Patents

Literature

60results about How to "Short smelting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rapid solidification Al-Ti-B-Sc intermediate alloy refiner and preparation method thereof

InactiveCN103589916AImprove grain refinement effectImprove adsorption capacityRare-earth elementMulti element

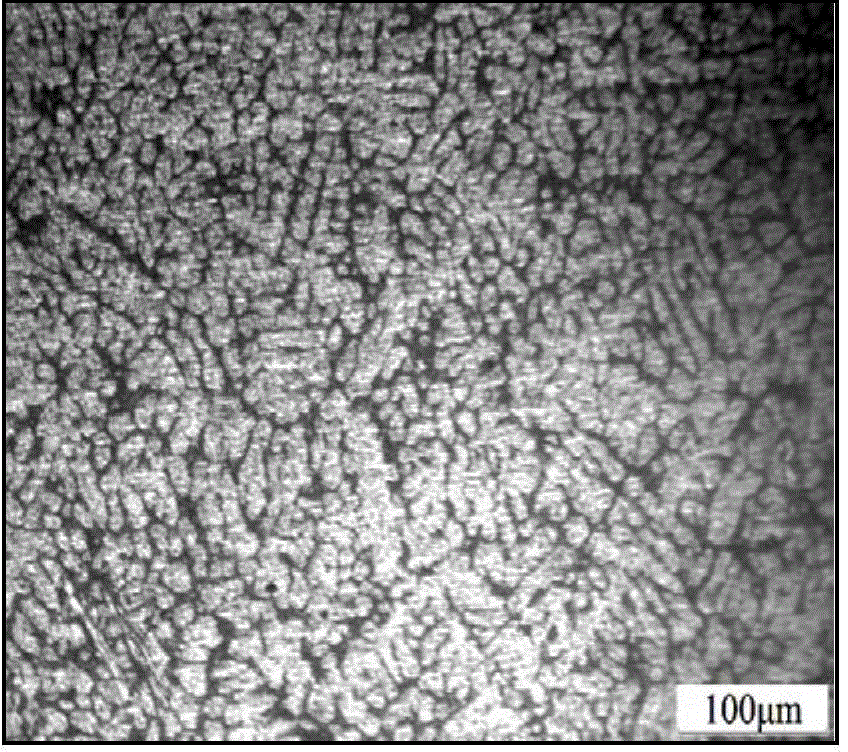

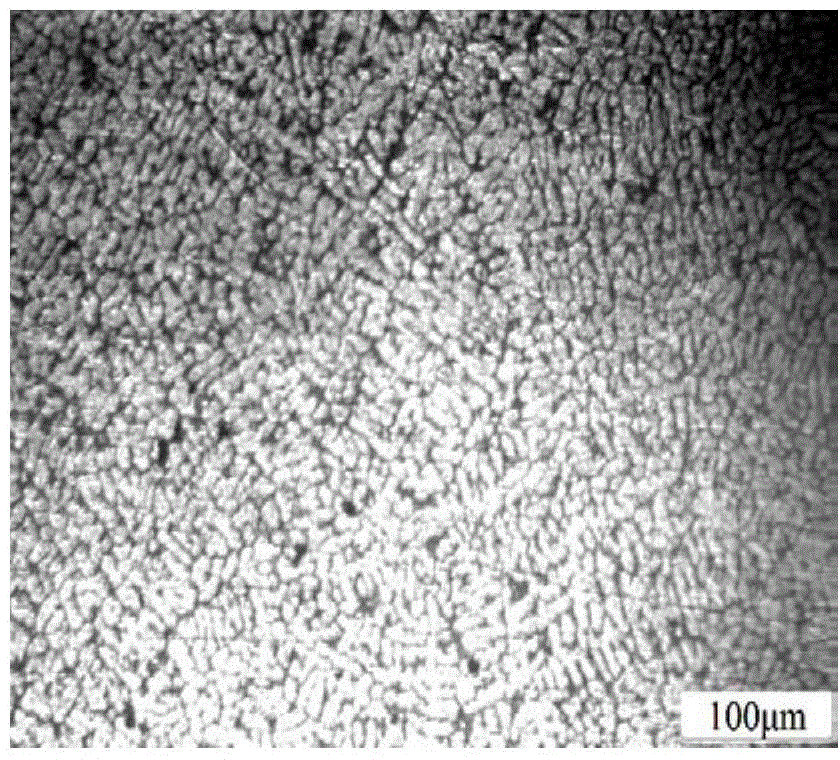

The invention provides a rapid solidification Al-Ti-B-Sc intermediate alloy refiner. The refiner is intermediate alloy and comprises, by mass, 3.75%-5% of Ti, 0.75%-1% of B, 0.1%-0.5% of Sc, and the balance Al. The cast structure of the refiner comprises particulate alpha-Al, TiAl3, TiB2, AlB2 and Al3Sc. The aluminum alloy refiner is an Al-Ti-B-Sc multi-element alloy refiner which comprises the rare earth element Sc and is acquired through rapid solidification. When the refiner is added to aluminum alloy, the aluminum alloy can be molten within a short time and can be evenly distributed more easily. When the refiner is applied, melting time can be shortened, and electric energy losses can be reduced.

