Metered drop push button dispenser system

a dispenser system and push button technology, applied in the field of dispensers or delivery systems, can solve the problems of limiting the effectiveness of flowable substances, affecting the use of users, and affecting the physical and mental health of people with disabilities,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

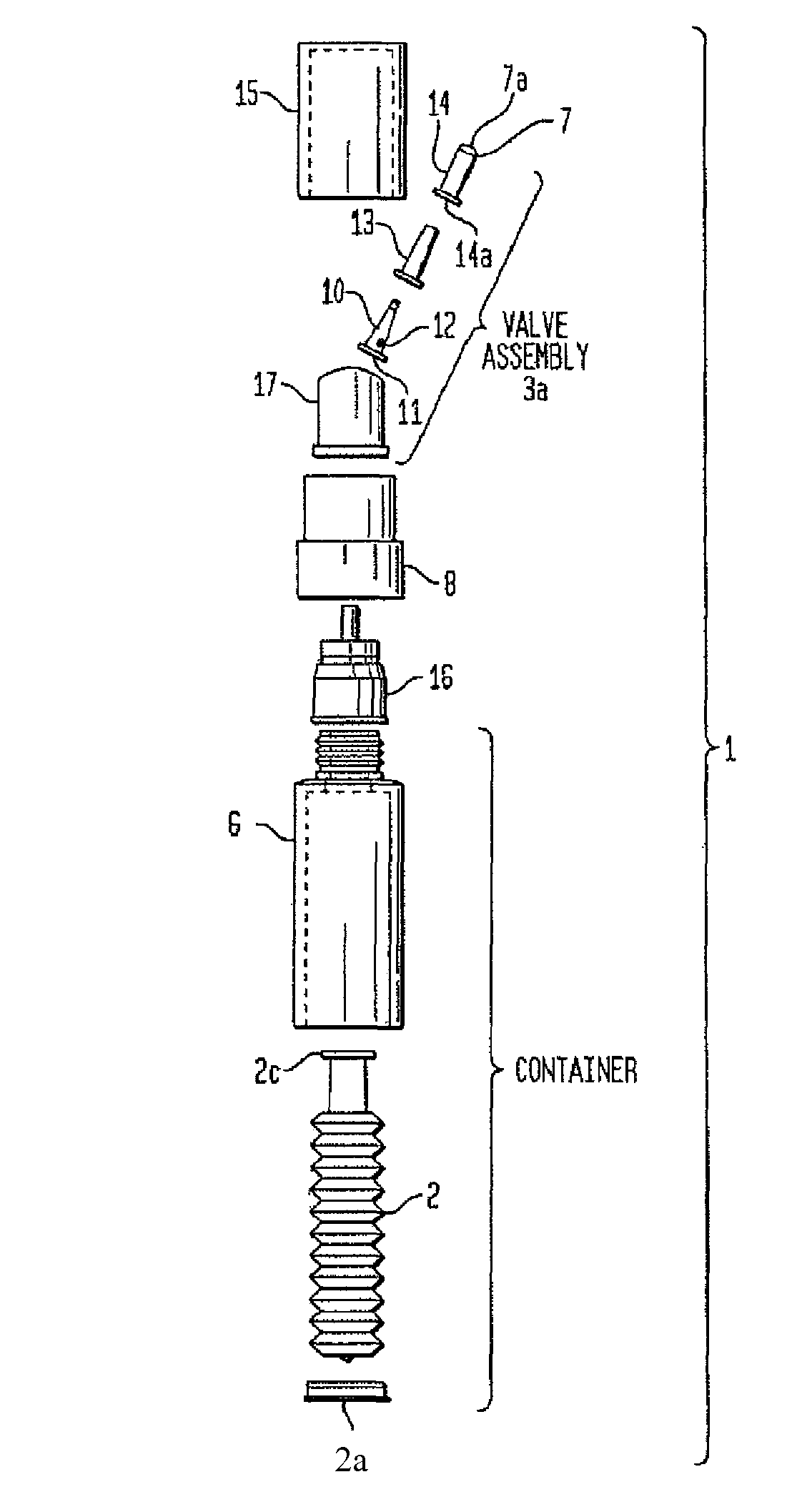

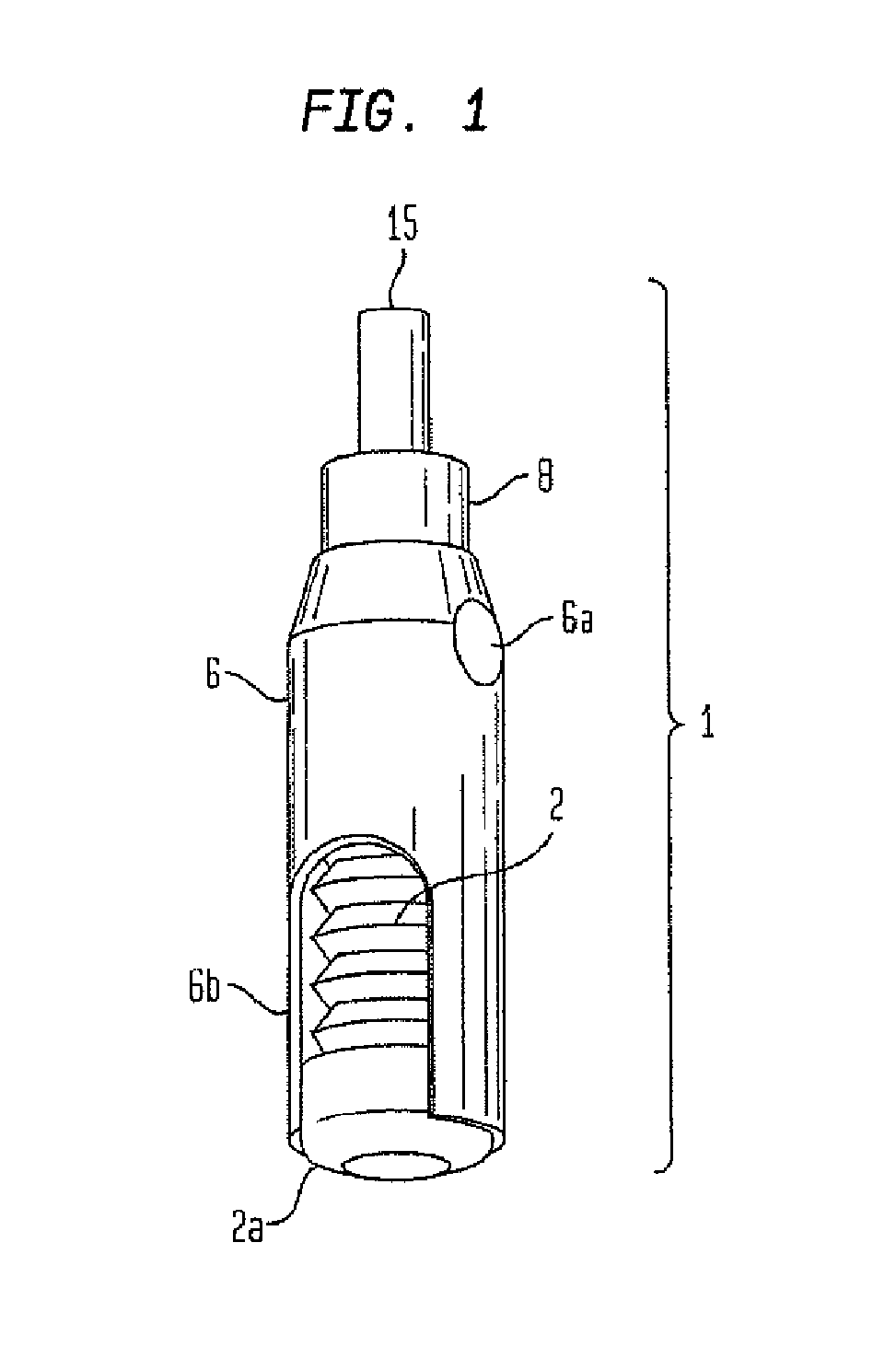

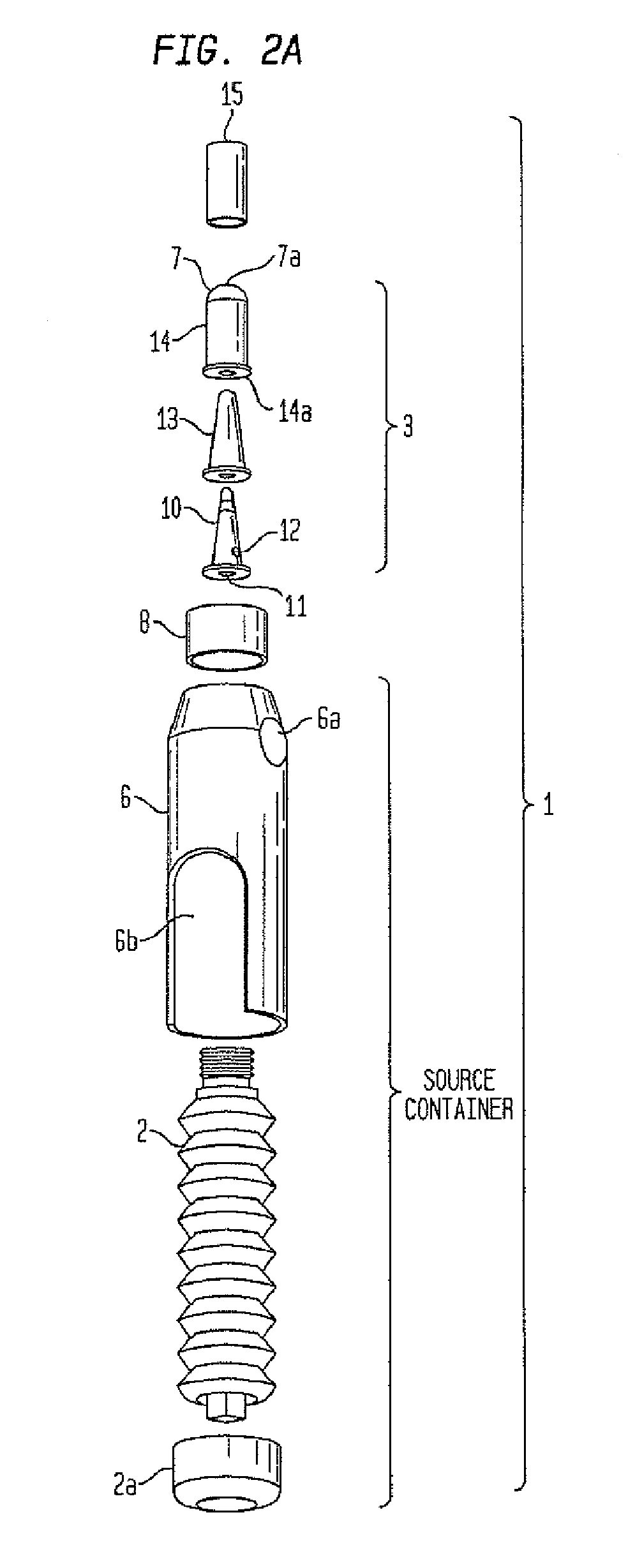

Image

Examples

example 1

[0097]In an exemplary embodiment, preservative free opthalmological products are amenable to storage and dispensing from a multidose metered delivery system having the continuously sealing one way valve assembly of the present invention. For example, eye drops, and preferably those eye drops involved in chronic care, for example, dry eye, glaucoma, allergies and NSAIDs, and also those eye drops intended for acute care, for example during ocular surgery, are amenable to storage and