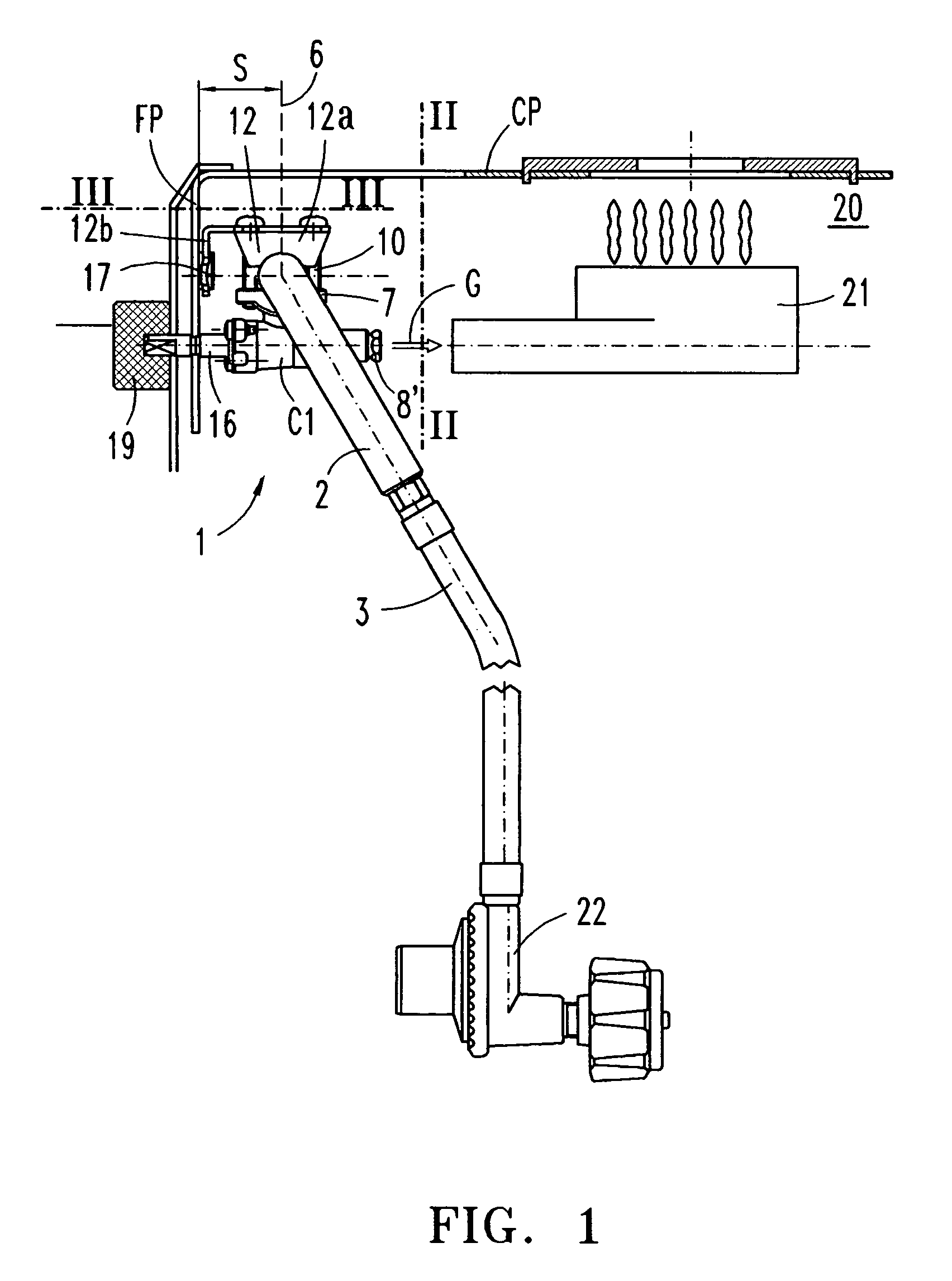

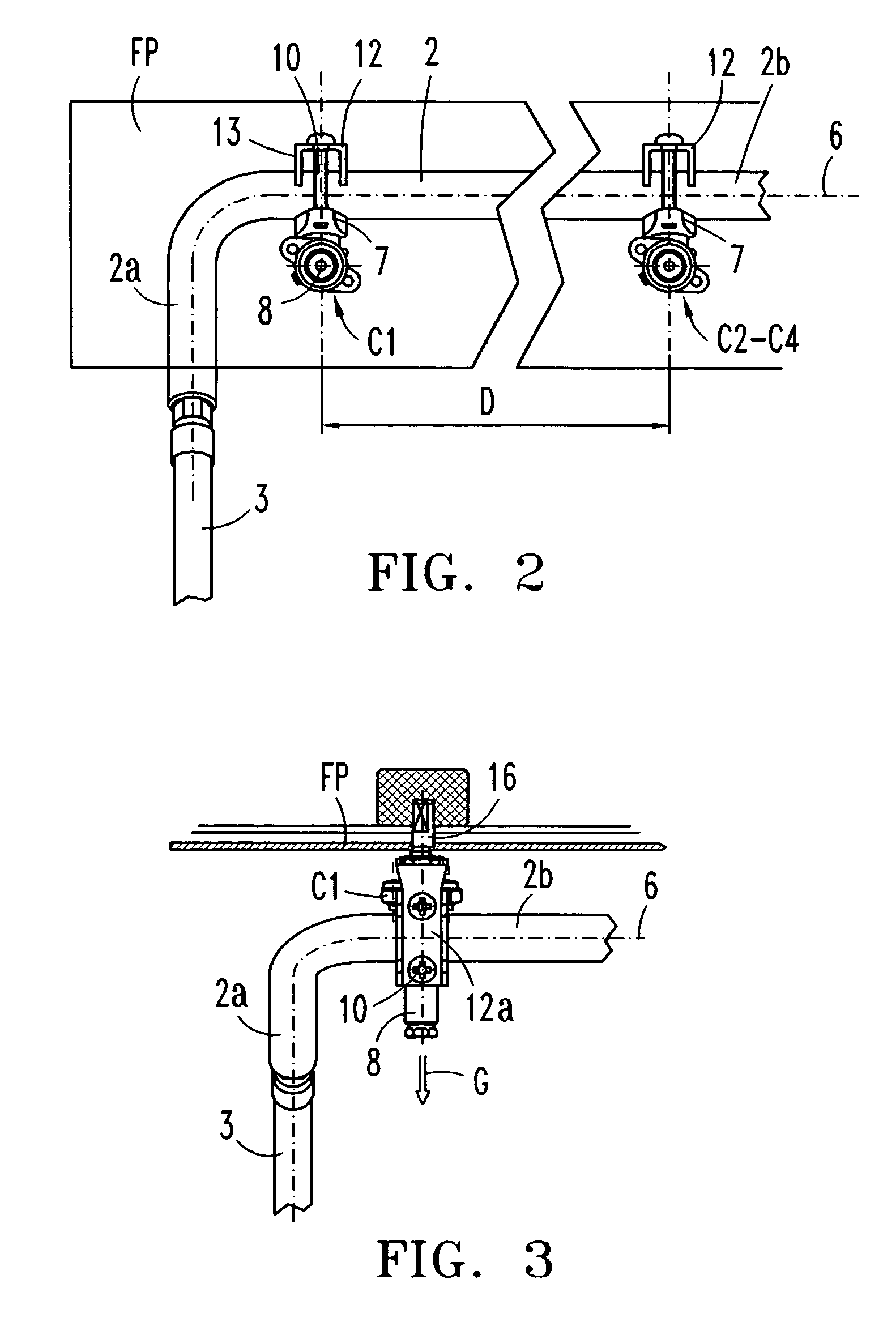

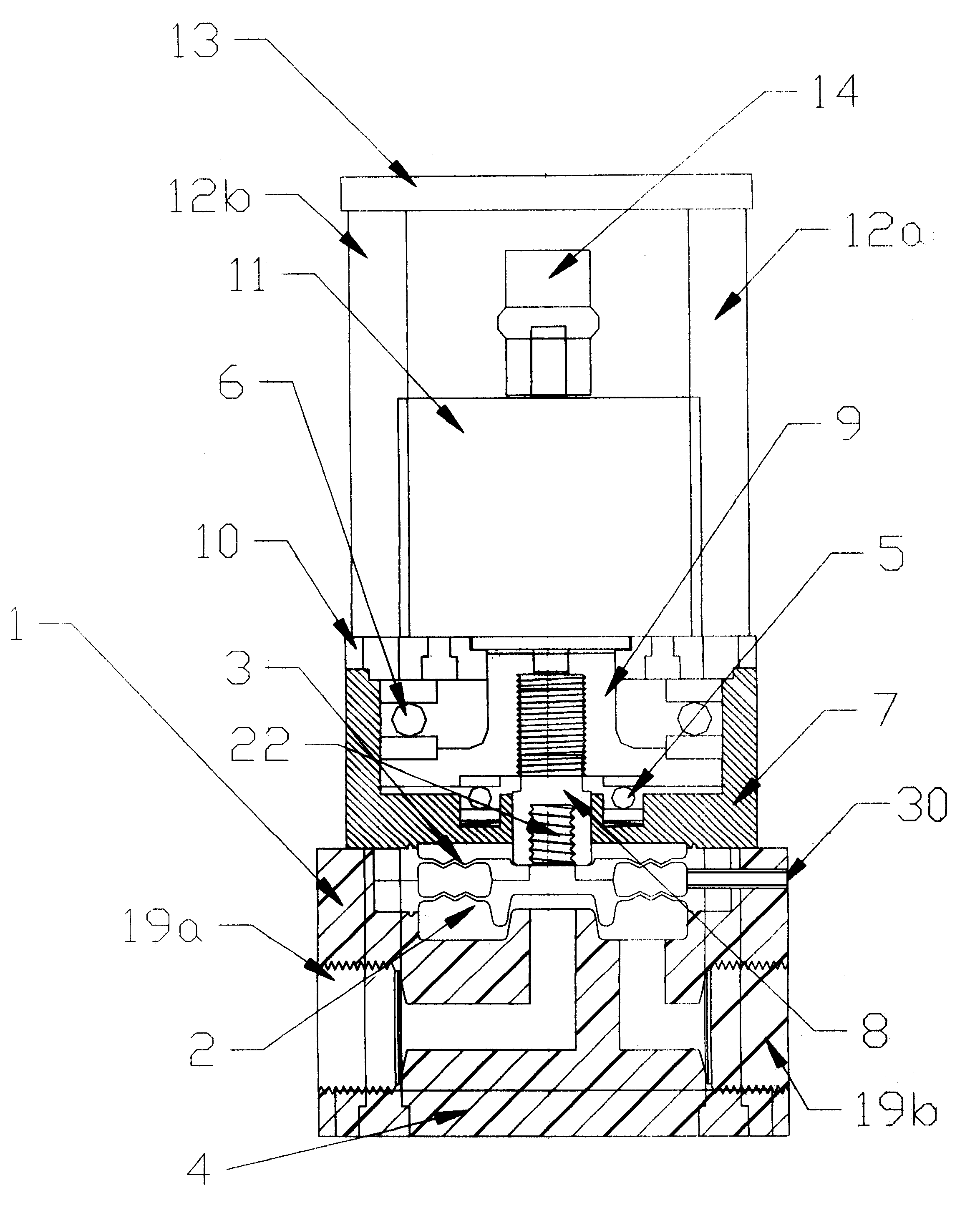

Gas manifold assembly with a mounting device in a cooking appliance

InactiveUS7299799B2Simple configurationEasy to installDomestic stoves or rangesLighting and heating apparatusCombustorDrive shaft

The gas manifold assembly (1) is adapted to a cooking appliance for supplying the burners (21) thereof, and is equipped with various taps (C1-C4) of the rotary type, installed on a elongated tubular-shaped manifold conduit (2), which is disposed parallel to the front wall (FP) of the appliance and supported on it. The taps (C1-C4) have a respective installation seat (7) with a built-in gas intake connected to the elongated conduit (2), and mounting is carried out by means of a one-piece mounting device (12), which in turn has an integral means (12b) for supporting and fastening the manifold assembly (1) to the front wall (FP), for which purpose the aligned tap drive shafts (16) stand proud of the front wall (FP) and the tap outlet conduits (8) face and adjoin their respective burner (21).

Owner:COPRECITEC

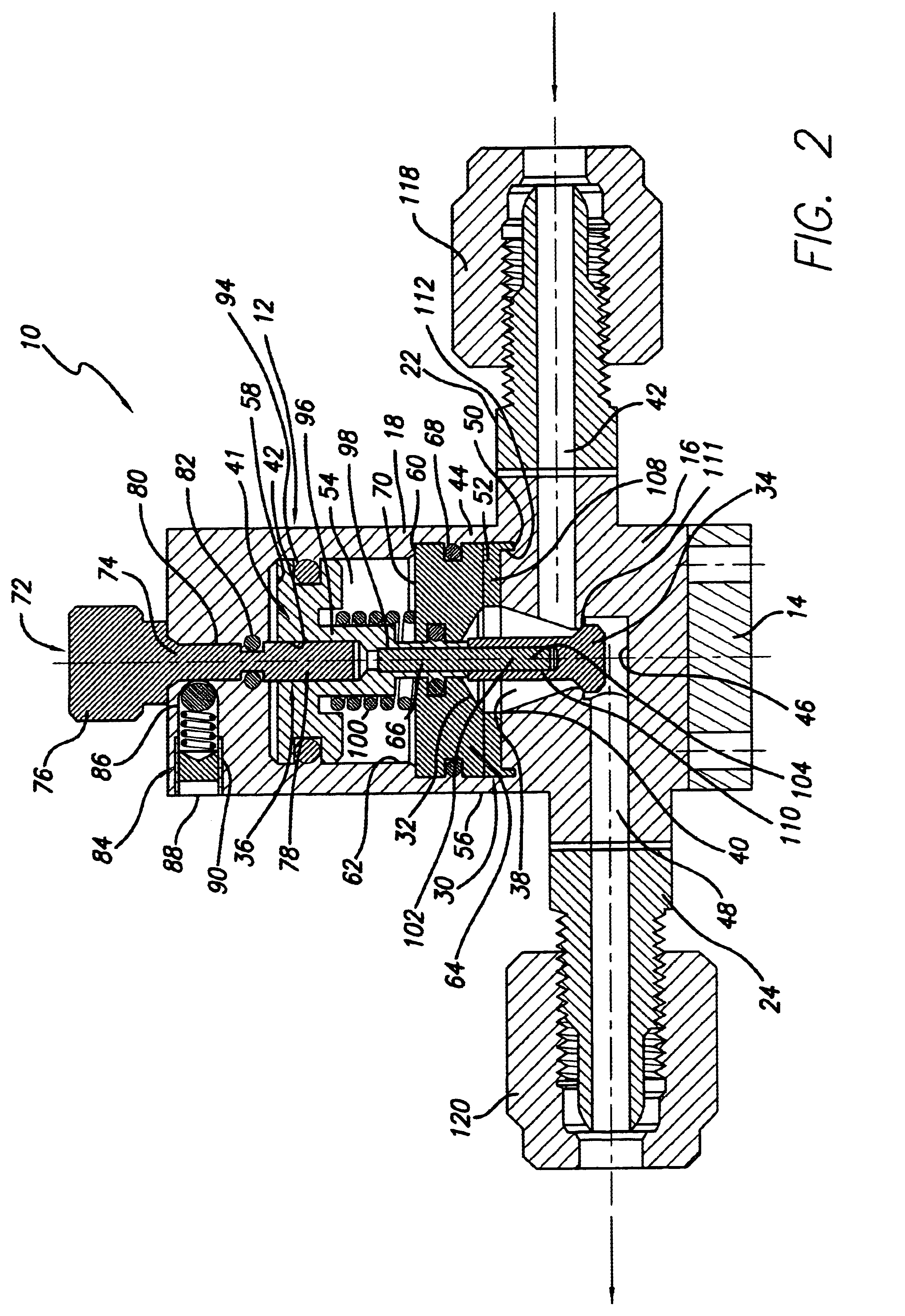

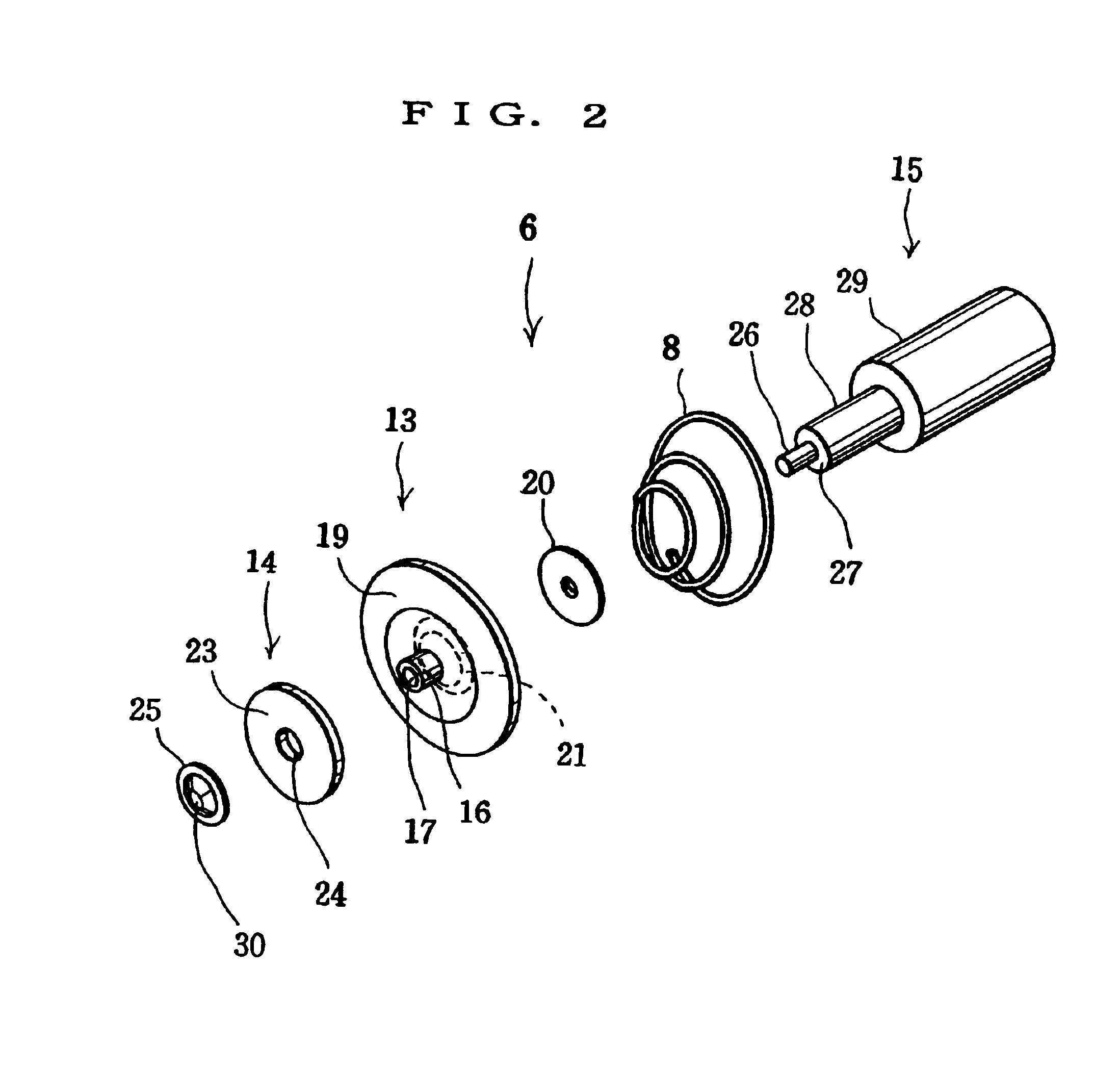

Double diaphragm precision throttling valve

InactiveUS6321776B1Conservative marginMinimize backlashDiaphragm valvesOperating means/releasing devices for valvesFluid controlDiaphragm seal

A throttling valve assembly actuated by a stepper motor having a double diaphragm seal and integral throttling surface. The throttling surface interfaces to a mating orifice and port arrangement to provide a smooth control regime for various process fluids. Because of the unique design of the flow paths the fluids will remain in a laminar flow state throughout the throttling range, thus providing smooth and continuous response to the control input. The valve opening to the fluid controlled by a stepper motor through a direct drive mechanism. The embodiment shown here employees all PTFE construction for the wetting parts, but any material could be used that would be compatible with the process fluid. Additional features are minimal capture of the process fluid, free draining, and no metallic parts in close communication with the process fluid.

Owner:ENTEGRIS INC

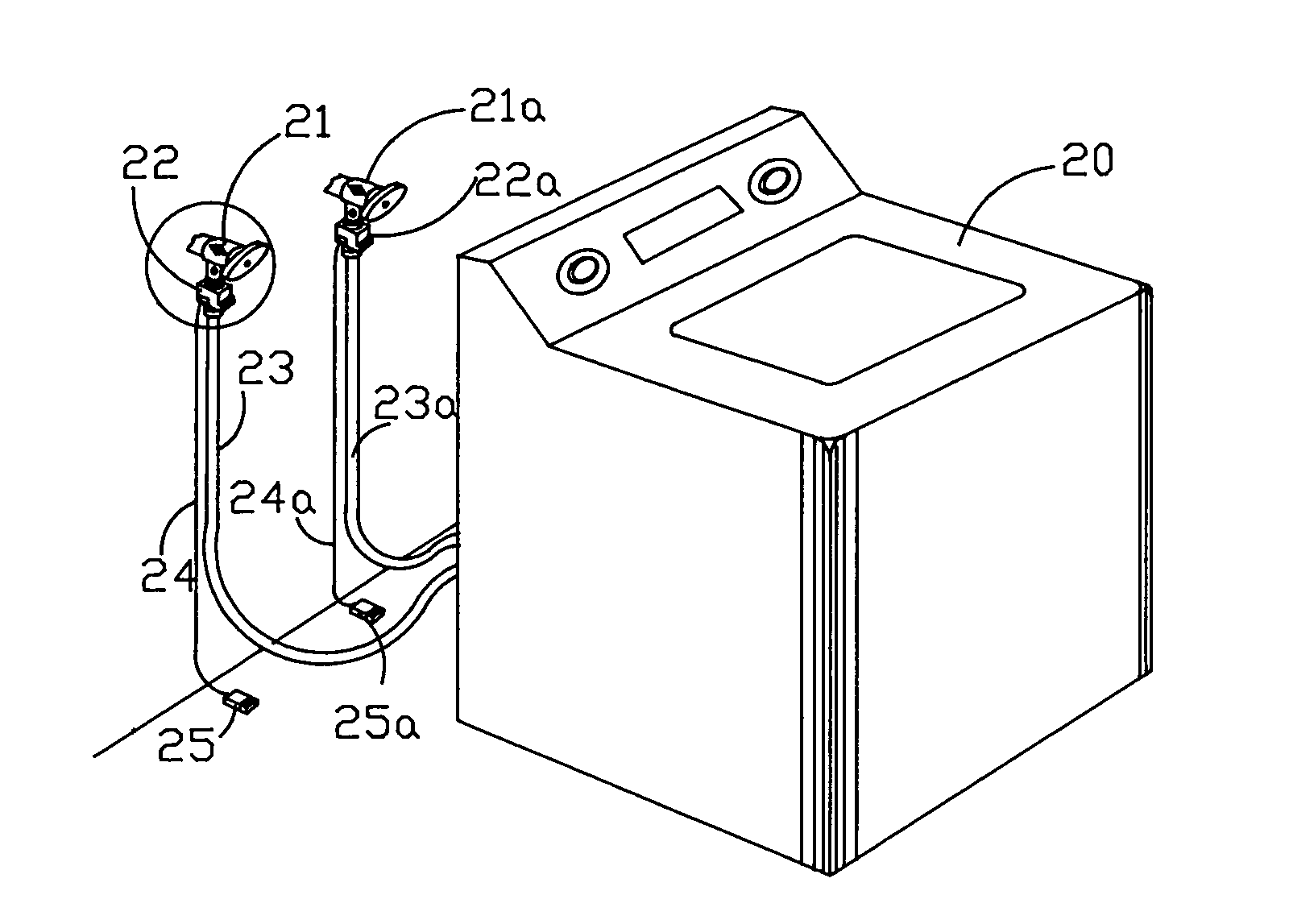

Apparatus and method for protection against appliance leaking

A water protection system apparatus for detecting and stopping a flow of water which includes a power supply, a water ionization switch, and a controlled valve assembly. The water ionization switch selectively conducts electricity when exposed to water and includes an initially dry non-conductive crystallized compound. The compound ionizes when exposed to water to form an electrolyte which conducts electricity. This switch is connected to a controlled valve assembly to stop the flow of water in response to the detection of water by the switch. Other refinements include modifications to the switch housing and condition indicators for monitoring the system and signaling water detection and shutdown operations.