Owner:HEBEI UNIV OF TECH

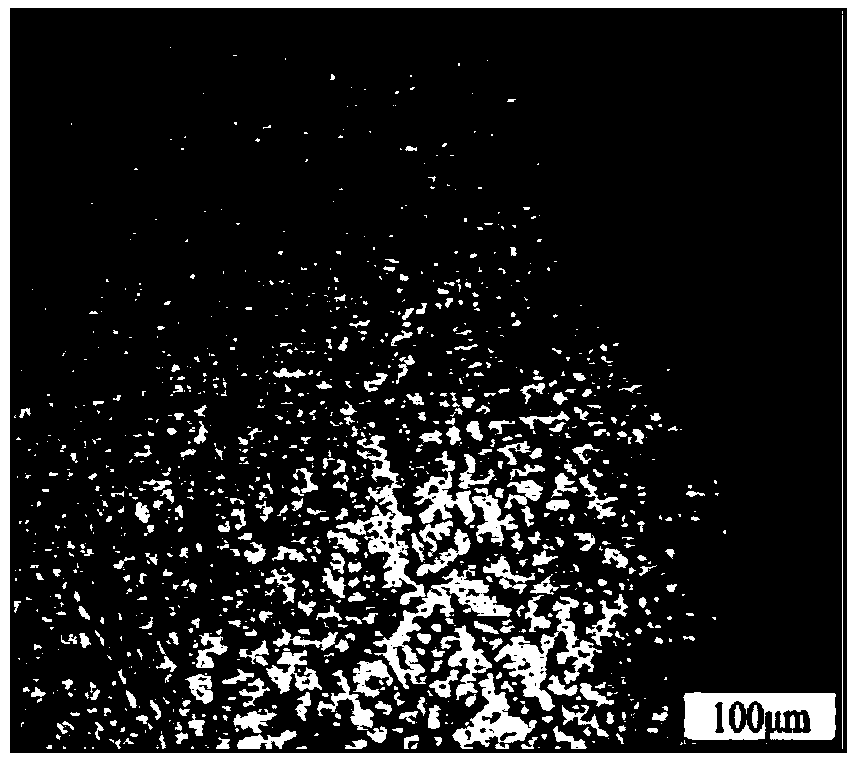

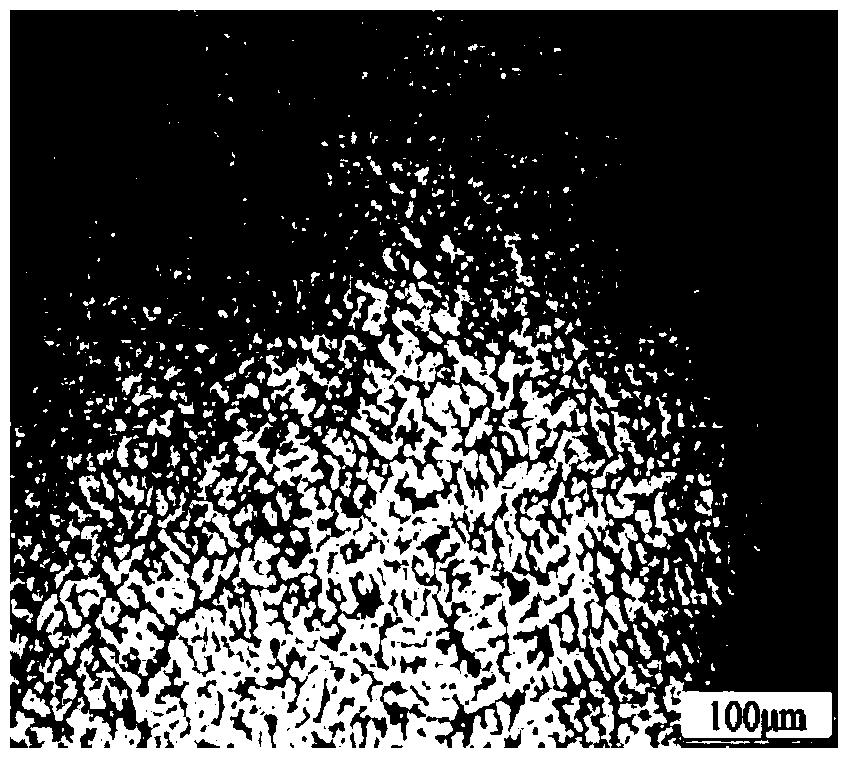

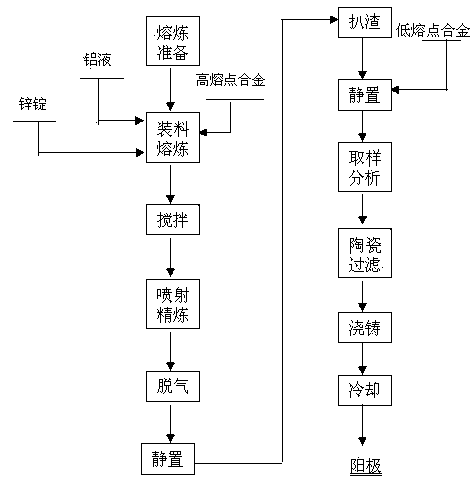

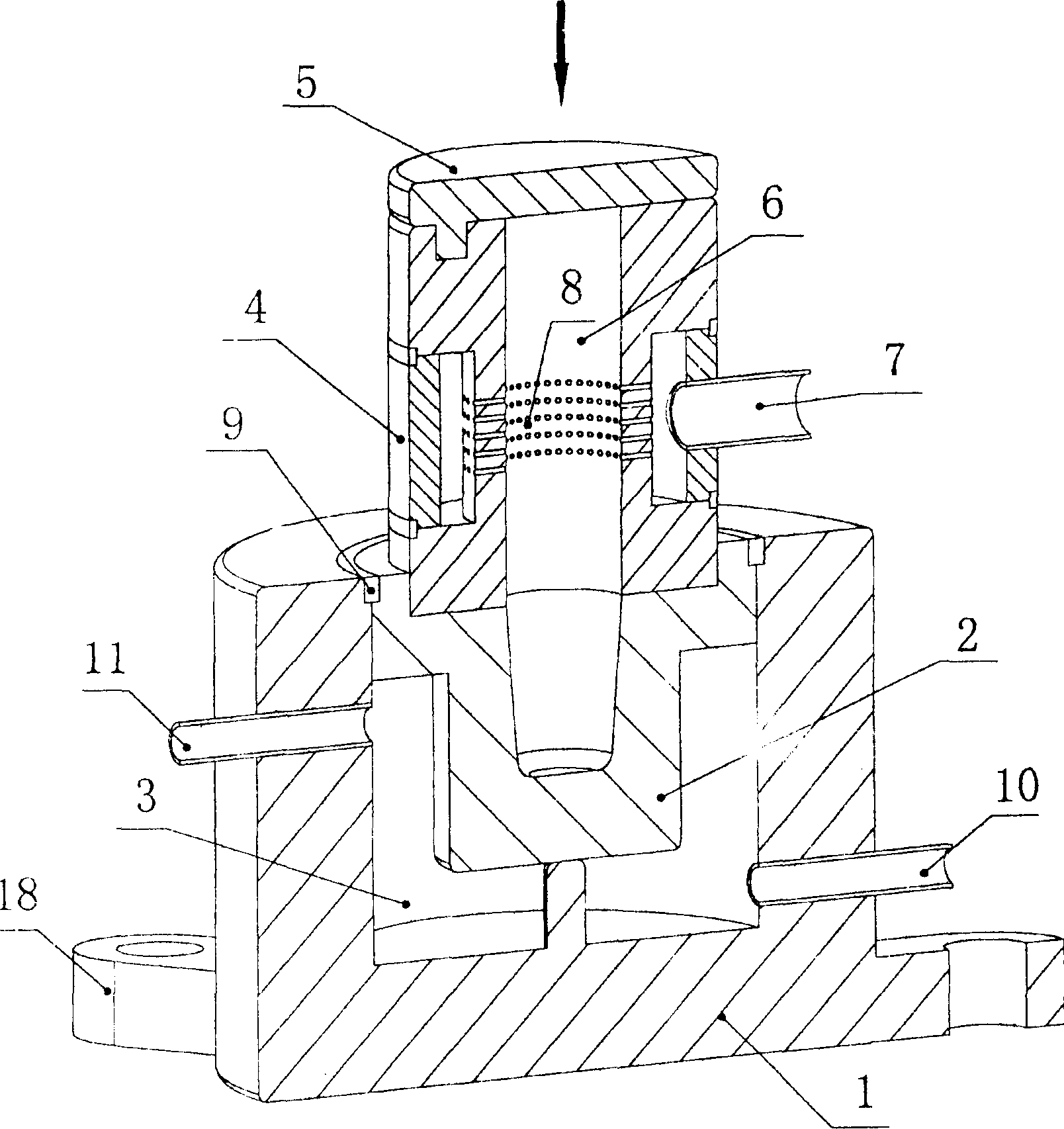

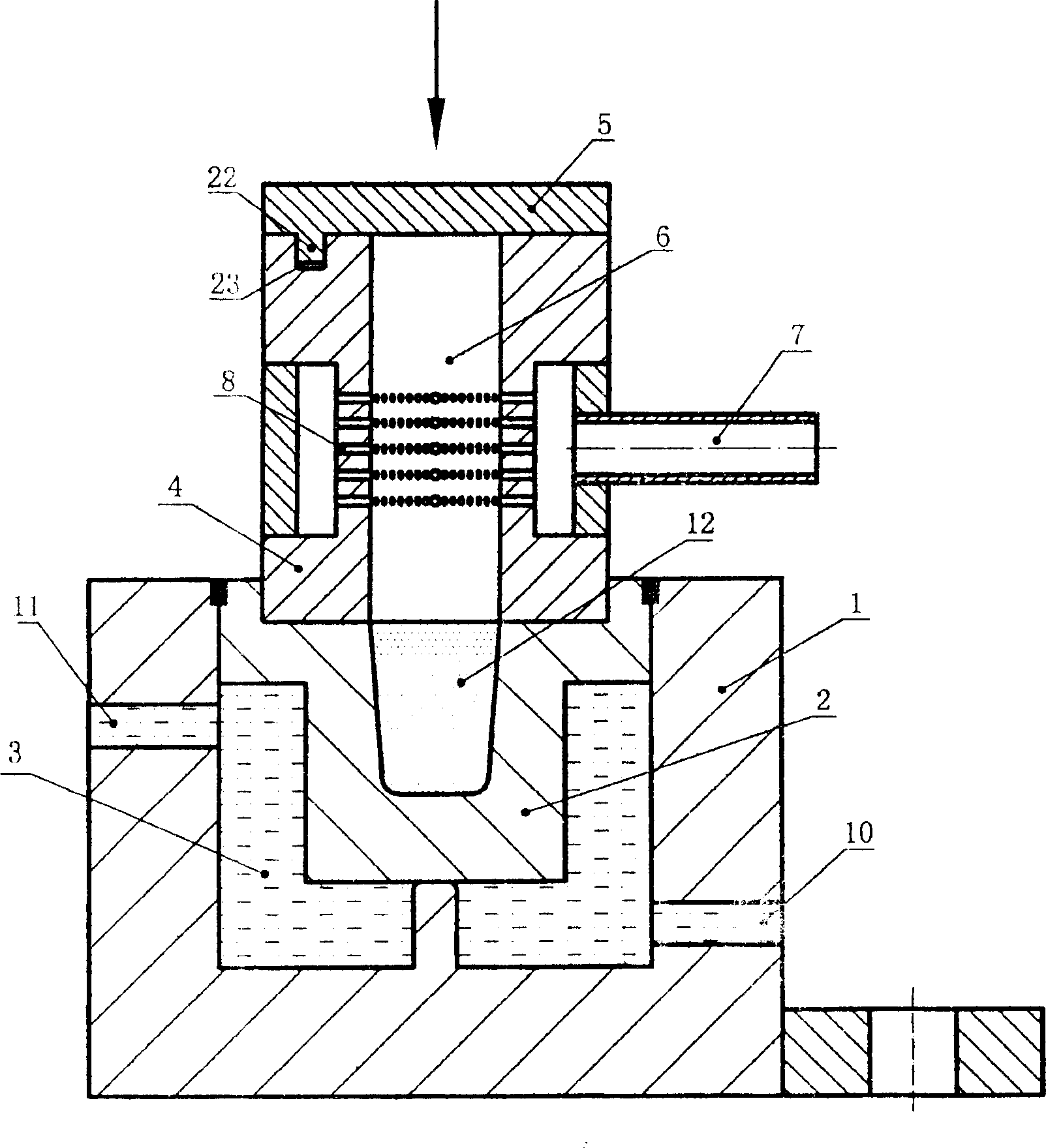

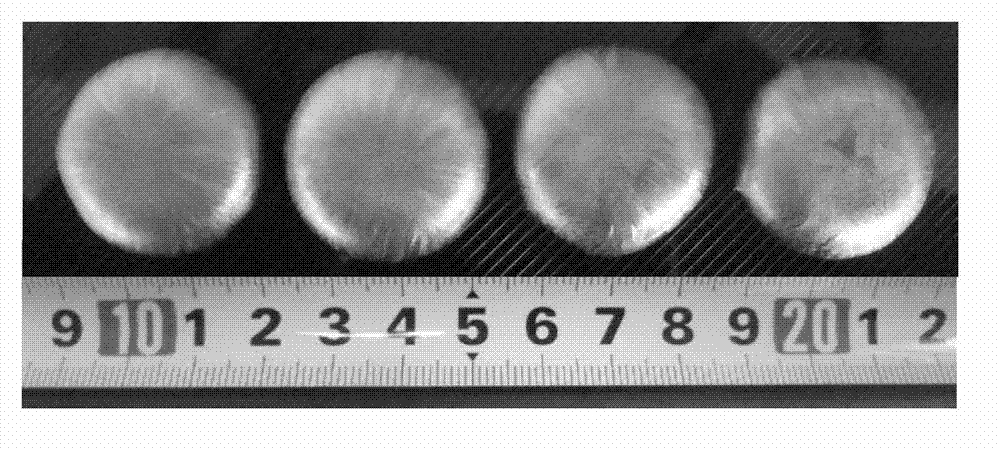

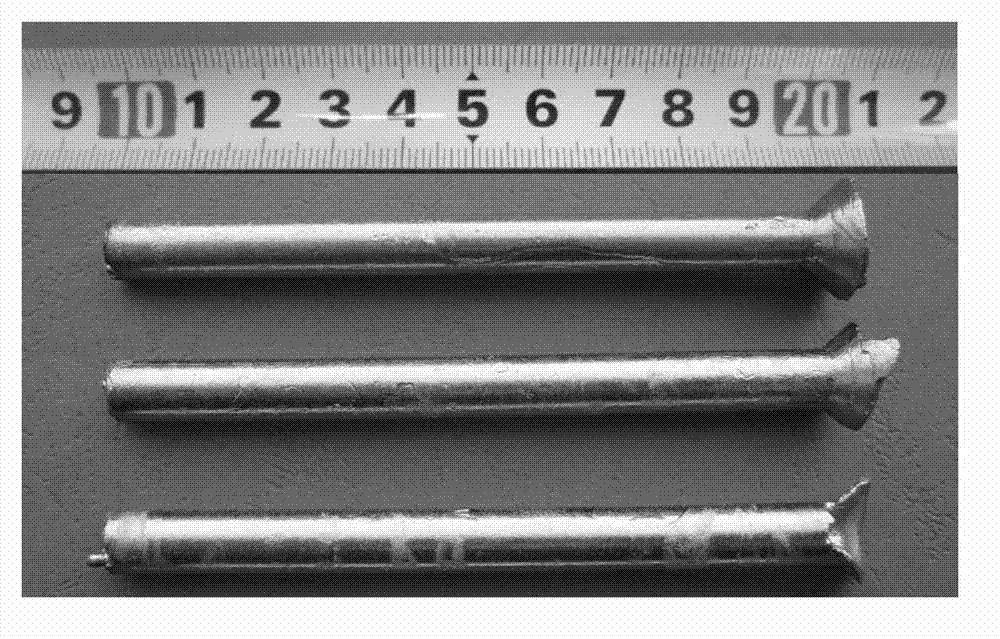

Casting method of aluminum alloy sacrificial anode

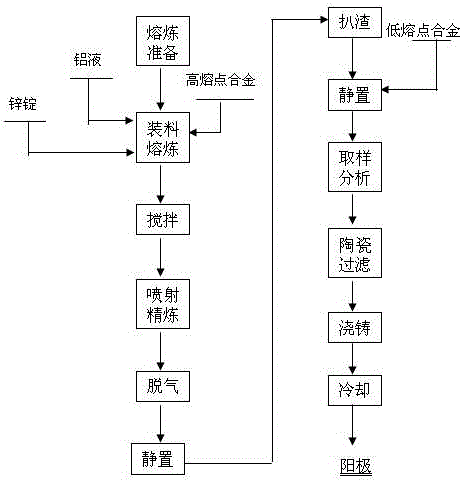

The invention belongs to the technical field of corrosion and prevention, and in particular relates to a casting method of an aluminum alloy sacrificial anode. The casting method comprises the following steps: adding basic electrolytic molten aluminum to a resistance furnace; then adding a zinc ingot to obtain molten aluminum alloy; performing jet refining on the molten aluminum alloy by adopting an argon located refining agent; charging argon to refined aluminum alloy melt to degas; drossing oxidizing scum on the surface of the aluminum alloy melt through a drossing tool; adding a low melting point metallic element to drossed aluminum alloy melt; electromagnetically agitating the melt after pressing the low melting point metal; carrying out ceramic filtering; pouring and casting the aluminum alloy melt to a preheated iron anode mould at an even casting speed under the temperature of 700 to 740 DEG C until the mould is full of the aluminum alloy melt; and moving the aluminum alloy melt out of the mould after cooling, solidifying and molding, so as to obtain the aluminum alloy sacrificial anode. The casting method has the characteristics of being short in smelting time, small in loss of iron scale, high in degassing and purifying performances, and low in smelting cost.

Owner:NORTHEASTERN UNIV +1

Laser smelting furnace with water cooled copper mould and method for smelting ingot

Owner:BEIHANG UNIV

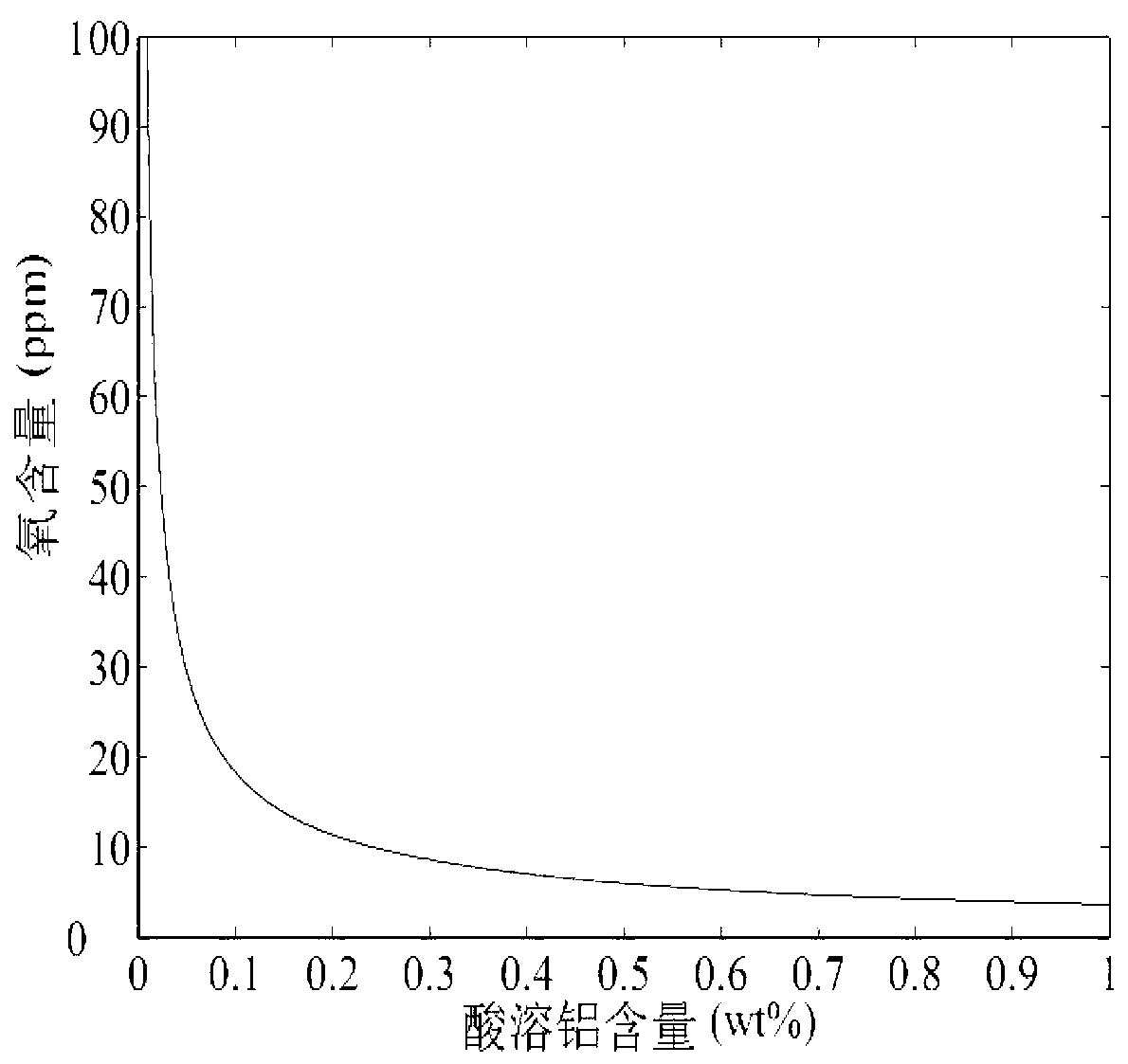

Method for smelting ultra-low-carbon steel by using single-nozzle refining furnace

The invention relates to a smelting method of ultra-low-carbon steel, which is an operating method for decarburizing by using a single-nozzle refining furnace. The invention is a smelting method for smelting ultra-low-carbon steel by using the single-nozzle refining furnace. The method is used for smelting the ultra-low-carbon steel with C of being less than or equal to 20ppm, and adjusts the inserting depth of a single-nozzle furnace dipping pipe, lance position of an oxygen lance, vacuum degree, oxygen supplying flow and eccentric bottom-blown argon of a steel ladle to stir molten steel under the vacuum condition by controlling the initial conditions of the thickness of a tapping slag layer, the temperature of arrived molten steel, the content of arrived carbon and the like so as to achieve the purpose of decarburization. The method has the following advantages that: 1. the treatment time of the molten steel is short, the refractory material consumption is low, and the scaffolding of the dipping pipe is little; and 2. the smelting time is short, the splashing is little, the consumption of sealing rings is less, the corrosion of the steel ladle is not serious, the cost is low and the operation is simple.

Owner:北京北科三泰科技发展有限公司

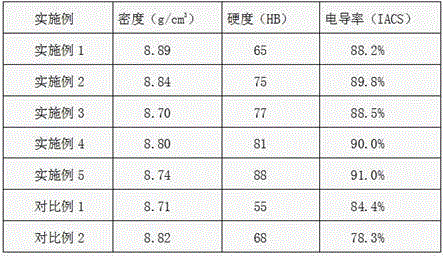

Electric contact material and preparation method thereof

The invention relates to an electric contact material, in particular to a graphene reinforced copper-matrix electric contact composite material and a preparation method of the material. The electric contact material consists of the following components in percentage by weight: 0.1-1.0% of nickelized graphene and 99.0-99.9% of copper alloy. The preparation method comprises the steps of graphene nickelizing, copper alloy pulverizing, ball-milling and powder mixing, densification processing and vacuum electric arc smelting. According to the electric contact material disclosed by the invention, the nickelized graphene is added in the copper alloy and serves as the framework, so that the material has high hardness, mechanical impact-resistance and electric arc ablation resistance; and the lowering of the electric conductivity and the heat conductivity is avoided. Vacuum electric arc smelting is adopted, so that the smelting time is short; segregation of graphene particles is avoided; and the oxidation of the copper matrix is effectively prevented.

