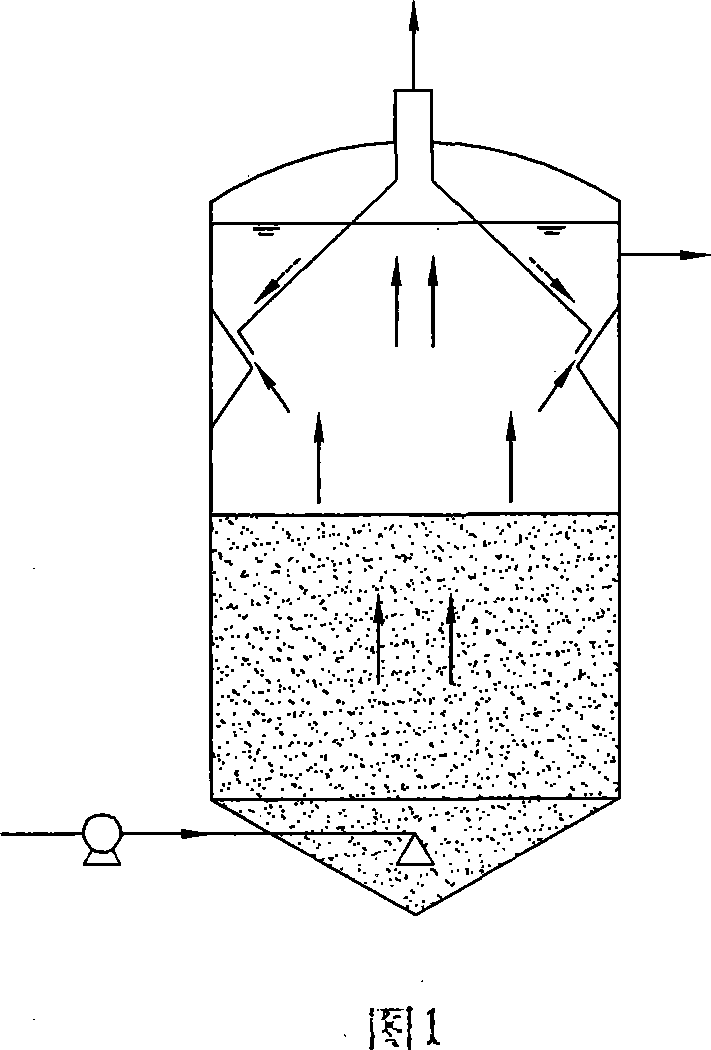

Upflow type anaerobic reactor

An anaerobic reactor and reactor technology, applied in anaerobic digestion treatment, waste fuel and other directions, can solve the problems of unmaintainable, high sludge concentration, long sludge age, etc., and achieve increased volume and high sludge concentration. , the effect of long sludge age

