Patents

Literature

72results about How to "Increase sludge concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

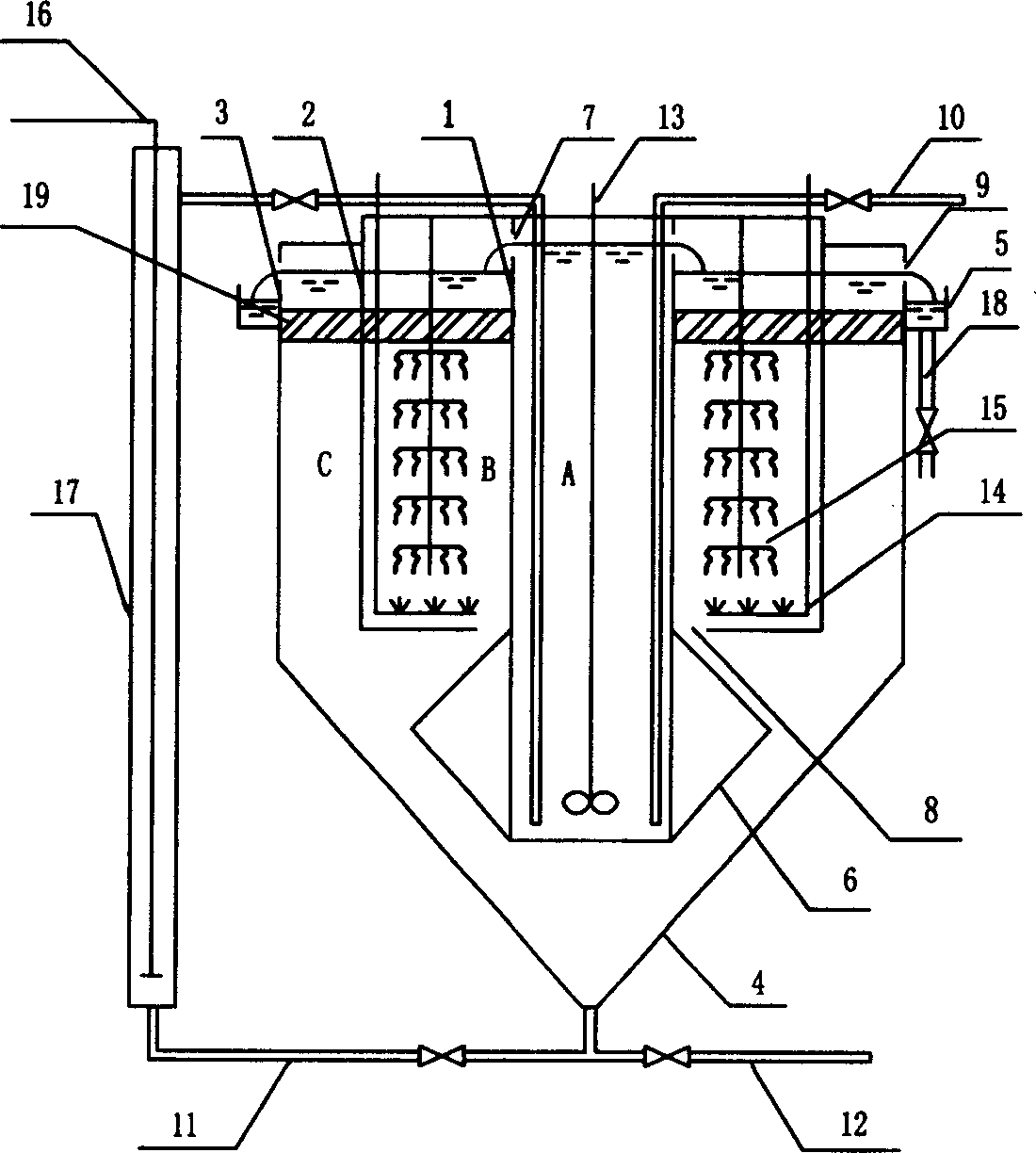

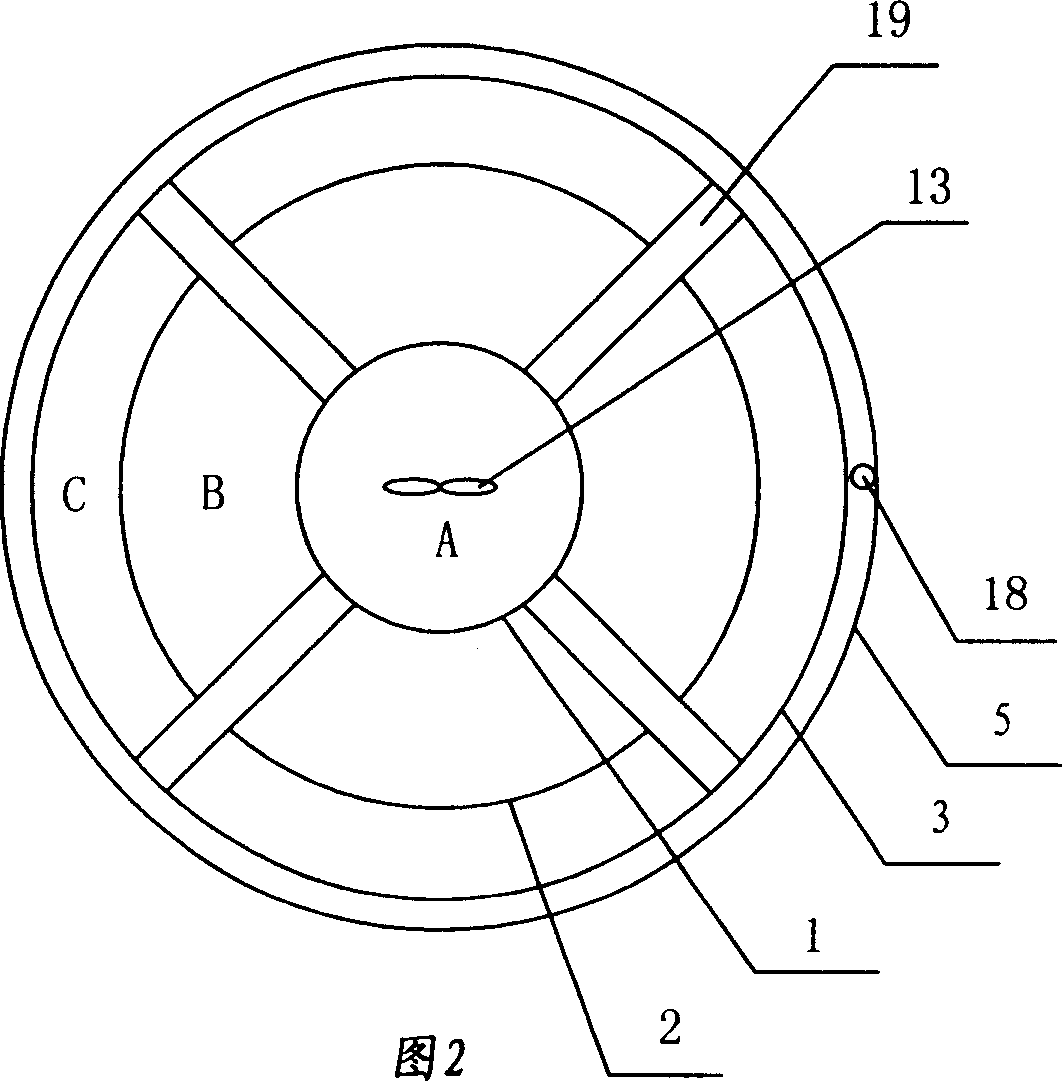

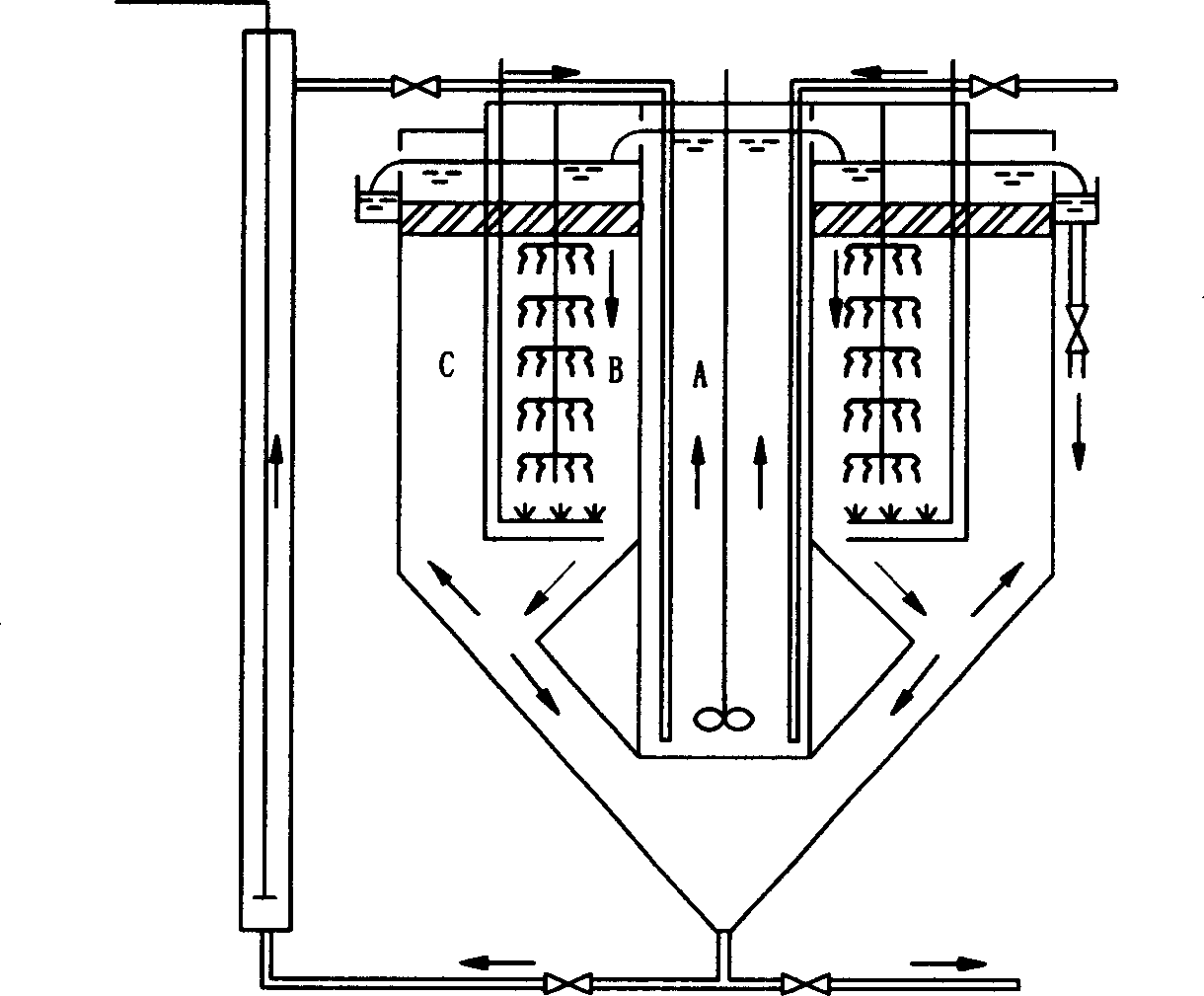

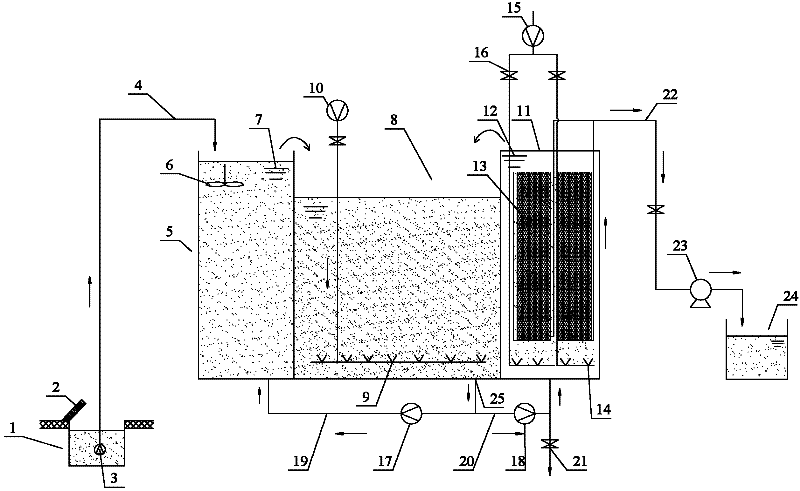

Active sludge-biomembrane compounding integral sewage treating method and apparatus

InactiveCN1887739AIncrease sludge concentrationAvoid churnTreatment with aerobic and anaerobic processesActivated sludgeEngineering