Owner:UNIV OF JINAN

Smelting method of low-phosphorous steel

ActiveCN102839251ALow viscosityImprove liquidityManufacturing convertersProcess efficiency improvementSlagLiquid steel

The invention discloses a smelting method of low-phosphorous steel, which comprises the steps that after melted iron is added to scrap steel, the scrap steel is dephosphorized through converter blowing to obtain dephosphorized liquid steel and dephosphorized slag; bauxite is added to a converter, the adding quantity is 5-15kg every ton of steel, and the mass percentage of Al2O3 in the dephosphorized slag is controlled at 10-15%; 1-2 minutes after the bauxite is added, the dephosphorized slag is discharged from the converter; the dephosphorized liquid steel is dephosphorized through the converter blowing to obtain low-phosphorous liquid steel and decarbonized slag; the converter tapping is conducted; and the decarbonized slag is discharged from the converter. With the adoption of the smelting method of the low-phosphorous steel, the proportion of the discharged slag amount to the total dephosphorized slag amount is equal to or greater than 70% in the converter dephosphorization process; rephosphorization is prevented; in addition, the slag formation raw material is more environmental-friendly without pollution of the environment; and the mass percentage of phosphorus in the finally obtained low-phosphorous liquid steel can be less than 0.0060%.

Owner:SHOUGANG CORPORATION

Method for smelting ultra-low-carbon steel by using single-nozzle refining furnace

The invention relates to a smelting method of ultra-low-carbon steel, which is an operating method for decarburizing by using a single-nozzle refining furnace. The invention is a smelting method for smelting ultra-low-carbon steel by using the single-nozzle refining furnace. The method is used for smelting the ultra-low-carbon steel with C of being less than or equal to 20ppm, and adjusts the inserting depth of a single-nozzle furnace dipping pipe, lance position of an oxygen lance, vacuum degree, oxygen supplying flow and eccentric bottom-blown argon of a steel ladle to stir molten steel under the vacuum condition by controlling the initial conditions of the thickness of a tapping slag layer, the temperature of arrived molten steel, the content of arrived carbon and the like so as to achieve the purpose of decarburization. The method has the following advantages that: 1. the treatment time of the molten steel is short, the refractory material consumption is low, and the scaffolding of the dipping pipe is little; and 2. the smelting time is short, the splashing is little, the consumption of sealing rings is less, the corrosion of the steel ladle is not serious, the cost is low andthe operation is simple.

Owner:北京北科三泰科技发展有限公司

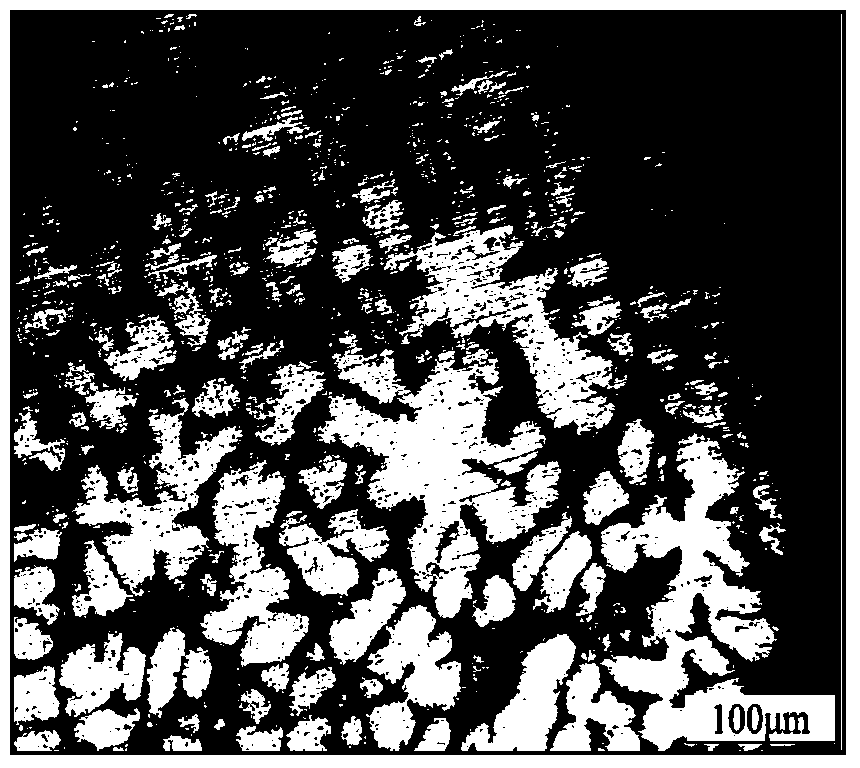

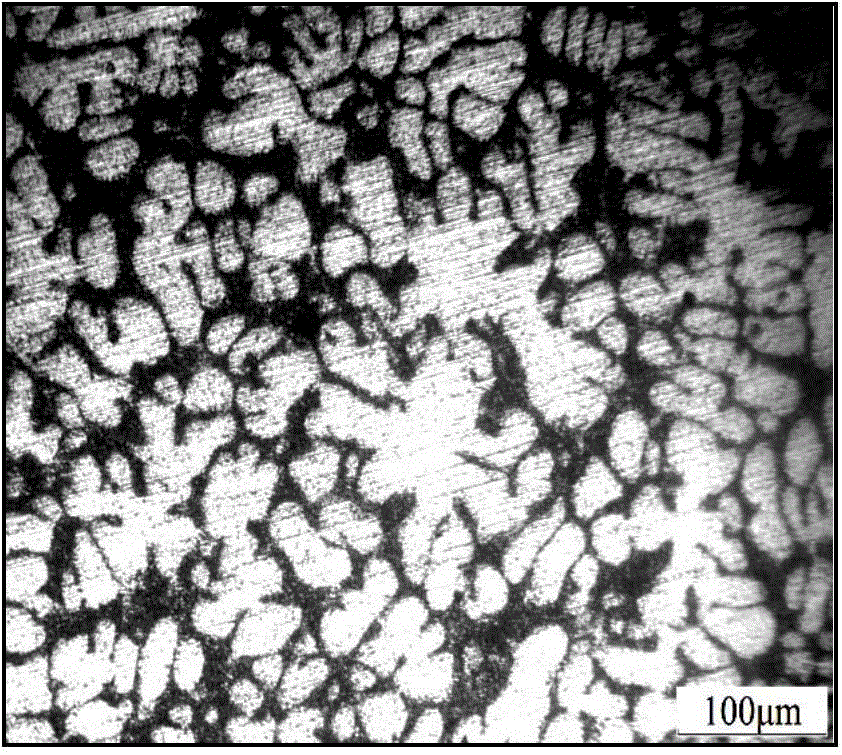

Zinc alloy and manufacturing method thereof

The invention discloses a zinc alloy and a manufacturing method thereof. The zinc alloy comprises the following elements: 4-7% of Al, 0.5-1.5% of Cu, 0.4-0.7% of Ti, 0.07-0.1% of B, 0.02-0.025% of Mg,0.1-1% of others, and the balance Zn. The method comprises the following steps: (1) pure aluminum is heated to a molten state, and is sprayed on the inner surface of a crucible; and a filter structure is fixed on the side surface of the inner surface; (2) zinc alloy raw materials are put in the crucible, and are vacuumized and heated until the raw materials are totally molten to obtain a molten pool; (3) a graphite stirring device is started; and a refining agent is continuously added to obtain a purified molten pool; (4) the purified molten pool is modified, and is cast and molded by a cooling extrusion process to obtain a zinc alloy ingot to be treated; and (5) the zinc alloy ingot to be treated is subjected to spheroidizing annealing to obtain the needed zinc alloy. The zinc alloy is high in purity, low in large-size dendritic segregation, uniform in overall grain size refining and low in primary structure multiple eutectic dendritic crystals.

Owner:GUIZHOU INST OF METALLURGY & CHEM ENG

Electric-arc furnace converter process for smelting steel and iron slag

ActiveCN103667590AShort smelting timeShorten smelting timeProcess efficiency improvementElectric furnaceMelting tankElectric arc furnace

The invention discloses an electric-arc furnace converter process for smelting steel and iron slag, belongs to the field of metallurgy, and aims to solve the technical problem about providing the electric-arc furnace converter process for smelting steel and iron slag with short duration of heat and low power consumption. In order to solve the technical problem, the invention provides the following technical scheme: furnace burden comprises molten iron, steel and iron slag, and steel scrap; molten iron is put into the furnace to enable the tapping of the molten iron accounts for 30-60% of that of all furnace burden; steel and iron slag is put into the furnace to enable the tapping of the steel and iron slag accounts for 35-70% of that of all furnace burden; when the steel scrap is put into the furnace for the first time, the tapping of the steel scrap accounts for 0-5% of that of all furnace burden; when the steel and iron slag is put into the furnace for the first time, the steel scrap is also put into the furnace, and the steel scrap is distributed on the steel and iron slag. With adoption of the process, the physical and chemical heat brought about by the molten iron is fully utilized to accelerate furnace burden melting and formation of the furnace burden in the furnace hearth, shorten melting time, reduce smelting power consumption, improve productivity and reduce production cost.

Owner:RUI STEEL INDAL OF PANZHIHUA GANGCHENG GROUP

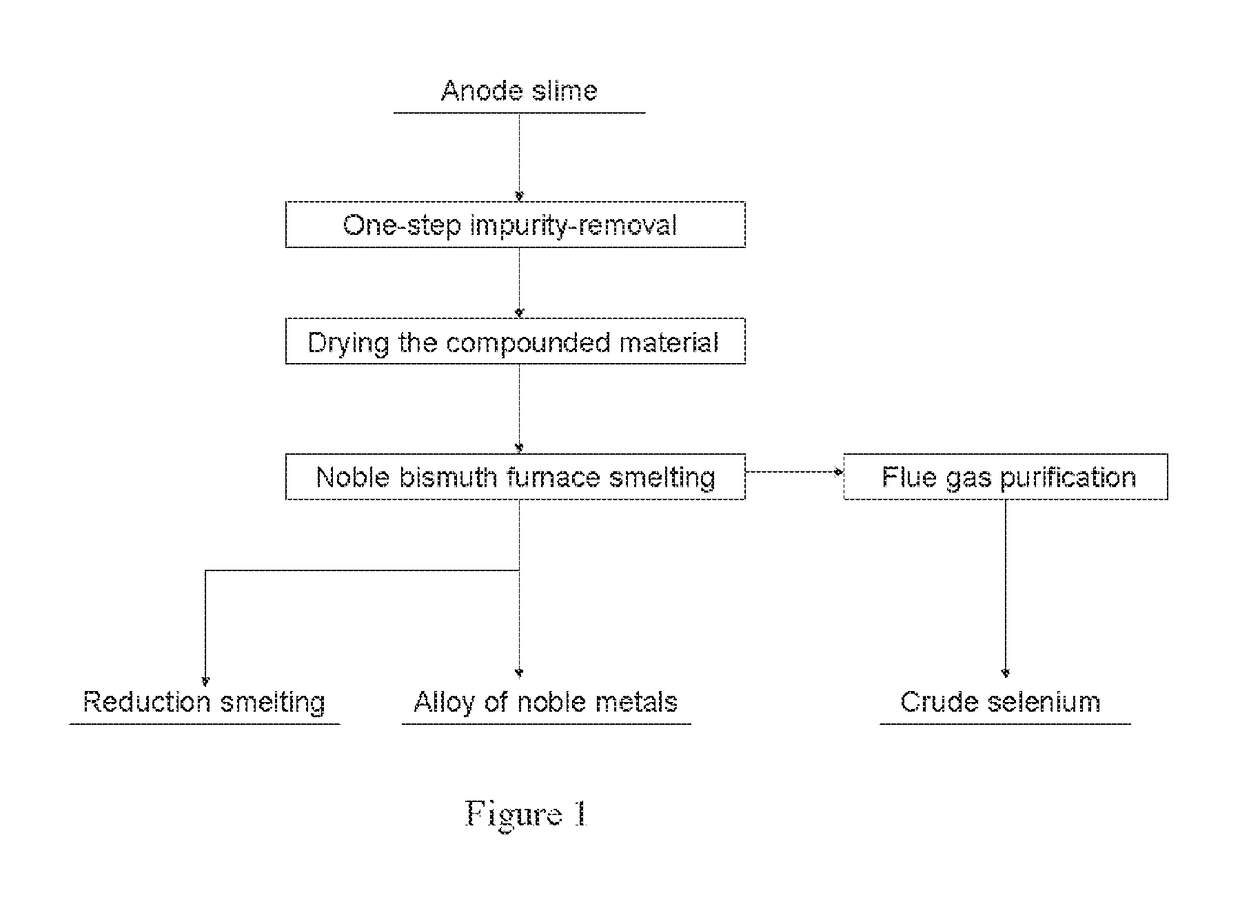

Process for extracting noble metals from anode slime

InactiveUS20170145541A1Avoid pollutionShort smelting timeProcess efficiency improvementAlloyImpurity

The present invention provides a process for extracting noble metals from anode slime, comprising: mixing sodium carbonate, quartz and coke powder and impurity-removed anode slime, and subjecting the mixture to smelting and converting to obtain alloys of noble metals. The present invention avoids problem of lead pollution by using metallic bismuth to collect noble metals; meanwhile, metallic bismuth has low melting point, high specific gravity, and formation heat of bismuth oxide of 45.6 kcal / g atomic oxygen, thus it is easy to be reduced and the reduction temperature is low, which are beneficial for saving energy consumption and reduction time; the much smaller amounts of copper, nickel, antimony and arsenic entering noble bismuth in a slightly reductive smelting atmosphere than those entering noble lead make the converting of noble bismuth become simple, thereby decreasing smelting time and increasing the direct recovery rate of noble metals in anode slime.

Owner:YANGGU XIANGGUANG COPPER

Process and product of nickel and chromium containing pig iron with fume or scale containing nickel and chromium

In a an ore smelting furnace or an electric furnace, nickel and chromium containing pig iron is produced with nickel and chromium containing fume or oxide scale, fluorite in 5-7 wt% of the nickel content, coke powder in 20-25 wt% and limestone or lime in 5-10 wt%. The present invention has the advantages of sufficient recovering of nickel and chromium, high output, low cost and short smelting period.

