Deoxidation method for high-nitrogen steel

A high-nitrogen steel and molten steel technology, applied in the field of iron and steel metallurgy, can solve the problem of reducing the total oxygen content of high-nitrogen steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

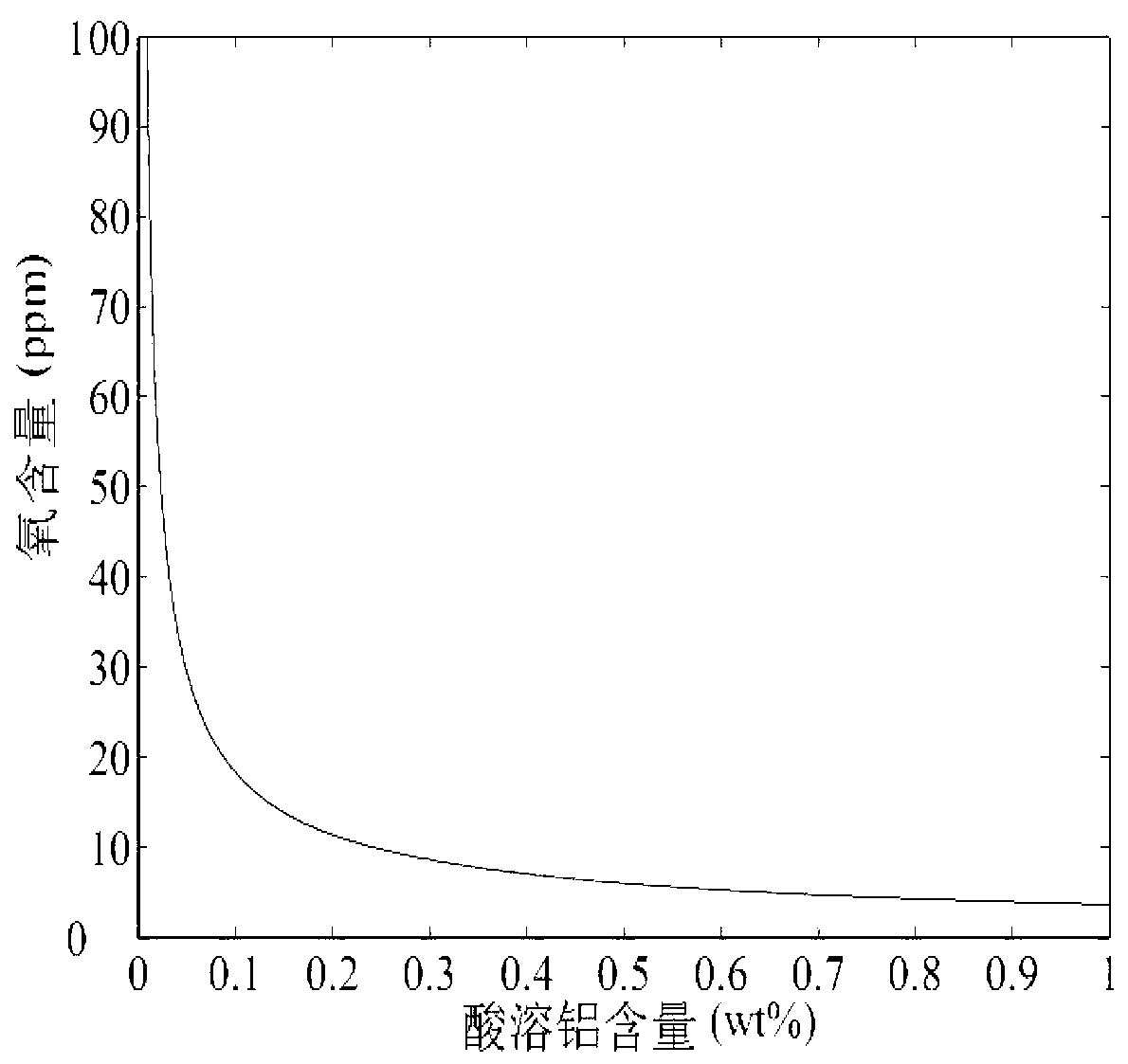

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Steel type: Fe-20%Cr-10%Mn-6%Ni.

[0059] Process flow:

[0060] (1) Melting molten steel in a vacuum induction furnace: Add 6.36Kg of pure iron, 2.0Kg of chromium, 0.6Kg of nickel and 0.54Kg of manganese into an intermediate frequency vacuum induction furnace for preheating, melting and stirring evenly. The crucible composition is MgO: 97.5%, SiO 2 : 0.67%, CaO: 1.21%, Al 2 o 3 : 0.15%, Fe 2 o 3 : 0.29%, NaOH: 0.17%. The smelting is carried out under the pressure of 5Pa, and the smelting temperature is controlled at 1600°C.

[0061] (2) Add nitrogen to molten steel: Add 0.5Kg of manganese nitride, melt and stir evenly. Fill nitrogen into the induction furnace until the pressure increases to 0.06MPa before adding manganese nitride.