Owner:STAY DRY INT

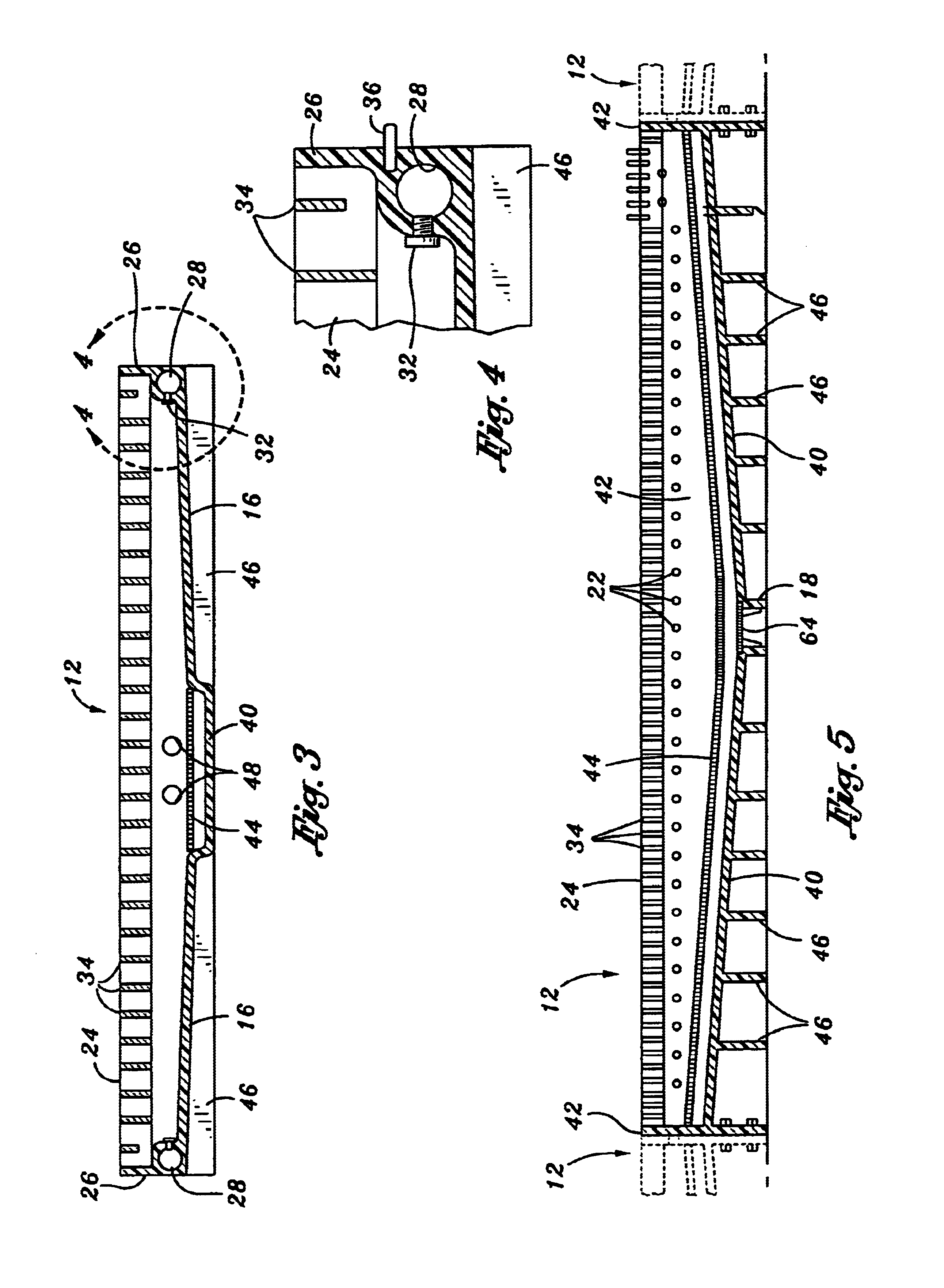

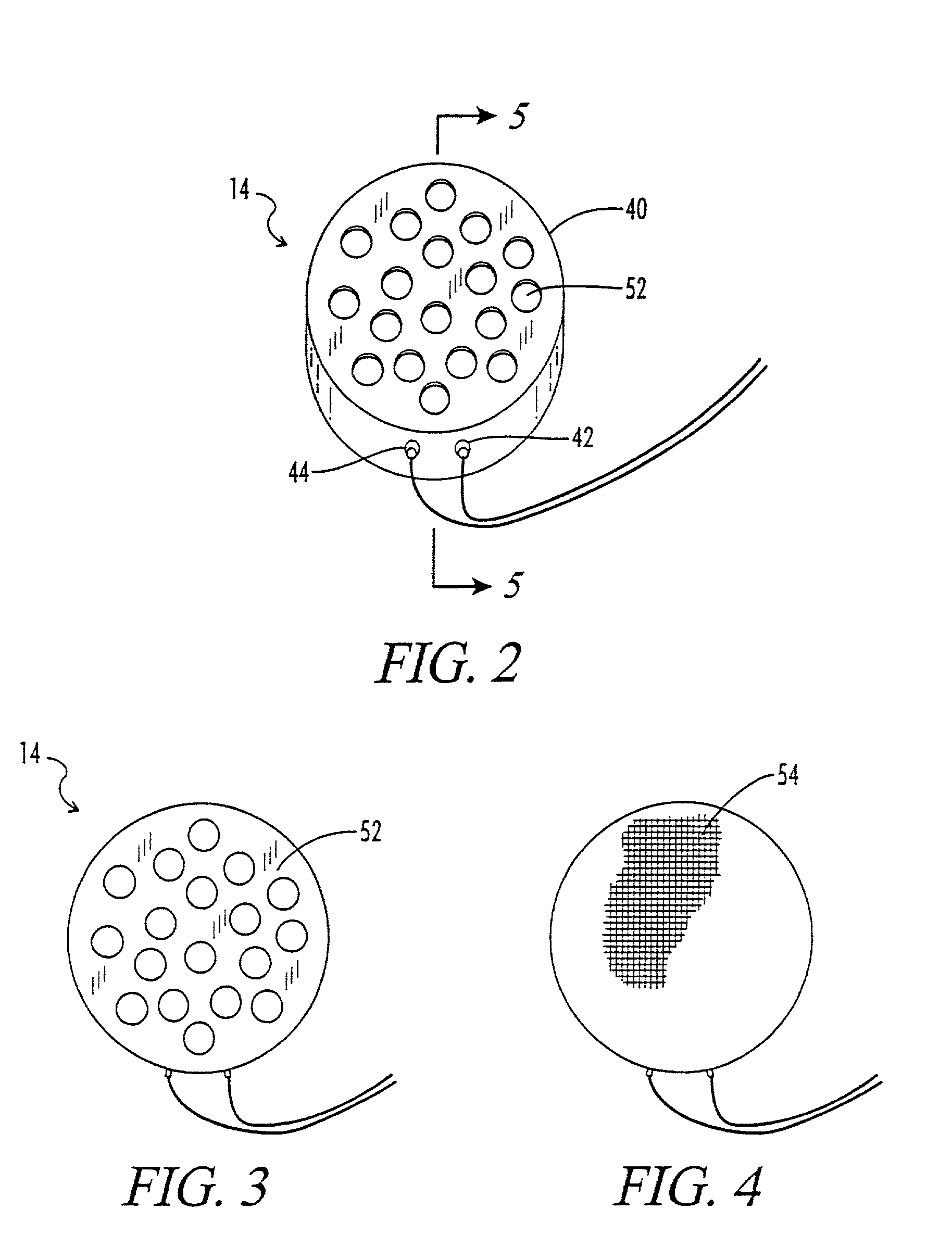

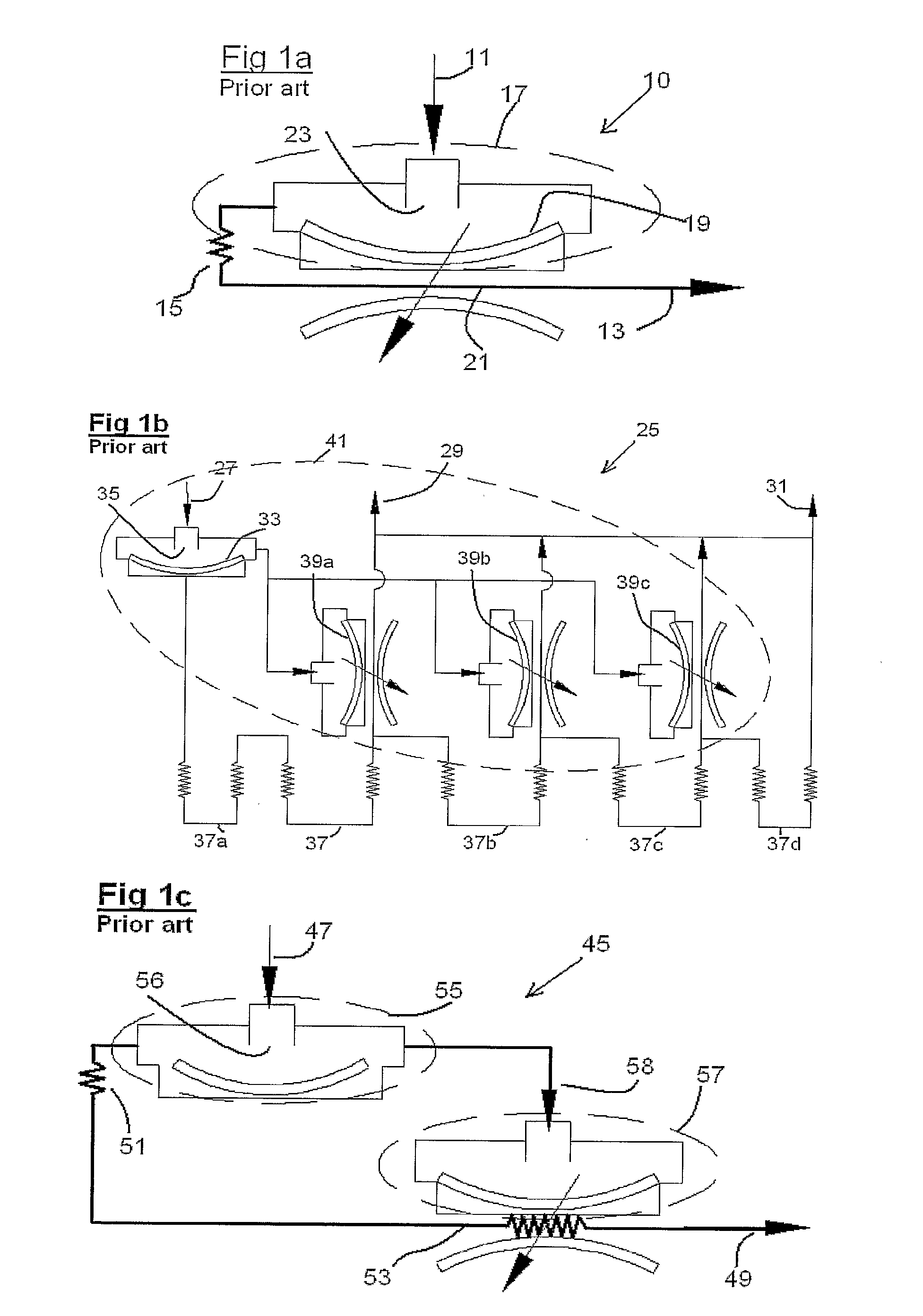

Drip emitter with an independent non-drain valve

An elastomer membrane based, regulated drip emitter unit, equipped with a non-drip valve, wherein the drip emitter is characterized by that it includes an opening that is exposable to an approximate atmospheric pressure that prevails on the water outlet from the drip emitter; and an additional elastomer membrane portion that is strained and biased against the water inlet opening of the drip emitter for creating a seal with its one side for a non-drain valve and on its other (second) side it is connected to that atmospheric pressure prevailing opening, and wherein the elastomer membrane portion is movable towards that opening in order to open the water inlet opening for enabling a water flow passage from a water supply conduit to the drip emitter, and this from the specific instant that the force exerted by the water pressure prevailing in the water supply conduit on one side of that elastomer portion, overcomes the strain at which that portion was strained and biased against the water inlet opening, as well as the approximate atmospheric pressure that prevails on the other side of that elastomer portion.

Owner:RIVULIS PLASTRO LTD

Drip emitter with an independent non-drain valve

An elastomer membrane based, regulated drip emitter unit, equipped with a non-drip valve, wherein the drip emitter is characterized by that it includes an opening that is exposable to an approximate atmospheric pressure that prevails on the water outlet from the drip emitter; and an additional elastomer membrane portion that is strained and biased against the water inlet opening of the drip emitter for creating a seal with its one side for a non-drain valve and on its other (second) side it is connected to that atmospheric pressure prevailing opening, and wherein the elastomer membrane portion is movable towards that opening in order to open the water inlet opening for enabling a water flow passage from a water supply conduit to the drip emitter, and this from the specific instant that the force exerted by the water pressure prevailing in the water supply conduit on one side of that elastomer portion, overcomes the strain at which that portion was strained and biased against the water inlet opening, as well as the approximate atmospheric pressure that prevails on the other side of that elastomer portion.

Owner:RIVULIS PLASTRO LTD

Metered drop push button dispenser system

InactiveUS7874467B2Prevent backflowLess elasticPackage recyclingCheck valvesPreservative freeEngineering