Owner:刘光火 +1

Crude zinc smelting method and smelting kiln used thereby

InactiveCN101665879AHigh recovery rateReduce lossRotary drum furnacesNon-ferrous extractive metallurgySmall footprint

The invention discloses a crude zinc smelting method and a smelting kiln used thereby. The method comprises the following steps: a pyrometallury technique is adopted for smelting and the smelting steps comprise loading, preheating, high-temperature smelting and condensing; the smelting kiln is internally provided with a preheating section, a high-temperature smelting section and a condenser; the raw materials are loaded into the smelting kiln by a feed inlet of the smelting kiln, and then enter the high-temperature smelting section for heating after the preheating section is preheated, and thegenerated zinc steam enters the condenser for condensation; the condensed waste gas enters the preheating section to preheat the raw material, and is exhausted out the smelting kiln by a gas outlet arranged on the smelting kiln, and the waste gas uses a cloth bag for removing dust; and the zinc solution generated by condensation is discharged to a zinc storing tank by a liquid outlet arranged onthe smelting kiln, and the waste residue is discharged out the smelting kiln by a spiral residue-discharging device arranged at the tail part of the smelting kiln. The invention is characterized by small occupied area, large yield, high heat utilization ratio, high recovery ratio, low production cost, capability of treating various renewable zinc ash raw materials and the like, not only is suitable for crude zinc smelting, but also is suitable for smelting other similar non-ferrous metals.

Owner:徐建成

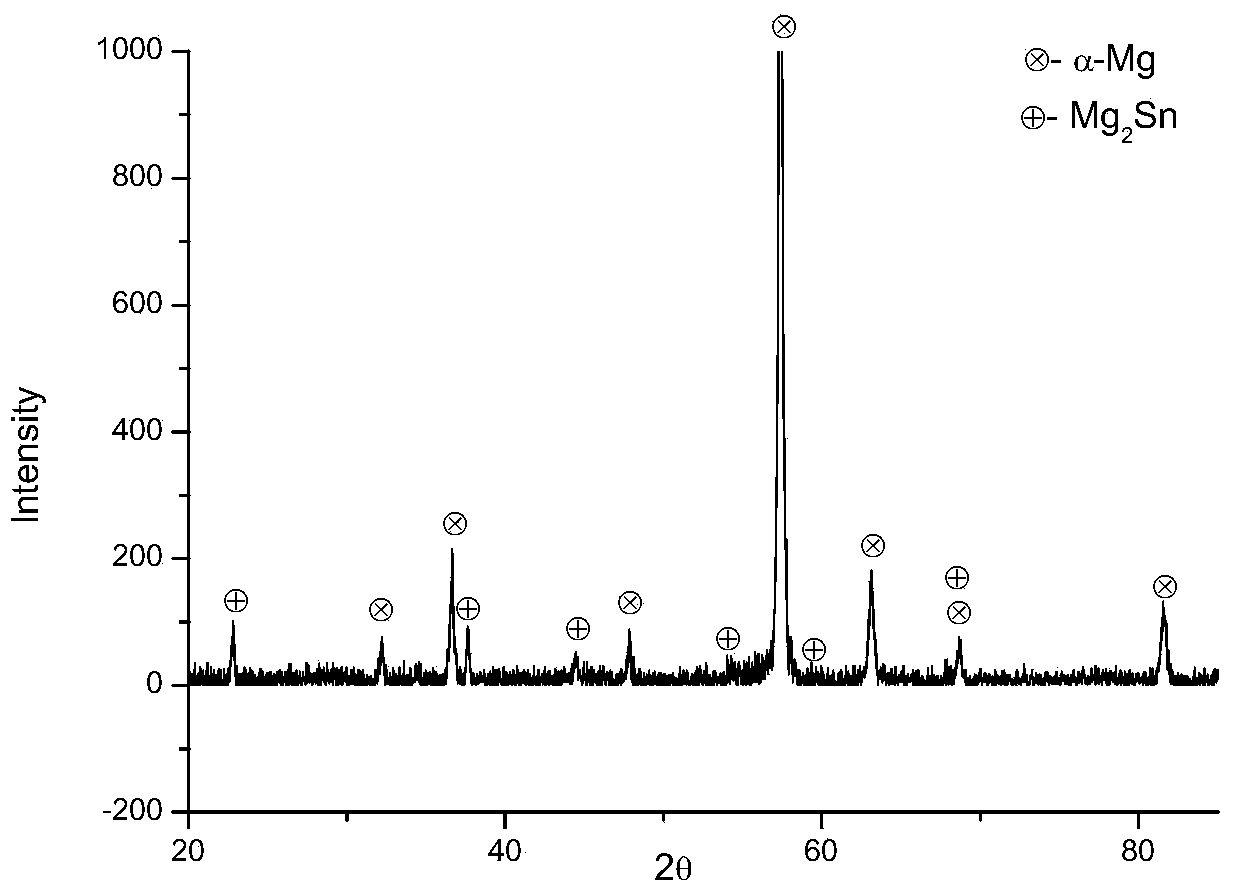

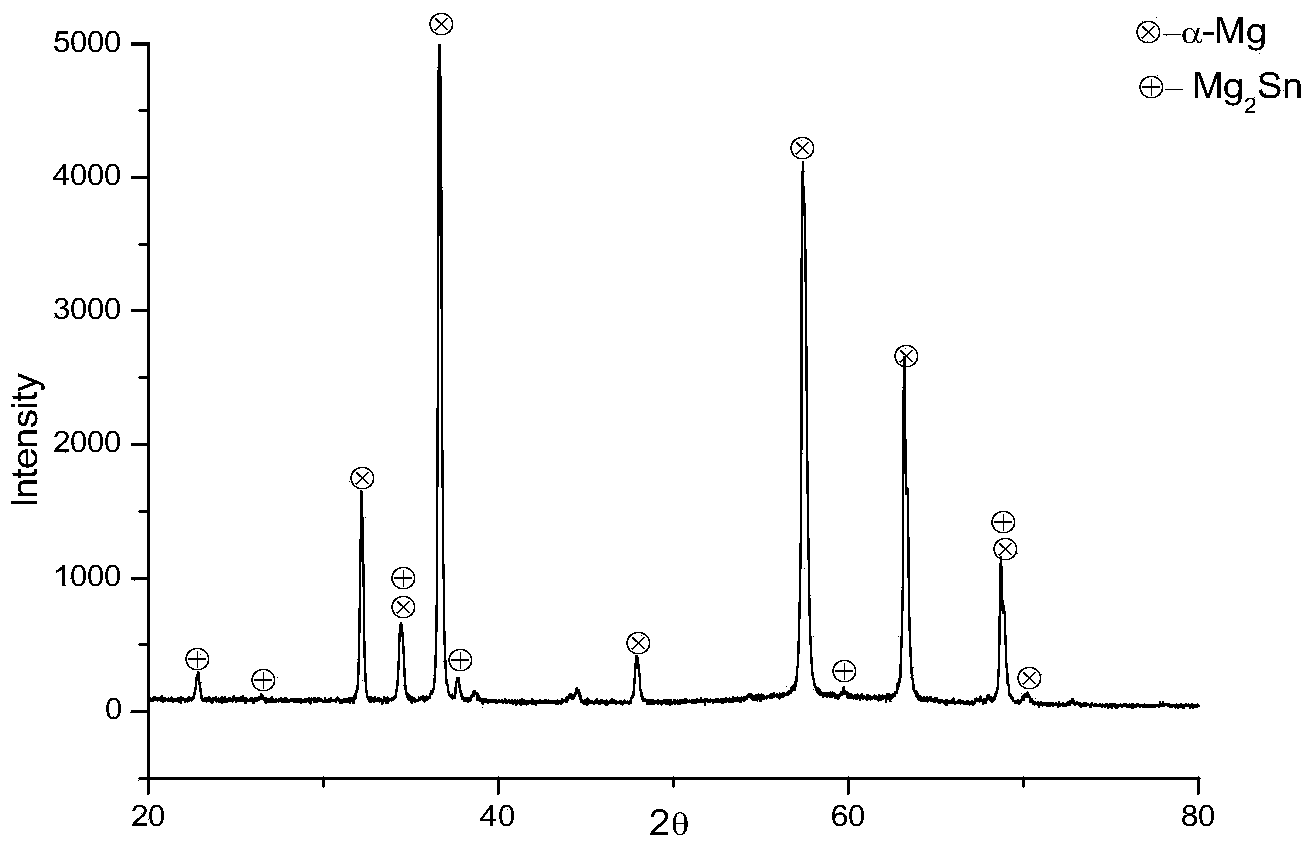

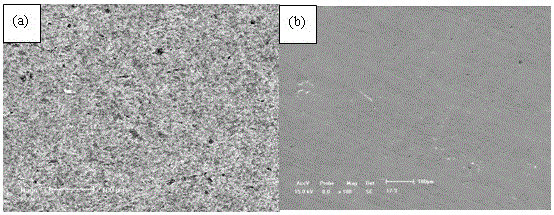

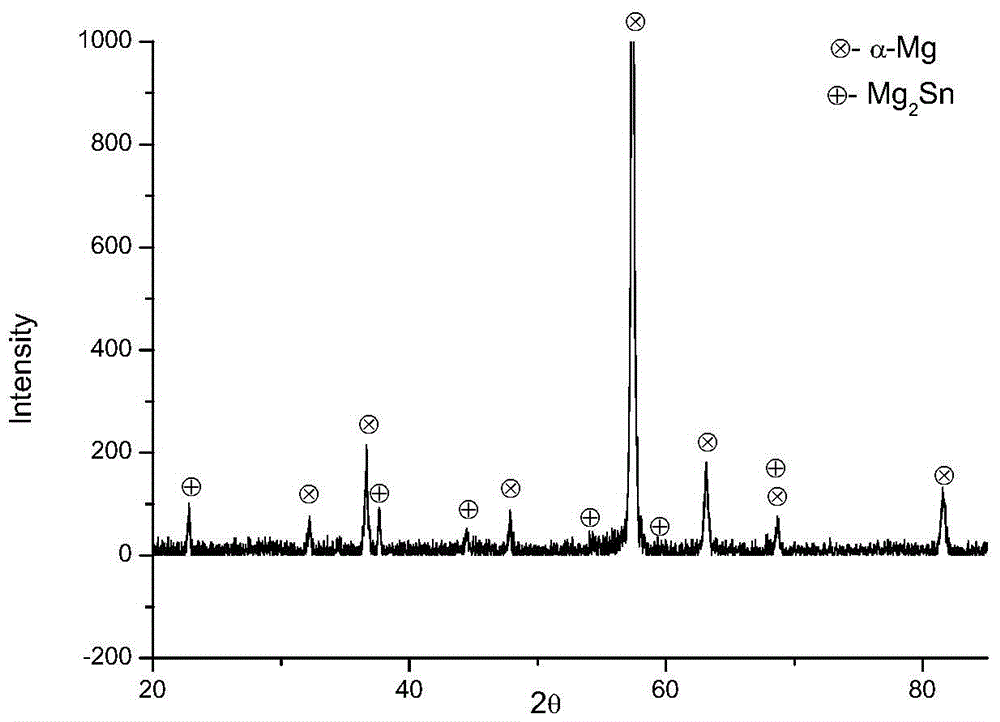

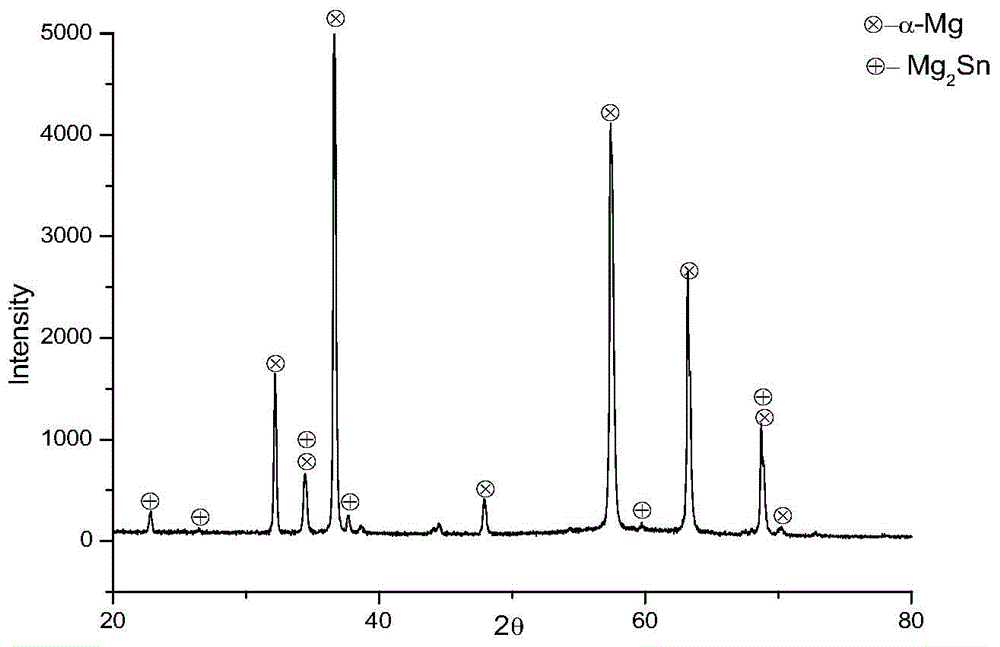

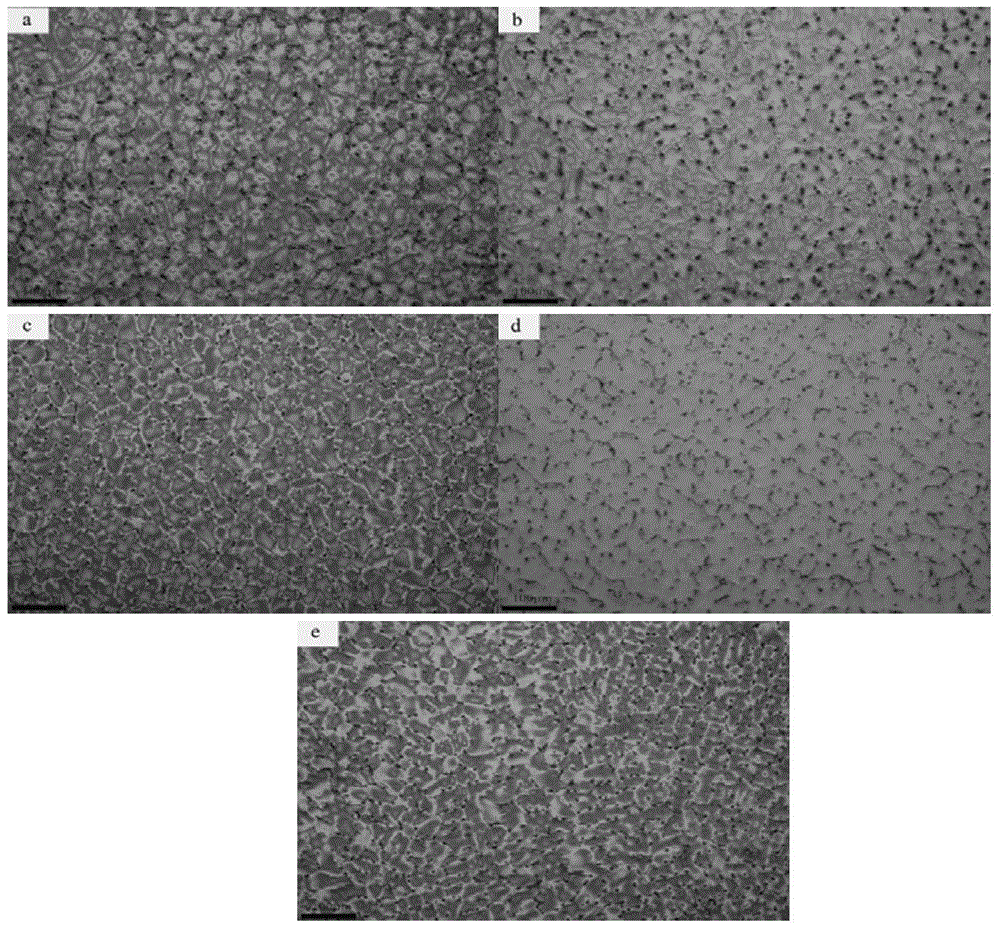

Magnesium-stannum-zinc-aluminum wrought magnesium alloy suitable for being extruded

