Preparation method of spherical amorphous alloy powder

A technology of amorphous alloy and powder, applied in the field of preparation of spherical amorphous alloy powder, can solve the problem of low amorphous rate of spherical amorphous alloy powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

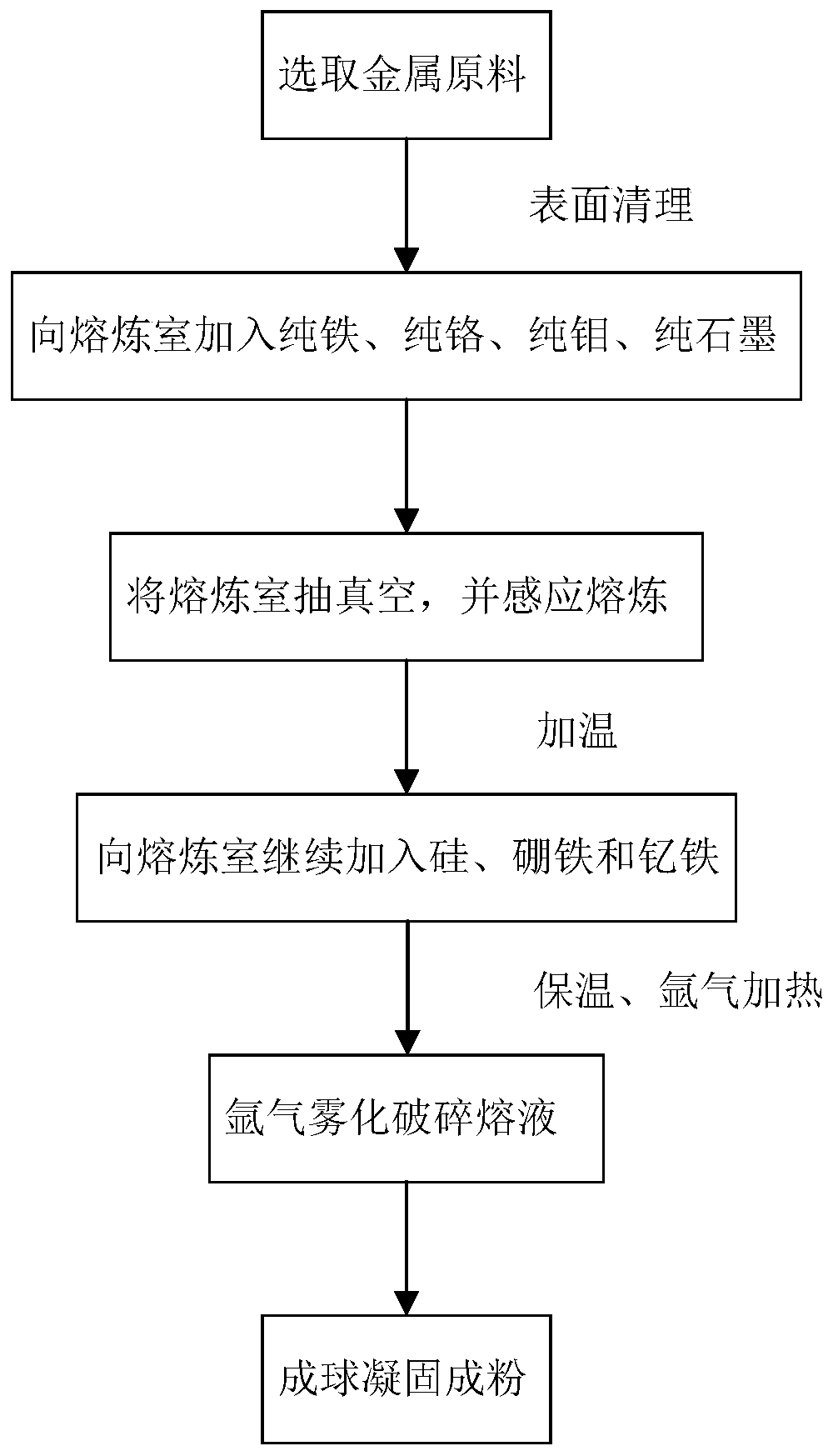

Method used

Image

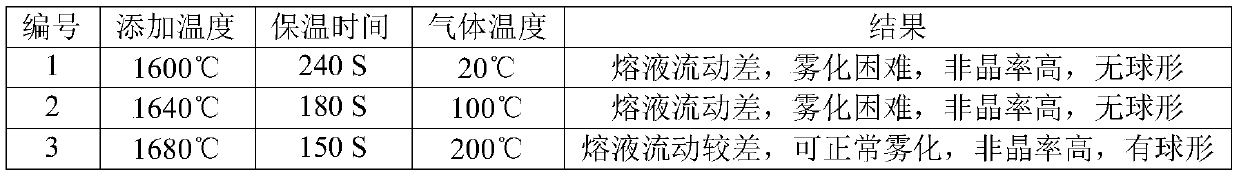

Examples

Embodiment 1

[0050] Pure iron, pure chromium, pure molybdenum, pure graphite, silicon, ferroboron and yttrium iron are selected, and the purity of the selected metal raw materials is higher than 99.8%. The Fe, Cr, Mo, B, C, Si and Y elements in the raw materials are proportioned according to the atomic ratio of 44:19:14:6:14:1:1 to prepare 50kg of alloy materials. If there are impurities and oxide scales on the metal surface, the metal surface can be polished with sandpaper to remove surface impurities and oxide scales and prevent the alloy composition from being affected by impurities.

[0051] When feeding, add 1 / 2 pure iron first, prepare the atomization device after feeding, first vacuumize the melting chamber to 0.1Pa, and then start heating the chemical material by means of medium frequency induction heating, keep vacuuming during the heating process, and the 1 to be added When / 2 pure iron becomes a molten liquid, add pure graphite, pure molybdenum and 1 / 2 pure chromium; finally add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com