Owner:RESEAL INT

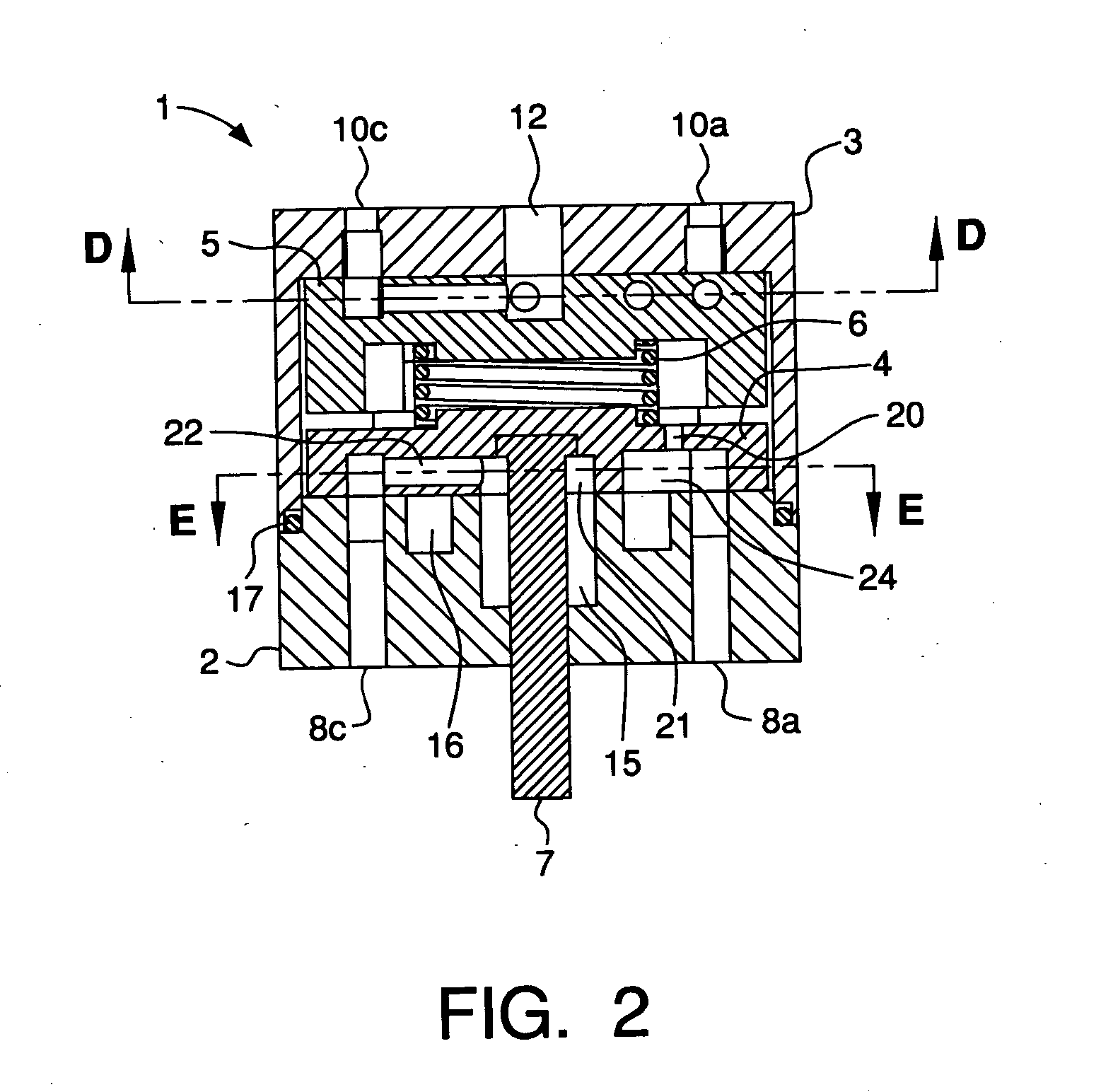

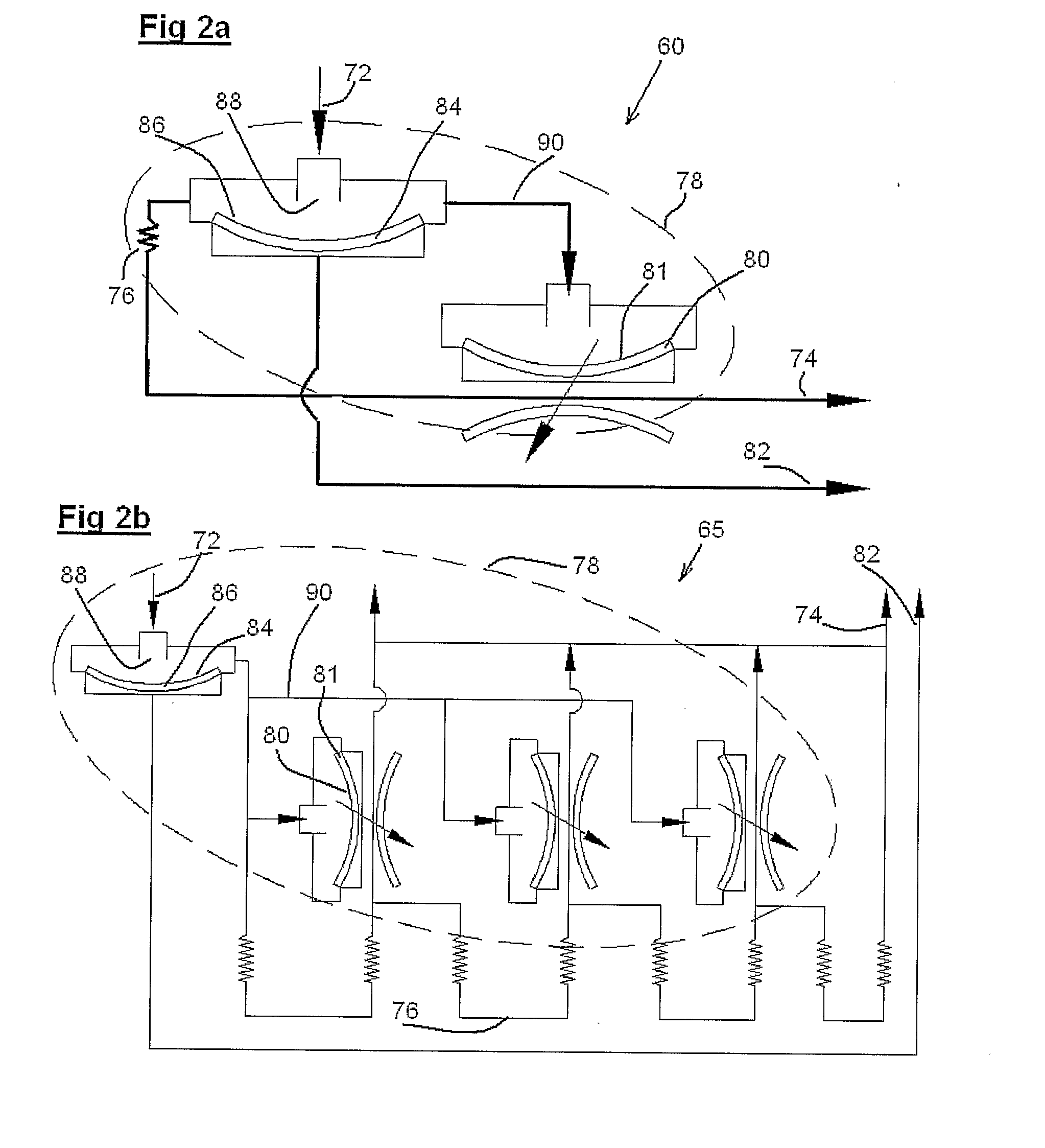

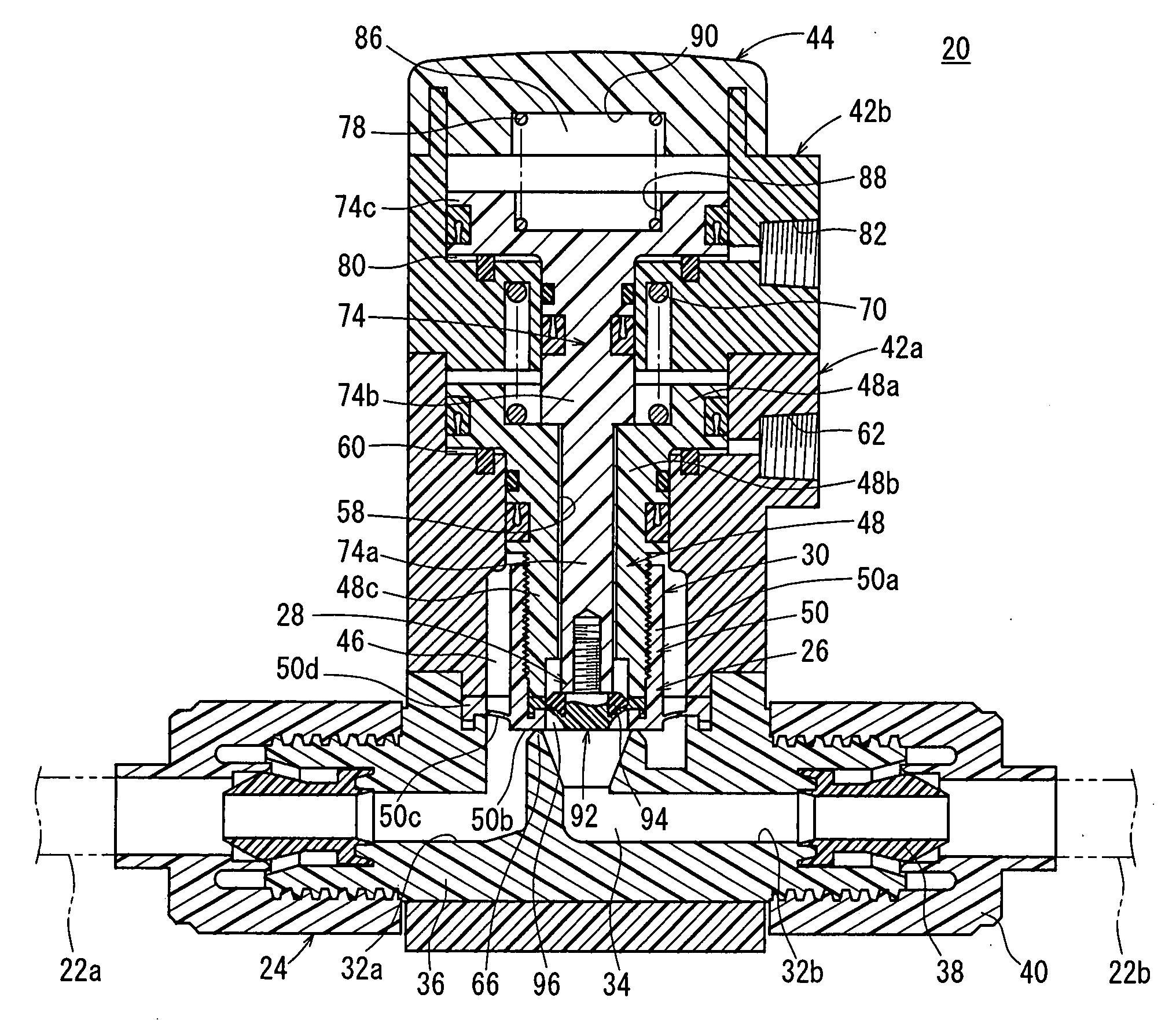

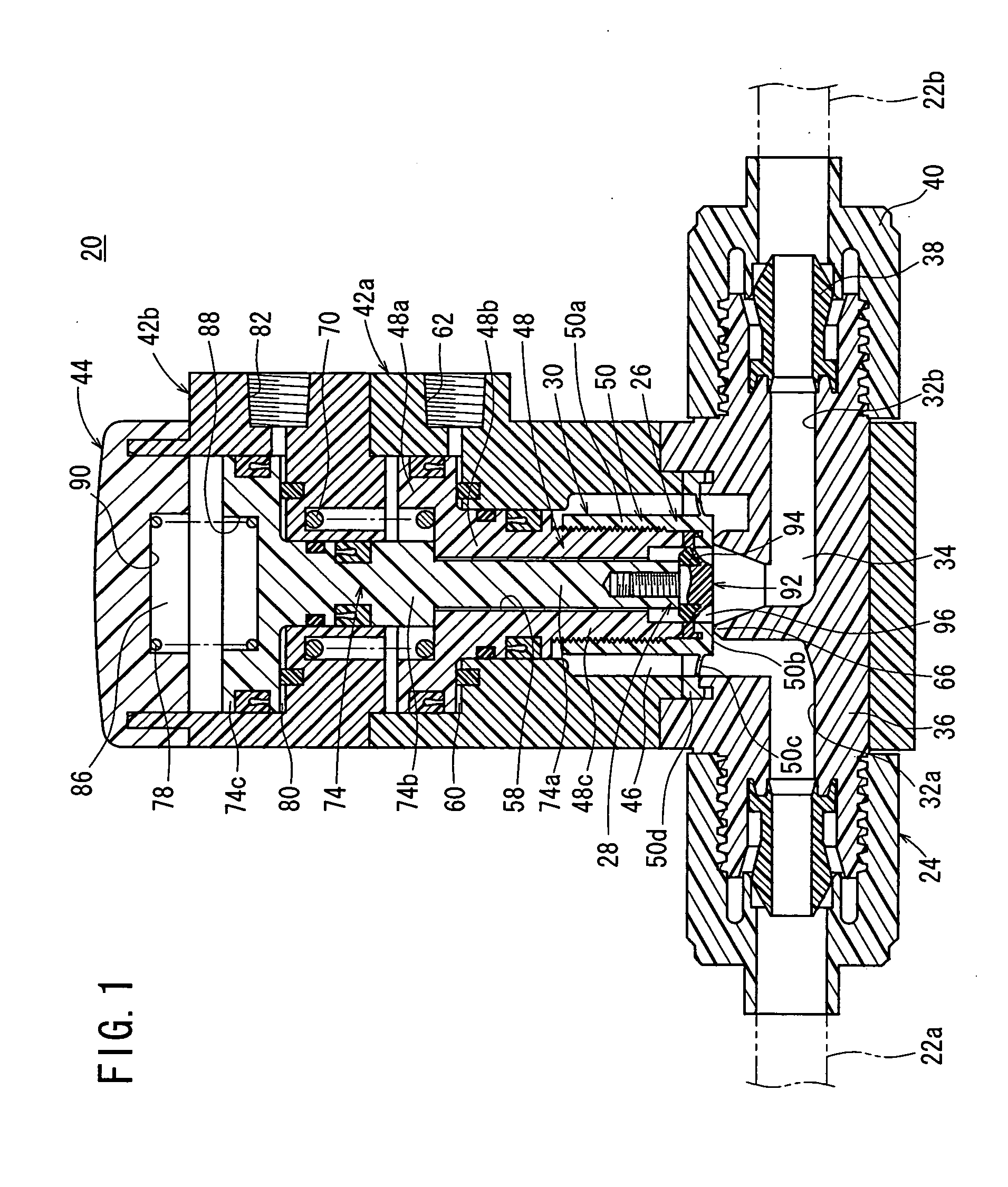

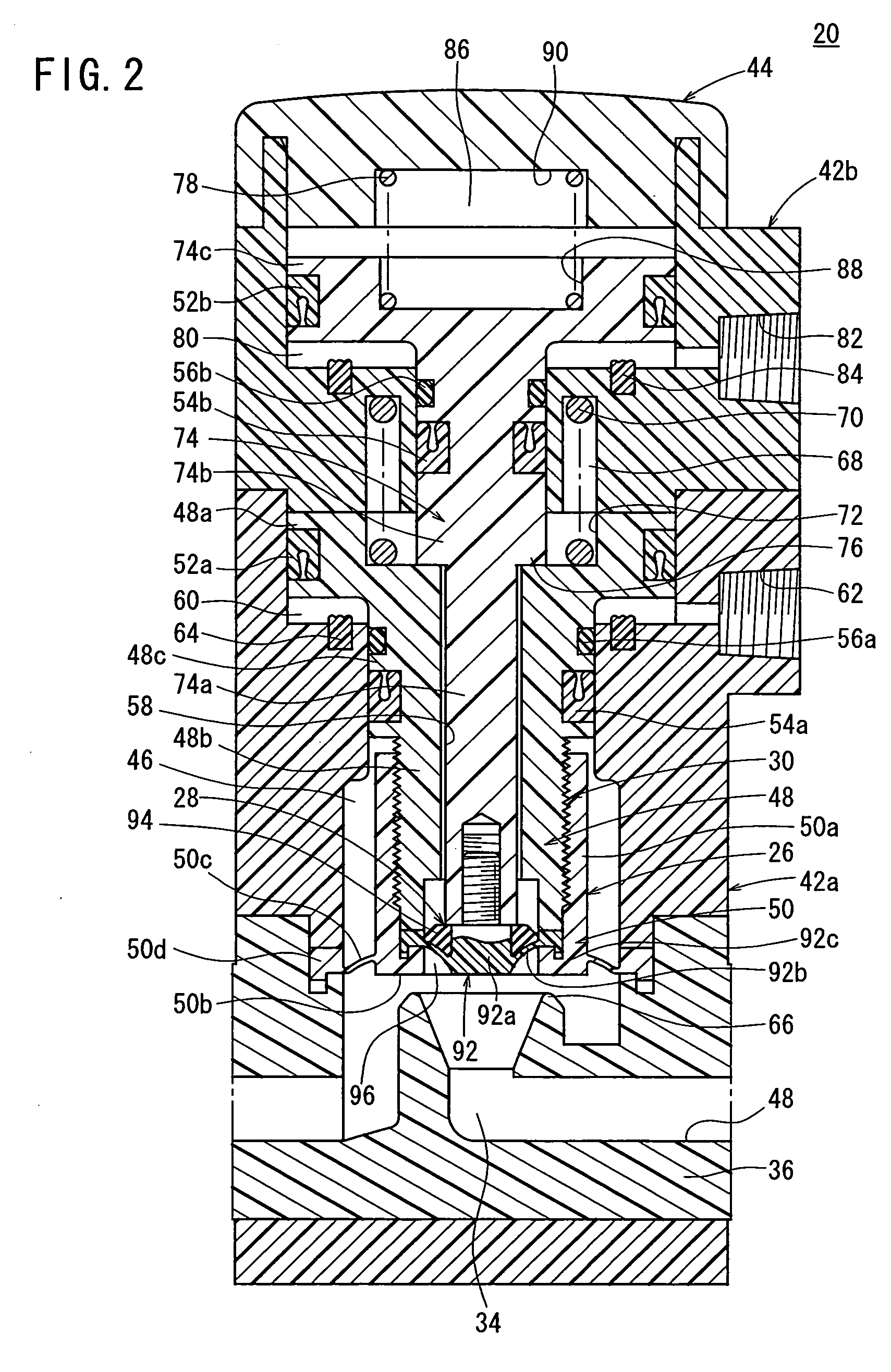

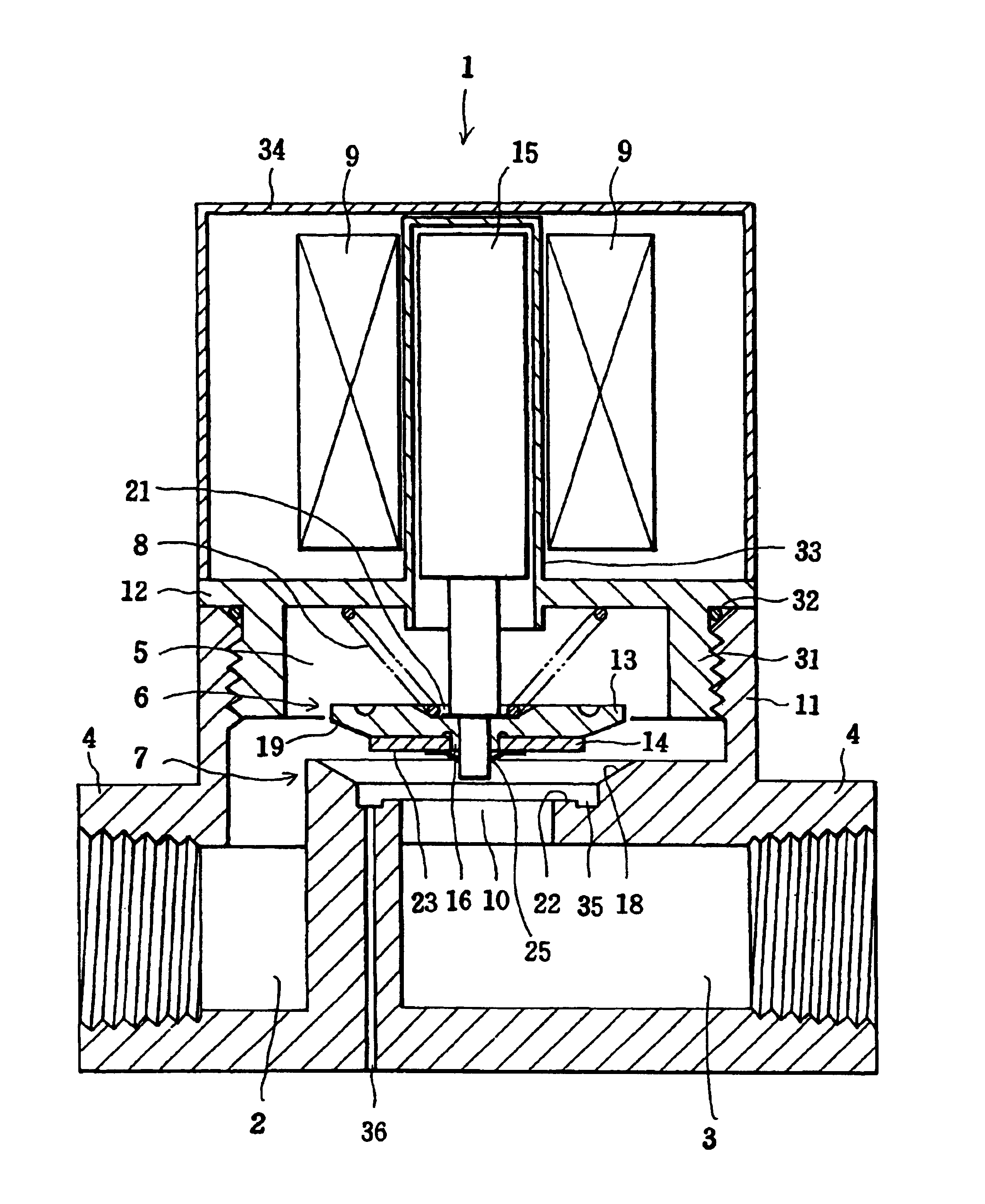

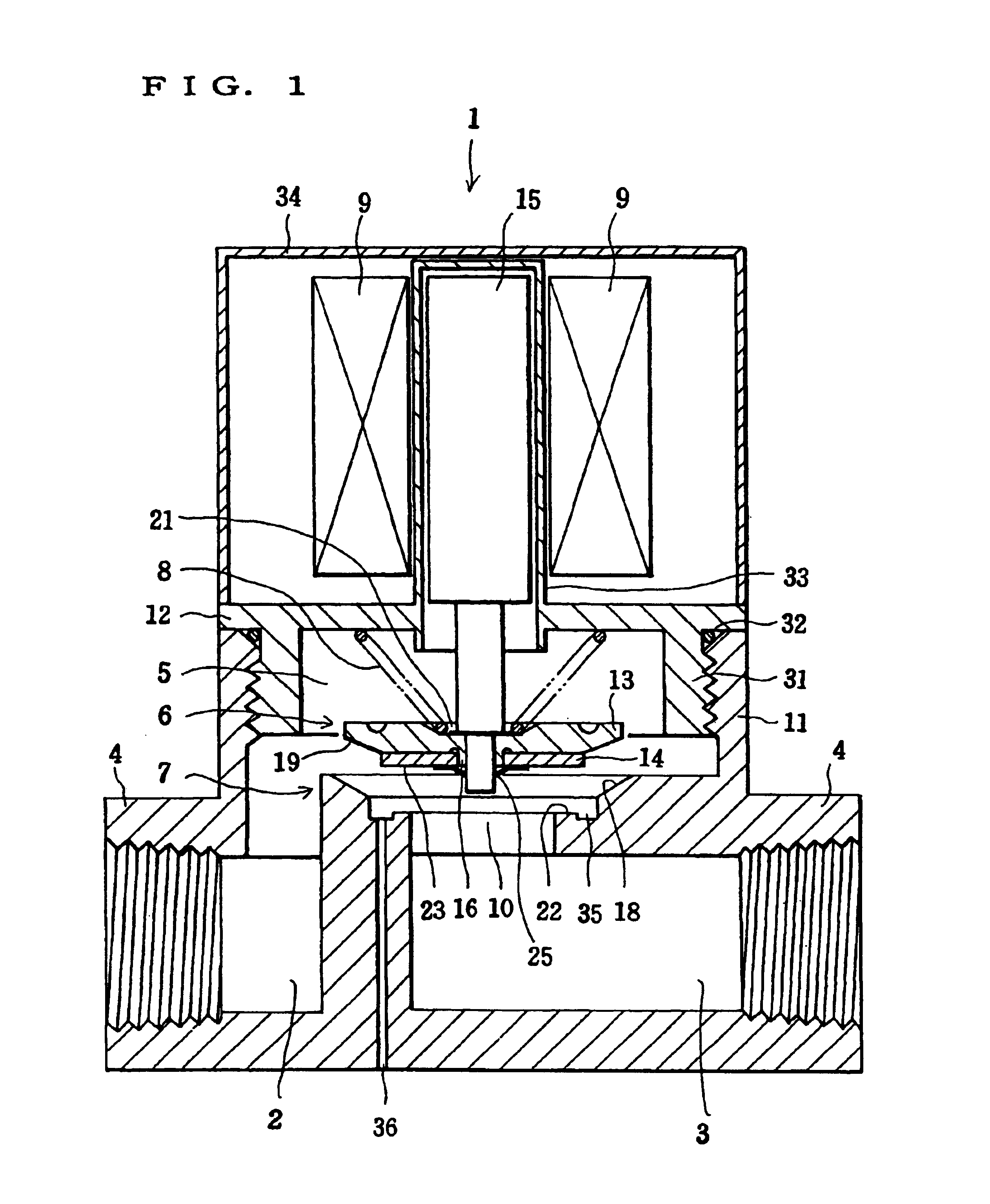

Suck back valve

ActiveUS20050006609A1Reduced space required for installationSmall sizeLiquid surface applicatorsSemiconductor/solid-state device manufacturingEngineeringPiston

A suck back valve includes an ON / OFF valve mechanism which opens / closes a fluid passage by displacing a valve member together with a first piston under an action of a pressure fluid supplied into a first cylinder chamber, and a suck back mechanism which has a suction member formed deformably in a flow chamber to suck a pressure fluid contained in the fluid passage by displacing the suction member together with a second piston under an action of the pressure fluid supplied to a second cylinder chamber. The ON / OFF valve mechanism and the suck back mechanism are assembled coaxially and integrally.