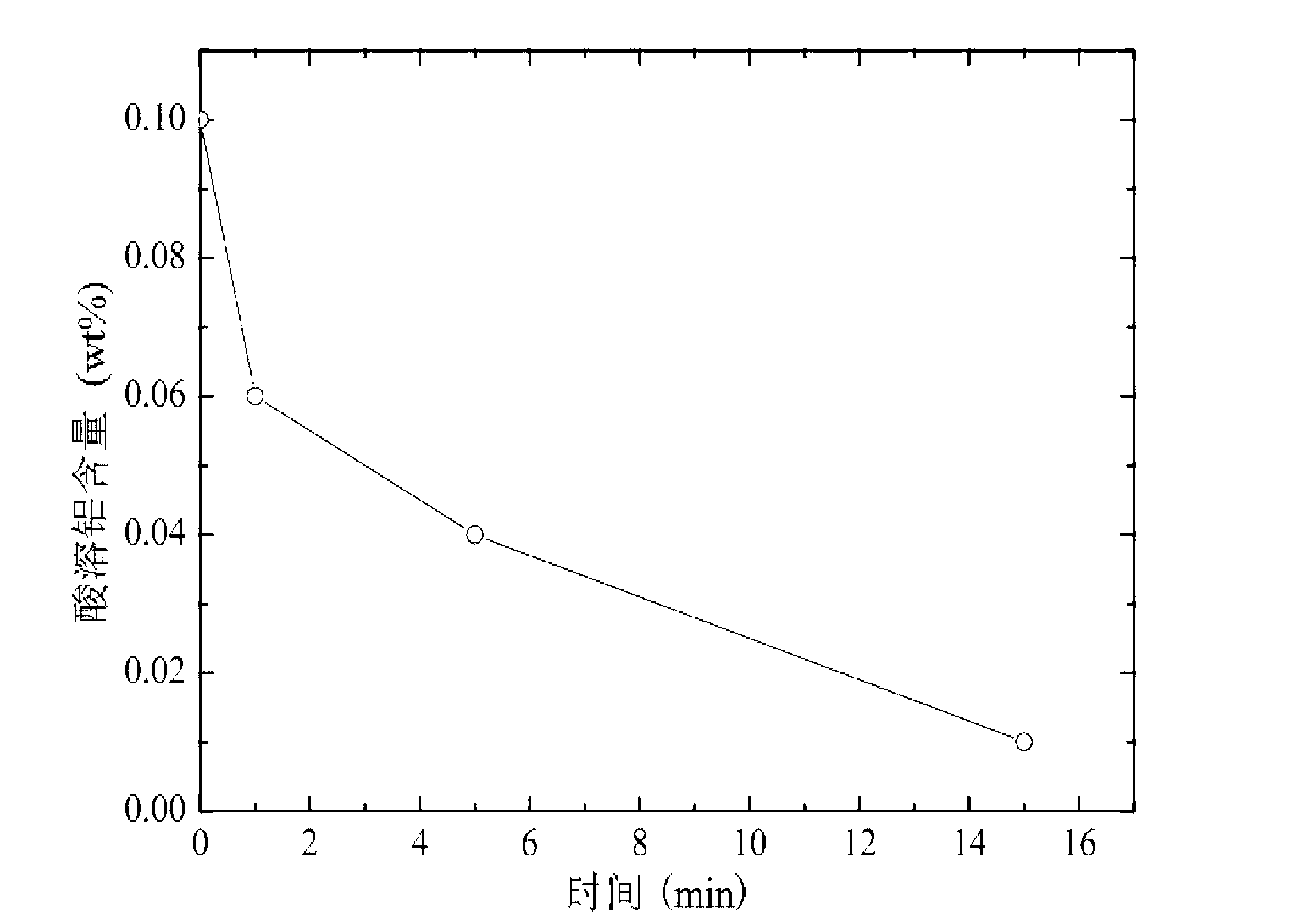

[0062] (3) Use aluminum as a deoxidizer for deoxidation: after the manganese nitride is melted and homogenized, an aluminum ingot accounting for 0.23% of the total mass of molten steel is added at one time for deoxidation. After ad...

Embodiment 2

[0066] Steel type: Fe-21%Cr-9%Mn-7%Ni.

[0067] Process flow:

[0068] (1) Melting molten steel in a vacuum induction furnace: Add 6.4Kg of pure iron, 2.1Kg of chromium, 0.7Kg of nickel and 0.44Kg of manganese into an intermediate frequency vacuum induction furnace for preheating, melting and stirring evenly. The crucible composition is MgO: 97.5%, SiO 2 : 0.67%, CaO: 1.21%, Al 2 o 3 : 0.15%, Fe 2 o 3 : 0.29%, NaOH: 0.17%. The smelting is carried out under the pressure of 5 Pa, and the smelting temperature is controlled at 1550°C.

[0069] (2) Add nitrogen to molten steel: Add 0.5Kg of manganese nitride, melt and stir evenly. Fill nitrogen into the induction furnace until the pressure increases to 0.06MPa before adding manganese nitride.

[0070] (3) Use aluminum as a deoxidizer for deoxidation: after the manganese nitride is melted and homogenized, an aluminum ingot accounting for 0.2% of the total mass of molten steel is added at one time for deoxidation. After addi...

Embodiment 3

[0074] Steel type: Fe-20%Cr-10%Mn-6%Ni.

[0075] Process flow:

[0076] (1) Melting molten steel in a vacuum induction furnace: add 6.36Kg of pure iron, 1.24Kg of chromium, 0.6Kg of nickel and 1Kg of manganese into an intermediate frequency vacuum induction furnace for preheating, melting and stirring evenly. The crucible composition is MgO: 97.5%, SiO 2 : 0.67%, CaO: 1.21%, Al 2 o 3 : 0.15%, Fe 2 o 3 : 0.29%, NaOH: 0.17%. The smelting is carried out under the pressure of 5Pa, and the smelting temperature is controlled at 1500°C.

[0077] (2) Add nitrogen to molten steel: Add 0.8Kg of chromium nitride, melt and stir evenly. Before adding chromium nitride, fill the induction furnace with nitrogen until the pressure increases to 0.08MPa.

[0078] (3) Use aluminum as a deoxidizer for deoxidation: add aluminum ingots and continue smelting for 15 minutes, and the smelting temperature is controlled at 1500°C.

[0079] (4) Tapping and pouring: stop the power supply, let the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com