Rapid solidification Al-Ti-B-Sc intermediate alloy refiner and preparation method thereof

An al-ti-b-sc and master alloy technology, which is applied in the field of preparation of rapidly solidified Al-Ti-B-Sc master alloy refiners, can solve the problems of poor dispersibility of refiners, numerous raw materials, complicated processes, etc. , to achieve the effects of increased solubility, short smelting time and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The first step is to prepare Al-Ti-B-0.1Sc master alloy ingot

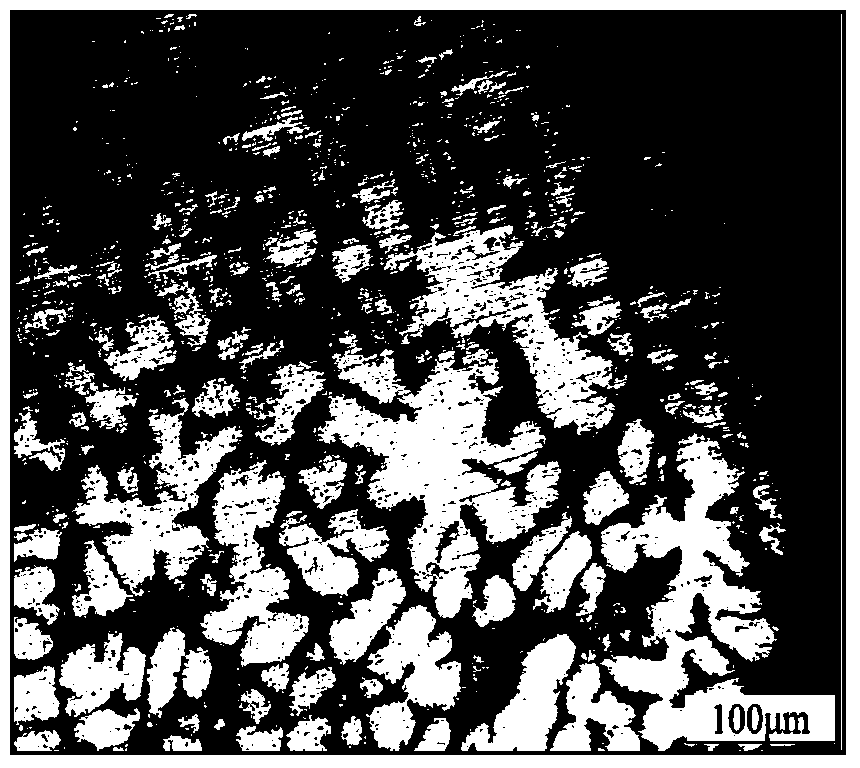

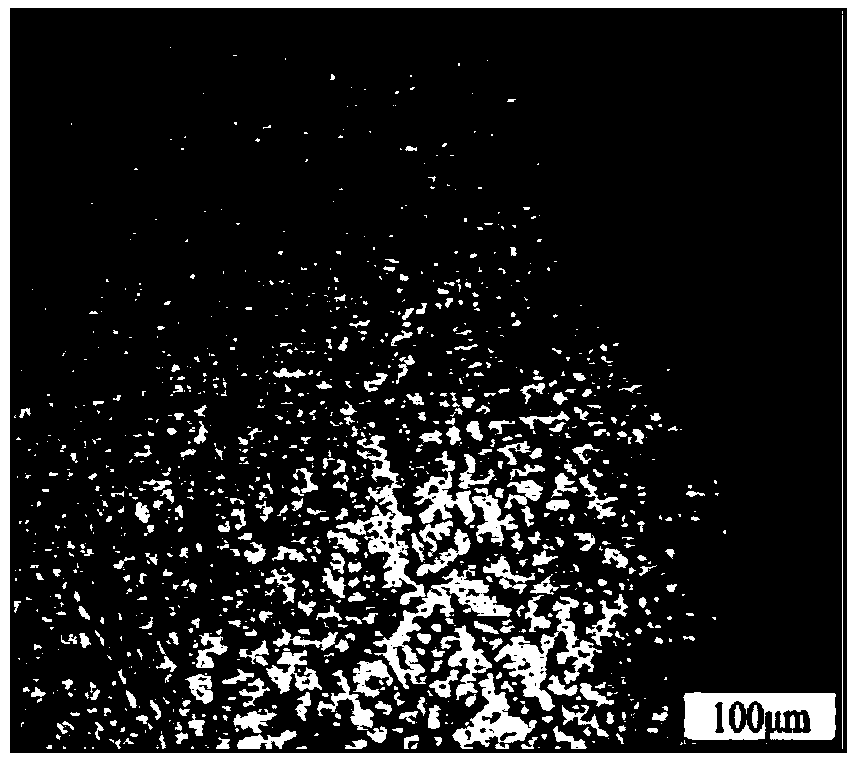

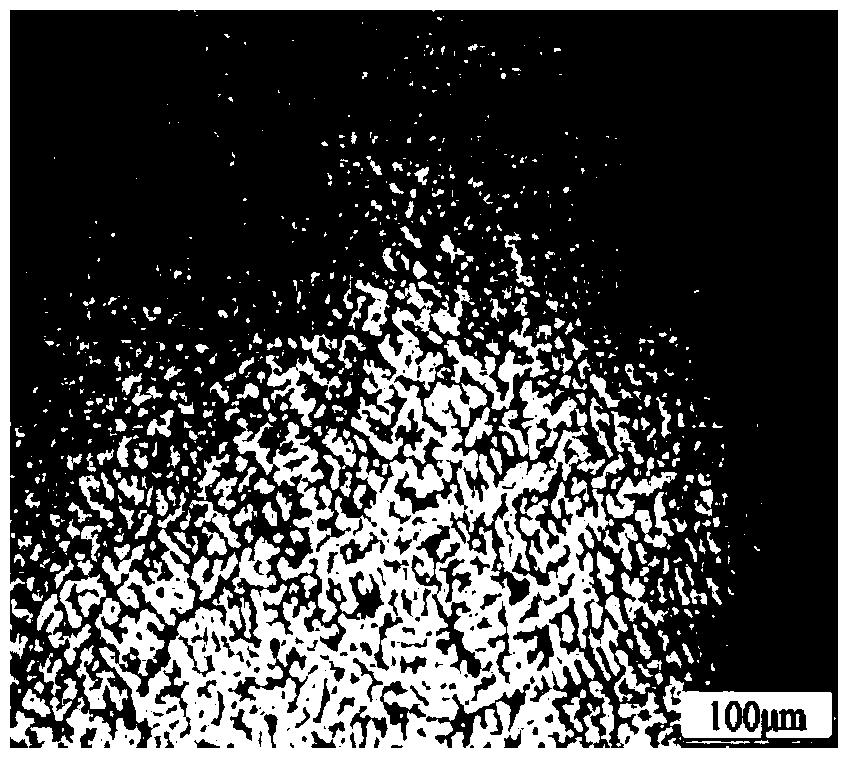

[0037] According to the mass percentage of each component element in the target alloy: Ti is 4.75%, B is 0.95%, Sc is 0.1%, and the rest is Al. The raw materials are traditional Al-5Ti-1B alloy and Al-2Sc alloy ingot, scandium When the content of the obtained Al-Ti-B-Sc master alloy is 0.1%, carry out the proportioning and prepare the materials; melt the weighed Al-5Ti-1B alloy at 700°C until all the Al-5Ti-1B alloy ingots are completely melted Afterwards, stir for 1 minute to remove surface impurities. After standing for 1 minute, add the weighed Al-2Sc alloy into the melt, raise the temperature to 740°C, and stir for 1 minute after the added Al-2Sc alloy is completely melted. Minutes, remove surface impurities, keep it for 2 minutes, pour into a mold preheated at 150 ° C, and make an Al-Ti-B-0.1Sc alloy ingot, the as-cast structure includes α (Al) and TiAl 3 、TiB 2 、Al 3 Sc and other particles.

[003...

Embodiment 2

[0045] The first step is to prepare Al-Ti-B-0.3Sc master alloy ingot