Owner:SMC CORP

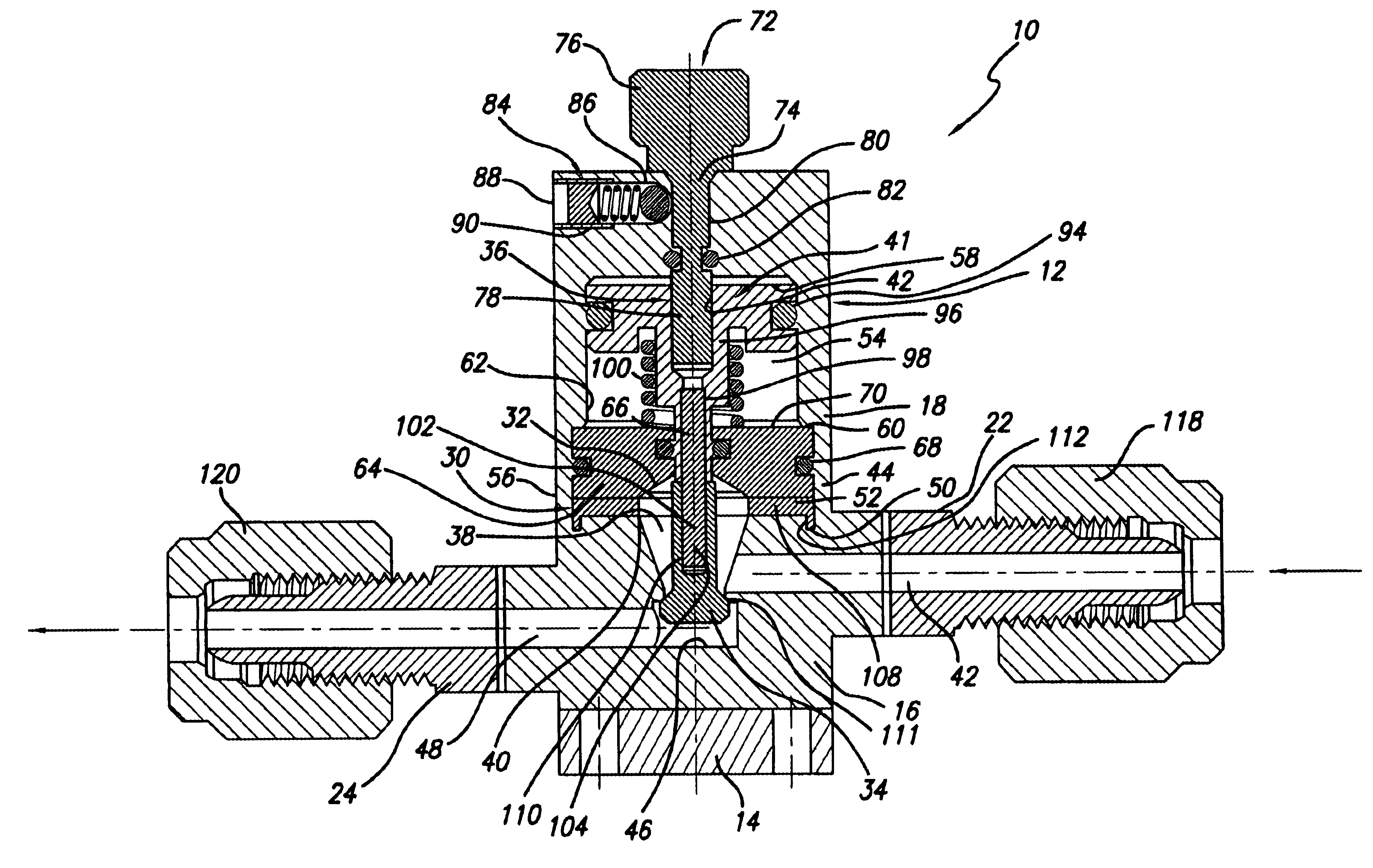

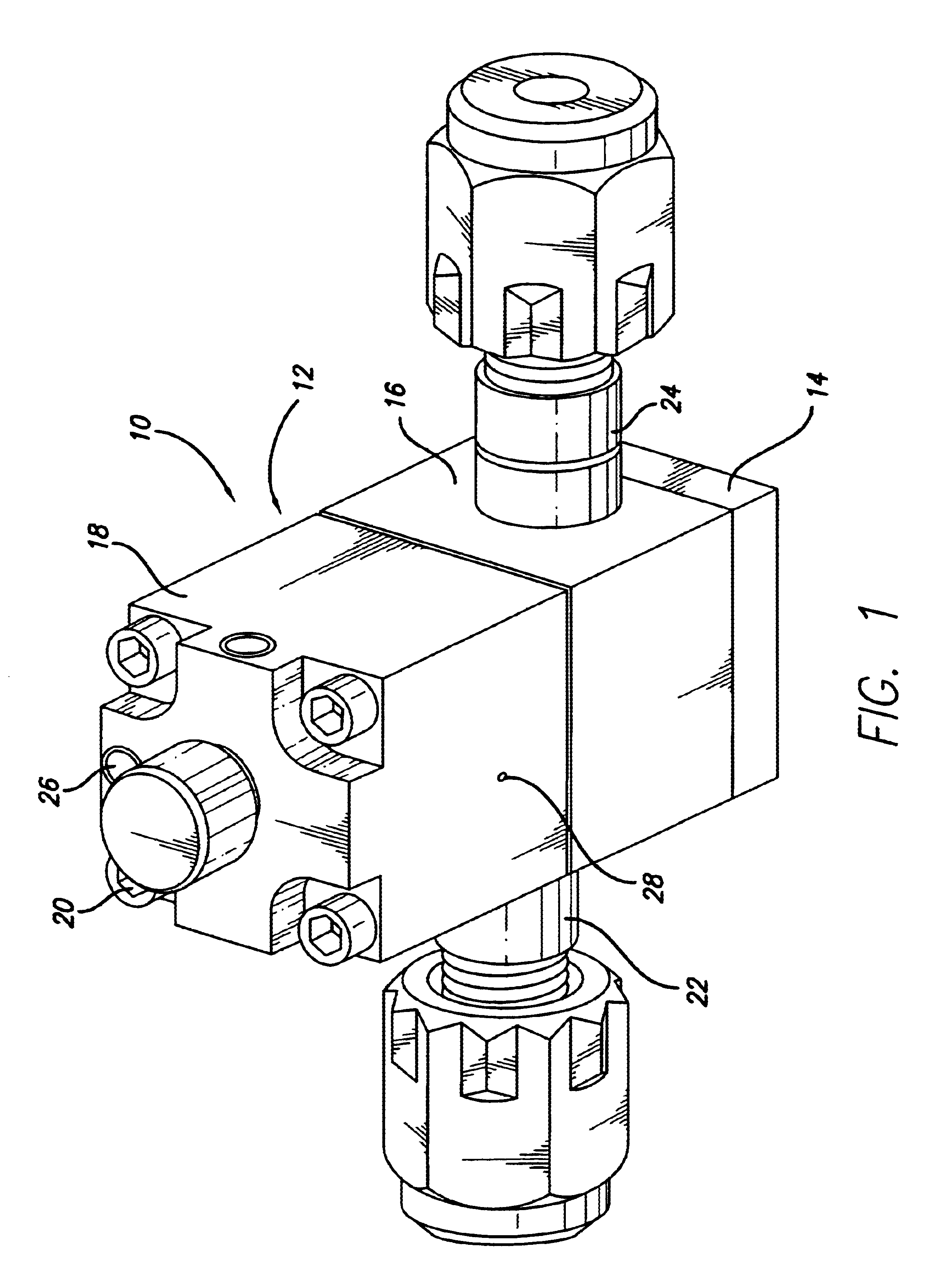

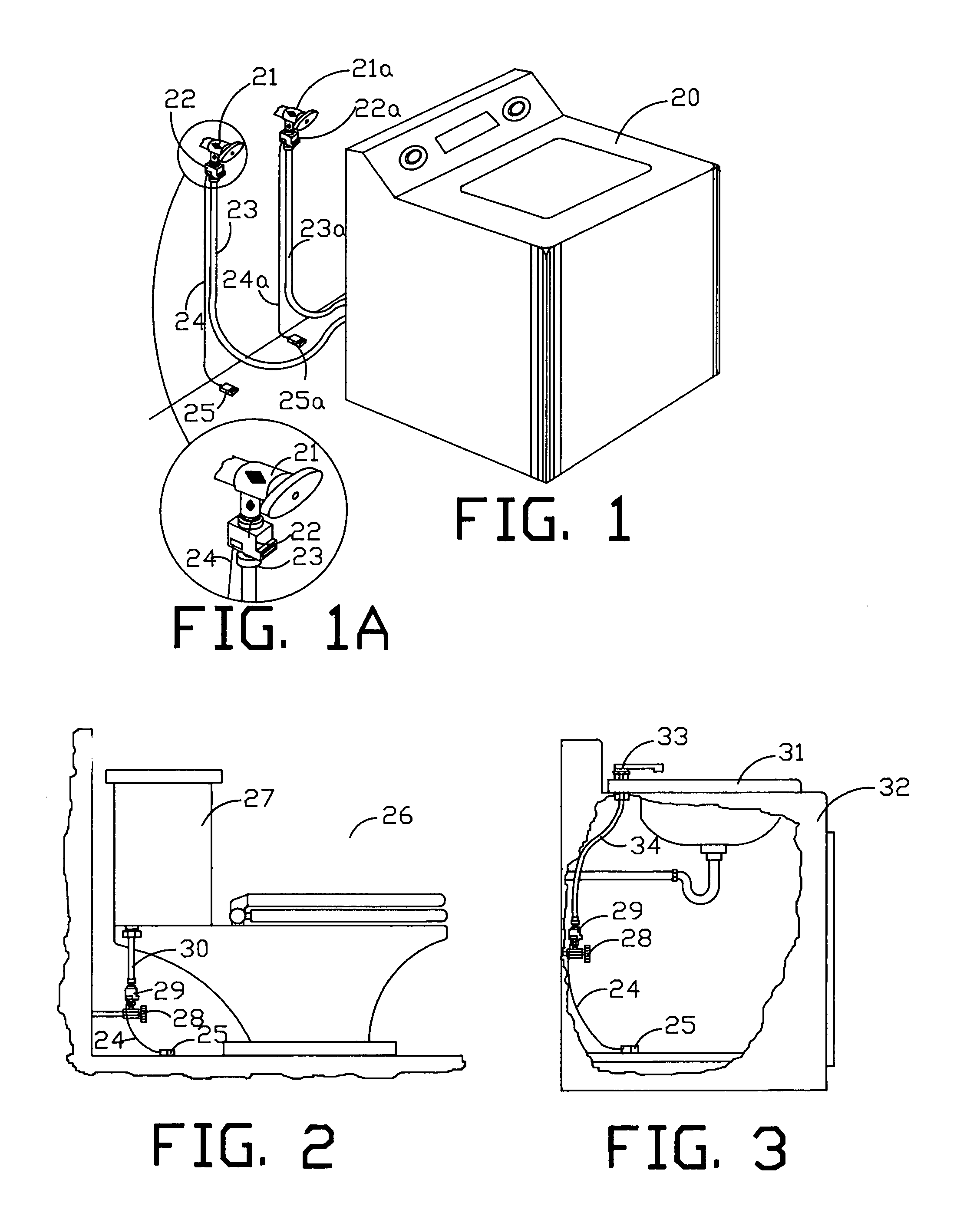

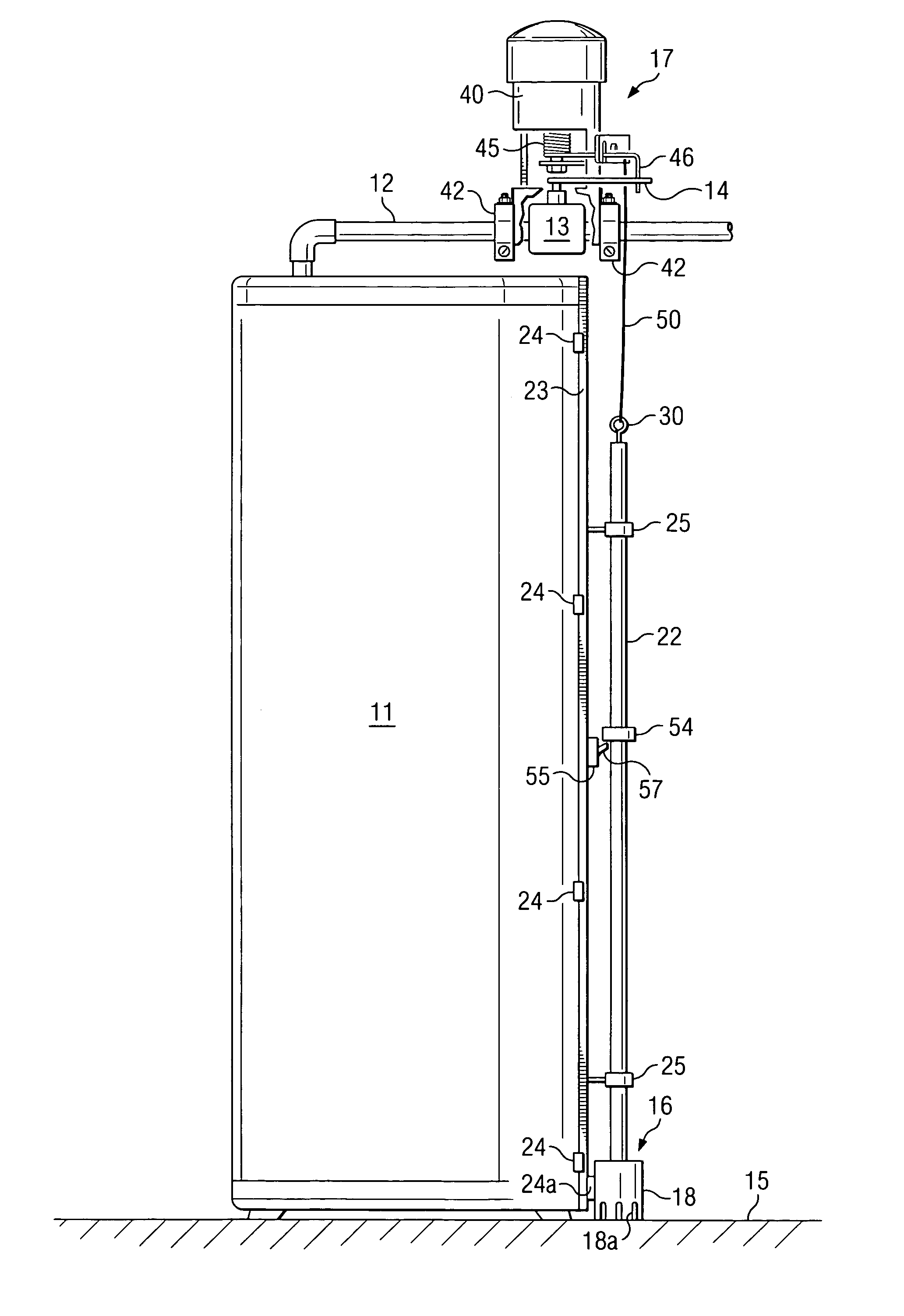

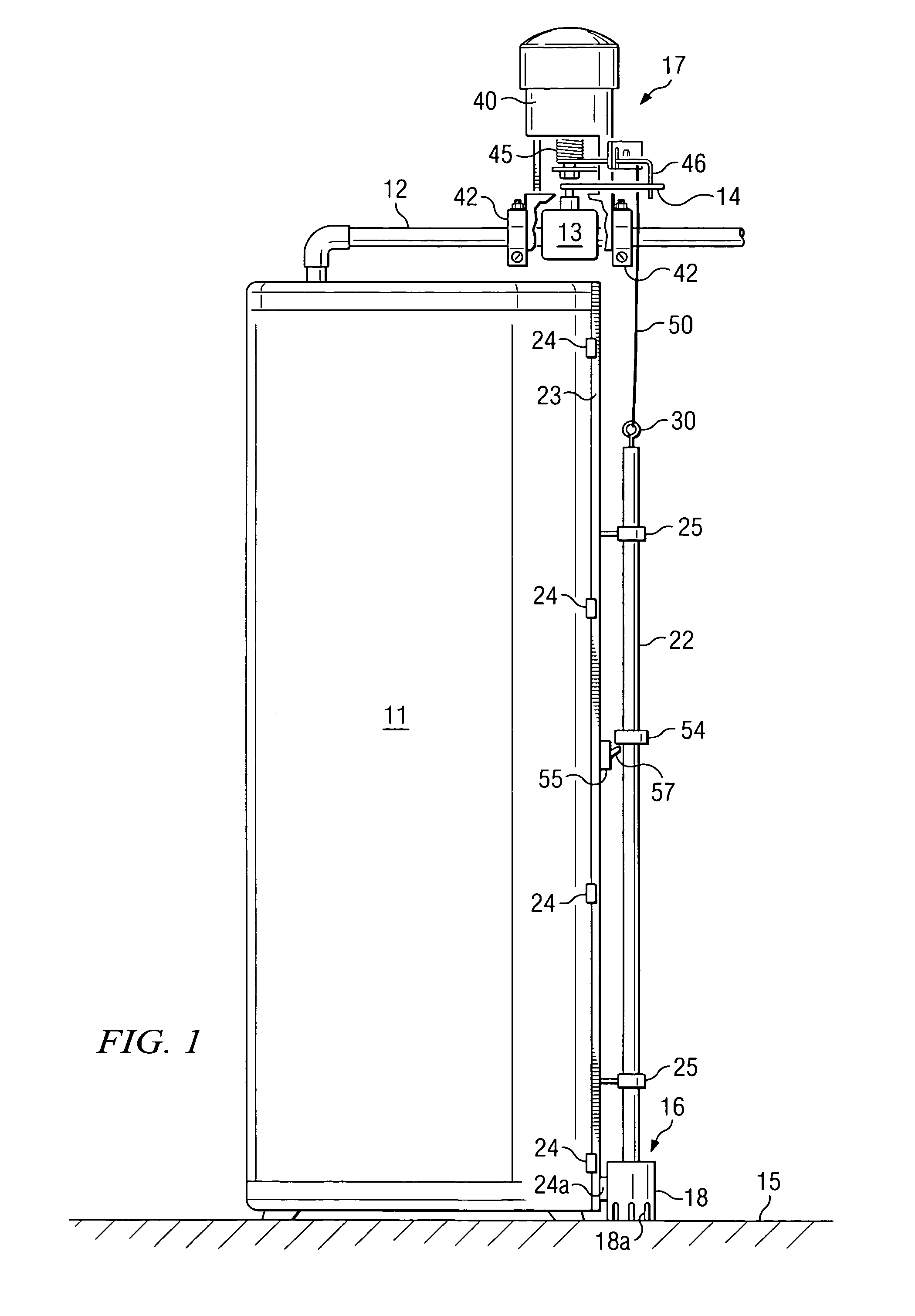

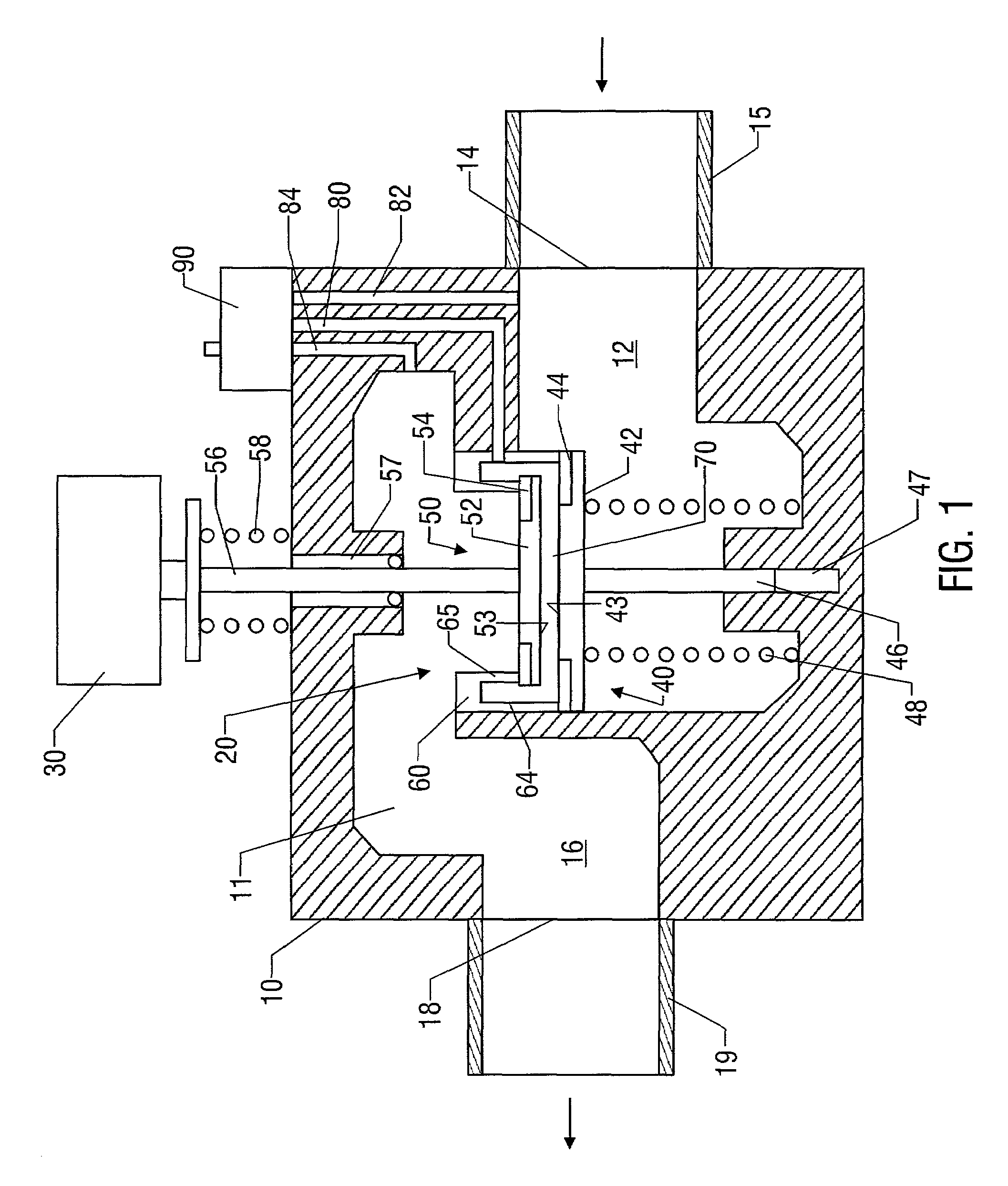

Shutoff valve system with leak detector

ActiveUS7082959B1Simple and reliable processSimple and compactDetection of fluid at leakage pointMeasurement of fluid loss/gain rateEngineeringRefrigerated temperature

A pilot operated shutoff valve system with leak detector for automatically shutting off a water supply to appliances such as a clothes washing machine, dishwashing machine, sink, toilet, or refrigerator equipped with an ice maker, comprising a sealing member movable within said valve body between an open position wherein the sealing member does not block main fluid flow, and a closed position wherein the sealing member blocks main fluid flow.