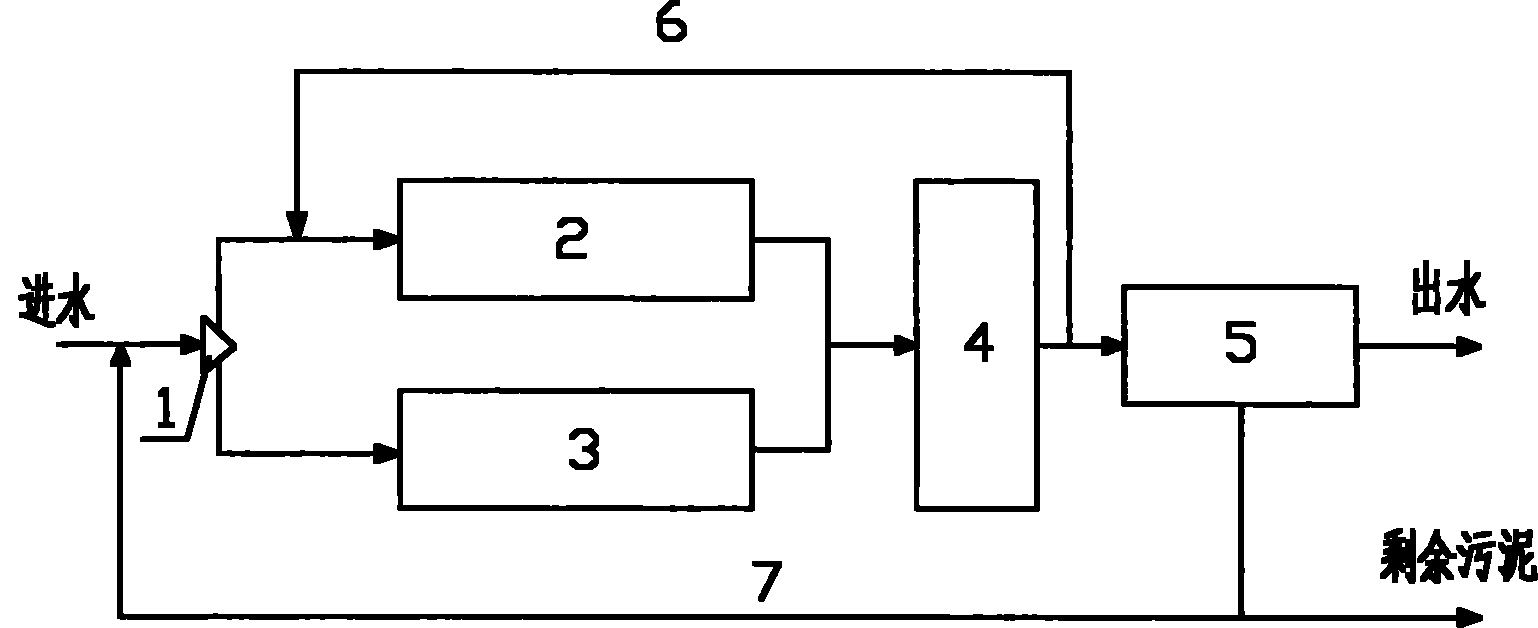

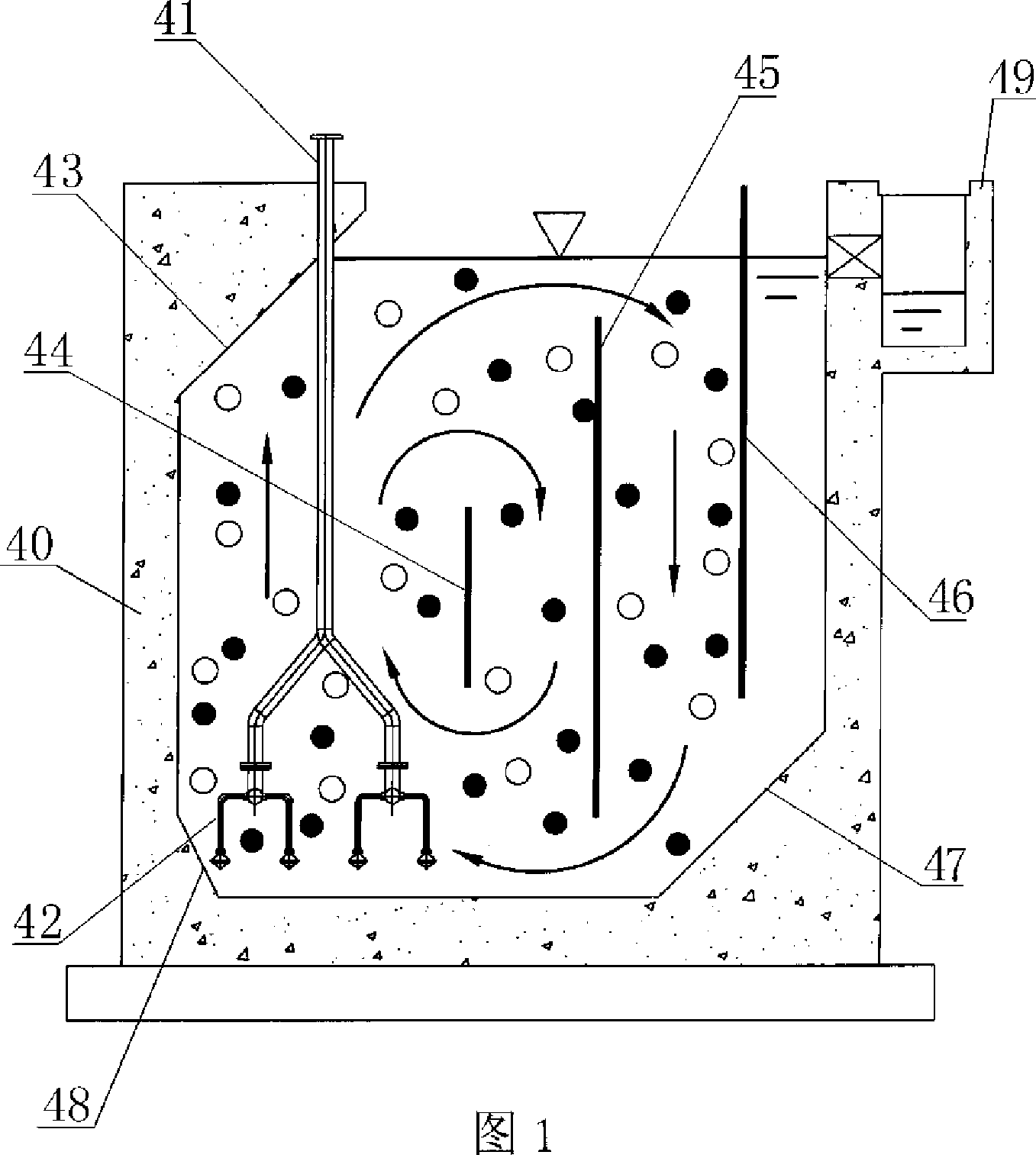

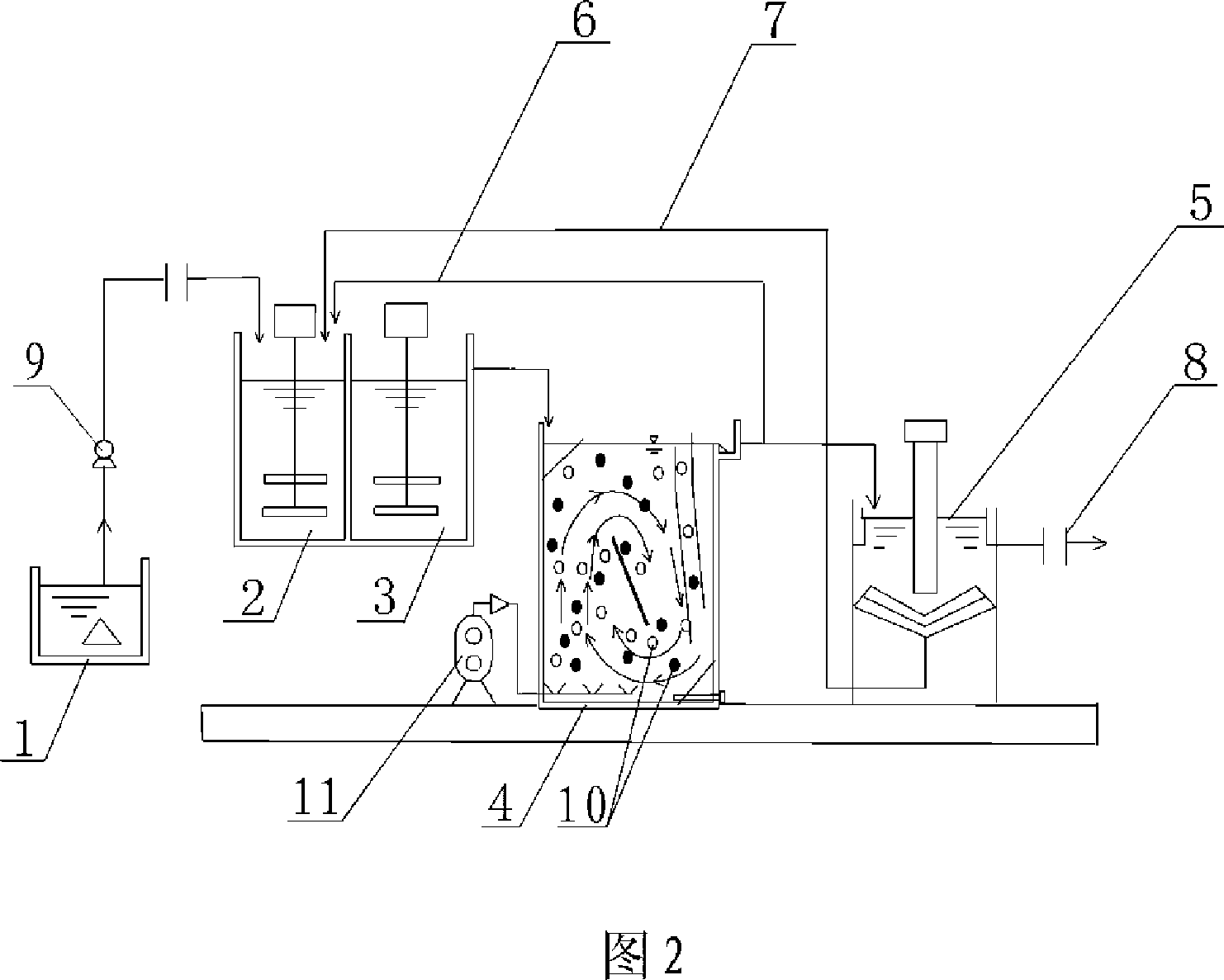

The active sludge-biomembrane compounding integral sewage treating method includes the first leading the sewage to be treated to the anoxic area through stirring for mixing sewage to be treated and active sludge, the subsequent leading the sewage to aerobic area with stuffing for aeration treatment with combined active sludge and biomembrane, and final leading the sewage to the precipitation area for natural deposition to separate sludge and water, leading out purified water, reflowing the mixed sludge liquid to the anoxic area and draining the residual sludge. The present invention also relates to the corresponding sewage treating apparatus. The present invention has the advantages of high treating capacity, resistance to impact load, simple operation, etc. and is especially suitable for use in medium and small towns.