[0046] According to the mass percentage of each component element in the target alloy: Ti is 4.25%, B is 0.85%, Sc is 0.3%, and the rest is Al. The raw materials are traditional Al-5Ti-1B alloy and Al-2Sc alloy ingot, scandium When the content of the obtained Al-Ti-B-Sc master alloy is 0.3%, the proportion is prepared and the material is prepared; the weighed Al-5Ti-1B alloy is melted at 700°C until all the Al-5Ti-1B alloy ingots are completely melted Afterwards, stir for 1 minute to remove surface impurities. After standing for 1 minute, add the weighed Al-2Sc alloy into the melt, raise the temperature to 740°C, and stir for 1 minute after the added Al-2Sc alloy is completely melted. Minutes, remove the surface impurities, let it stand for 2 minutes, pour it into a mold preheated at 150 ℃, and make an Al-Ti-B-0.3Sc alloy ingot, the as-cast structure includes α (Al) and TiAl 3 、TiB 2 、Al 3 Sc and other p...

Embodiment 3

[0054] The first step is to prepare Al-Ti-B-0.5Sc master alloy ingot

[0055]According to the mass percentage of each component element in the target alloy: Ti is 3.75%, B is 0.75%, Sc is 0.5%, and the rest is Al. The raw materials are traditional Al-5Ti-1B alloy and Al-2Sc alloy ingot, scandium When the content of the obtained Al-Ti-B-Sc master alloy is 0.5%, carry out the proportioning and prepare the materials; melt the weighed Al-5Ti-1B alloy at 700°C until all the Al-5Ti-1B alloy ingots are completely melted Afterwards, stir for 1 minute to remove surface impurities. After standing for 1 minute, add the weighed Al-2Sc alloy into the melt, raise the temperature to 740°C, and stir for 1 minute after the added Al-2Sc alloy is completely melted. Minutes, remove the surface impurities, let it stand for 2 minutes, pour it into a mold preheated at 150 ℃, and make an Al-Ti-B-0.3Sc alloy ingot, the as-cast structure includes α (Al) and TiAl 3 、TiB 2 、Al 3 Sc and other particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com