Owner:FRLIN ROBERT C

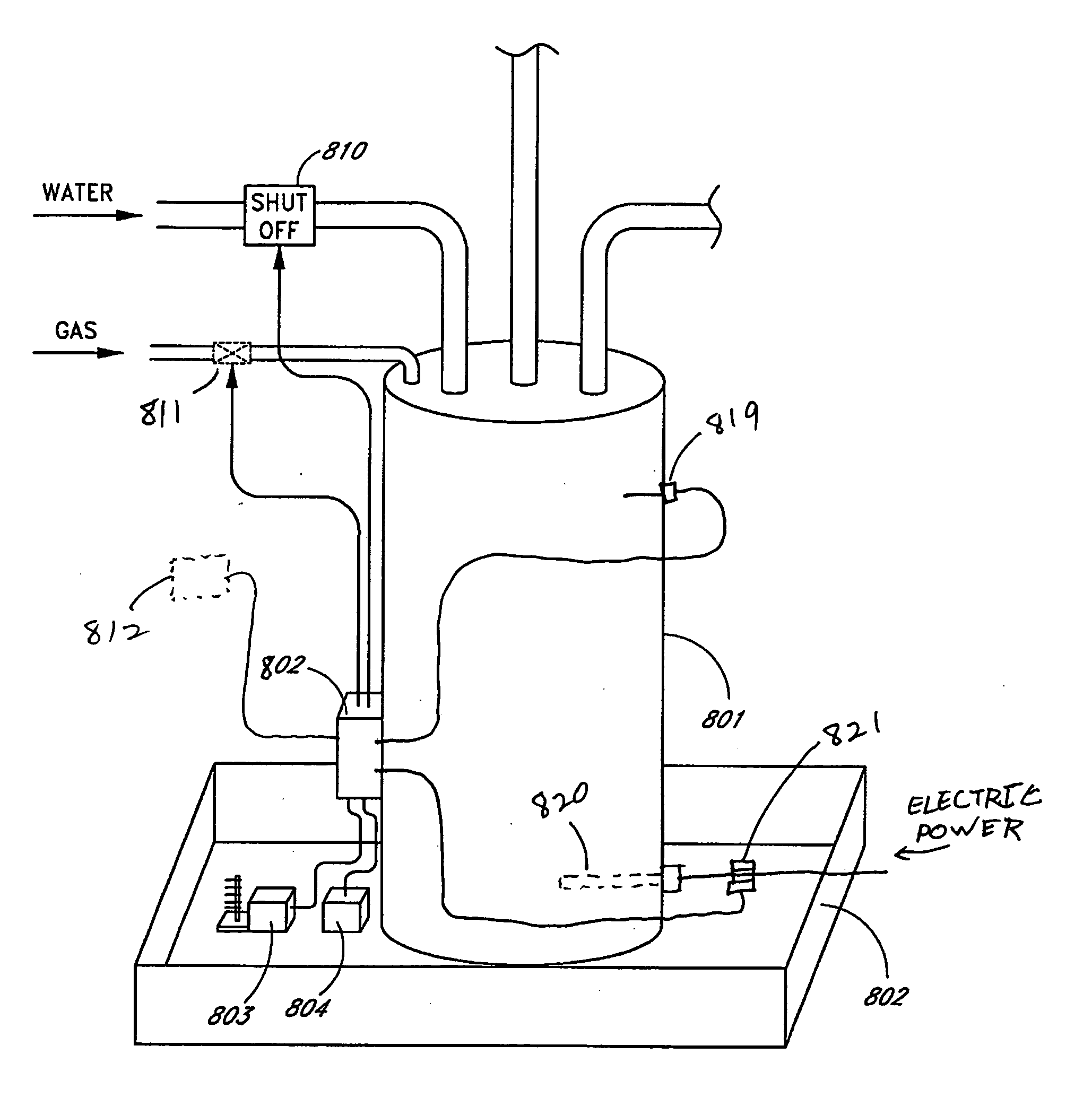

Secure wireless leak detection system

InactiveUS20060124171A1Easy to installReduce power consumptionDetection of fluid at leakage pointOther washing machinesTransceiverMagnetic valve

A method utilizing a wireless leak detection and prevention system, used for preventing property damage and personal injury caused by liquid or gas leak. The system comprised of a wireless, battery operated apparatus having sensor(s) incorporated with an RF transmitter, used for detecting liquid or gas leaks, and transmits signal(s) to a wireless valve shutoff control unit. The valve shutoff control unit containing an RF transceiver and a processor designed to receive the detected signals and activate a supervised solenoid or motorized valve shut-off mechanism to stop the detected leak. In a preferred embodiment of the invention, the wireless valve control unit is connected to a motor, which is mounted on manual shutoff valve. Wherein the valve control unit activates the motor to produce torque to turn the valve towards a close position in response to a received detected leak signal from a sensor. An electronic or electromechanical circuitry is provided, to detect motor or gear turn cycles. The motor rotation is being controlled by the valve control unit processor, which stops motor rotation in response to a detected preset number of motor turn cycles. A digital, voice, SMS text message phone dialer is add to dispatch the detected leak signals, and notify monitoring personnel of the supervised system operation status. And provide user access to turn on or off a valve(s) from a remote location.

Owner:RUGGIERI MONICA L +1

Apparatus for dispensing paint and stain samples and methods of dispensing paint and stain samples

ActiveUS20050252934A1Improve recallEliminate needClosuresBarrels/casks fillingAdditive ingredientEngineering

An improved fluid dispenser specially adapted to provide sample-size amounts of a fluid mixture is shown and described. An automated closure and seal system is provided for the manifold that moves, on command from a controller, from a closed or sealed position thereby limiting exposure of the manifold and fluid outlet nozzles from the ambient atmosphere, to a dispense system where a sample-size container is held up against and engaging a lower end of the manifold for a sealing element disposed on a lower portion of the manifold. When the dispense is complete, the system automatically moves back toward a closed position where the filled container is held open and ready to be removed by a technician before it is capped and labeled. An improved shelving system is also provided for housing a large quantity of different ingredients conveniently within a relatively compact cabinet thereby making the system suitable for a retail environment. An improved method of preparing a sample quantity of a fluid mixture is also disclosed.

Owner:FLUID MANAGEMENT LLC

Automatic flow shut-off system

InactiveUS7424896B1Prevent significant damage to areaOperating means/releasing devices for valvesOther washing machinesValve actuatorEngineering

An automatic system which includes a tripper unit for actuating a device (e.g. valve-closing actuator) upon contact with water. Basically, the tripper unit is comprised of a housing having a cartridge therein which, in turn, is wrapped with an adsorbent paper which prevents a plunger from moving downward. When a leak occurs, water will flow into the housing and into contact with the absorbent paper which will quickly disintegrate allowing the plunger to move downward to thereby actuate the valve actuator to close the valve. The tripper unit may be a separate component of the system or both the tripper unit and the valve actuator can be incorporated into a single unit.

Owner:MARTIN JAMES B +1

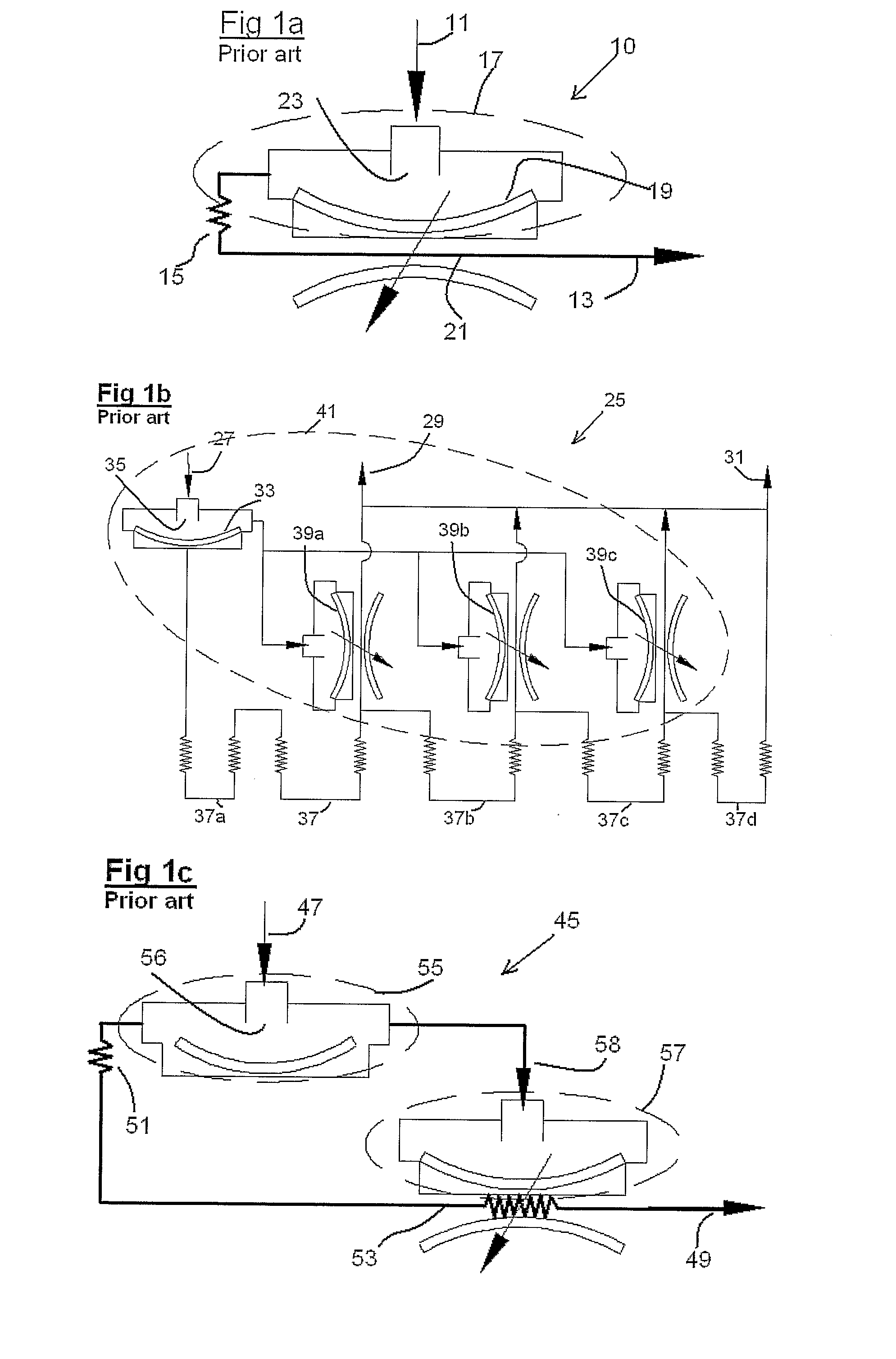

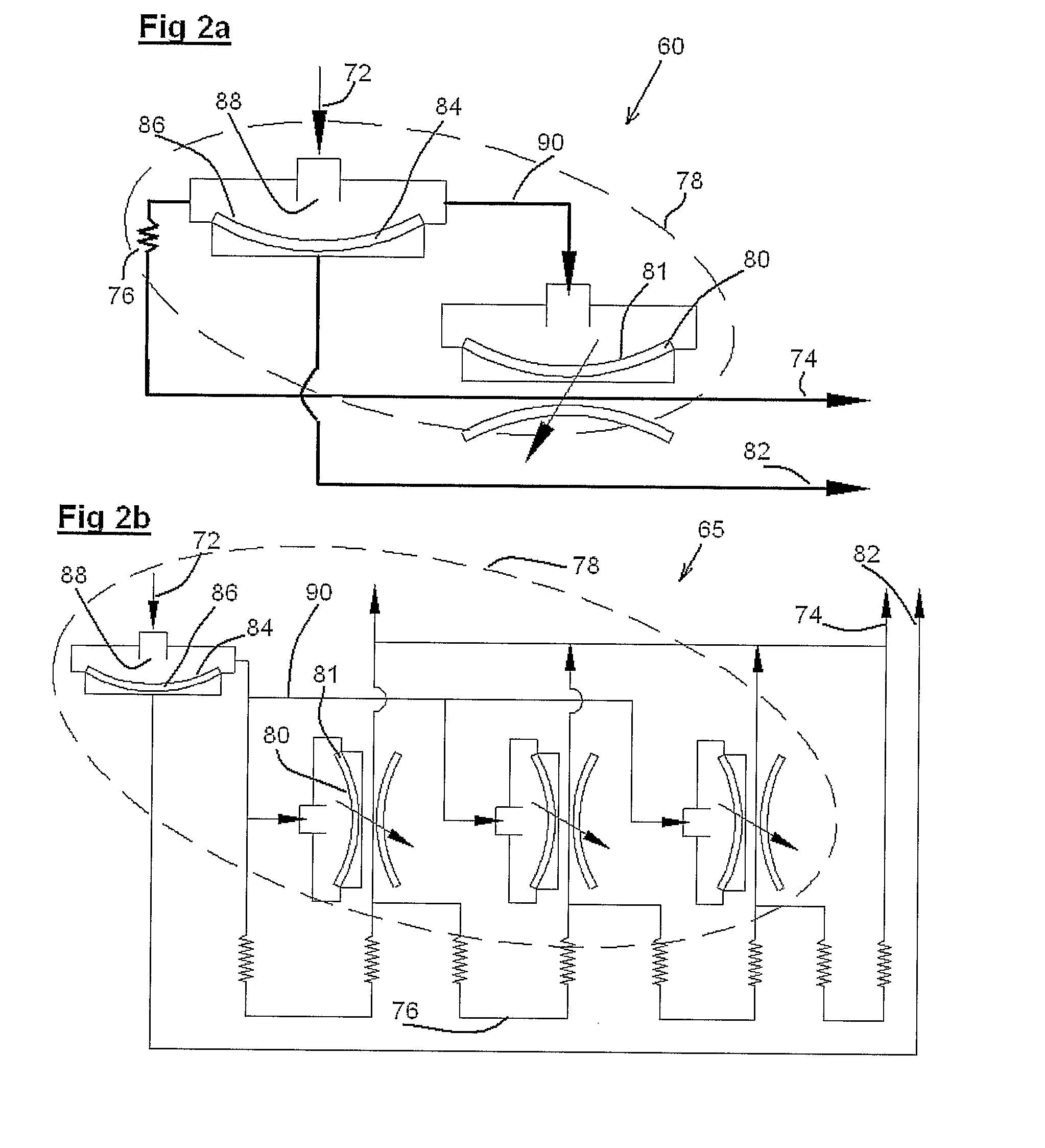

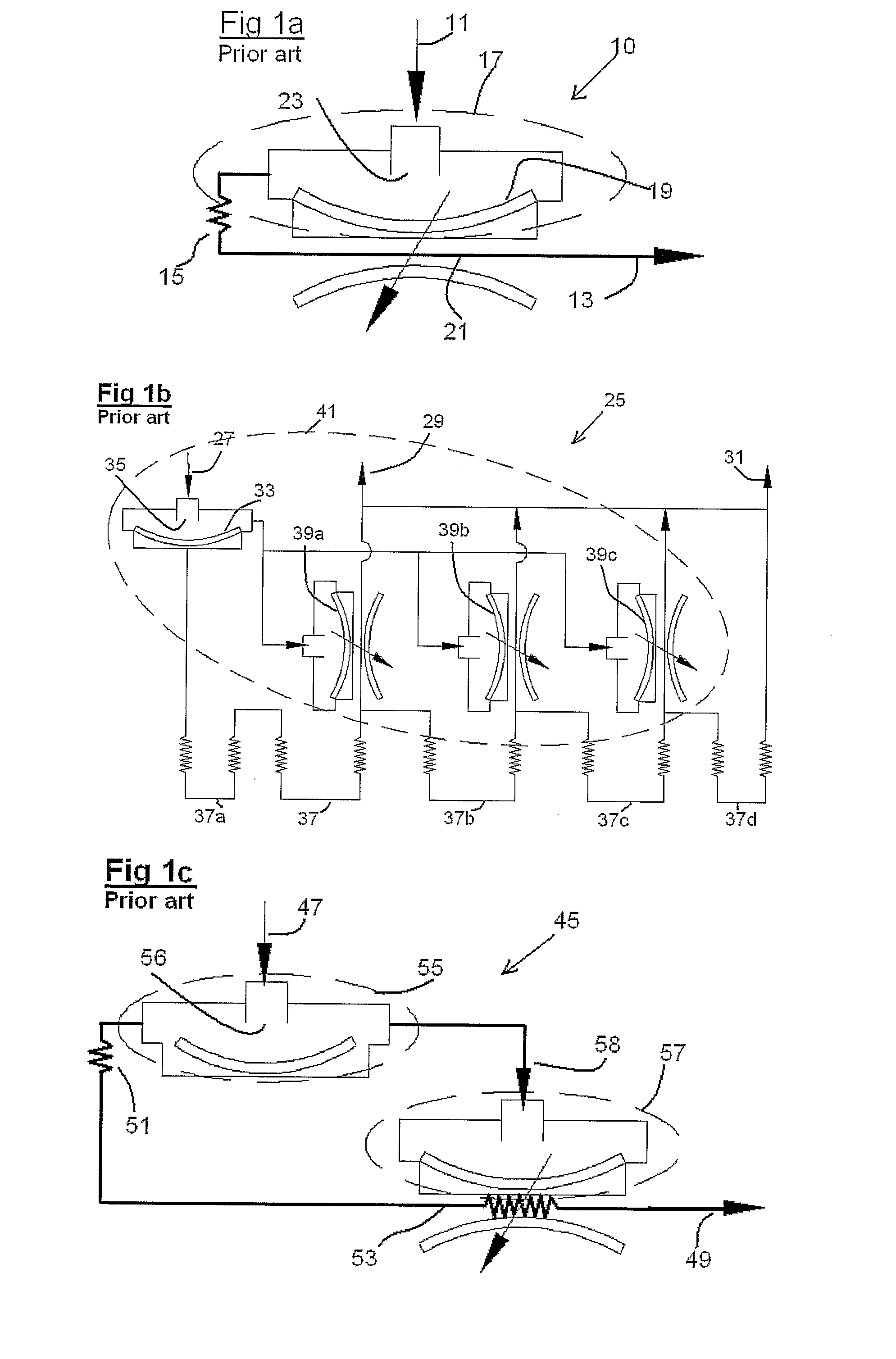

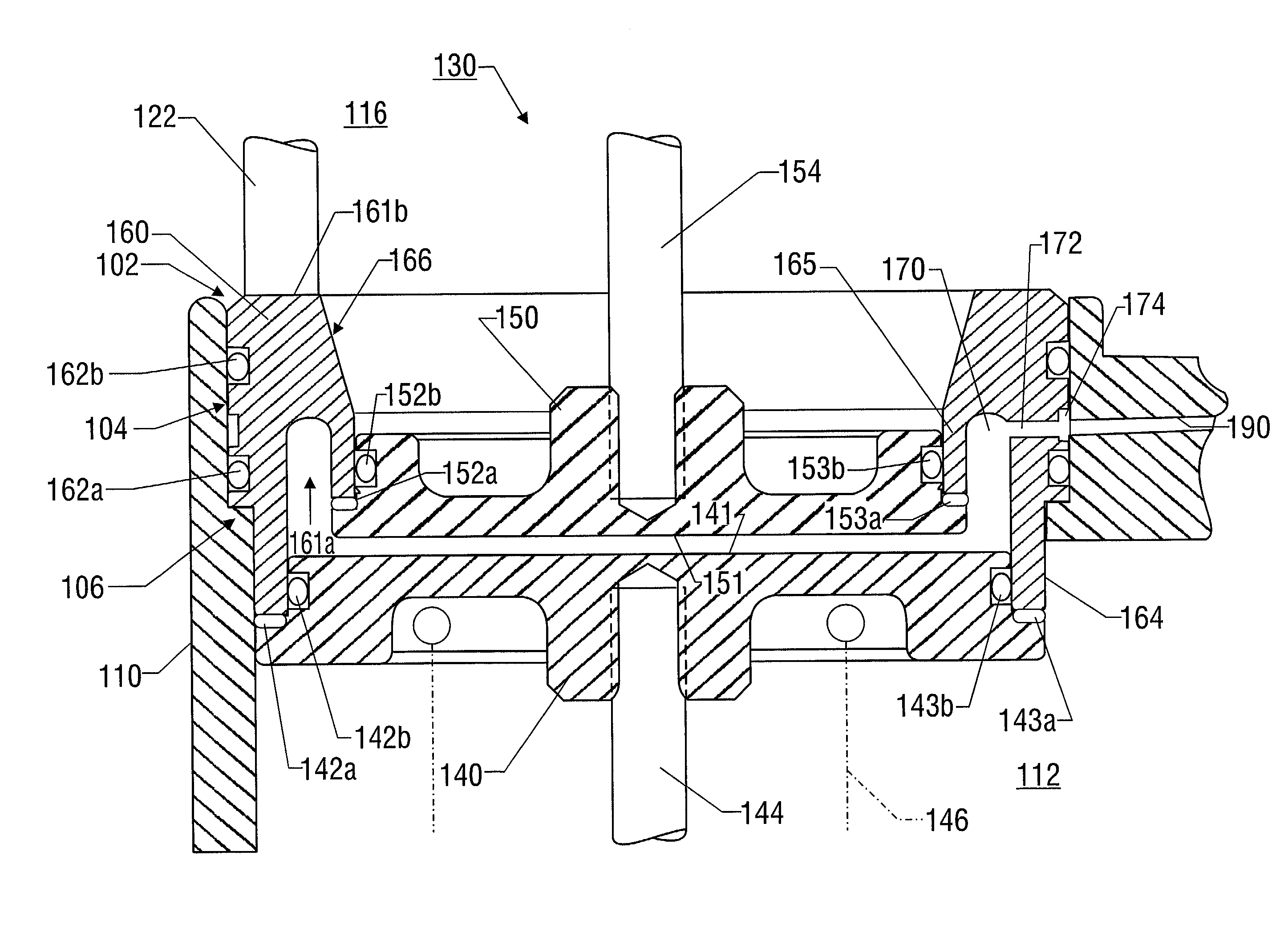

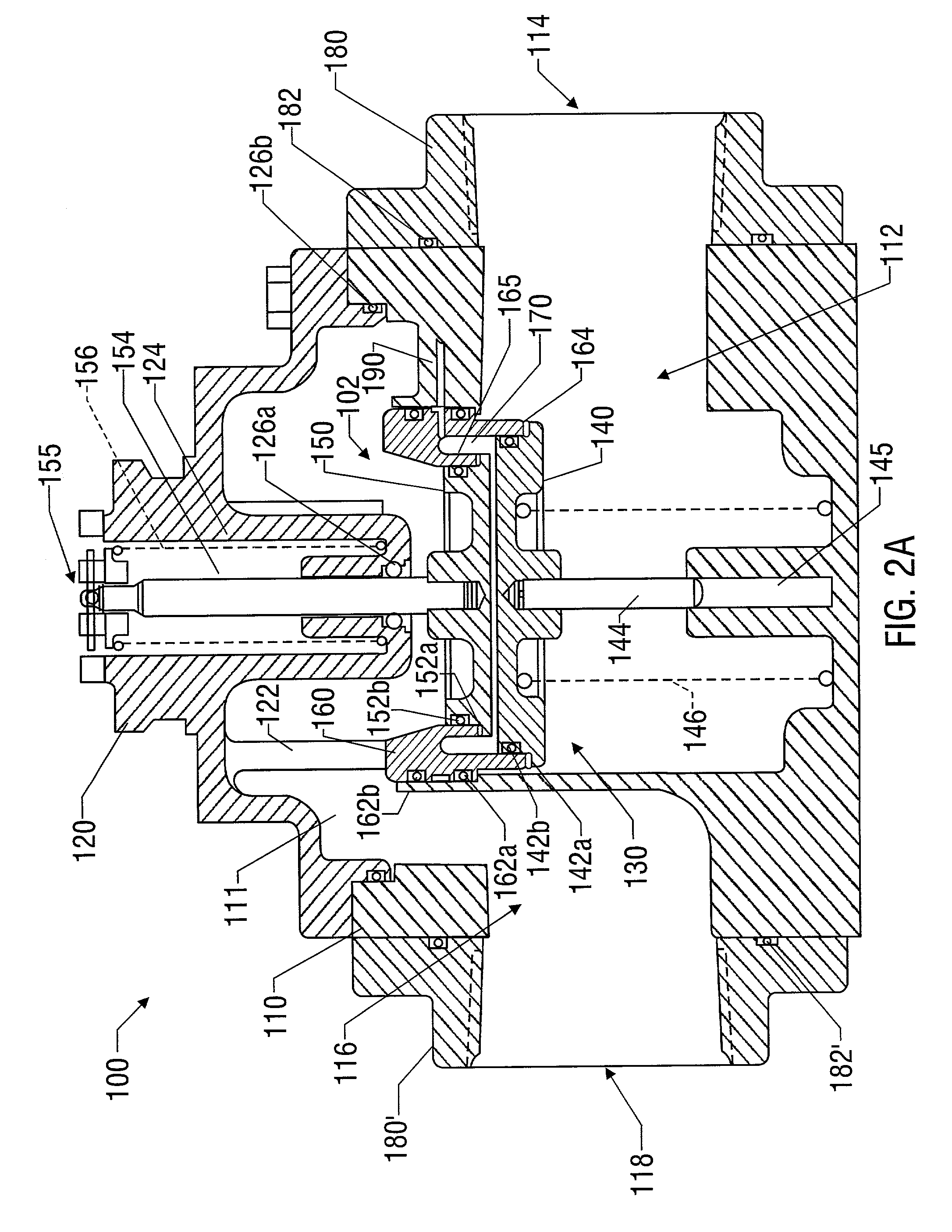

Double block valve with proving system

A double block valve and a valve proving system are disclosed. The double block valve is actuated by a single actuator and includes a valve body housing a cavity. The cavity defines an upstream portion with a fluid inlet and a downstream portion with a fluid outlet. A seating assembly is interposed between the upstream and the downstream portions. A first and a second blocking element are disposed in the valve body and are both movable within the cavity between opened and closed positions. With the first and second blocking elements both contacting the seating assembly, the space therebetween defines an enclosed space with a finite volume. The proving system is used for two safety shut-off valves on a valve train, such as a double block valve. The proving system connects to an enclosed space established between the two safety shut-off valves and includes a pair of three-way valves, oppositely biased pressure switches, and a pump, all of which are interconnected through pneumatic conduits. The proving system uses pressure accumulation and timed decay to determine the integrity of the two safety shut-off valves of the valve train.

