Liquid control system for double-fluid injector

A technology of liquid control and injector, which is applied in the direction of liquid injection device, injection device, and device for coating liquid on the surface, etc. It can solve the problem of inconsistency in glue supply volume, increase the overall size of the injector, and affect the consistency of glue points, etc. problem, achieve the effect of eliminating inconvenience, preventing liquid backflow and reducing shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

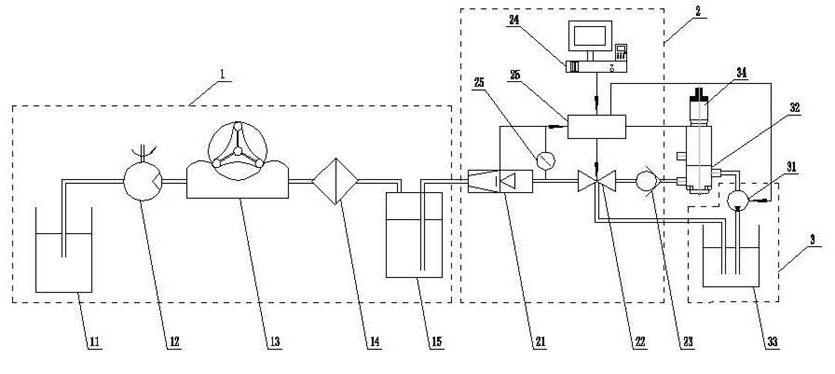

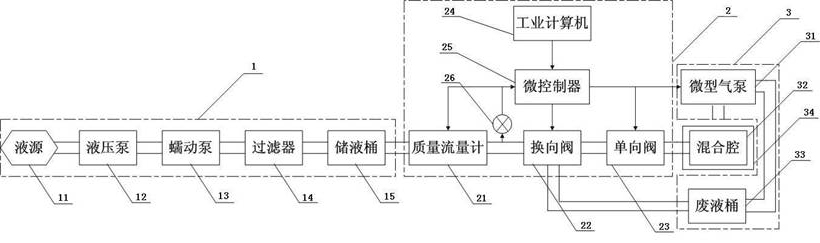

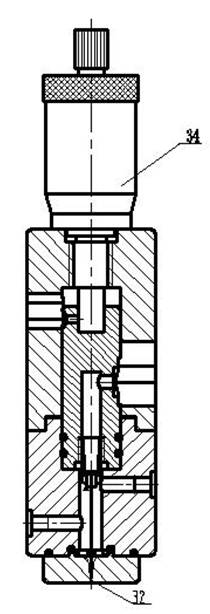

[0035] refer to figure 1 , figure 2 and image 3 , a liquid control system for dual-fluid injection, including a liquid source device (1), a liquid control device (2), a suction device (3) and a dual-fluid injector (34), characterized in that: the liquid source The device (1), the liquid control device (2), the dual-fluid injector (34) and the suction device (3) are sequentially connected through hoses to realize the liquid supply and liquid recovery of the dual-fluid injector.

Embodiment 2

[0037] refer to figure 1 , figure 2 and image 3 , this embodiment is basically the same as Embodiment 1, especially that the liquid source device (1) provides a liquid source for the system and ensures the existence of the working medium; the structure of the liquid source device (1) is: a The liquid source (11) is sequentially connected to a hydraulic pump (12), a peristaltic pump (13), a filter (14) and a liquid storage tank (15), and the hydraulic pump (12) and the peristaltic pump (13) have The signal port is connected with the microcontroller (25) in the liquid control device (2).

Embodiment 3

[0039] refer to figure 1 , figure 2 and image 3 , this embodiment is basically the same as Embodiment 1, the special feature is that the liquid control device (2) adjusts the flow of liquid, changes the flow direction, and provides constant flow, pulsating or continuous liquid to downstream equipment; the liquid source device The structure is: a mass flow meter (21) is sequentially connected to a liquid reversing valve (22) and a liquid check valve (23), the mass flow meter (21), liquid reversing valve (22) and liquid check valve The direction valves (23) all have signal ports, which are connected with the signal ports of the microcontroller (25), and the microcontroller (25) is connected with the industrial computer (24) and set parameters through the industrial computer (24), the quality The outlet of the flow meter (21) is provided with a flow display meter (26), and its display signal is transmitted to the microcontroller (25).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com