Method for recovering waste hydrogen storage alloy powders

A technology of hydrogen storage alloy powder and hydrogen storage alloy, which is applied in the direction of improving process efficiency, etc., and can solve problems such as equipment damage, large slagging, affecting the uniformity of smelting alloy composition and alloy composition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 A recovery method of waste hydrogen storage alloy powder

[0035] This embodiment is a method for recovering waste hydrogen storage alloy powder, which is performed in sequence according to the following steps:

[0036] (11) Pass the waste hydrogen storage alloy powder through 100 mesh sieve, 150 mesh sieve and 200 mesh sieve in sequence to obtain coarse waste hydrogen storage alloy powder A11, medium waste hydrogen storage alloy powder A12 and fine waste hydrogen storage alloy powder A13 in sequence;

[0037] (12) Add A11 to one-fifth of the weight of A11 hydrogen storage alloy ultra-fine powder (the hydrogen storage alloy ultra-fine powder has a particle size of 4-20 µm), mix it evenly and press it at 35 MPa into a diameter of 60 mm and a thickness of 6 -10mm disc, denoted as B11; press A12 at 20MPa into a disc with a diameter of 60mm and a thickness of 12-20mm, denoted as B12; A12 and A13 at a weight ratio of 1:2 under 20MPa Press into a disc with a diameter of 6...

Embodiment 2-4

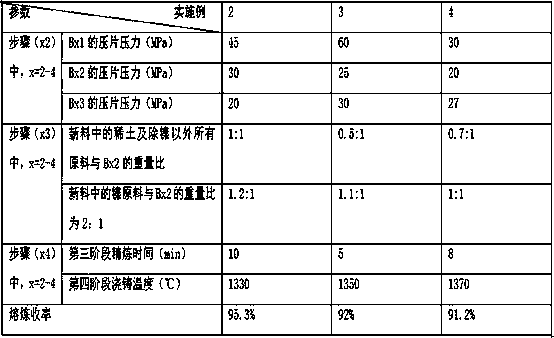

[0045] Embodiment 2-4 Recovery method of waste hydrogen storage alloy powder

[0046] This embodiment is a method for recovering waste hydrogen storage alloy powder. The preparation steps are similar to those in Example 1, except that the control parameters of the corresponding steps are different during the preparation process, as shown in the following table for details.

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com