Owner:ASCO CONTROLS LP

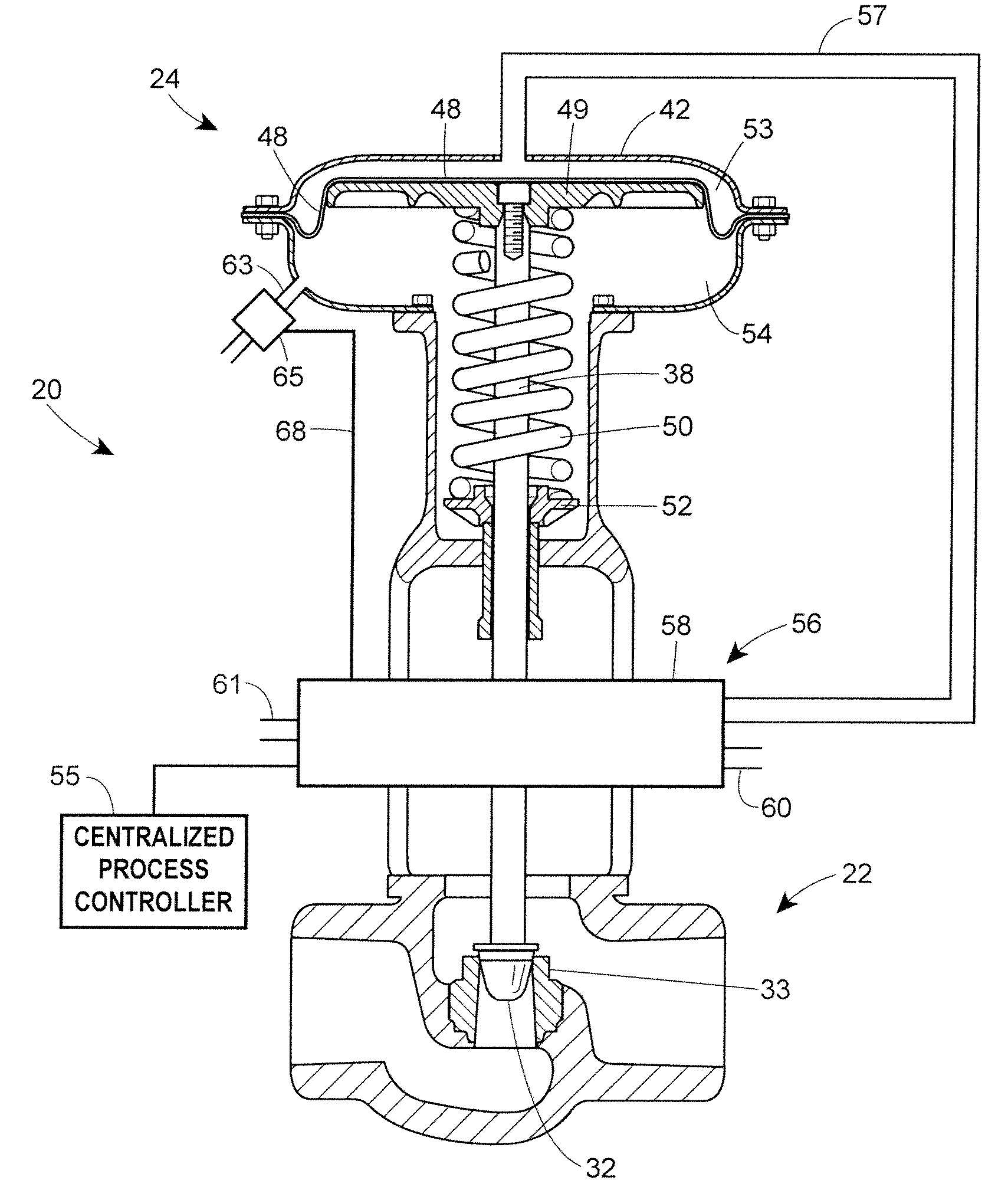

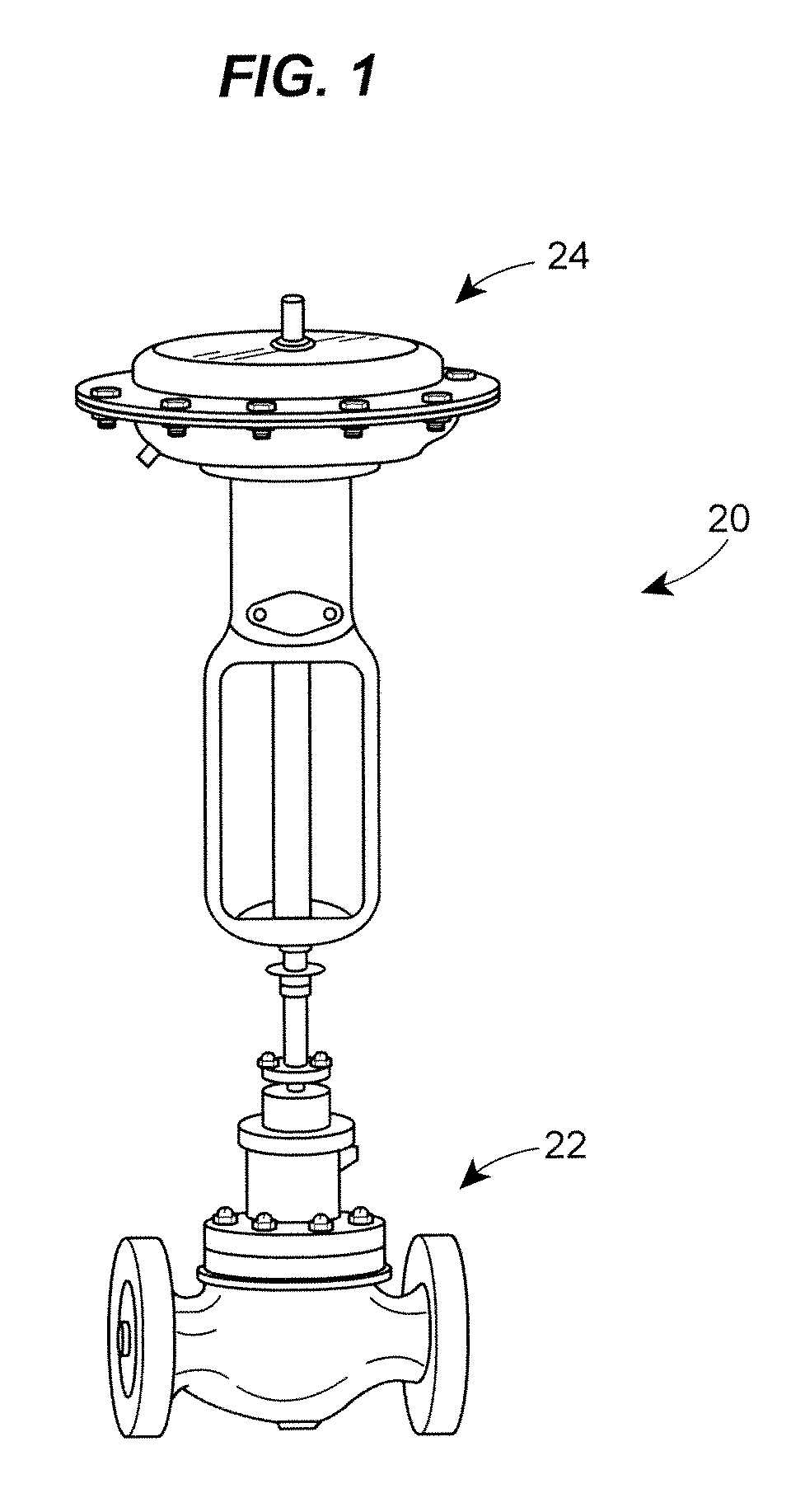

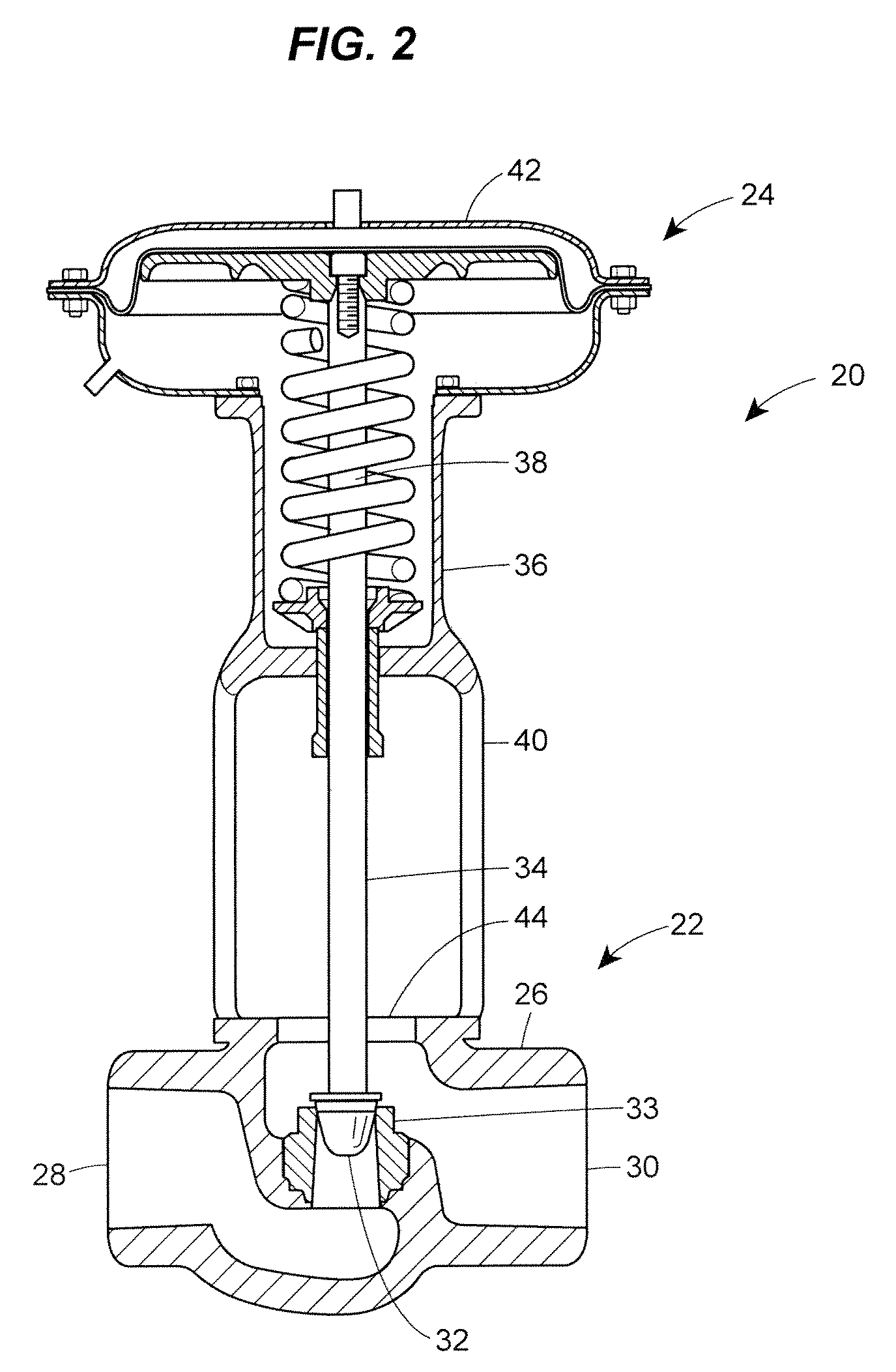

Device and Method for Determining a Failure Mode of a Pneumatic Control Valve Assembly

ActiveUS20110001070A1Operating means/releasing devices for valvesOther washing machinesControl lineControl valves

A control valve assembly is capable of diagnosing malfunctions in the control valve assembly and discerning a location of a control fluid leak in the control valve assembly. The control valve assembly includes a control valve, an actuator and a positioner. The actuator includes an actuator vent in an actuator housing, the actuator vent being connected to a flow switch. By determining a flow condition through the actuator vent, the positioner determines whether a control fluid leak is located in a control line or in a diaphragm.

Owner:FISHER CONTROLS INT LLC

Medical fluid collection and removal device

Liquid collection apparatus usable during surgery, comprising a shallow tray defining a liquid receiving zone that is upwardly exposed for receiving liquid dropping from a surgery area, and a liquid collector in a zone for collecting dropping liquid while allowing a surgeon to tread over a collector, during surgery.

Owner:TYPENEX MEDICAL

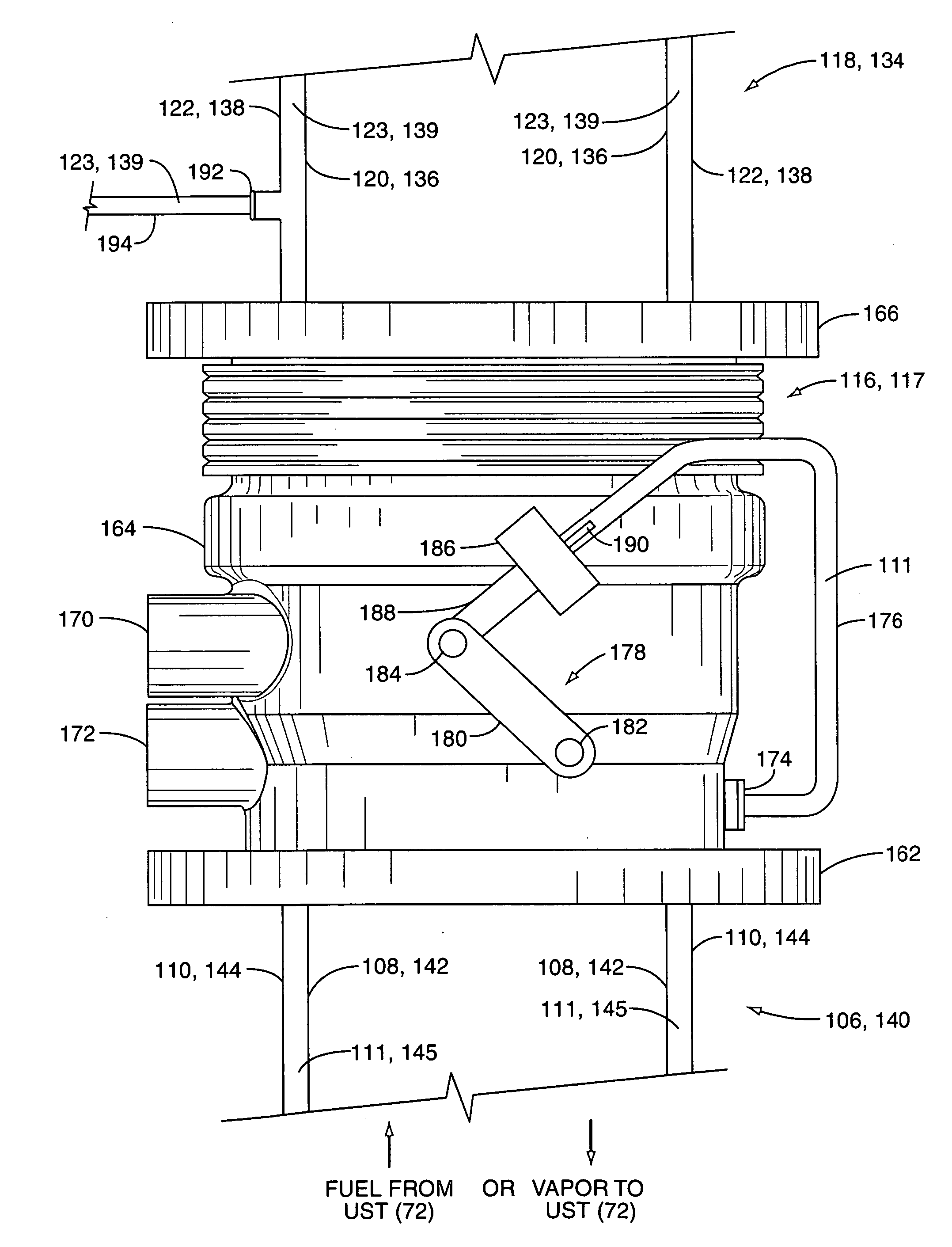

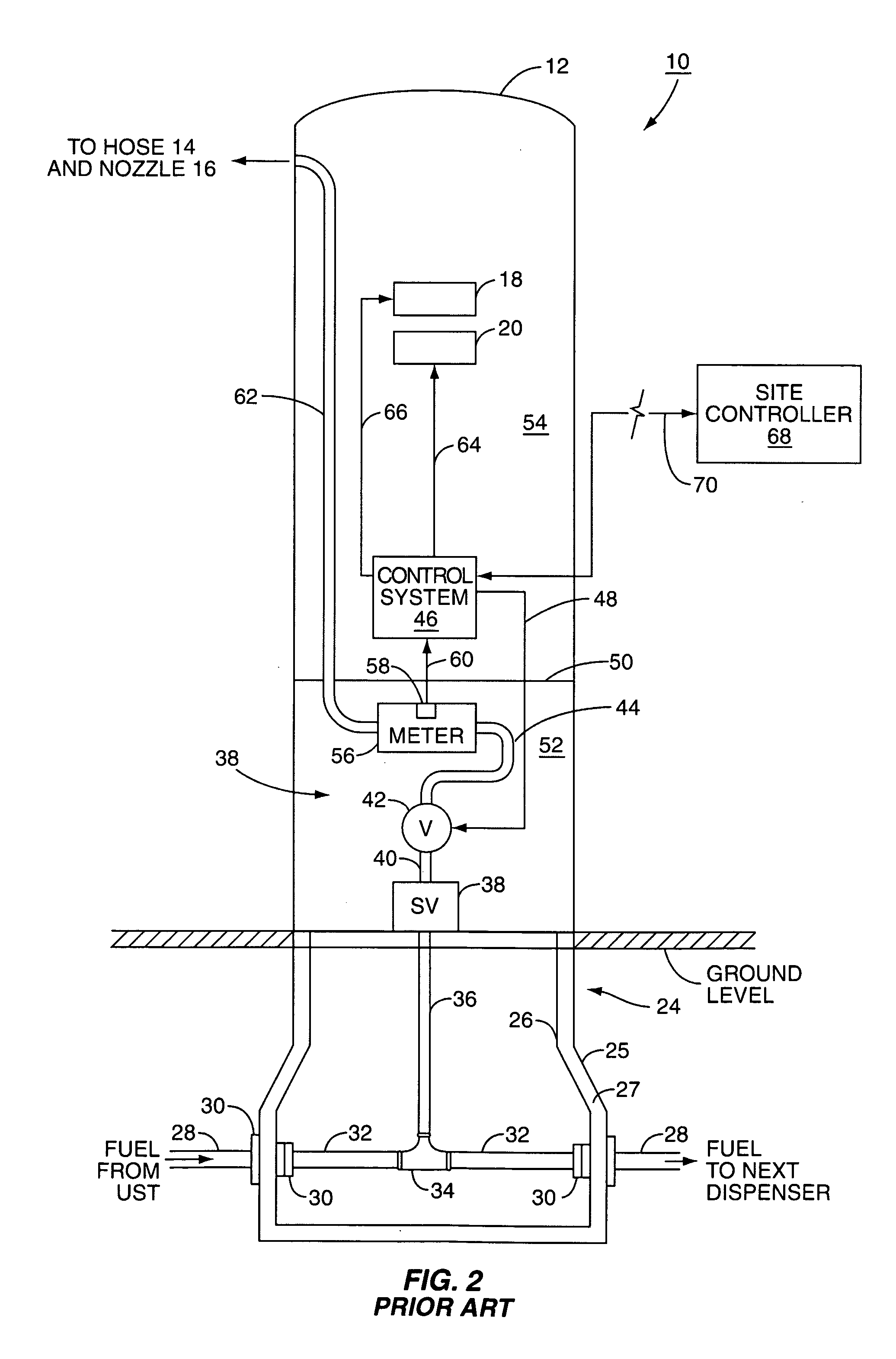

Vacuum-actuated shear valve device, system, and method, particularly for use in service station environments

ActiveUS20060260680A1Prevents fuel flowService is blockedDetection of fluid at leakage pointOther washing machinesVacuum levelEngineering

A vacuum-actuated shear valve coupled between piping from a storage tank and piping internal to a fuel dispenser that automatically opens and closes in response to a vacuum level. A vacuum actuator is provided to control a fuel flow valve inside the shear valve. When a sufficient vacuum level is generated to the vacuum actuator, the actuator keeps the flow path valve inside the shear valve open. When the vacuum is lost, the vacuum actuator releases the flow path valve inside the shear valve, which closes it. The vacuum actuator is coupled to a secondary containment space of a fuel-handling component that is drawn under a vacuum level by a vacuum-generating source to monitor for leaks. Thus, if a leak occurs in the monitored secondarily contained space, the shear valve is automatically closed to prevent the flow of fuel from continuing to be supplied to the source of the leak.