The invention relates to a magnesium-stannum-zinc-aluminum wrought magnesium alloy suitable for being extruded. The wrought magnesium alloy comprises the following components in percentage by mass: 3-5% of Sn, 1% of Al, 0.5-2.0% of Zn, less than or equal to 0.10% of inevitable impurities and the balance of Mg. According to the alloy provided by the invention, the Mg-Sn magnesium alloy is subjected to modification treatment by adopting Zn and Al, so that the grains can be refined and the alloy tissue can be improved. Meanwhile, the tensile strength and the ductility of the alloy are improved to facilitate processing and moulding in the later period. The wrought magnesium alloy provided by the invention is simple in preparation method, relatively low in equipment cost and easy to implement.

Owner:CHONGQING UNIV

Method for preparing wear-resistant cast steel bucket tooth

The invention relates to a method for preparing a wear-resistant cast steel bucket tooth, which belongs to the technical field of metal wear-resistant materials. The prior bucket tooth and the processing technique thereof have the problems of high cost, complex technique and the like. In the method, tinplate leftover material, high carbon ferro-chrome, mid-carbon ferromanganese, silicoferrite, ferroboron, ferrozirconium and ferrotitanium are mixed up respectively according to the following mass percent: 96.3 to 97.0 percent, 1.5 to 1.8 percent, 0.8 to 1.2 percent, 0.4 to 0.6 percent, 0.025 to 0.035 percent, 0.045 to 0.055 percent and 0.18 to 0.25 percent; the mixture is compacted by a forcing press to form a quadrel which is then put in an induction furnace for heating and melting down and is cast to form the bucket tooth in a cere shuttering; the bucket tooth is put in water directly for cooling after being congealed, and is tempered under the low temperature at last to obtain the wear-resistant cast steel bucket tooth. The method for preparing the wear-resistant cast steel bucket tooth has the advantages of low manufacture cost, high productivity effect, long service life of the bucket tooth, etc.

Owner:BEIJING UNIV OF TECH

Method for recovering waste hydrogen storage alloy powders

ActiveCN110819809AShort smelting timeEasy to controlProcess efficiency improvementTabletingNew materials

The invention discloses a method for recovering waste hydrogen storage alloy powders. The method sequentially comprises the following steps: (1) carrying out particle size classification on the wastehydrogen storage alloy powders; (2) tabletting powders with different particle sizes; (3) loading different kinds of tablets and new materials into a furnace; and (4) carrying out smelting and casting. The preparation method is simple, the process is easy to control, the waste hydrogen storage alloy powders with different particle sizes are respectively pressed into tablets in the smelting processand then layered with the different rare earth alloy new materials in the induction smelting furnace, staged smelting is carried out, the induction effect is good during electromagnetic induction heating, the smelting is fast, environment friendliness is achieved, the energy is saved, the slagging is low, and the yield is high.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Method for producing ferronickel through reduction smelting of laterite-nickel ore flash furnace

The invention relates to the technical field of pyrometallurgy, in particular to a method for producing ferronickel through reduction smelting of a laterite-nickel ore flash furnace, which is short inflash reduction smelting time, high in speed, high in production efficiency, energy-saving and environment-friendly, and the reduction time is within one minute. Iron in the slag is reduced to prepare the iron-containing semi-steel alloy; remelting of said alloy is carried out to form qualified molten steel, meanwhile, submerged arc furnace slag is also obtained; the submerged arc furnace slag can serve as cement clinker to be conveyed to a cement plant to produce high-quality cement. The process is simple, the flow is short, qualified molten steel can be smelted and recycled, cement can be manufactured, economic benefits are good, environmental protection is facilitated, and hot materials subjected to multi-stage cyclone drying and pre-reduction directly enter a rotary kiln to be roasted; on one hand, the material buffering effect is achieved, and the material blocking problem caused when the hot materials directly enter the rotary kiln can be avoided; and on the other hand, throughfurther pre-reduction roasting of the rotary kiln, agglomeration of the materials can be achieved, and equipment and operation safety problems caused by direct feeding of the powdery materials into the furnace is avoided.

Owner:QINGDAO ZHONGZI ZHONGCHENG GROUP CO LTD

Vacuum smelting method of zinc oxide ore

ActiveCN108642303AReduce reduction smelting temperatureReduce energy consumptionCatalytic oxidationMicrowave irradiation

The invention provides a vacuum smelting method of zinc oxide ore. The vacuum smelting method comprises the steps of mounting vacuum microwave smelting equipment and conducting smelting operation. Byutilizing the characteristics that the melting boiling point of metal zinc in a vacuum state is greatly reduced and a zinc oxide material can absorb microwave radiation to produce instantaneous high temperature and catalyze reduction reaction of zinc oxide after mixing carbon powder, the method reduces the reduction smelting temperature of zinc oxide and can uniformly do the reduction reaction from the inner part of a granulating briquette together inside and outside, and no heat conduction process exists. Meanwhile, when microwaves radiate in a vacuum, no energy loss exists, and the microwaves can be quickly absorbed by zinc oxide particles. Thus, the method can perform low-energy high-efficiency smelting.

Owner:GUIZHOU HONGDA ENVIRONMENTAL PROTECTION TECHNOLOGY CO LTD

Melting technology suitable for producing nodulizing agent by using 3-ton intermediate frequency furnace

ActiveCN106755724AHigh yieldLow costProcess efficiency improvementElectric furnaceIntermediate frequencyRoom temperature

The invention discloses a melting technology suitable for producing a nodulizing agent by using a 3-ton intermediate frequency furnace. The melting technology for the nodulizing agent includes the steps of 1, silicone and iron are added into the bottom of the 3-ton medium-frequency furnace, then magnesium ingots are added, and waste steel is added, wherein the waste steel includes two types, firstly the blocky waste steel is added into the intermediate frequency furnace, and then Re and Ca components are added; 2, the current of the 3-ton medium-frequency furnace is controlled to be 450-750A, then the strip-shaped waste steel is added into the intermediate frequency furnace to be melted, the temperature in the intermediate frequency furnace is controlled to be 1250-1270 DEG C, and the furnace burden is stirred uniformly after being completely melted; and 3, the current is reduced to be 0A, then the furnace is tilted, the molten iron is poured into a nodulizing agent mold, when the temperature is lowered to 1150 DEG C, a nodulizing agent lifting hook is inserted into the nodulizing agent solution, then the nodulizing agent solution is air-cooled to room temperature, and when the nodulizing agent is cooled until the surface becomes dark red, the nodulizing agent can be lifted to a nodulizing agent stacking site by using a travelling crane.

Owner:南京浦江合金材料股份有限公司

Glass powder for solar back-silver electrode and preparation method of glass powder

The invention relates to glass powder for a solar back-silver electrode in the field of solar cells. The glass powder comprises the following components in parts by mass: 58 parts of Bi2O3, 10-30 parts of B2O3, 5-15 parts of SiO2, 3-10 parts of ZnO, 5-10 parts of BaO2, 0.5-5 parts of BeO, 0.5-5 parts of MgO and 0.5-2 parts of MoO2, wherein a colored glaze powder binding phase has the softening point of 550-630 DEG C, the density of 2-3g / cm<3>, and the expansion coefficient of (38-50)*10<-7> / DEG C. The expansion coefficient, softening point and density of the glass powder are matched with those of a cell silicon wafer and an aluminum-back surface field, so that the adhesion of the glass powder to the silicon wafer and the aluminum-back surface field after sintering can be obviously improved, the welding property of silver paste and the matching property with aluminum paste can be improved, and the printing quantity can be reduced. The glass powder disclosed by the invention is moderate in expansion coefficient and softening point; in the sintering process of configured silver paste, with the increase of the temperature, the glass powder begins to be softened and melt, and silver powder begins to be melt; in the cooling process, the glass powder is shrunk to ensure that a back-surface silver electrode is densified, the excellent anti-aging property of the silver electrode is ensured, and the reliability of components is improved.

