Natural gas wet desulphurization and regeneration integrated apparatus

A wet desulfurization and regeneration device technology, applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems that natural gas cannot enter the external transportation pipeline network, corrosion of the collection and transportation pipeline network, and affect crude oil production, etc., to achieve enhanced separation ability, Less investment in equipment and improved regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

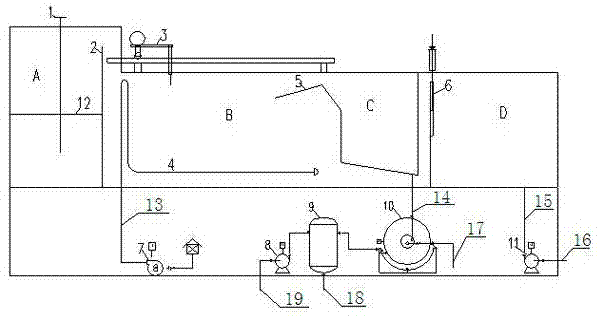

[0020] In order to further disclose the technical solution of the present invention, the following will be described in detail through specific implementation methods in conjunction with the accompanying drawings:

[0021] The invention includes a regenerative separation reactor and a filtration circulation skid, and is characterized in that the natural gas wet desulfurization integrated regeneration device is designed in two layers, the regeneration separation reactor is on the upper layer, and the filtration circulation skid is on the lower layer, separated by a skid frame; the regeneration separation The device includes spray chamber A, separation chamber B, sulfur foam chamber C and lean liquid chamber D arranged from left to right. The spray chamber A communicates with the separation chamber B through the weir plate 2, and the separation chamber B communicates with the separation chamber through the overflow plate 5. The sulfur foam chamber C is connected and communicated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com