Owner:VEEDER ROOT

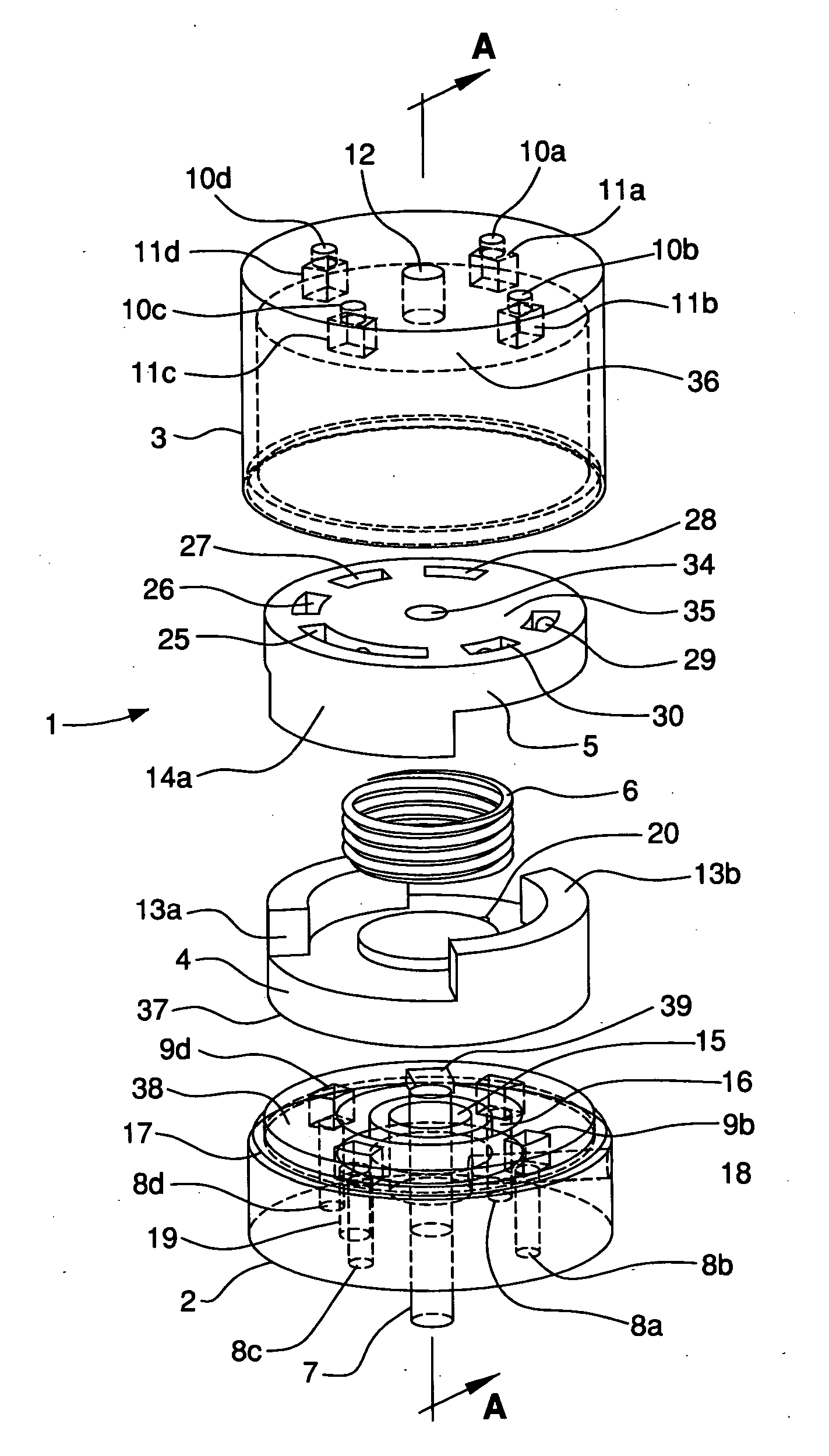

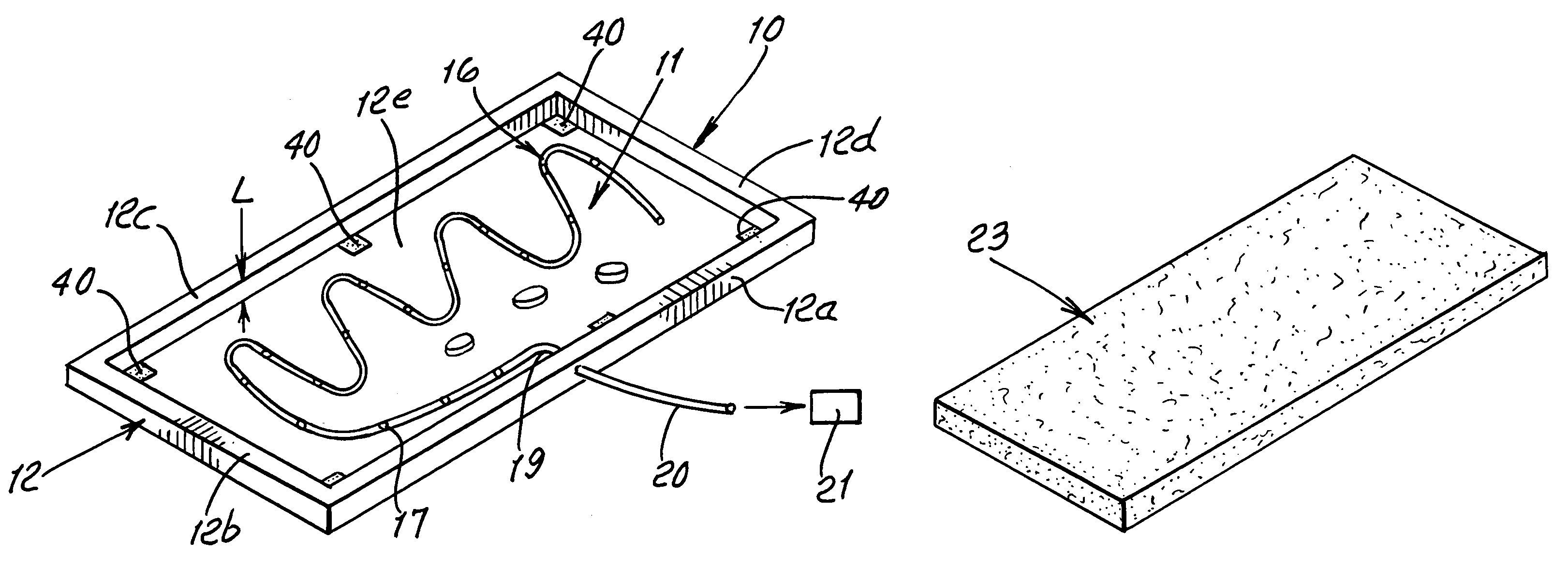

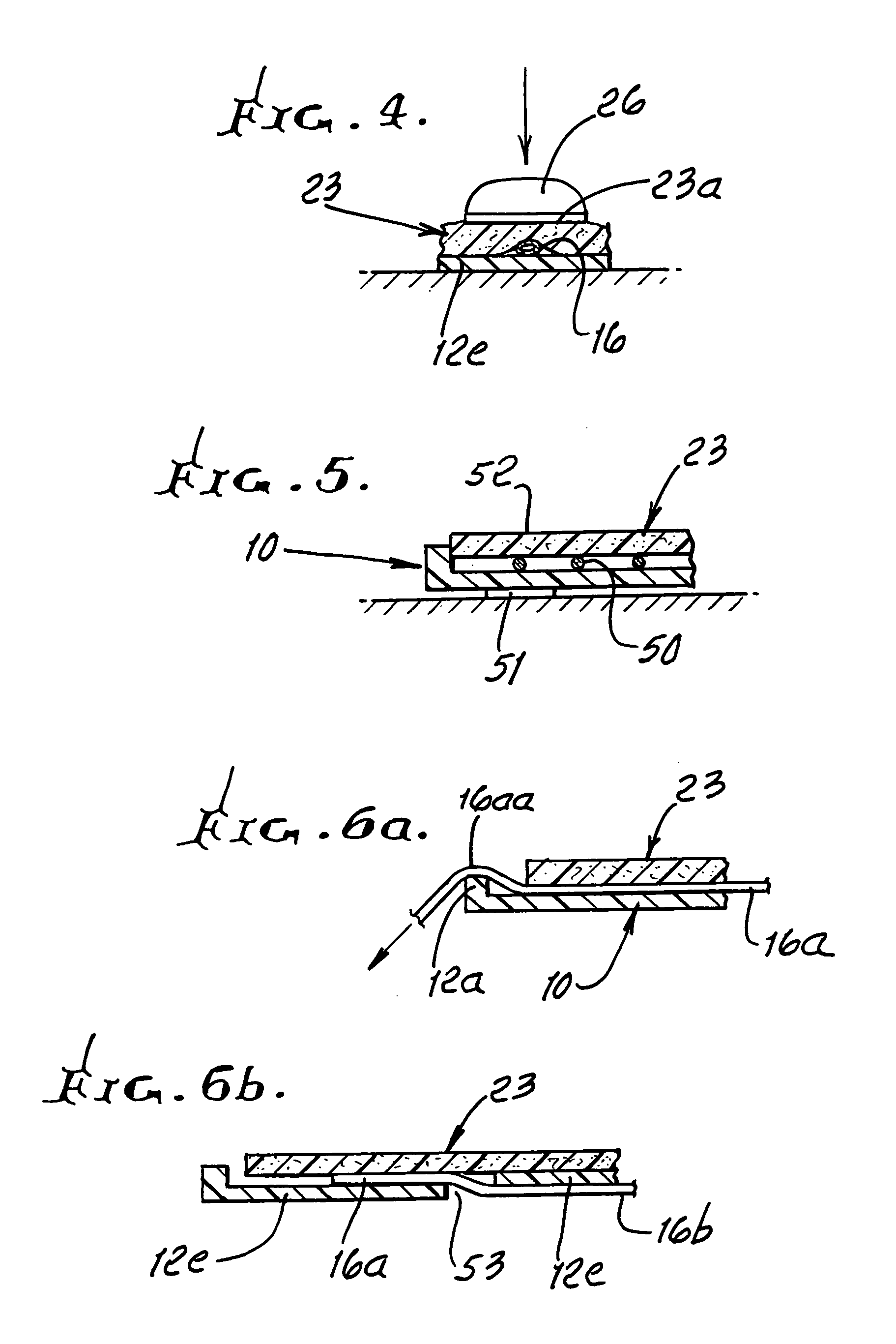

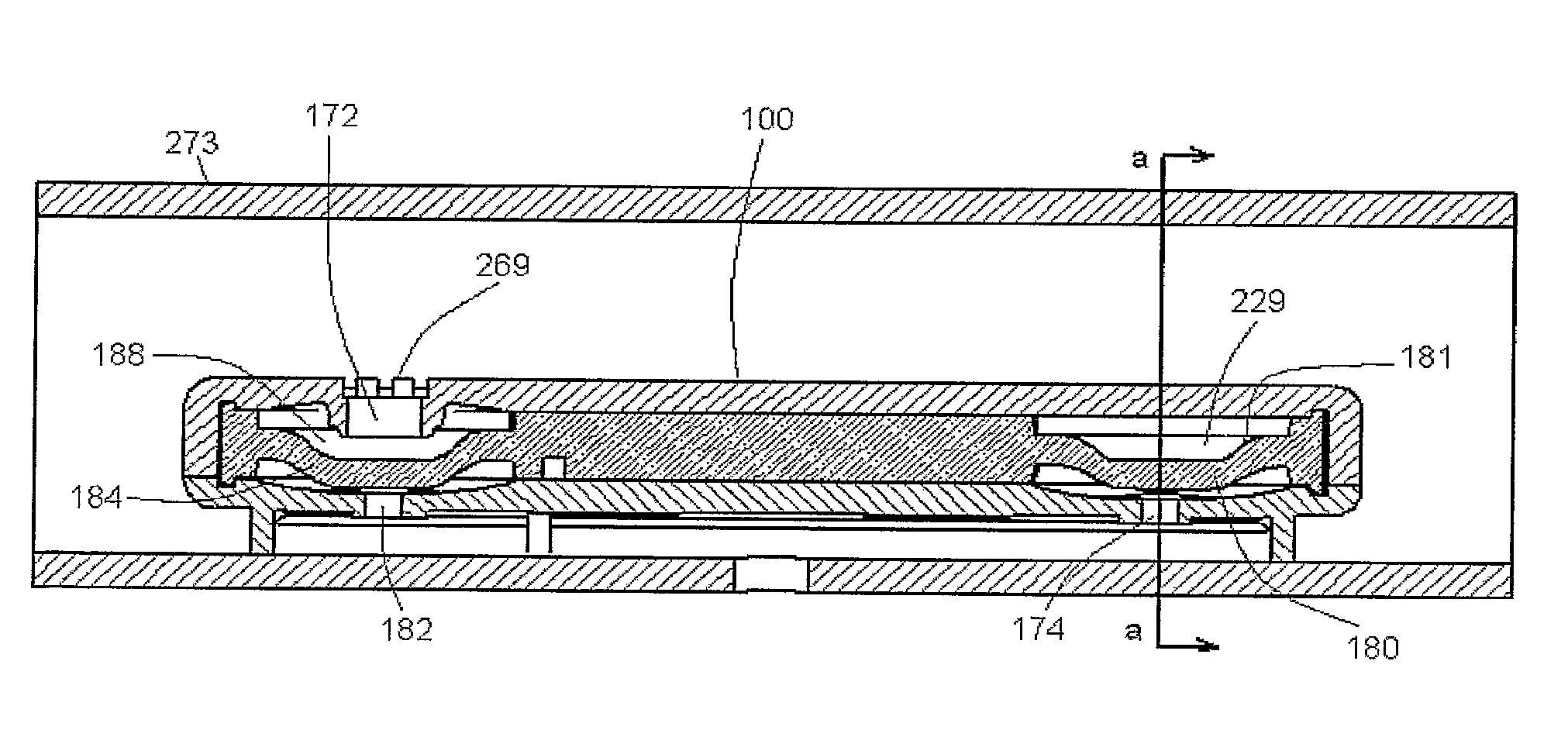

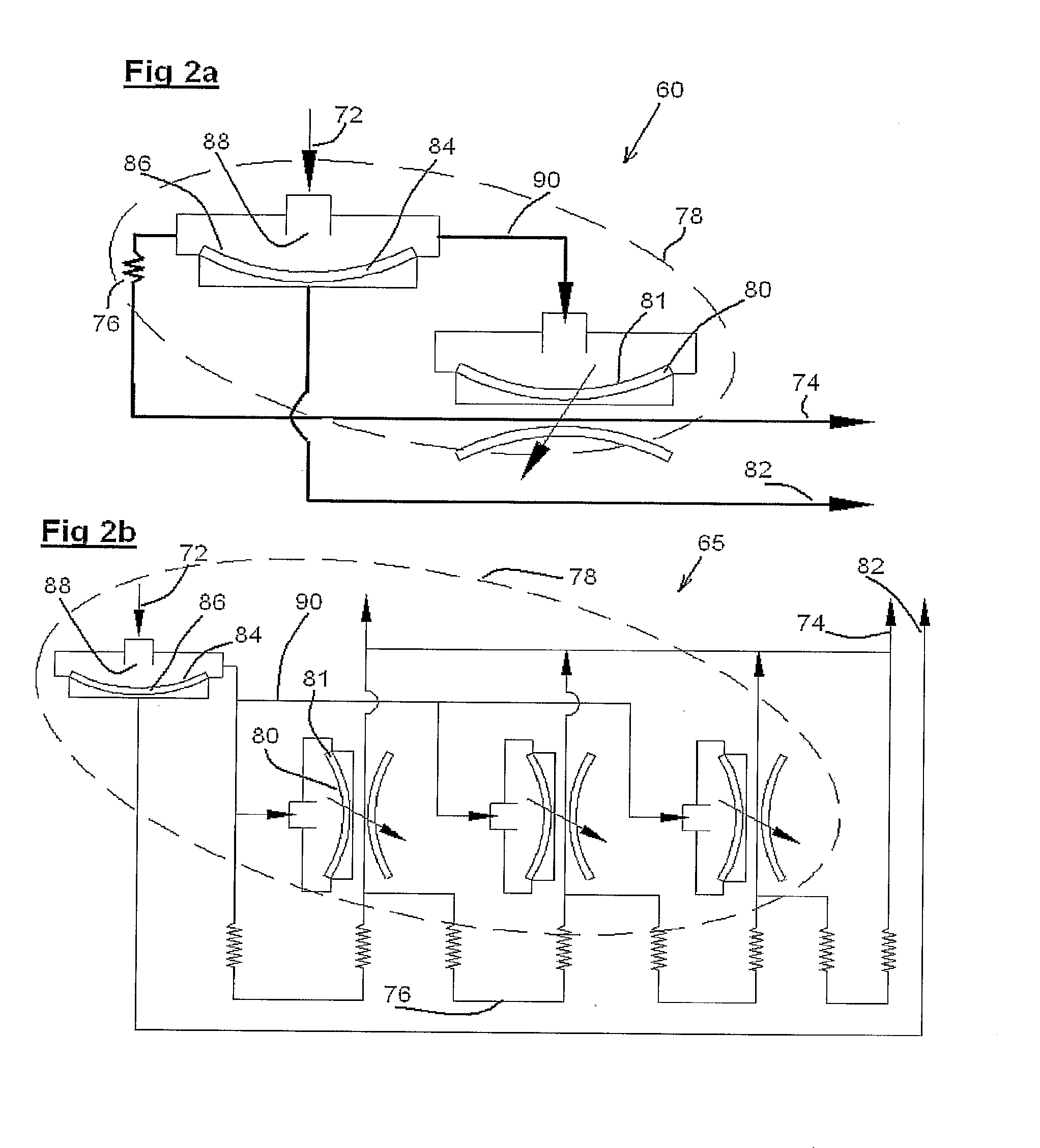

Drip emitter with an independent non-drain valve

ActiveUS20120160926A1Low costEasy to assembleWatering devicesSpray nozzlesElastomerDifferential pressure

A flat type pressure regulated drip emitter with a non-drain valve capabilities that is installable inside a water supply conduit during the conduit manufacturing process and characterized by that the emitter's non-drain valve function is executed independently and separately from its pressure regulation function, through a portion of the emitter's elastomer component that is strained and biased against the emitter's water inlet opening and is moveable towards and away from an additional opening (additional to the emitter's water outlet opening), exposed to the pressure prevailing in the emitter's water exit pool and therefore, at any given time, this portion of the elastomer component is exposed to the maximum differential pressure that prevails in the system—on its one side to the water pressure prevailing in the water supply conduit and on its other (second) side—to the approximate atmospheric pressure.

Owner:RIVULIS PLASTRO LTD

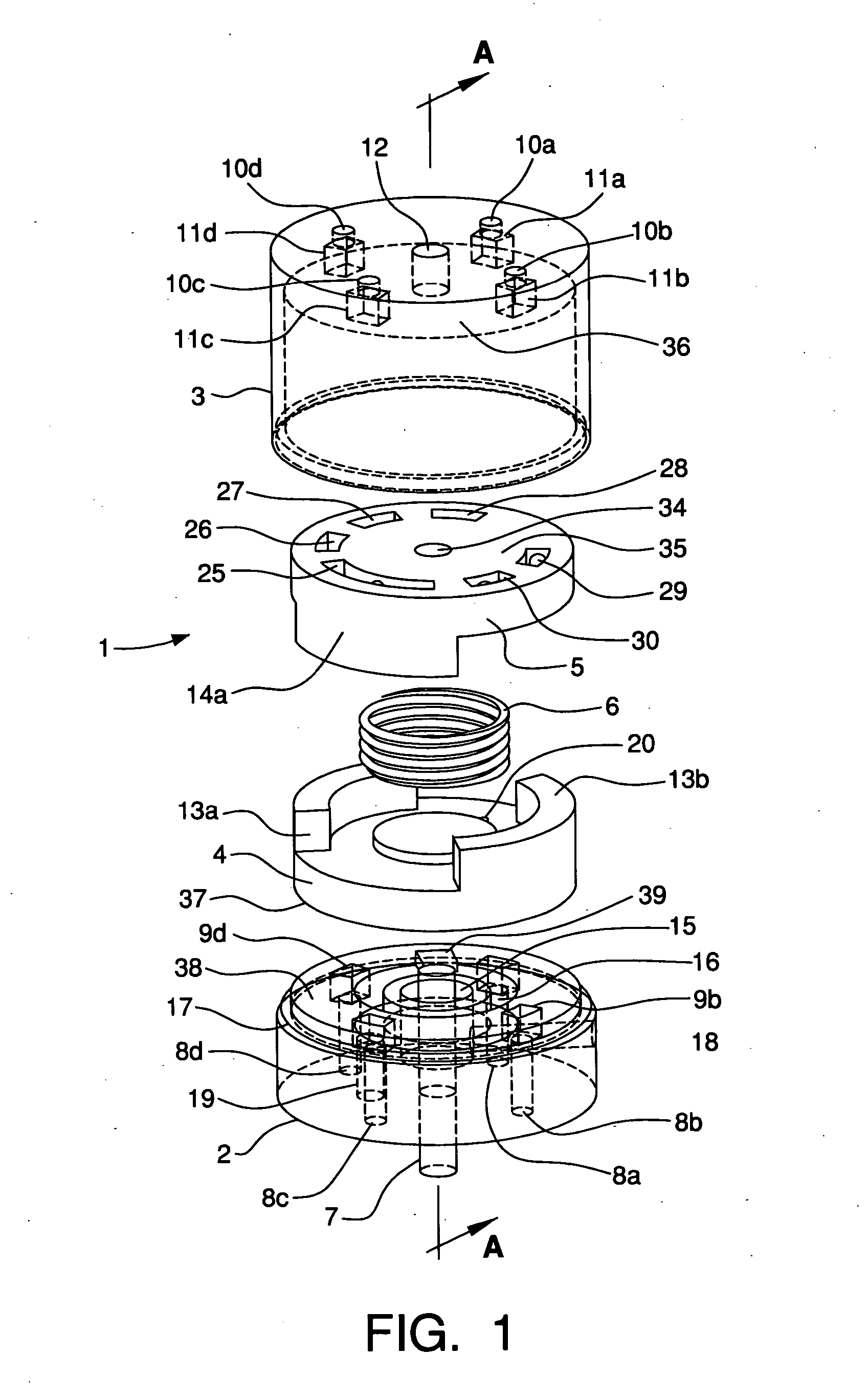

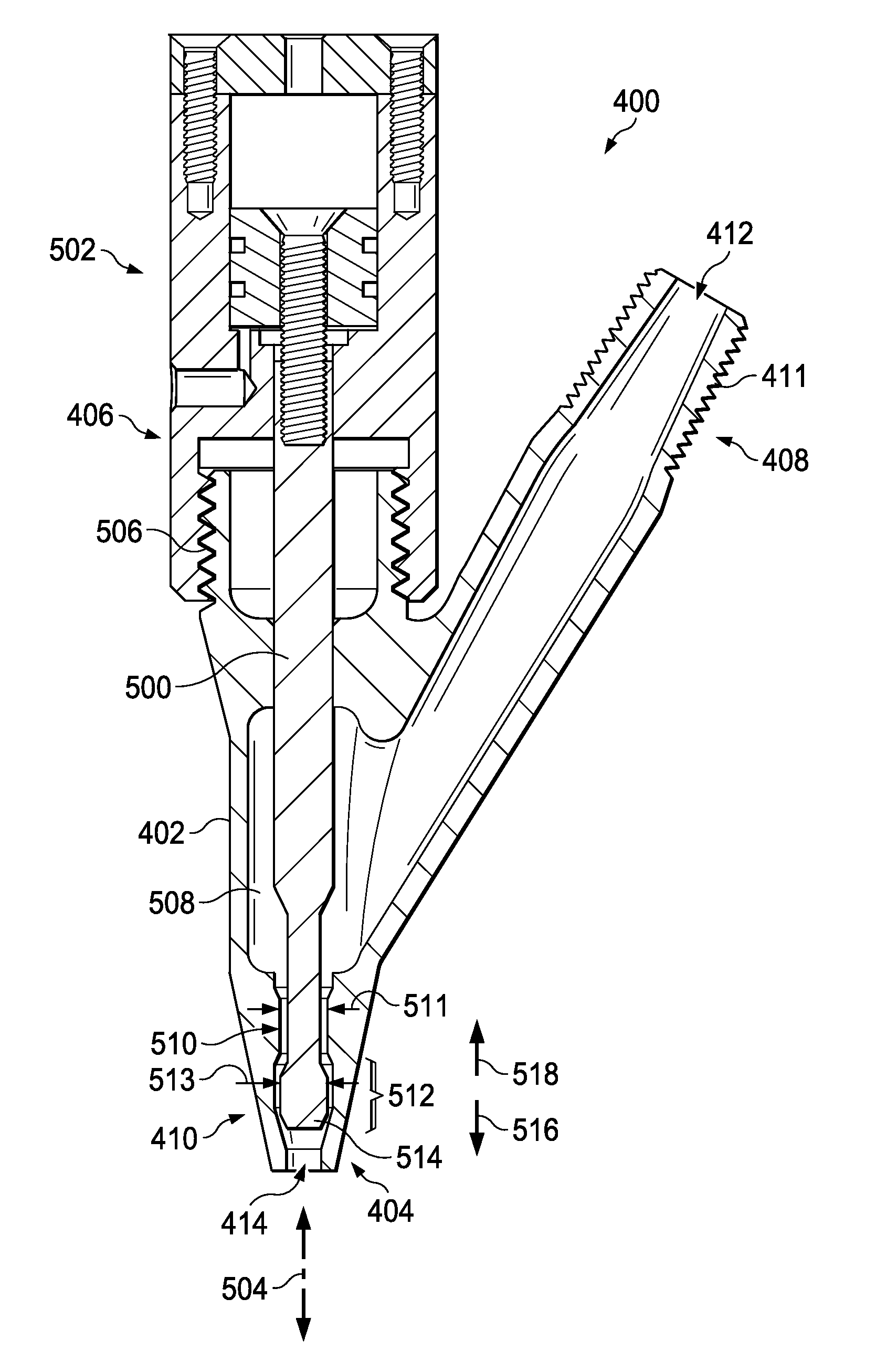

Valve

There is provided a valve enabling complete prevention of leakage and a backflow and having durability and less noise, and further there may be implemented a valve capable of predicting the tendency of occurrence of damage on the functions of the valve before the functions of the valve are actually damaged. In a valve having a valve chamber 5 formed between a fluid inlet 2 and a fluid outlet 3, a valve element 6 disposed in the valve chamber 5 is composed of an elastic member and an inelastic member.