Owner:JIANGSU ZHENGNENG ELECTRONICS TECH CO LTD

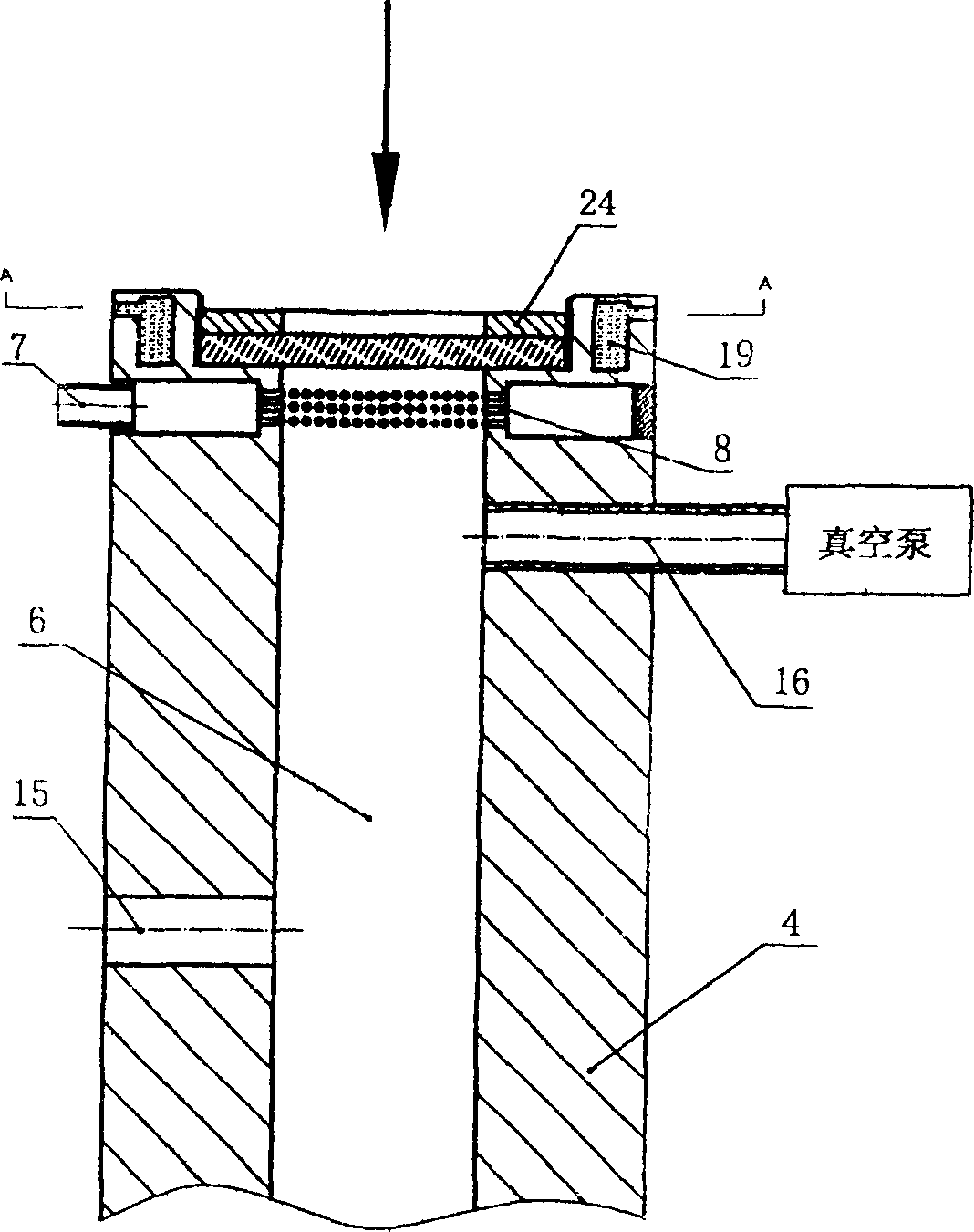

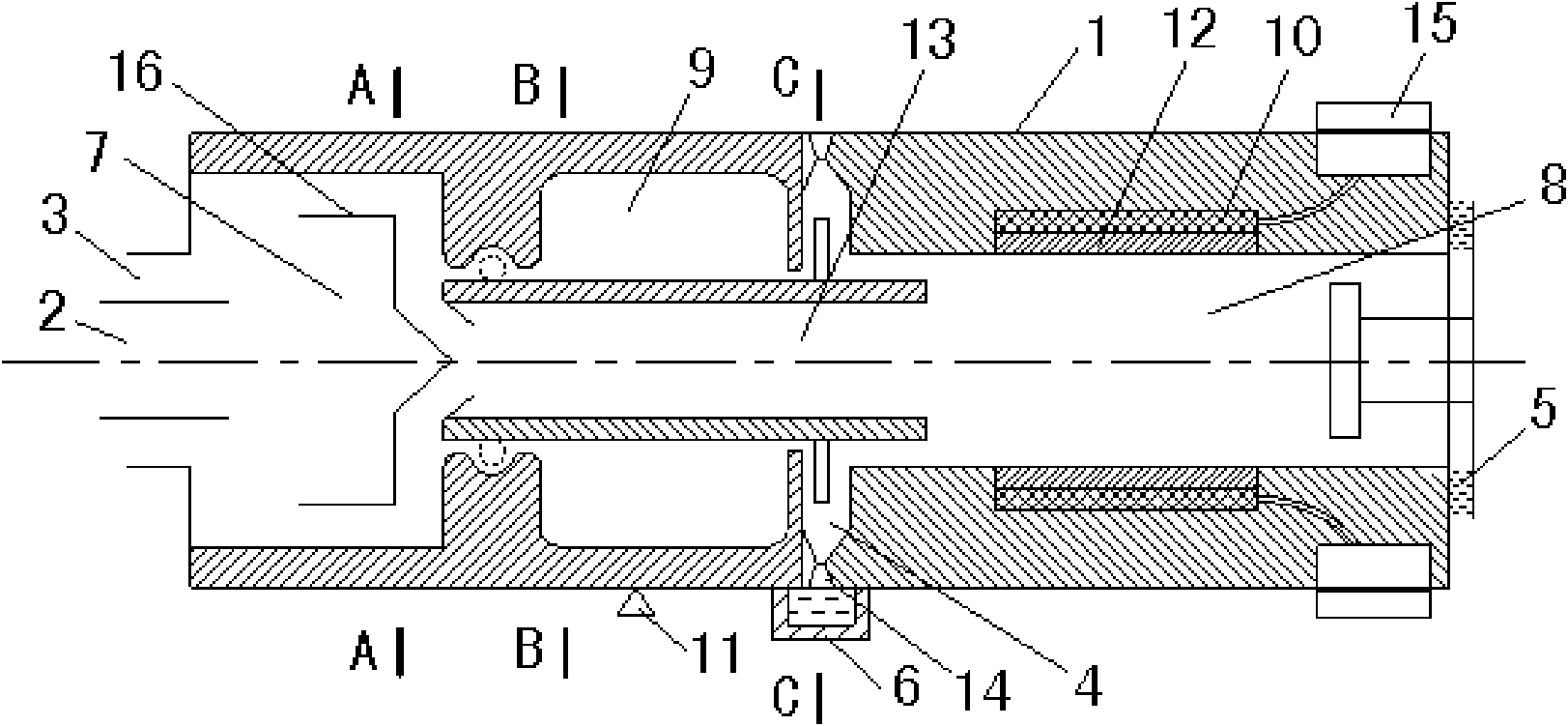

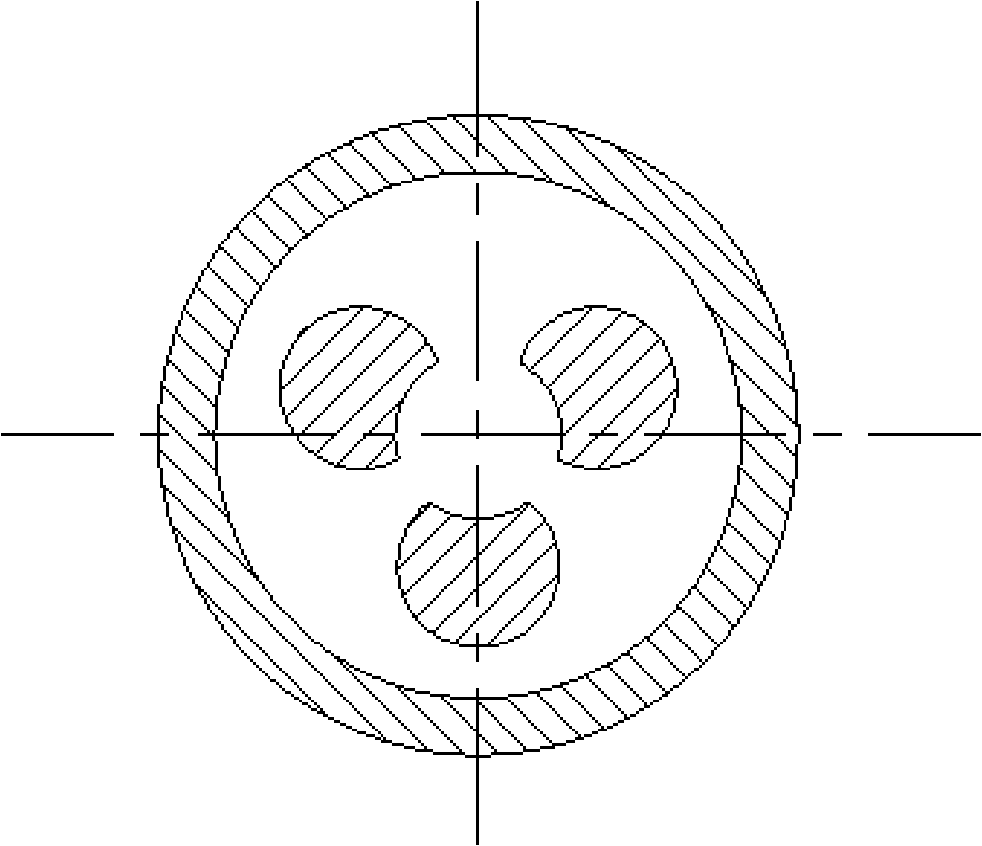

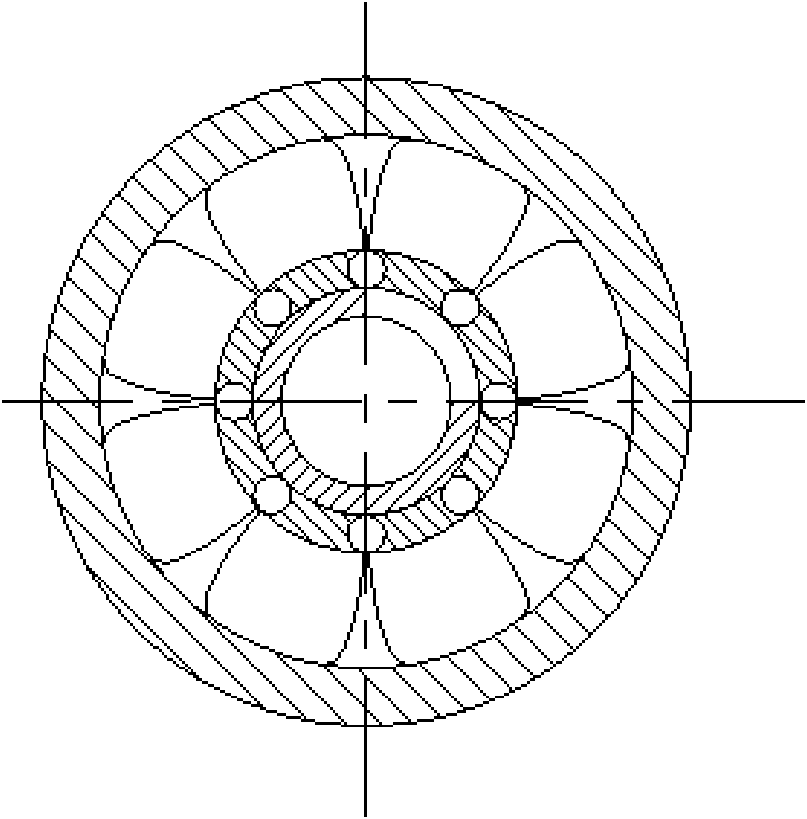

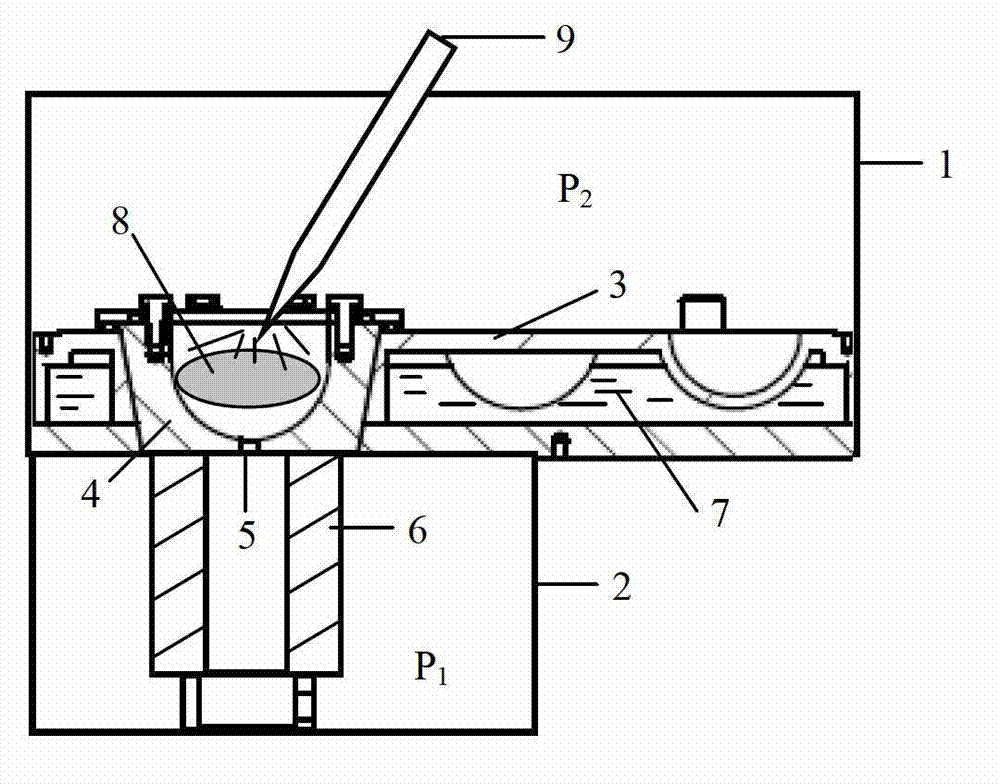

Vacuum suction casting equipment and method of high-activity, high-purity and high-melting-point alloy

The invention discloses vacuum suction casting equipment and a method of high-activity, high-purity and high-melting-point alloy. The equipment comprises an upper vacuum chamber and a lower vacuum chamber which are arranged up and down; an electric arc gun is arranged at the top end of the upper vacuum chamber; a plurality of station copper crucibles are arranged at the bottom end to tightly separate the upper vacuum chamber and the lower vacuum chamber; the peripheries of the copper crucibles are cooled by circulating water; an alloy ingot crucible is tightly matched and embedded in one station copper crucible; a through hole is preserved at the bottom, and the upper vacuum chamber and the lower vacuum chamber are communicated. Nozzles such as graphite and the like are replaced by a high-melting-point alloy ingot which has good conduction performance and large heat capacity and comprises a hole at the bottom, and embedded into the copper crucibles to form an indirect water cooling structure. Automatic suction casting is carried out by combining with a differential-pressure method; the problems of pollution and low success ratio of the alloy in the existing suction casting equipment are solved; the clean suction casting process of the alloy is effectively achieved; the melting point of the suction casting alloy can be up to 1600-1800 DEG C, and the pollution degree is smaller than or equal to 0.01wt %.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Deoxidation method for high-nitrogen steel

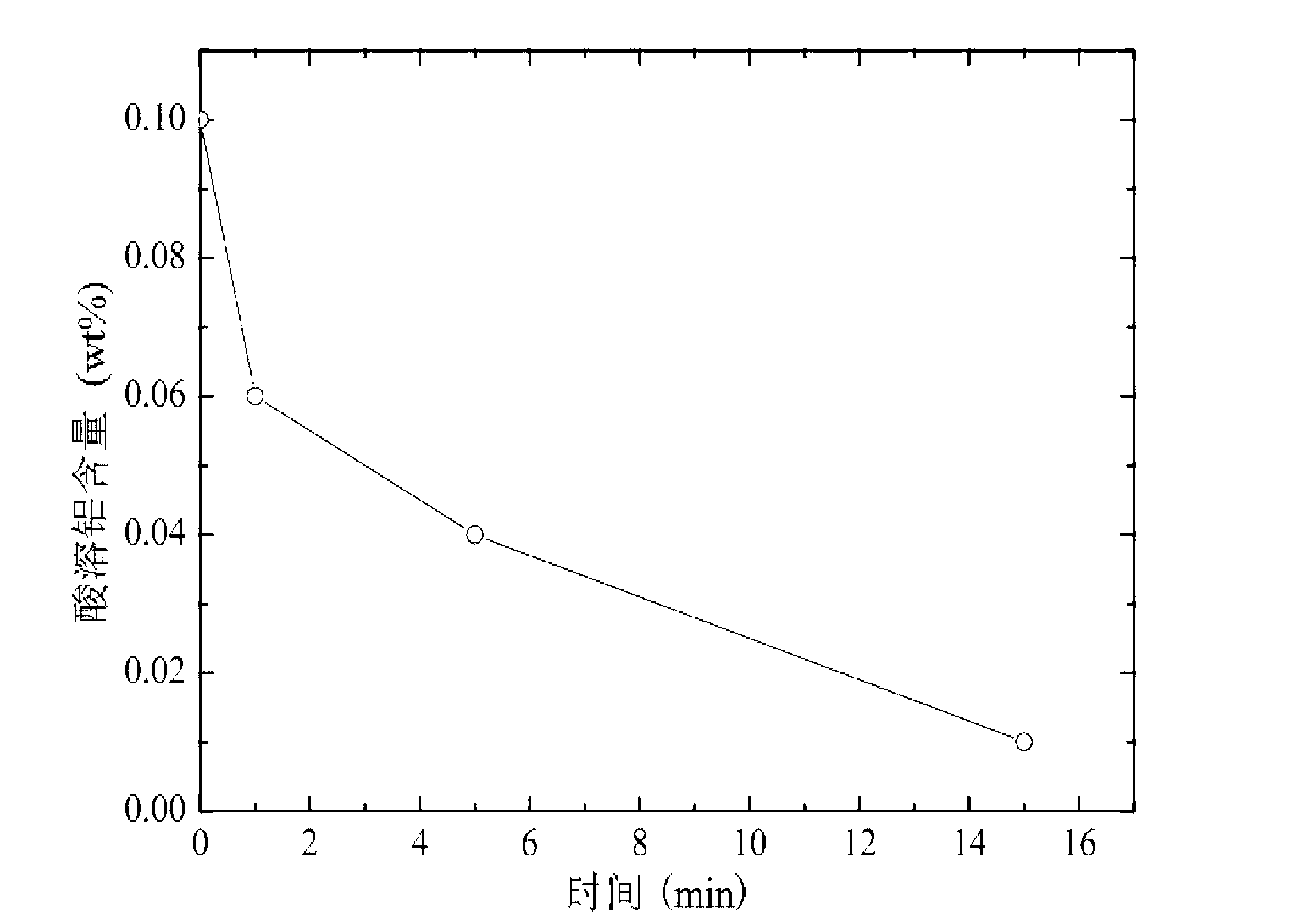

InactiveCN103060519ALow priceReduce residualProcess efficiency improvementAlkaline earth metalChromium nitride