Owner:CHONGQING UNIV

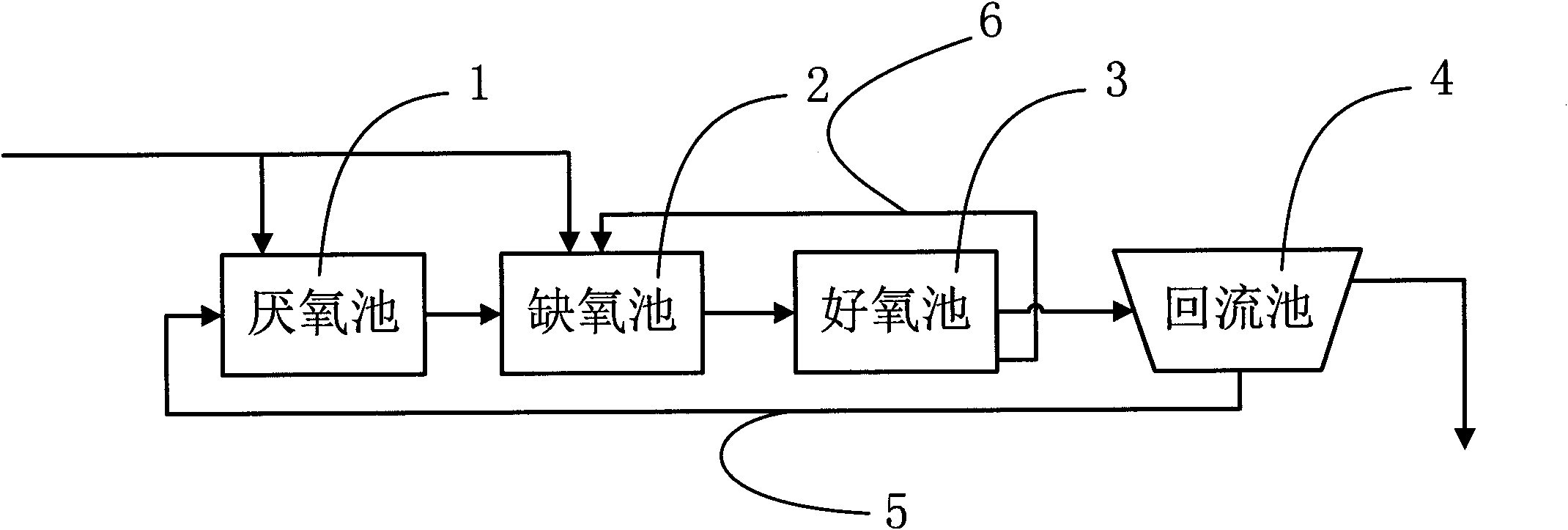

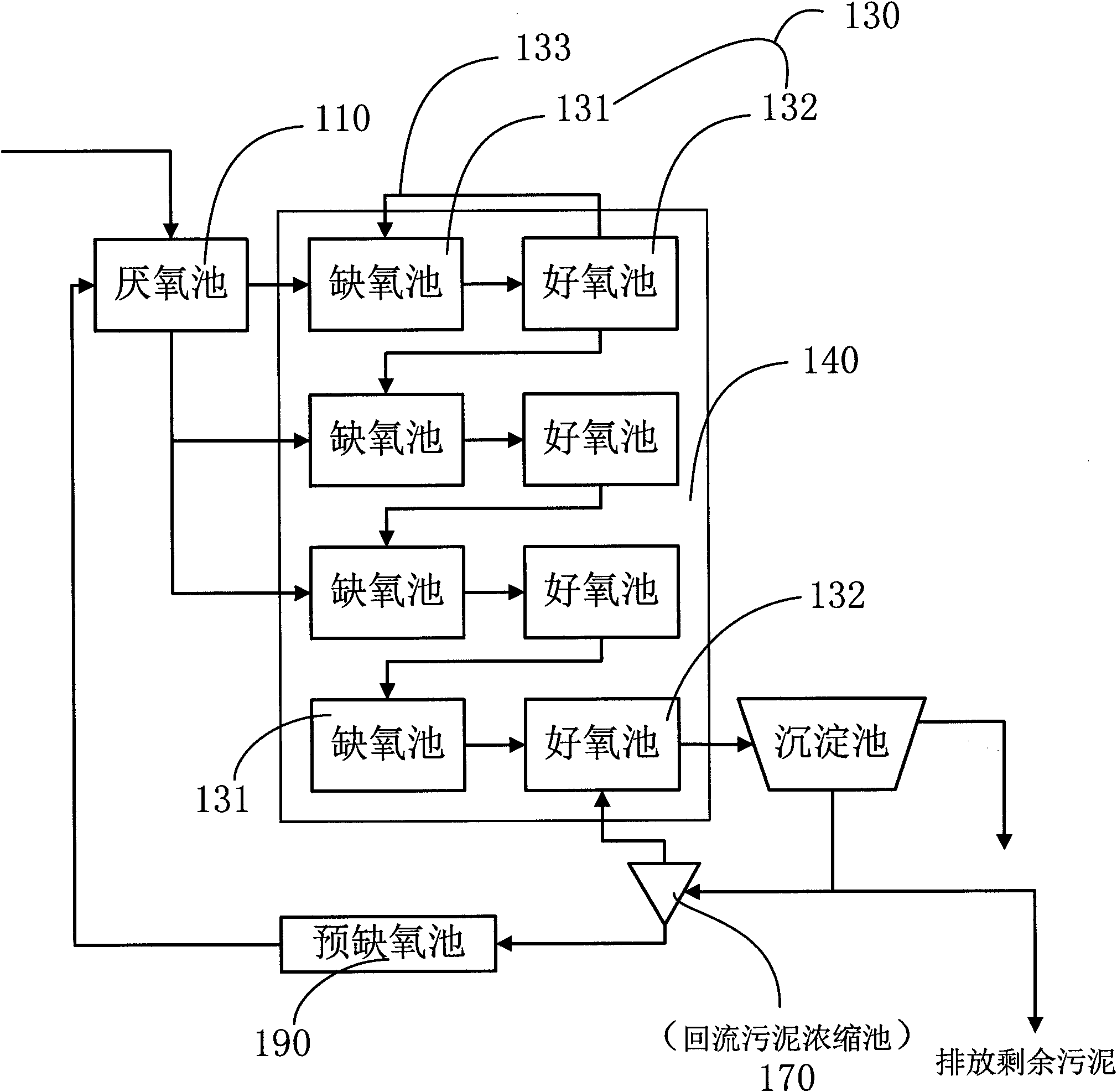

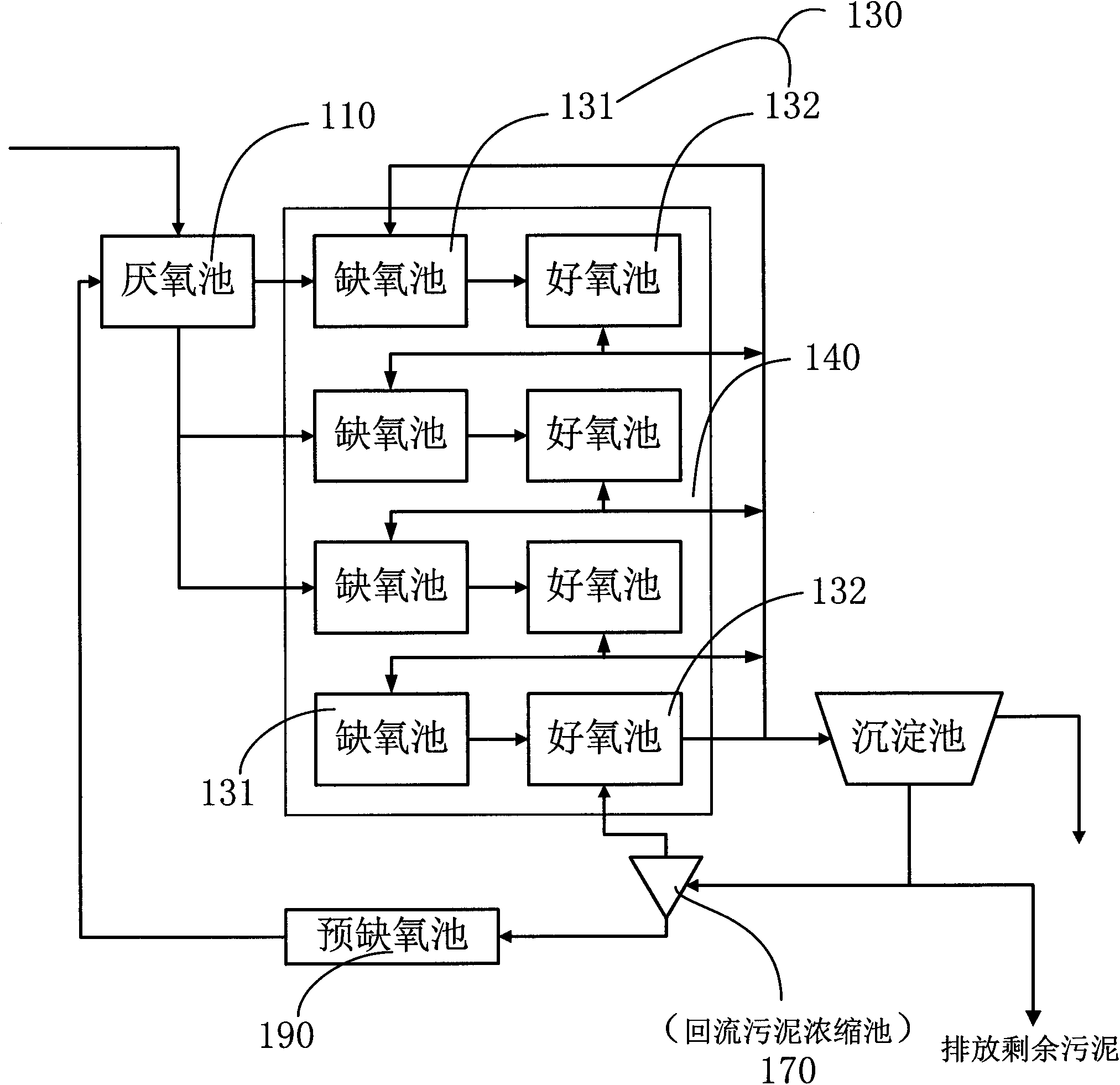

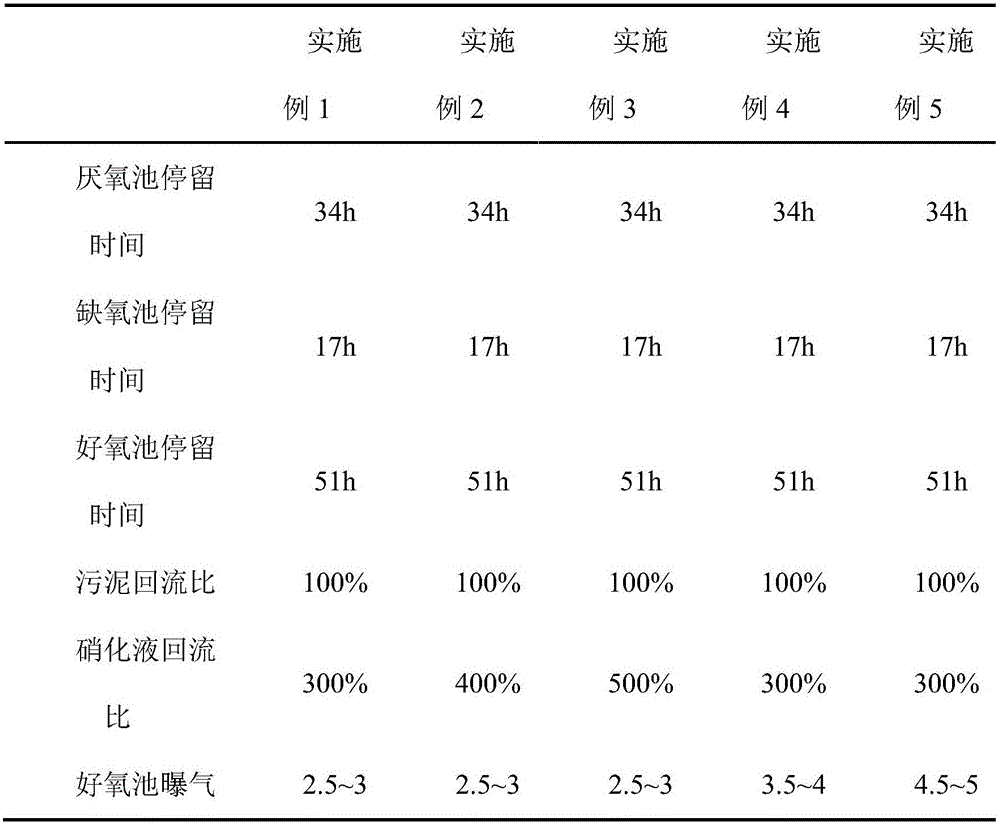

Multi-level biological nitrogen and phosphorus removal sewage treatment method and device

InactiveCN101885559AImprove filtration efficiencyReduce dilutionMultistage water/sewage treatmentBiological water/sewage treatmentSludgeNitrogen

The invention discloses a multi-level biological nitrogen and phosphorus removal sewage treatment method. The method comprises the following steps of: introducing sewage into an anaerobic pond; introducing the sewage treated in the anaerobic pond into an anoxic pond at the front section of an anoxic-aerobic treatment unit; draining all sewage into a settling pond through an aerobic pond of the last level; draining the