Production process of hot work die steel with high thermal conductivity and high heat strength

A technology for hot work die steel and production process, applied in the field of hot work die steel, can solve the problems of difficulty in meeting the high temperature service conditions of hot work die steel, reduction in thermal conductivity and toughness of die steel, and difficulty in simultaneously improving strength and toughness, etc. To achieve the effect of short melting time, improved hardenability and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

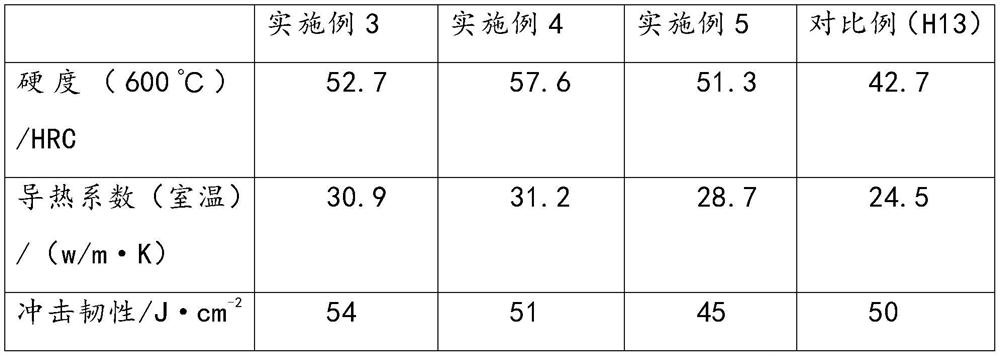

Examples

Embodiment 1

[0023] The present embodiment prepares a nucleation aid, and the specific implementation process is as follows:

[0024] Step A1: configure an ethanol aqueous solution with a volume fraction of 40%, and pour the ethanol aqueous solution into the water tank of an ultrasonic disperser to obtain a dispersion system;

[0025] Step A2: Take nano carbon powder, nano boron nitride and nano tantalum powder (sodium-reduced tantalum powder) according to the weight ratio of 1:2.2:0.8, mix them and pour them into the dispersion system, ultrasonically disperse them at 28kHz for 20min, and then let stand for 10h ;

[0026] Step A3: Add silane coupling agent KH550 to the standing water tank, and then ultrasonically disperse at 28 kHz for 20 min. After ultrasonic dispersion, the dispersion liquid is centrifuged and then evaporated to dryness, and the dispersion liquid is removed to obtain a nucleating aid.

Embodiment 2

[0028] Step A1: configure an ethanol aqueous solution with a volume fraction of 40%, and pour the ethanol aqueous solution into the water tank of an ultrasonic disperser to obtain a dispersion system;

[0029] Step A2: Take nano-carbon powder, nano-boron nitride and nano-tantalum powder (sodium-reduced tantalum powder) according to the weight ratio of 1:2.5:0.7, mix them, pour them into the dispersion system, ultrasonically disperse them at 28kHz for 20min, and then let stand for 10h ;

[0030] Step A3: Add silane coupling agent KH550 to the standing water tank, and then ultrasonically disperse at 28 kHz for 20 min. After ultrasonic dispersion, the dispersion liquid is centrifuged and then evaporated to dryness, and the dispersion liquid is removed to obtain a nucleating aid.

Embodiment 3

[0032] The present embodiment prepares high thermal conductivity and high thermal strength hot work die steel, and the specific implementation process is as follows:

[0033] Step S1: Make ingredients according to the following ingredients:

[0034] C: 0.32%;

[0035] W: 1.2%;

[0036] Mo: 3.6%;

[0037] V: 0.08%;

[0038] Mn: 0.1%;

[0039] Cr: 0.18%;

[0040] Si: 0.04%;

[0041] The balance is Fe and inevitable impurities;

[0042] The batches of the above components are added into the vacuum melting furnace and heated to 1450° C. to be smelted into molten steel. Before tapping, a powder blower is used to blow the nucleation aid prepared in Example 1 with a batch mass of 1.27% into the melting furnace. , control the tapping temperature to be 1550 °C, the casting temperature to be 1490 °C, and pour the molten steel into the mold to obtain the electrode rod;

[0043] Step S2: Install the electrode rod on the consumable electrode of the electroslag remelting furnace. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com