The invention belongs to the field of ferrous metallurgy, and in particular relates to a deoxidation method for high-nitrogen steel. The method is characterized in that the deoxidation process is carried out in a medium-frequency vacuum induction furnace; the suitable crucible comprises the components of 97.5%-99% of MgO, 0.5%-0.7% of SiO2, and 0.3%-2% of other components; the alloy components comprise 20%-21% of Cr, 6%-7% of Ni, 8%-10% of Mn, and the balance of Fe; the manner for increasing nitrogen in liquid steel adopts nitralloy, the alloy comprises chromium nitride or manganese nitride, and the nitrogen increasing process is carried out under the protection of nitrogen of 0.06MPa-0.08MPa; and aluminium is adopted as a deoxidant, and after aluminium is added, smelting process needs to be continued for 15-25 minutes. Compared with the deoxidation technology adopting a complex deoxidant comprising alkaline earth such as calcium, magnesium, barium and the like, the deoxidation method for high-nitrogen steel has the advantages that special requirements on smelting equipment is not needed; the deoxidant is cheap, does not need to be prepared specially, and can be added conveniently; and the smelting time is short, the deoxidation result is stable and reliable, residue of the deoxidation product is little, no harmful elements affecting the property of the steel are introduced, and the smelting cost is greatly lowered.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

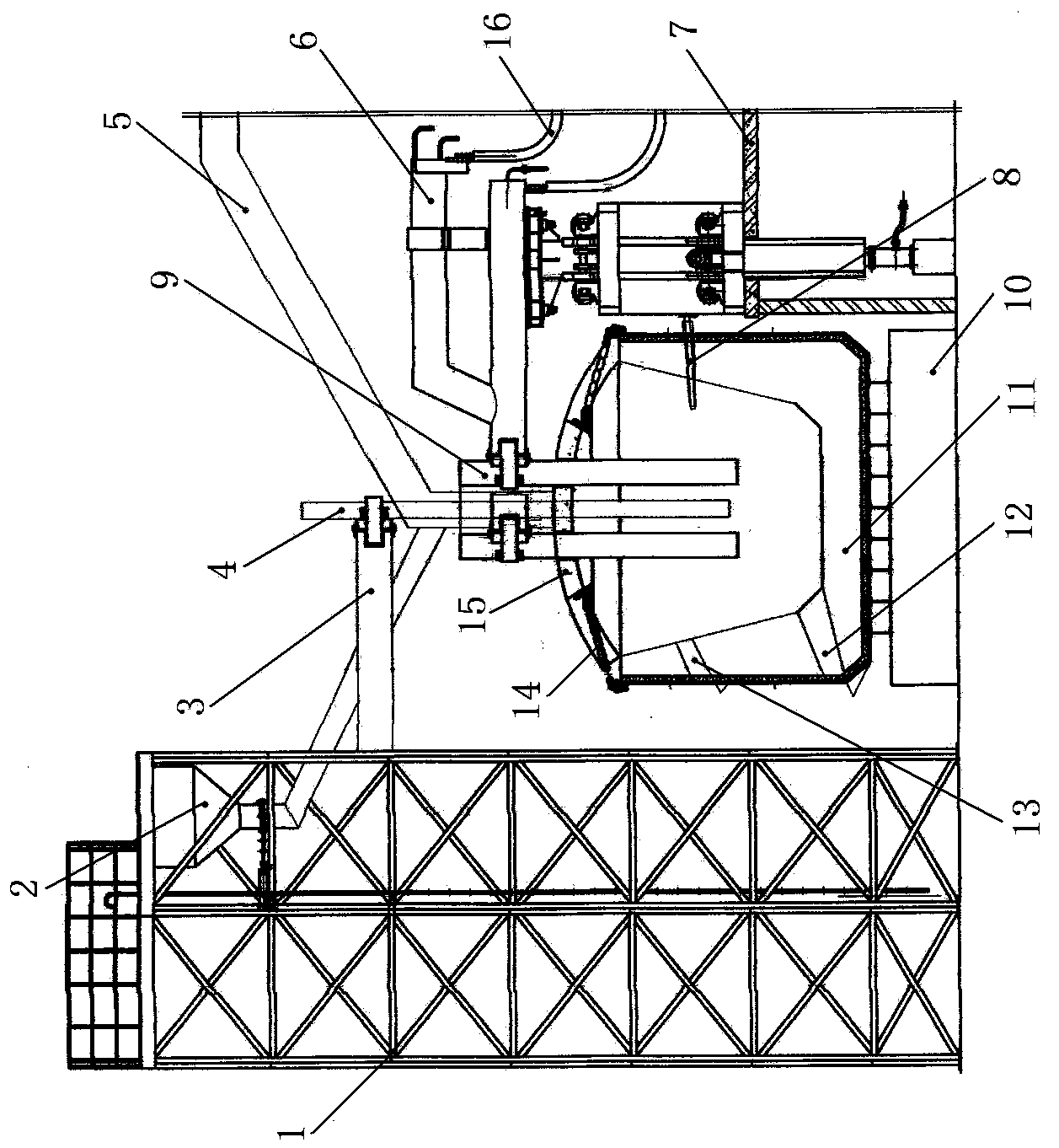

Smelting furnace for smelting reduction

The invention relates to a smelting furnace for smelting reduction, which is designed to be mainly used for solving the problems that an existing smelting furnace for smelting reduction is high in production cost and the like. The smelting furnace comprises a base, wherein a reduction furnace body is mounted on the base; a cooling water pipe is arranged in a furnace cover connected with the top of the reduction furnace body; the upper part of a feeding pipeline is fixed on a feeding supporting rack; the lower end of the feeding pipeline extends into a feeding inlet in the furnace cover; an oxygen lance crossarm is also arranged on the feeding supporting rack; an oxygen lance is arranged on the oxygen lance crossarm and extends into the reduction furnace body from the furnace cover or the side wall of the reduction furnace body; an electrode crossarm is fixed on an electrode supporting rack; an electrode is connected onto the electrode crossarm and extends into the reduction furnace body; the rear end of an electrode network cable is connected with an external transformer; the front end of the electrode network cable is connected with the electrode through the electrode crossarm; the tail end of a coal gas discharging pipeline is communicated with a coal gas discharging outlet in the furnace cover; a coal injection gun, a water outlet and a slag outlet are formed in the side wall of the reduction furnace body; the end of a coal injection opening of the coal injection gun extends into the reduction furnace body. The smelting furnace provided by the invention has the advantage of low production cost.

Owner:辽宁孺尚亿熔炉科技有限公司

Rapid solidification Al-Ti-B-Sc intermediate alloy refiner and preparation method thereof

InactiveCN103589916BImprove grain refinement effectImprove adsorption capacityRare-earth elementMulti element

Owner:HEBEI UNIV OF TECH

End point controlling process for smelting low carbon steel in electric furnace

InactiveCN1203196CRich production methodsFill in the blanksElectric furnaceProcess efficiency improvementElectric arc furnaceSlag

An end-point control process for smelting low-carbon steel with electric furnace includes proportioning raw materials by controlling C to 1-1.8%, controlling the C / O ratio to 1:2 at 1520 deg.C, 1:1 at 1520-1580 deg.C, and 2:1 at over 1580 deg.C, controlling the typical component of foam slag:CaO / SiO2=2.1-3.0 and FeO (25-30%), and tapping at 1620-1640 deg.C and a[0]=750-900 ppm. Its advantages areshort time and low energy consumption and cost.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

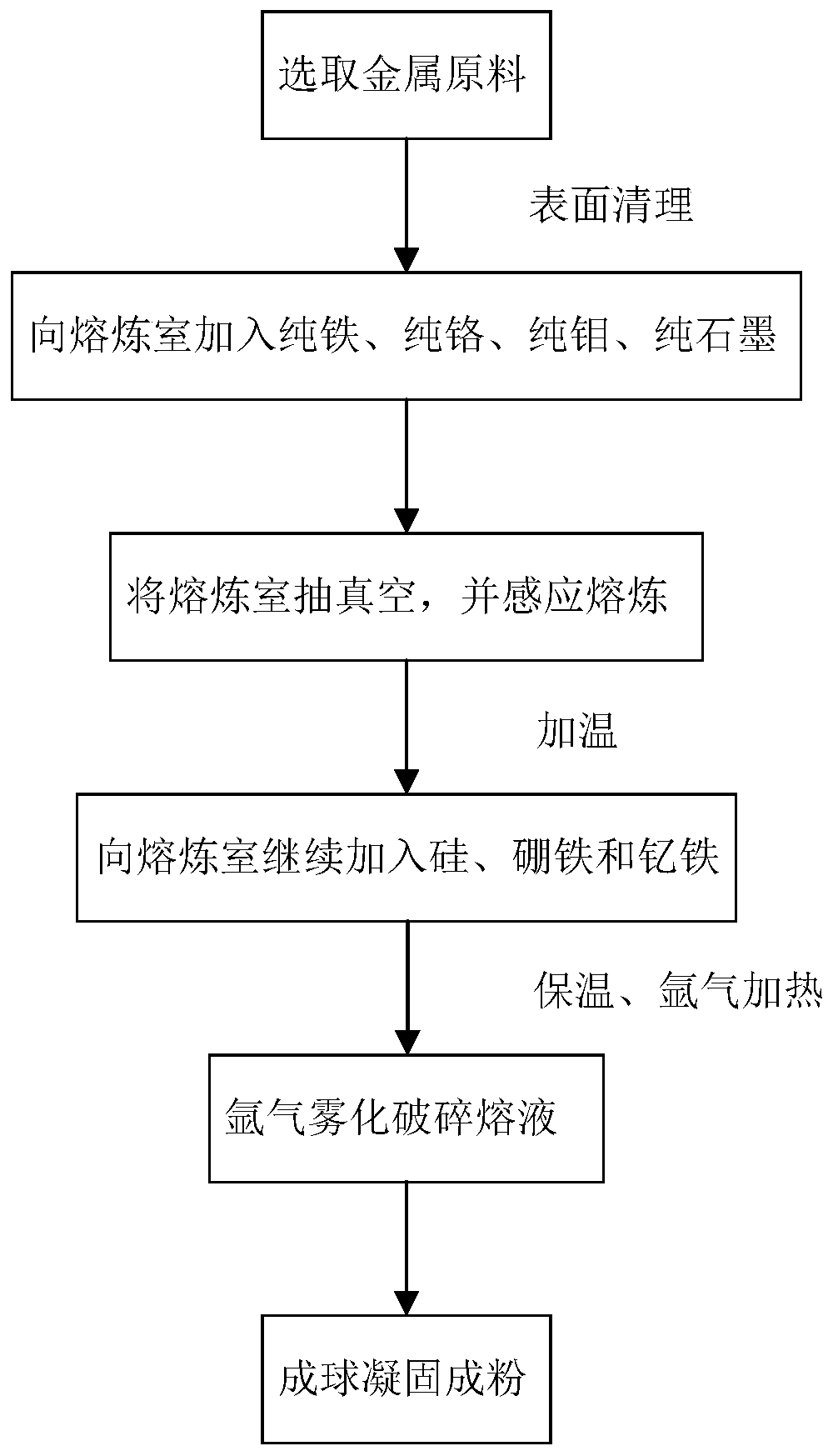

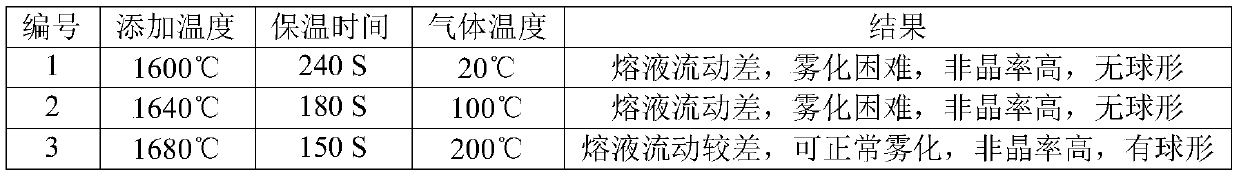

Preparation method of spherical amorphous alloy powder

ActiveCN110586947AInfluence segregationEnhanced Amorphous Formation AbilityTransportation and packagingMetal-working apparatusMolten stateAlloy

The invention provides a preparation method of spherical amorphous alloy powder, and relates to the technical field of amorphous alloy powder preparation, The preparation method comprises the following steps of selecting pure iron, pure chromium, pure molybdenum, pure graphite, silicon, boron iron and yttrium iron, and enabling the atomic ratio of Fe, Cr, Mo, B, C, Si and Y elements in the raw materials to satisfy the ratio range of 43.12-44.88: 18.62-19.38: 13.72-14.28: 5.88-6.12: 13.72-14.28: 0.98-1.02; smelting pure iron, pure chromium, pure molybdenum and pure graphite, and after smeltingto a molten state liquid, adding silicon, boron iron and yttrium iron together for smelting; and when all the raw materials are smelted to a molten state liquid, preparing the spherical amorphous alloy powder by using an air atomization method. In the preparation method, pure iron, pure chromium, pure molybdenum and pure graphite are fed and smelted firstly, the smelting is mainly used for fast dissolving materials, so that the oxygen increment in the material is reduced; and the silicon, the boron iron and the yttrium iron adopt a secondary feeding mode, mainly for controlling the components,the addition amount and time are precisely controlled through secondary feeding, and the burning loss of the Si, B and Y elements is reduced or avoided.