settled sludge into a returned sludge concentration pond; draining supernatant in the returned sludge concentration pond into the aerobic pond of the last level; and draining the sludge in the returned sludge concentration pond into the initial anaerobic pond through a pre-anoxic pond for circular treatment. The invention also provides a corresponding treatment device. The method and the device have the advantages of only adding the returned sludge concentration pond and the pre-anoxic pond compared with the A2O process in the prior art and improving the reaction efficiency by adjusting the connection relationship among the reaction ponds.

Owner:CORSTAR ENVIRONMENTAL EQUIP SHANGHAI

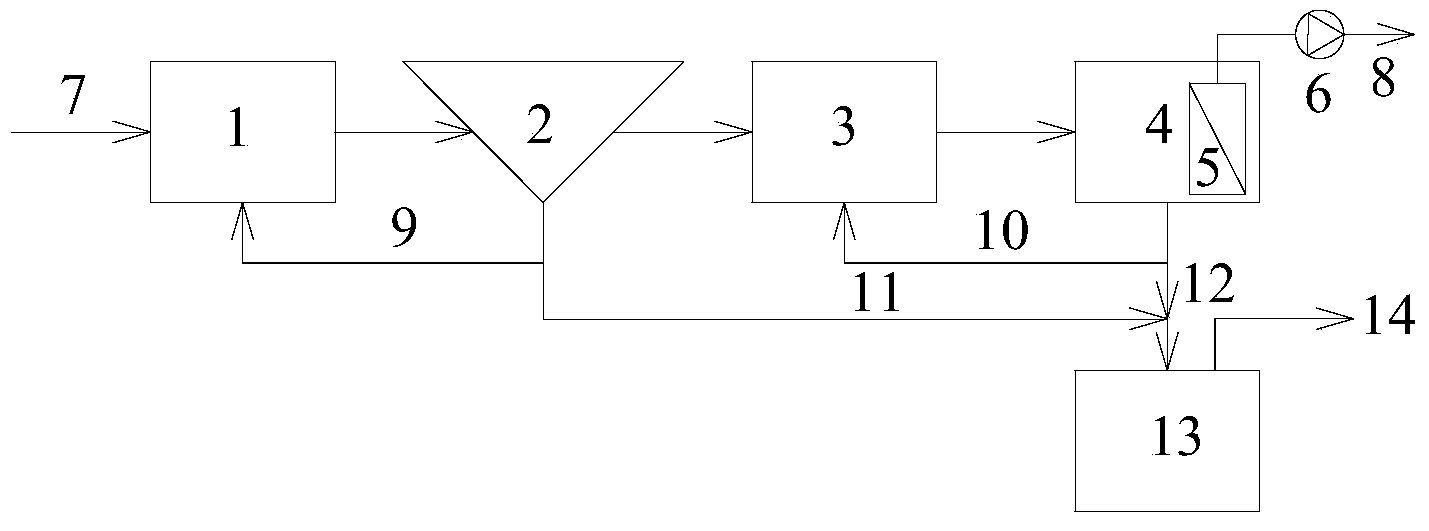

Anaerobic ammonia oxidation-based low-carbon nitrogen ratio urban sewage denitrification system and treatment process