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

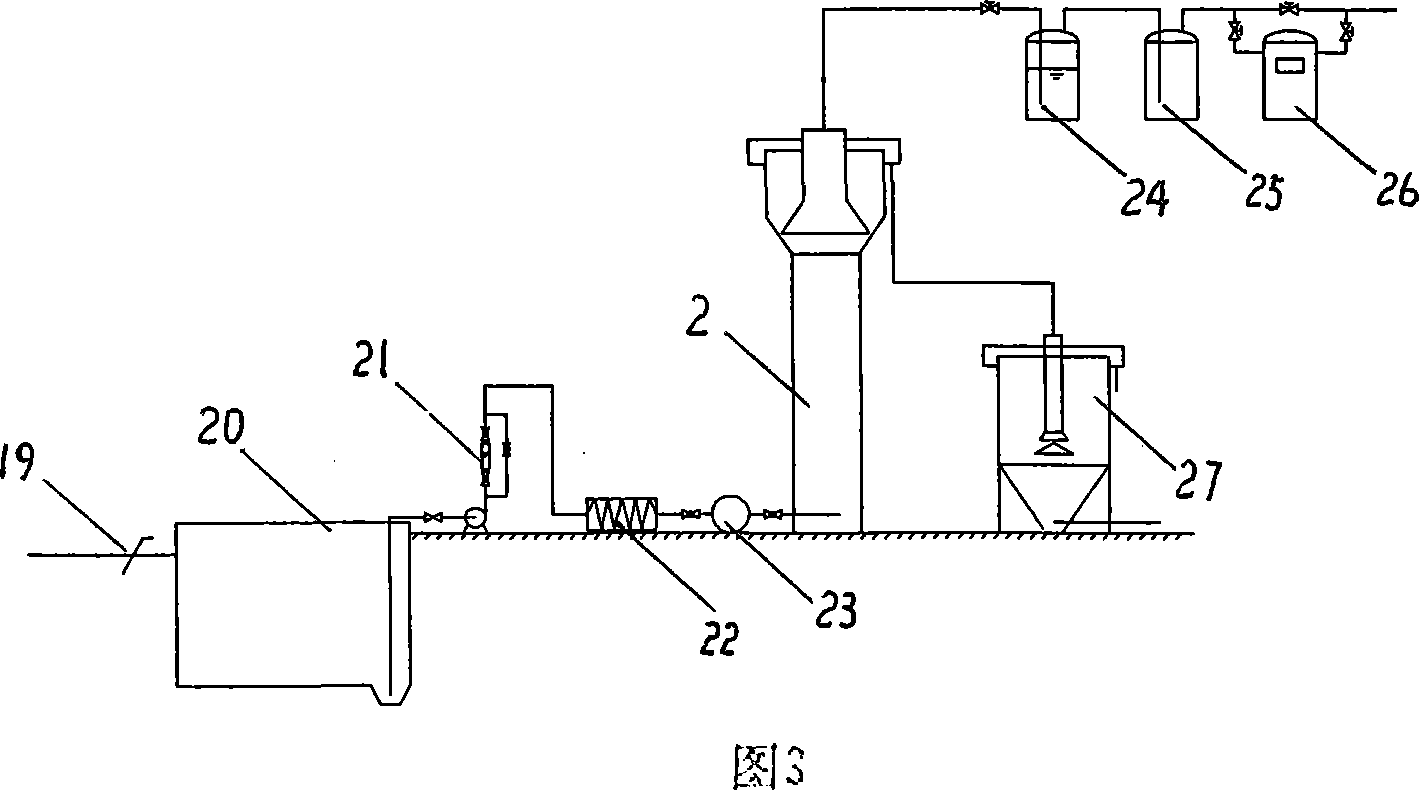

Method used

Image

Examples

Embodiment 1

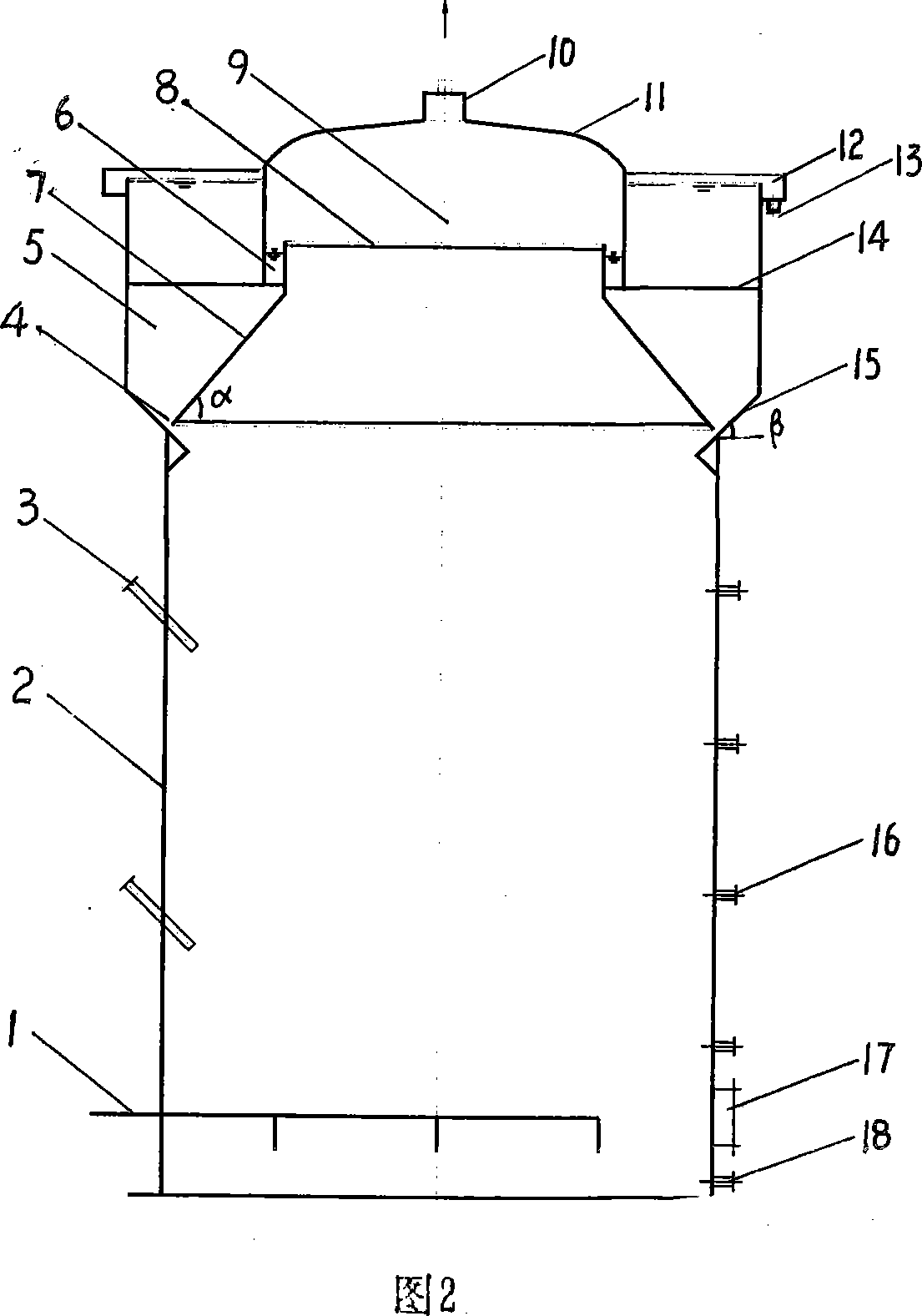

[0035] Embodiment 1: The structure of the present invention is as described above, wherein the diameter of the reactor shell 2 is 3 meters, the diameter of the wide mouth 8 of the conical draft tube is 2 meters, and the angle α of the inclined plate forming the conical draft tube 7 is 45 °, the angle β of reflecting plate 15 is 45 °, the diameter of cylindrical air cover 11 is 2.5 meters, the width of annular passage 6 is 0.25 meters, and the width of annular passage 4 is 0.03 meters. The diameter of the exhaust pipe 10 is 0.08 meters.

Embodiment 2

[0036] Embodiment 2: The structure of the present invention is as described above, wherein the diameter of the reactor cylinder body 2 is 13 meters, and the diameter of the wide mouth 8 of the conical draft tube is 9 meters, and the angle α of the inclined plate that constitutes the conical draft tube 7 is 60° °, the angle β of reflecting plate 15 is 60 °, the diameter of cylindrical air cover 11 is 10 meters, the width of annular channel 6 is 0.5 meter, and the width of annular channel 4 is 0.2 meter. The diameter of the exhaust pipe 10 is 0.4 meters.

Embodiment 3

[0037] Embodiment 3: The structure of the present invention is as described above, wherein the diameter of the reactor shell 2 is 6 meters, the diameter of the wide mouth 8 of the conical draft tube is 4.8 meters, and the angle α of the inclined plate forming the conical draft tube 7 is 50 °, the angle β of reflecting plate 15 is 50 °, the diameter of cylindrical air cover 11 is 5.1 meters, the width of annular passage 6 is 0.15 meters, and the width of annular passage 4 is 0.1 meter. The diameter of the exhaust pipe 10 is 0.2 meters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com