Owner:中航迈特增材科技(北京)有限公司

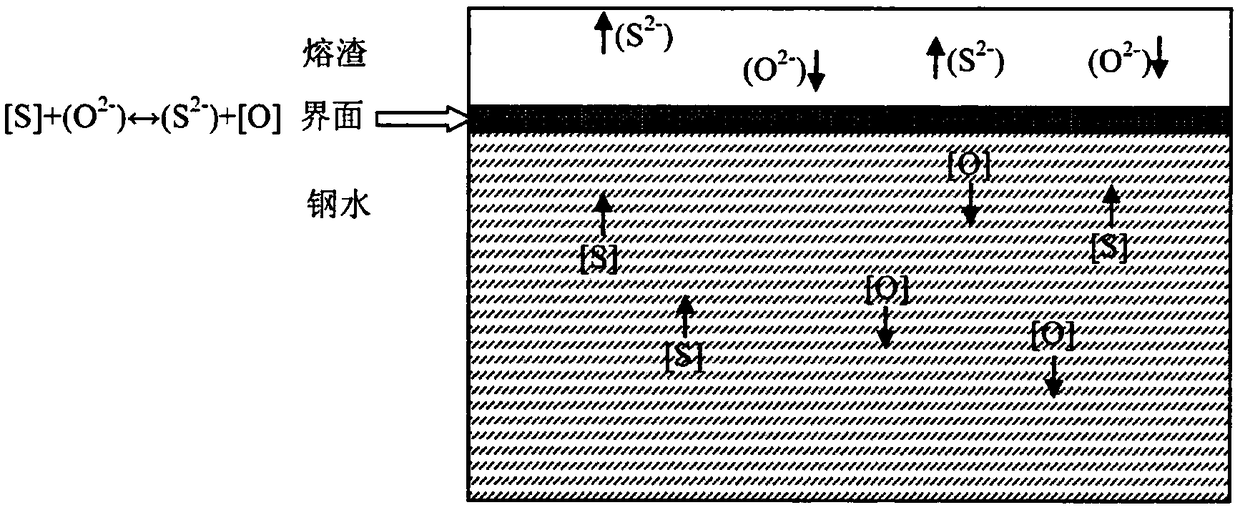

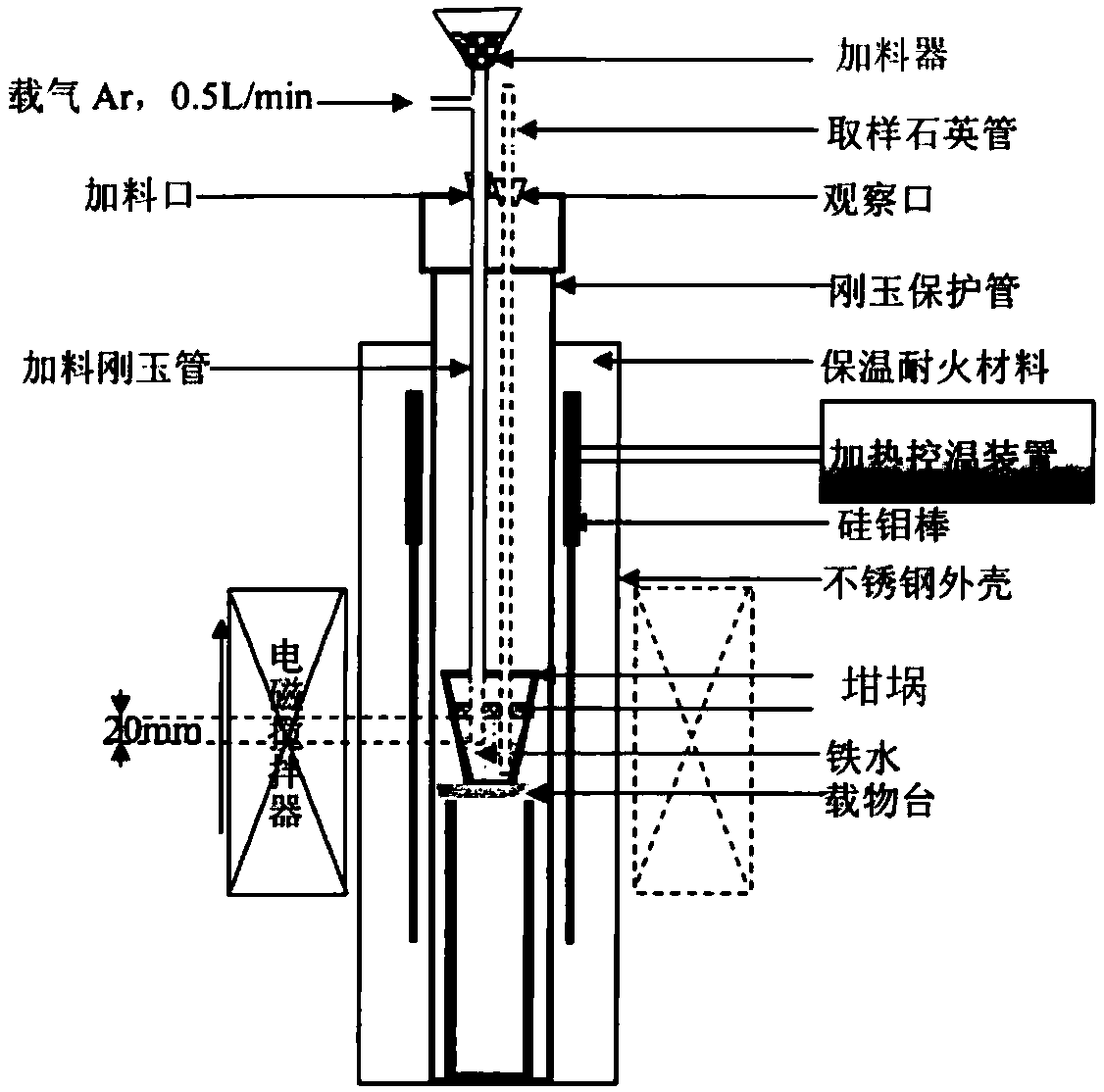

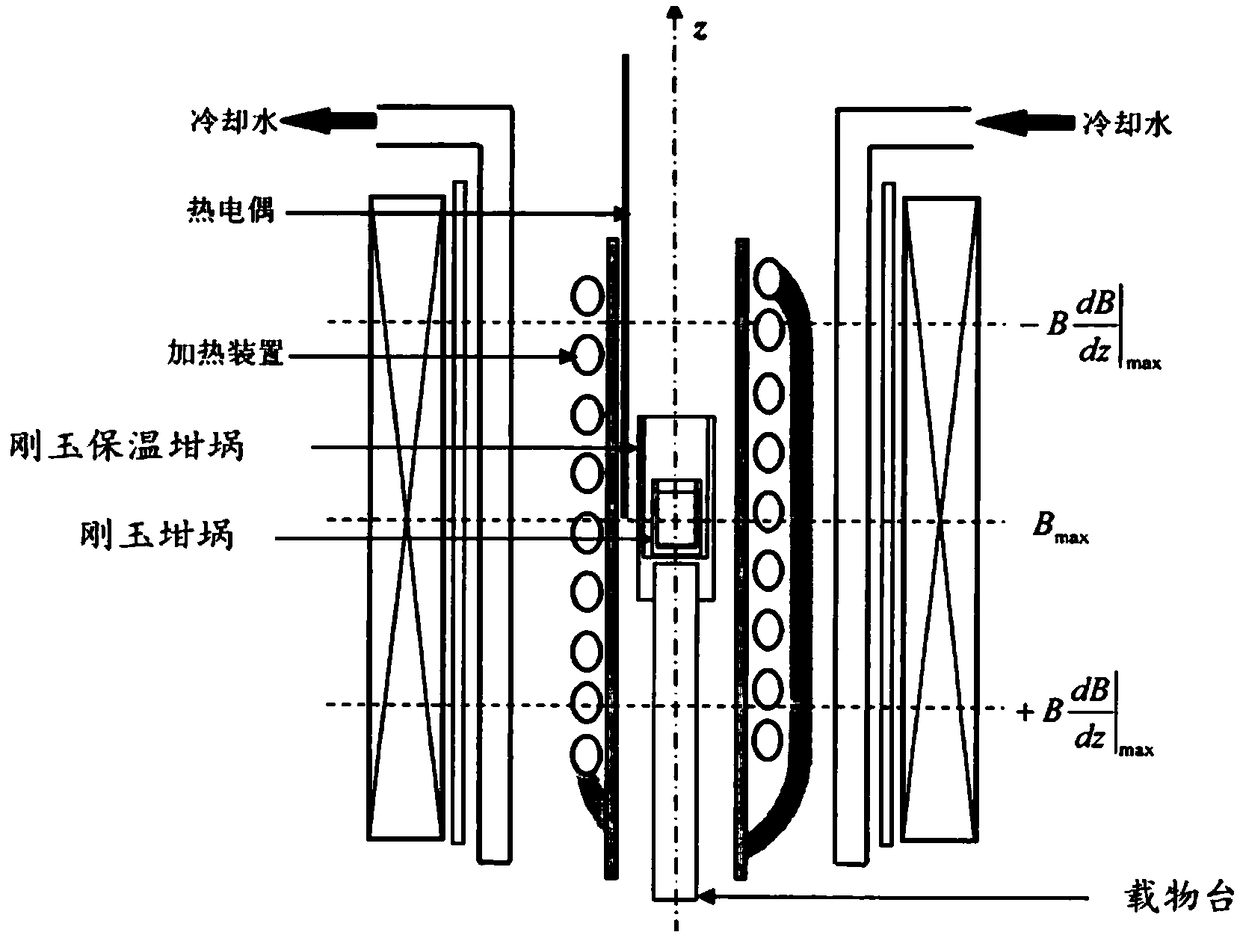

Control method for metal-slag reaction in sponge iron steelmaking process and device thereof

InactiveCN109055658ASimple process conditionsLow costProcess efficiency improvementElectric furnaceSteelmakingBall mill

The invention relates to the field of metallurgy and material heat treatment experiments, in particular to a control method for a metal-slag reaction in the sponge iron steelmaking process and a device thereof. Particularly, the control method comprises the steps that sponge iron is crushed and milled into powder with a planetary ball mill, then sponge iron powder is added into a feeder, and the sponge iron powder is added into a crucible through the feeder; the crucible is put on a carrying platform located at the magnetic field center of an electromagnetic stirrer; and the crucible containing the sponge iron powder is alternately heated and subjected to electromagnetic stirring treatment, the crucible is gradually separated from a silicon-molybdenum bar heat radiation area by pulling down the carrying platform located at the magnetic field and heat field center, and molten liquid is gradually cooled and solidified from the bottom of the crucible to the top. In addition, the inventiondiscloses a specific structure for a direct sponge iron steelmaking device. According to the control method for the metal-slag reaction in the sponge iron steelmaking process and the device thereof,the technological conditions are simple, the cost is low, energy consumption is relatively low, the yield is high, the smelting time is short, and the production scale is adjustable; and in addition,the cost is reduced, operation is easy and convenient, and environmental friendliness is achieved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Melting and casting method of aluminum alloy sacrificial anode

Owner:NORTHEASTERN UNIV LIAONING +1

Method of preparing molten steel refining agent by using industrial solid waste FCC catalyst

The invention discloses a method of preparing a molten steel refining agent by using an industrial solid waste FCC catalyst. The molten steel refining agent is prepared by mixing the industrial solidwaste FCC catalyst with lime powder as a primary raw material, handling difficulty of the industrial solid waste FCC catalyst and polluting problem caused by the industrial solid waste FCC catalyst can be solved effectively, recycling of the solid waste is achieved fully, waste is turned into wealth, the production cost is lowered greatly, and the additional value of a product is improved. The prepared refining agent is low in melting point, high in melting speed, large in sulfur capacity, short in smelting time and good in desulfurizing, deoxidizing and inclusion-removing effects. Meanwhile,reduced rare earth oxides in the FCC waste catalyst also can play a role of enhancing properties of steel. The method is simple in preparation process, environmental-friendly and favorable to popularize, and has a relatively large application potential.

Owner:WUHAN UNIV OF SCI & TECH

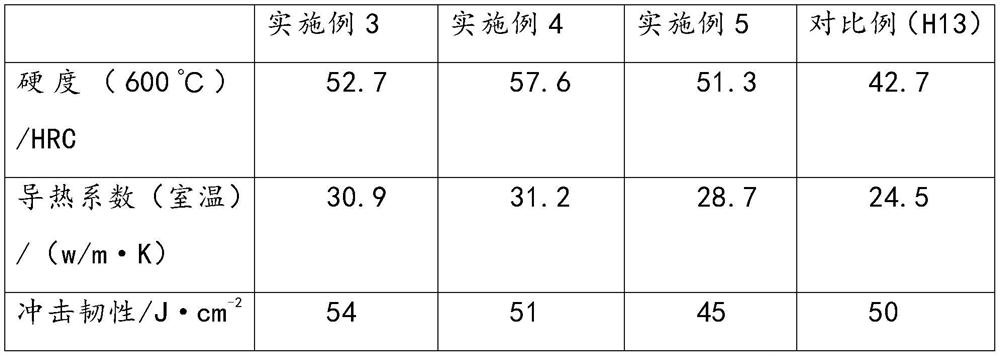

Production process of hot work die steel with high thermal conductivity and high heat strength

The invention relates to a production process of high-heat-conductivity and high-heat-strength hot work die steel, and belongs to the technical field of hot work die steel. A base body of the die steel comprises 0.32%-0.38% of C, 1.2%-1.6% of W, 3.6%-4.2% of Mo, 0.08%-1.4% of V, 0.06%-0.1% of Mn, 0.15%-0.18% of Cr, 0.02%-0.04% of S i and the balance Fe, a nucleating auxiliary is added into the base body, the nucleating auxiliary is prepared from nanoscale carbon powder, boron nitride and tantalum powder, more crystal nucleuses are provided for the base body, tantalum and carbon form tantalum carbide at the high temperature, the effects of refining grains and improving heat conductivity are achieved, and the heat conductivity of the die steel is improved. Meanwhile, a high-melting-point strengthening phase formed by tantalum carbide and boron nitride forms dispersion strengthening, so that the strength of the matrix is improved; through testing, the hardness of the hot work die steel reaches 51.3-57.6 HRC at the temperature of 600 DEG C, and the heat conductivity coefficient of the hot work die steel reaches 28.7-31.2 w / m.K at the room temperature.

Owner:冯希良

A Magnesium-Tin-Zinc-Al Deformed Magnesium Alloy Suitable for Extrusion

The invention relates to a magnesium-stannum-zinc-aluminum wrought magnesium alloy suitable for being extruded. The wrought magnesium alloy comprises the following components in percentage by mass: 3-5% of Sn, 1% of Al, 0.5-2.0% of Zn, less than or equal to 0.10% of inevitable impurities and the balance of Mg. According to the alloy provided by the invention, the Mg-Sn magnesium alloy is subjected to modification treatment by adopting Zn and Al, so that the grains can be refined and the alloy tissue can be improved. Meanwhile, the tensile strength and the ductility of the alloy are improved to facilitate processing and moulding in the later period. The wrought magnesium alloy provided by the invention is simple in preparation method, relatively low in equipment cost and easy to implement.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com