ActiveCN104058555AImprove resource utilizationReduce outputWater contaminantsWaste based fuelOperating energyTotal nitrogen

The invention provide an anaerobic ammonia oxidation-based low-carbon nitrogen ratio urban sewage denitrification system and treatment process. The system comprises a biological adsorption unit, an anaerobic ammonia oxidation unit, a nitrosation unit, a membrane technology unit and an anaerobic digestion unit, wherein the biological adsorption unit comprises an aeration tank and a settling pond; the aeration tank is connected with the settling pond; the settling pond is connected with an anaerobic ammonia oxidation tank; the anaerobic ammonia oxidation tank is connected with a nitrosation tank provided with a membrane component; the anaerobic digestion unit is an independent sludge treatment unit. The system is short in process flow, short in system startup time, stable and high-efficiency in denitrification performance, standard reach of effluent total nitrogen, low in operating energy consumption and material consumption and low in residual sludge yield. Organic matters in the urban sewage are subjected to biological adsorption removal by utilizing biological adsorption, sludge which is discharged through biological adsorption and is enriched in organic matters is subjected to medium-temperature anaerobic digestion treatment to produce biogas to be used for heating and heat preservation of the medium-temperature anaerobic digestion tank and the low-temperature anaerobic ammonia oxidation tank, the organic matters in the urban sewage can be recycled, and the operating energy consumption of the process is further reduced.

Owner:NORTH CHINA MUNICIPAL ENG DESIGN & RES INST

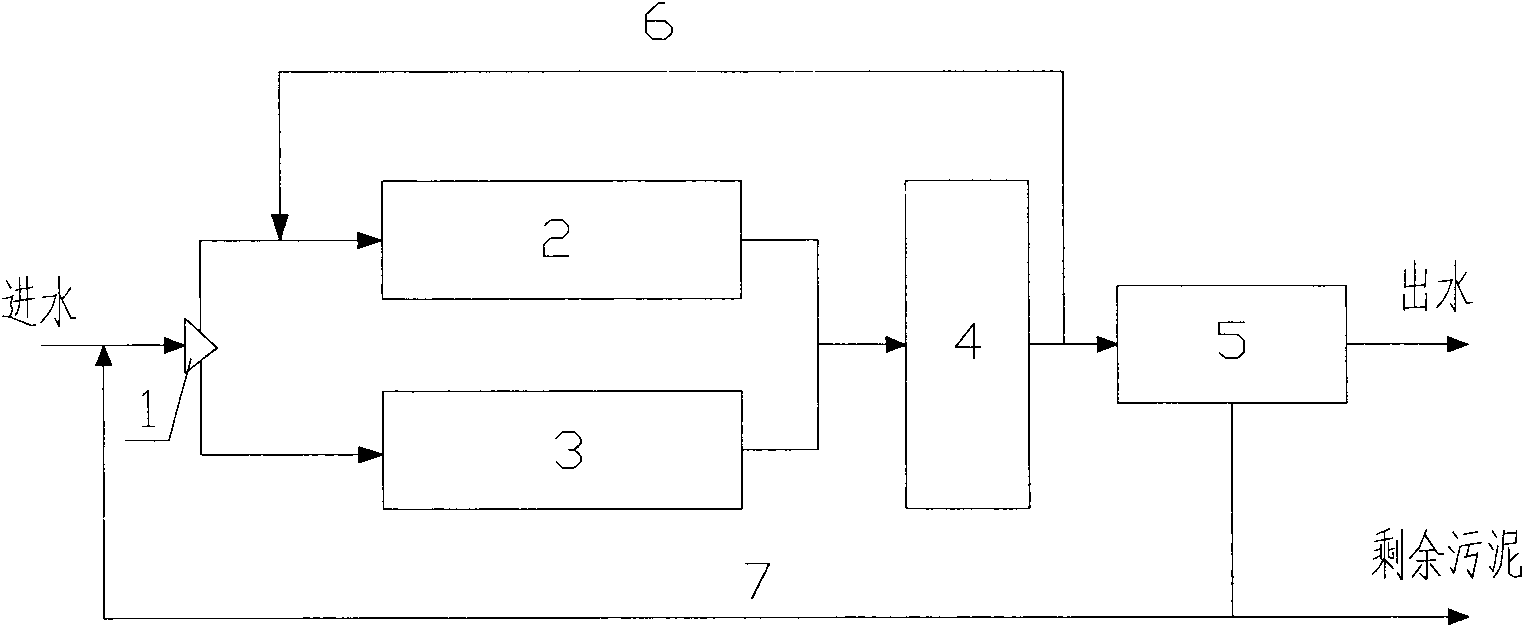

Parallel A2O-MBR denitrifying phosphorus removal method

InactiveCN102126810AEasy to controlPromote enrichmentMultistage water/sewage treatmentRefluxNitrogen

The invention belongs to the technical field of sewage treatment, and relates to a parallel anaerobic-anoxic-oxic (A2O)-membrane bioreactor (MBR) denitrifying phosphorus removal method. Adopted devices comprise an oxic tank, an anaerobic tank, an anoxic tank and a membrane tank, wherein the oxic tank is connected in parallel with the anaerobic tank; sewage to be treated and external reflux sludge are mixed in a distribution well and flow into the oxic tank and the anaerobic tank according to a proper proportion respectively, and internal reflux mixed liquid which reflows from the anoxic tank also flows into the oxic tank simultaneously; sewage which flows out of the oxic tank and sewage which flows out of the anaerobic tank are mixed and flow into the anoxic tank together for denitrifying phosphorus removal; and the sewage enters an MBR tank for sludge and water separation, and a part of residual sludge serves as the external reflux sludge to be fed into the distribution well. The parallel A2O-MBR denitrifying phosphorus removal method can be used for the new construction and modification engineering of a biological denitrifying phosphorus removal sewage plant, the volume and the aeration amount of an aeration tank can be reduced, and a secondary sedimentation tank can be eliminated simultaneously, so that the floor space of an urban sewage plant is reduced.

Owner:TIANJIN POLYTECHNIC UNIV

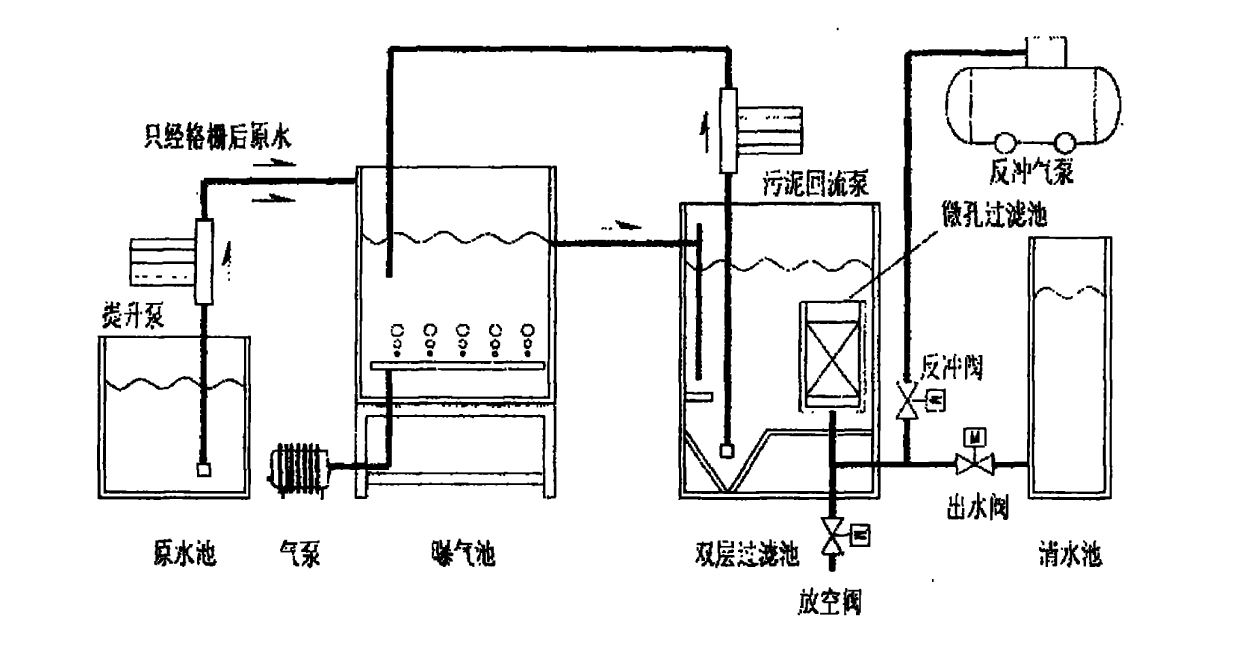

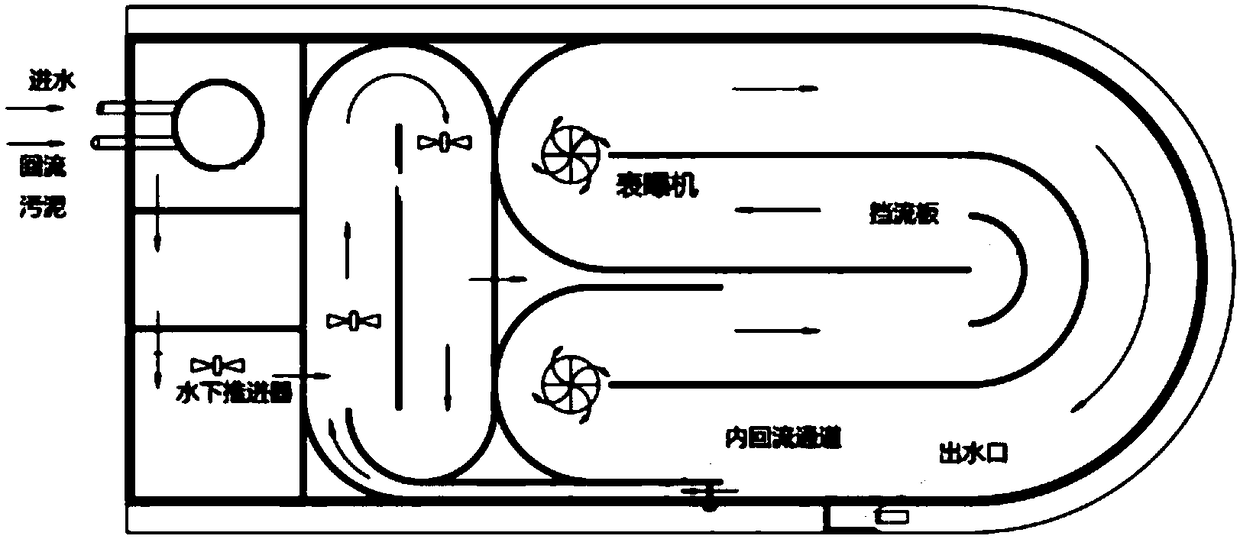

Biological cycle moving bed sewage treatment system and method thereof

InactiveCN101062810AMass transfer rate is fastIncrease sludge concentrationTreatment using aerobic processesTreatment with aerobic and anaerobic processesRefluxSludge