Owner:MIURA COMPANY LIMITED

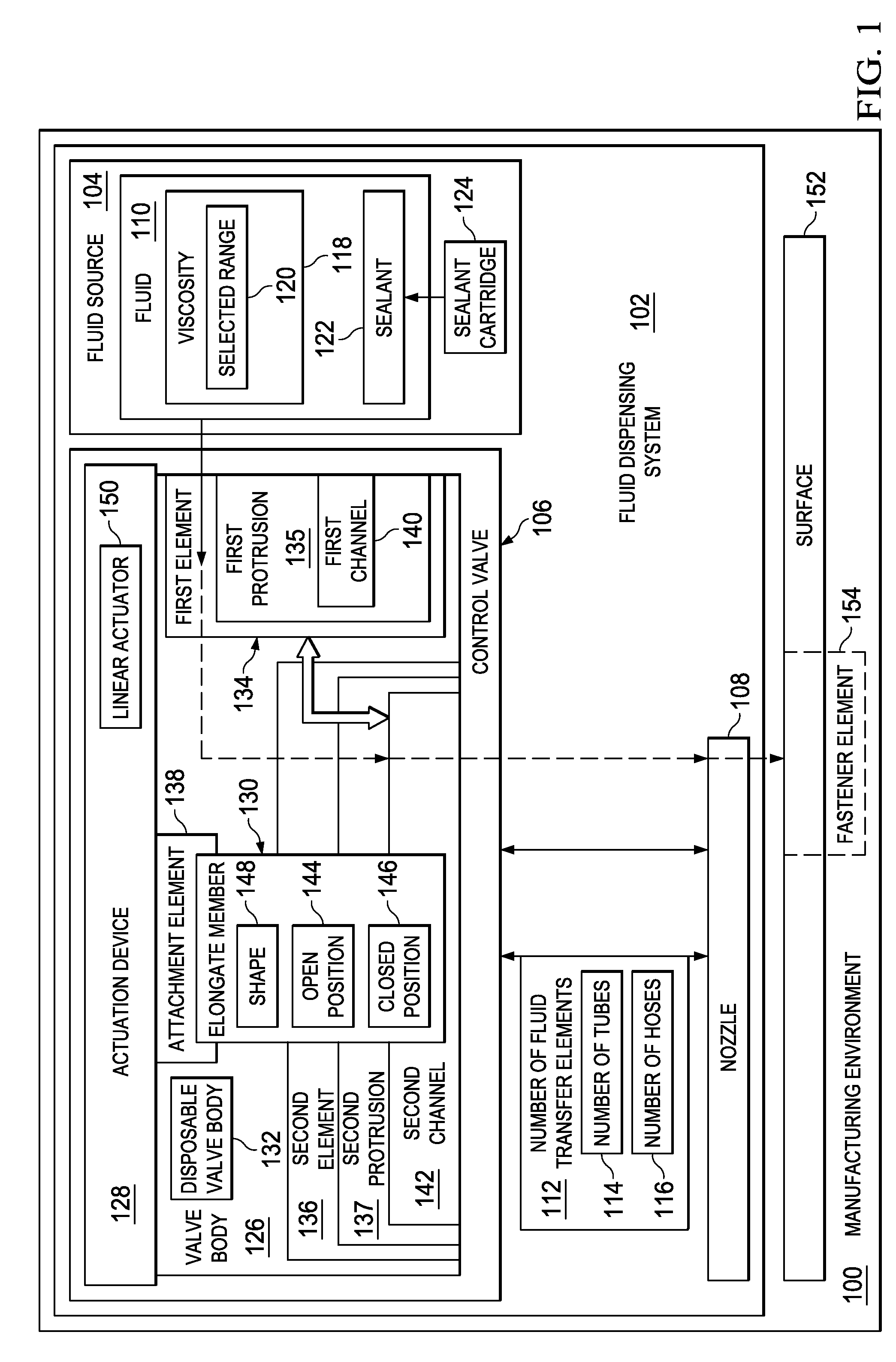

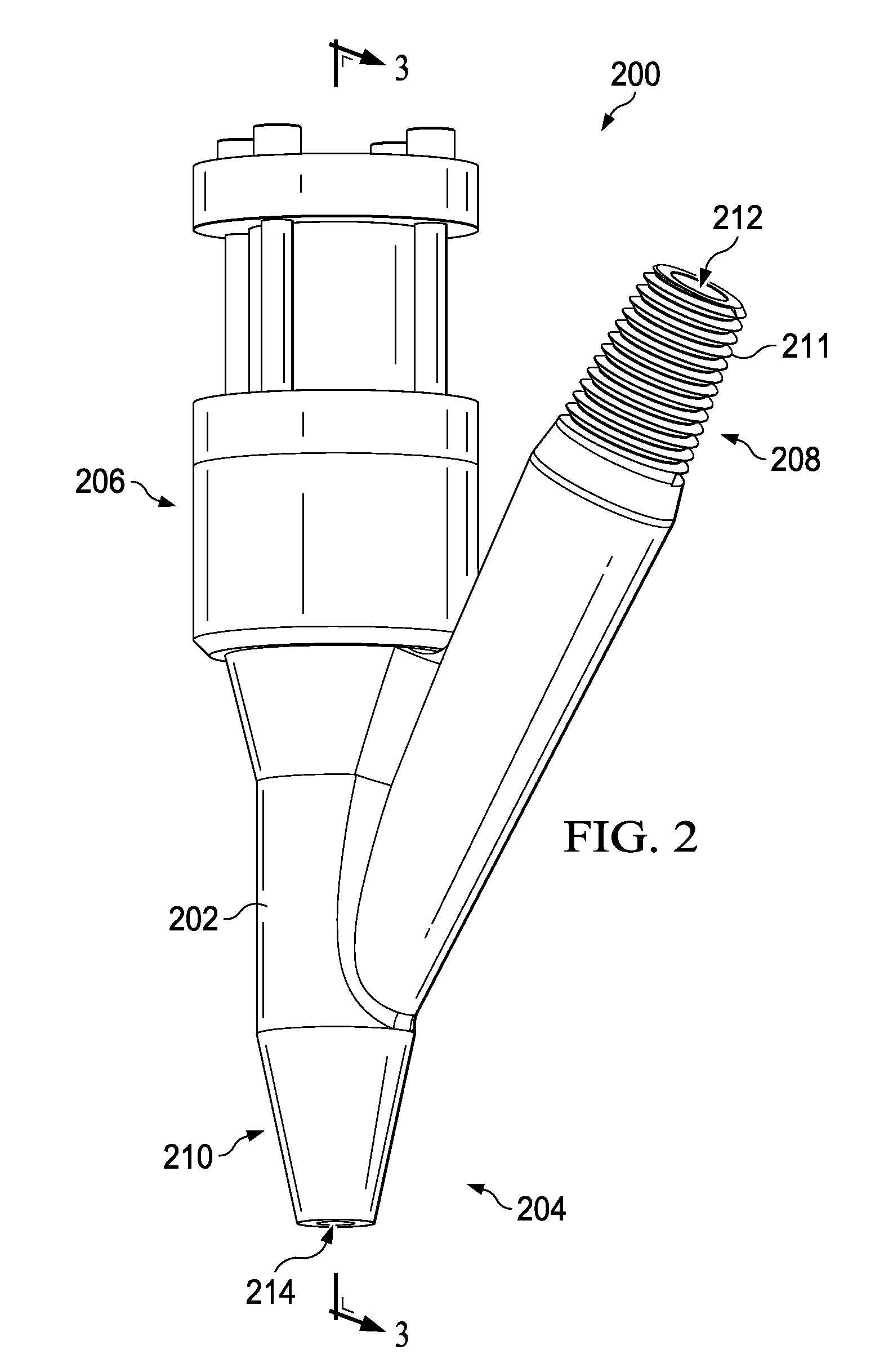

Control Valve Having a Disposable Valve Body

Owner:THE BOEING CO

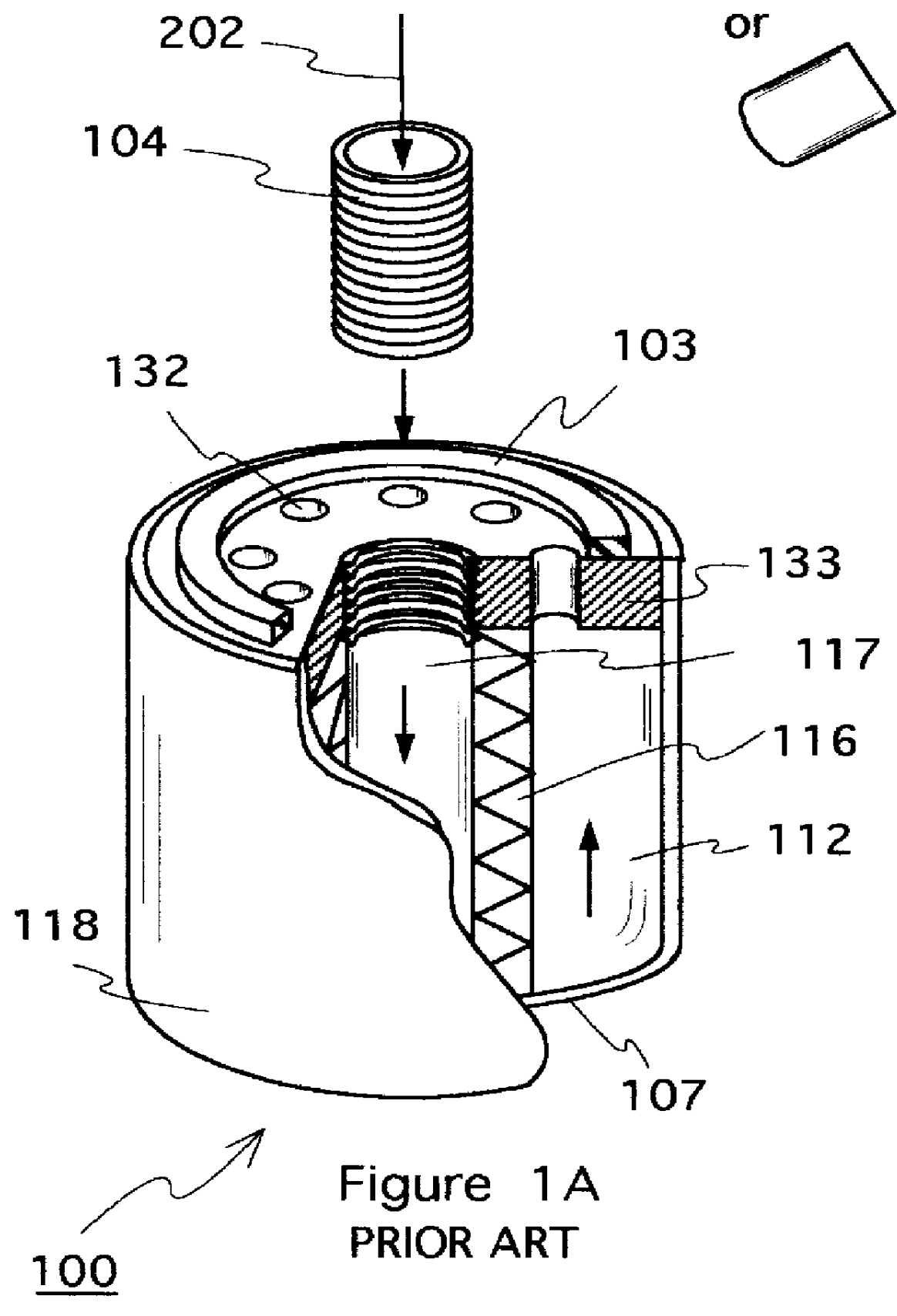

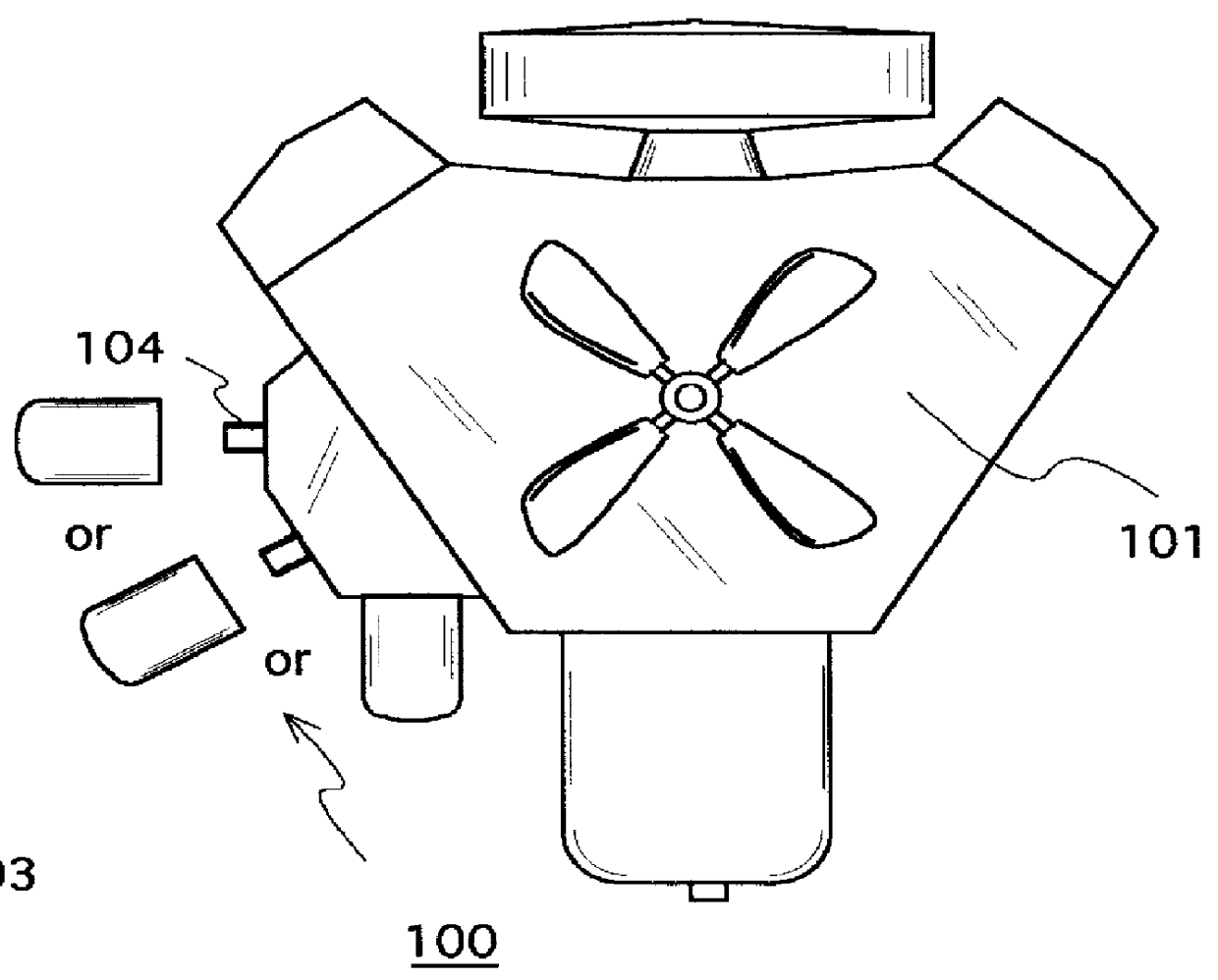

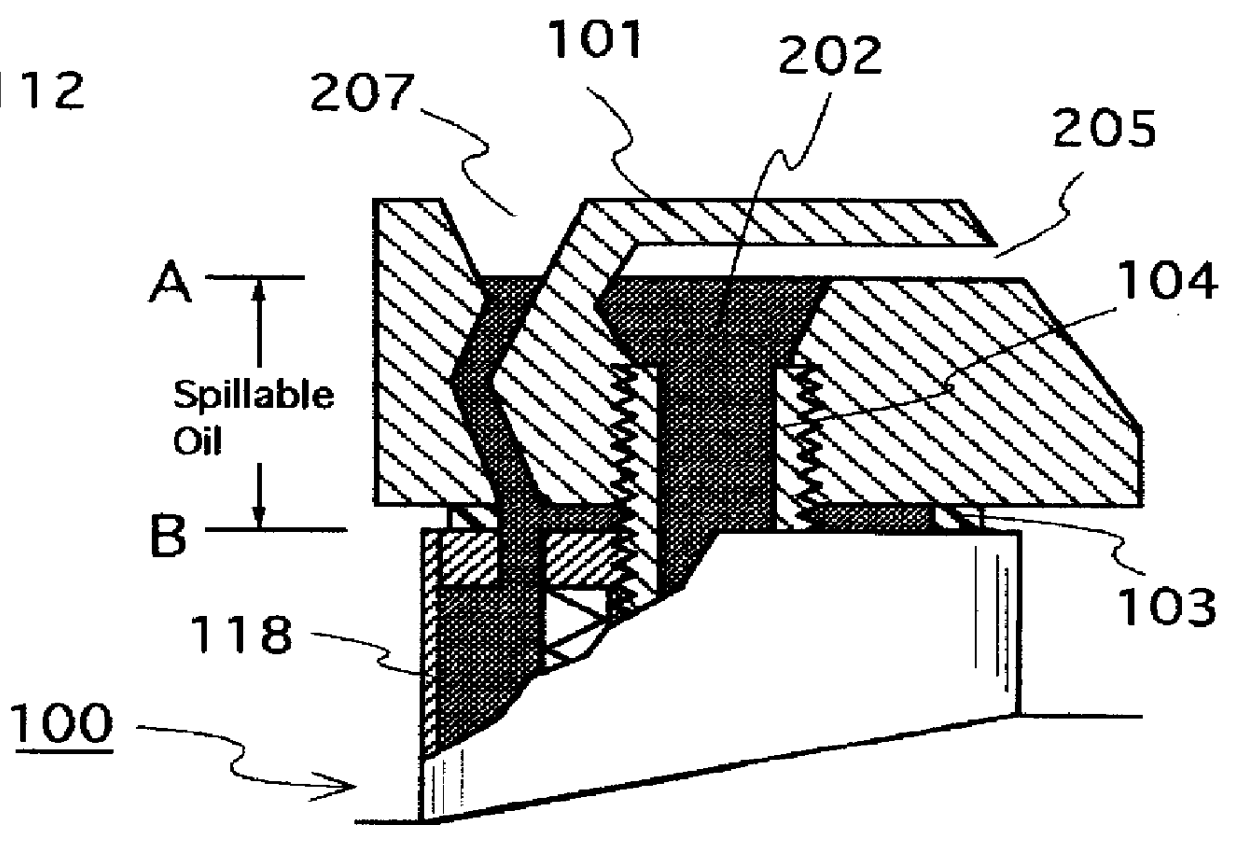

Piercing filter oil containment boot

InactiveUS6056874AFree from cleaningReduce internal volumeOther washing machinesMachines/enginesOil filterWrench

Spillable oil from an oil filter and adjacent engine cavities of trapped engine oil is transferred outwardly through filter housing sidewalls at designated low points to a temporary boot container by gravity following a piercing operation through the filter housing. Oil transfer to the container is performed prior to breaking the seal between the engine block and the filter. All of the spillable oil is caught in the boot containment device which incorporates internal tack like hollow piercing elements. The required piercing force to drive the tacks into the filter wall may be applied to the exterior of the filter boot using common filter strap wrenches, or by light taps from a hammer, wrench or similar tool.

Owner:GOODMAN LOWELL R

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com