dispensing from a multidose metered delivery system having the continuously sealing one way valve assembly of the present invention. As a further example, those eye drops used to relieve eye fatigue, those eye drops used to relieve dry eye, those eye drops used relieve dry eye due to computer use, television use, or fatigue due to prolonged awake periods are amenable to storage and dispensing from a multidose metered delivery system having the continuously sealing one way valve assembly of the present inve...

example 2

[0099]In an exemplary embodiment, preservative-free otorhinolarygological products are amenable to storage and dispensing from a multidose metered delivery system having the continuously sealing one way valve assembly of the present invention. For example, nasalia medicines, and preferably nasal sprays, external ear creams, ear drops, steroid ear drops, antibiotic ear drops, nose drops, and nose drops comprising phenylephrine 0.25% and pseudoephedrine 30 mg, are amenable to storage and dispensing from a multidose metered delivery system having the continuously sealing one way valve assembly of the present invention.

example 3

[0100]In an exemplary embodiment, preservative free dermatological products are amenable to storage and dispensing from a multidose metered delivery system having the continuously sealing one way valve assembly of the present invention. For example, preservative free skin preparations; scalp preparations; corticosteroid creams, lotions and ointments; topical antibiotics and topical anti-fungal agents are amenable to storage and dispensing from a multidose metered delivery system having the continuously sealing one way valve assembly of the present invention. Thus, these preservative free dermatological products are amenable to storage and dispensing from a multidose metered delivery system having the continuously sealing one way valve assembly of the present invention because they are preservative free formulations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com