The invention discloses a biological cycle moving bed sewage disposal system and method, which comprises the following steps: entering the raw water into anoxybiotic tank and anaerobic tank with pump from raw water tank; treating; feeding into the cycle moving bed reactor to proceed aeration oxygenation reaction; making the inner section in the tank body of current, inert support filler and bubble be directed with up-and-down cycle splitter, separating splitter and tailboard; forming circulatory flow; reacting the microbe of the current and the inert support filler completely; discharging into desilter; refluxing the depositing sludge in the bottom of the desilter into the anoxia tank; discharging the clear water in the upper of the desilter from the exhaust pipe; refluxing the treated water in the reactor into the anoxia tank through internal reflux pipe. This invention avoids the stratification, which can decrease the operating expense.

Owner:张文虎

Composite HBF (Honess Hybrid Biological&Fixed film Technology) module reactor and sewage treatment process

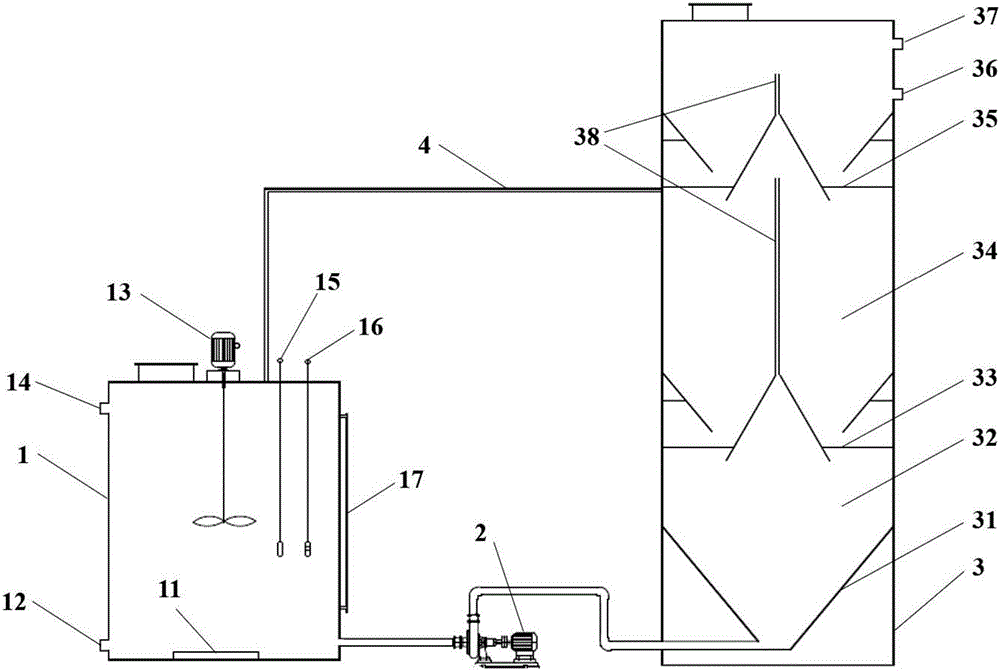

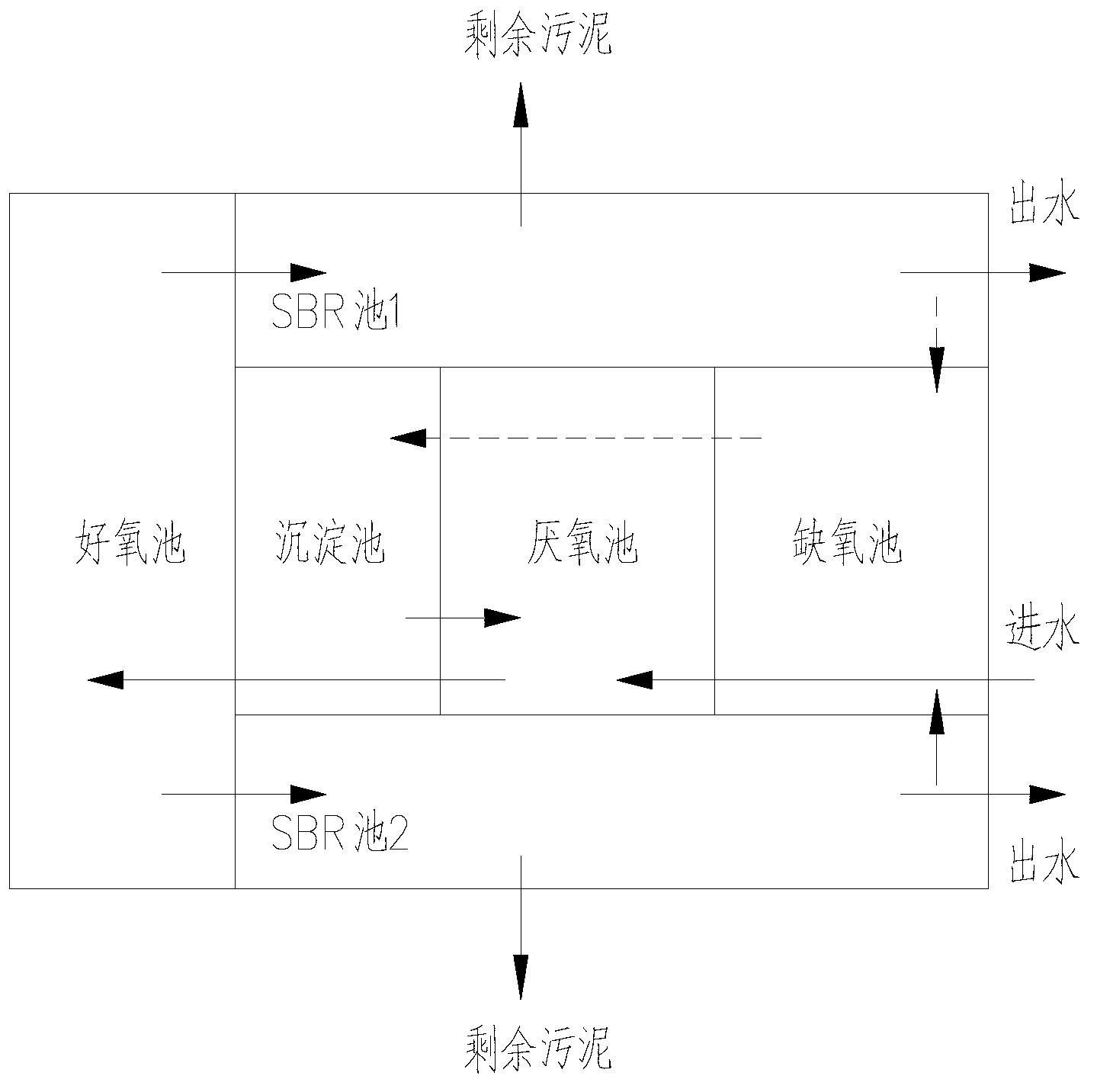

InactiveCN103145247ASimple structureSimple processTreatment with aerobic and anaerobic processesActivated sludgeSequencing batch reactor

The invention discloses a composite HBF (Honess Hybrid Biological&Fixed film Technology) module reactor which comprises an anaerobic pool, an anoxic pool, an aerobiotic pool and an SBR (Sequencing Batch Reactor) pool, wherein the SBR pool comprises a first SBR pool and a second SBR pool which are connected with the aerobiotic pool at the same time. The aerobiotic pool, the first SBR pool and the second SBR pool are internally provided with enzyme floating fillers, respectively. The anaerobic pool, the anoxic pool, the aerobiotic pool, the first SBR pool and the second SBR pool are module members. The invention further provides a sewage treatment process. Based on AAO-SBR (Anaerobic-Anoxic-Oxic-Sequencing Batch Reactor), the aerobiotic pool, the first SBR pool and the second SBR pool are internally provided with enzyme floating fillers respectively as biological attaching carriers, so that the biomass of the reactor is more than 2 times of that by an activated sludge process in volume, thereby greatly enhancing the processing capacity of the reactor and simplifying the structure of the reactor.

Owner:SHANGHAI HONESS ENVIRONMENTAL TECH CORP

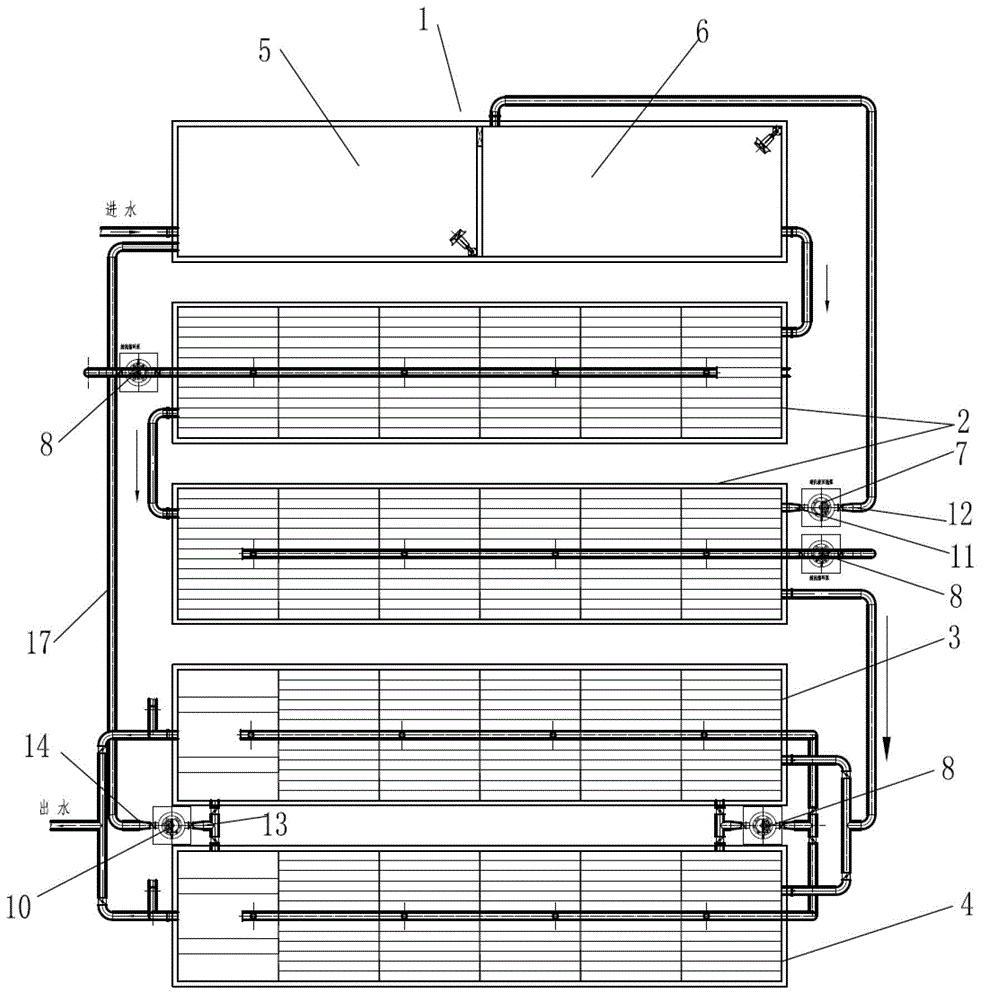

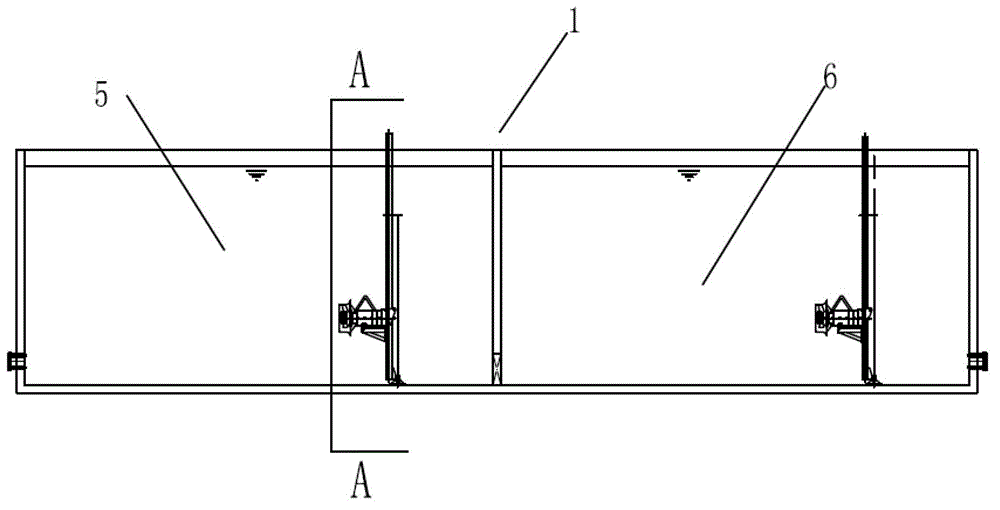

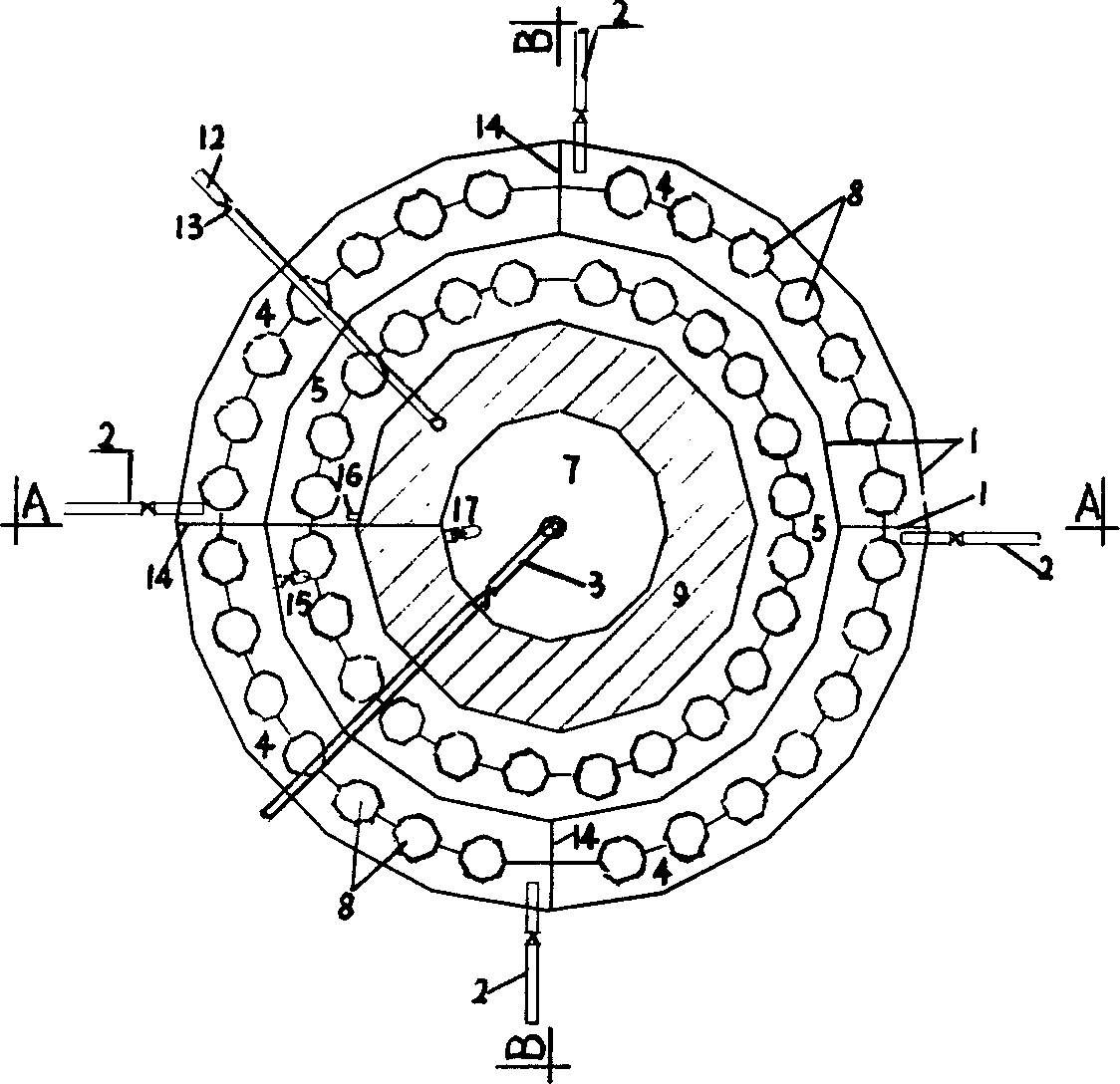

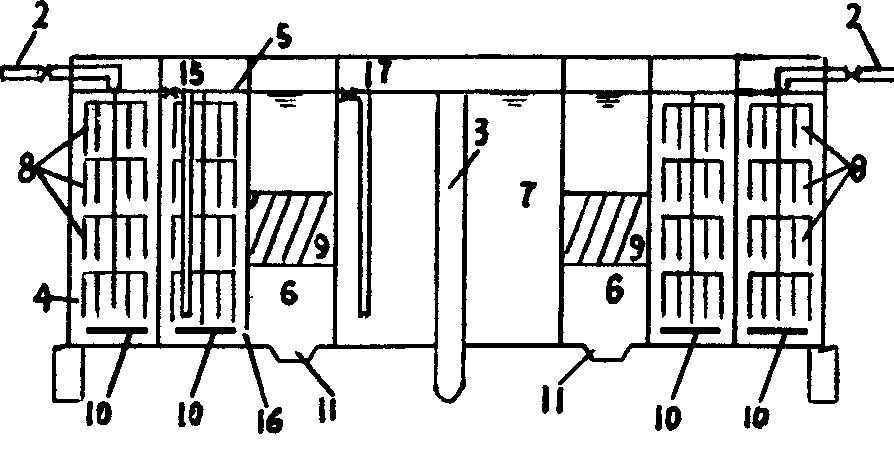

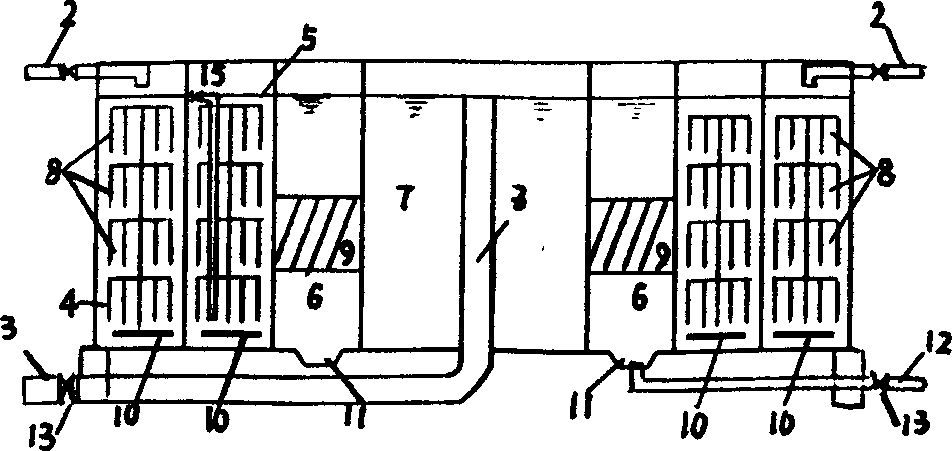

Integrated sewage treatment equipment with multi-biomembrane

InactiveCN1789172AEasy to handleCraft briefWater contaminantsTreatment with aerobic and anaerobic processesSludgeWastewater

The invention discloses an integral multistage biological membrane wastewater treating device, comprising tank, filling material, influent pipe and exhaust pipe. The said tank comprises a quaternary concentric circle, and the outer circle is separated into different reaction areas by baffle board with alternative operation of aerobic and anaerobic, semi-flexible composite filling material is equipped in every reaction area, the intermediate circle is filled with semi-flexible composite filling material, the inner circle is the settling area and the center is the sterilizing area. The said influent pipe is connected with the reaction areas of the outer circle, and supplies water in point, the reaction areas of the outer circle is connected with intermediate circle, inner circle and central sterilizing area in order through water pipe, the exhaust pipe is connected with the central sterilizing area to extends out and the underwater aerator is installed in the bottom of the outer circle and intermediate circle. The device is characterized by the resistance to impact load, high treating effect, low running energy consumption, small surplus sludge, short process, little accommodation area, low investment and convenient management.

Owner:CHONGQING UNIV

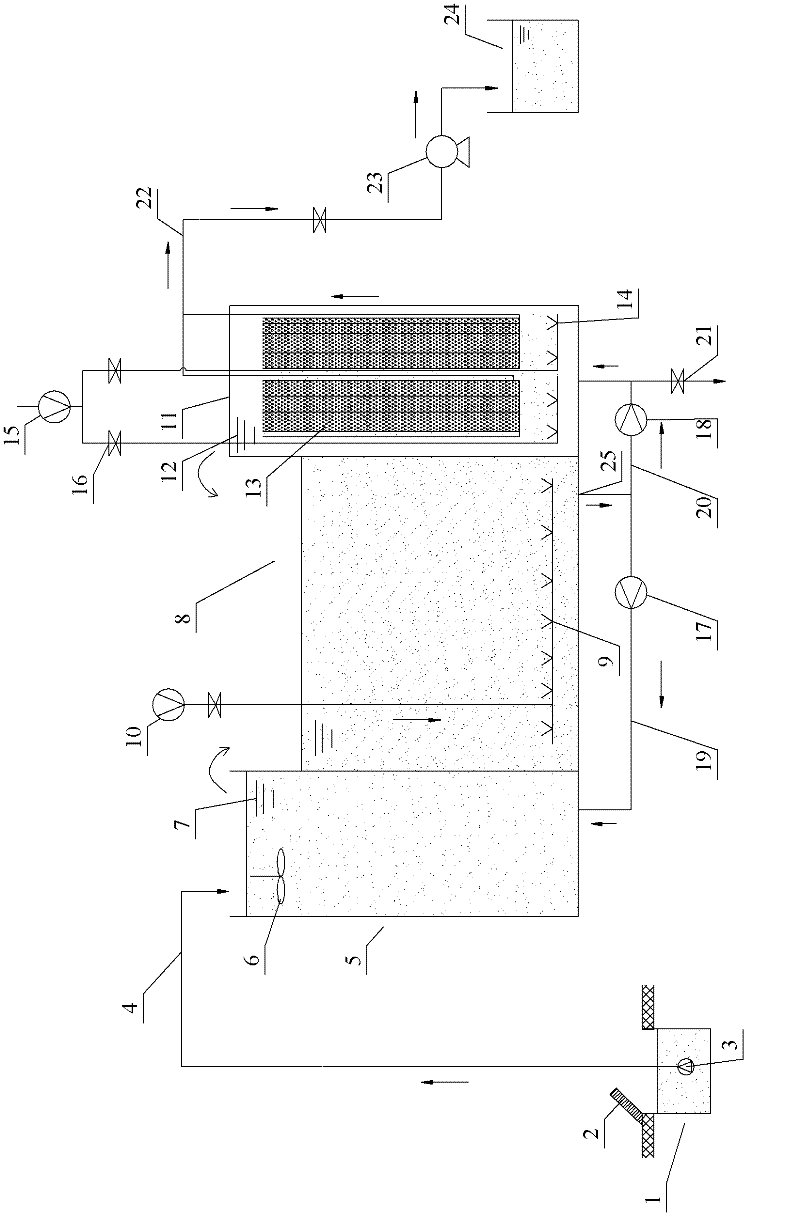

Biological treatment method, biological treatment system and bioreactor of coal chemical wastewater

ActiveCN102874927AHigh N/C valueIncrease concentrationTreatment with aerobic and anaerobic processesAnaerobic reactorOxygen

The invention relates to a biological treatment method of coal chemical wastewater, which adopts a biological reaction-muddy water separation integrated bioreactor. The method comprises the following steps of: sequentially feeding materialized and pre-treated coal chemical wastewater into an anaerobic bioreactor, an anoxic bioreactor, a first-stage aerobiotic bioreactor, a second-stage aerobiotic bioreactor and a third-stage aerobiotic bioreactor, selecting each aerobiotic bioreactor to discharge water and inflow into the anoxic bioreactor; and carrying out anaerobic acidification treatment by the anaerobic reactor, reinforcing a biological denitrification reaction in the anoxic reactor to remove non-gradable organic matters, completely decarbonizing by the first-stage aerobiotic bioreactor, and realizing the short-course nitratlon reaction and the whole-course nitratlon reaction by the second-stage aerobiotic bioreactor and the third-stage aerobiotic bioreactor, wherein the sludge concentration in the reactor can be guaranteed to be greater than 8mg / L due to the biological reaction-muddy water separation integrated bioreactor, the sludge age is greater than 60 days, the specific strains can be preferably cultured, and the function realization of a novel method can be guaranteed. The coal chemical wastewater is treated by the method, so that the discharged water can reach the requirement of the national wastewater comprehensive discharge standard.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

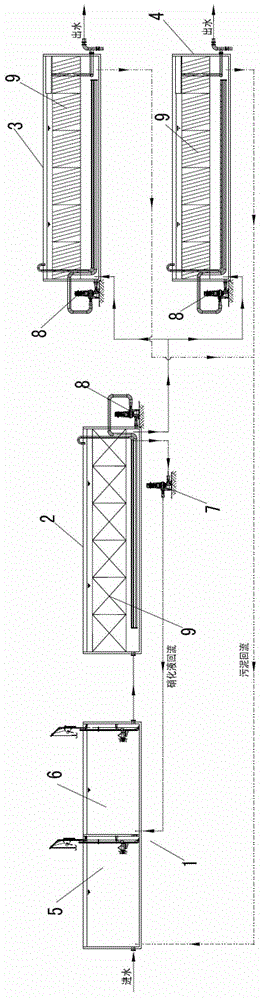

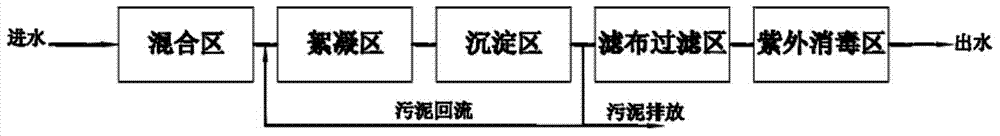

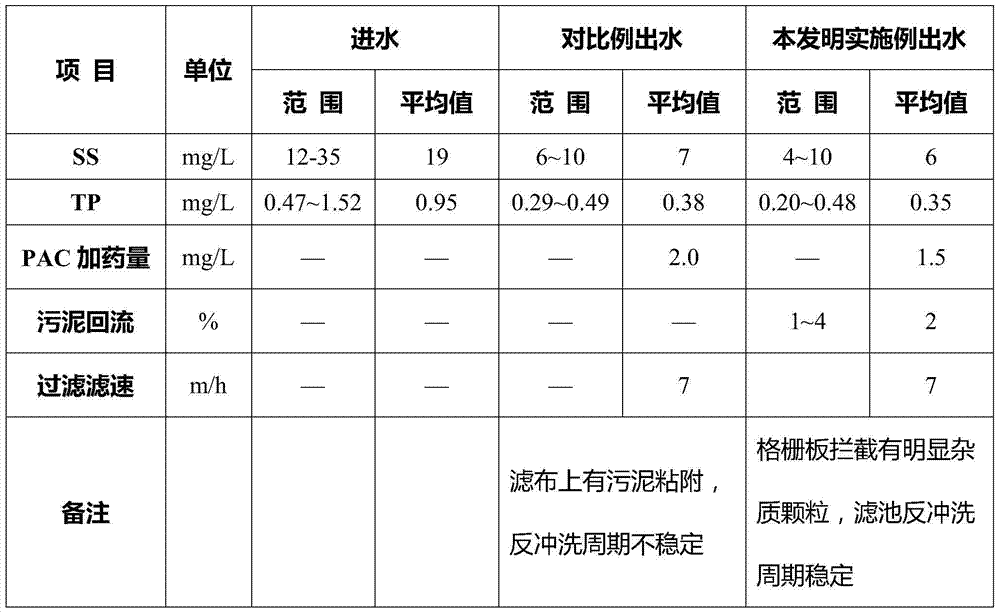

Integrated advanced wastewater treatment device and process

ActiveCN103922527AReduce thicknessReduce volumeMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFlocculationGrating

The invention relates to an integrated advanced wastewater treatment device and process. A sludge reflowing pipe is arranged at the bottom of a settling region, wherein one end of the sludge reflowing pipe is connected with a flocculation region, a sludge discharging pipe is arranged at the other end of the sludge reflowing pipe, and a filter cloth filtering region and a disinfecting region are arranged up and down and are adjacent to the settling region. Wastewater enters a mixing region through a wastewater inlet pipe, enters the flocculation region through a first water passing hole after being mixed, and enters the settling region through a second water passing hole after being flocculated; supernate overflows through an effluent weir after sludge and wastewater are separated through settling in the settling region, and enters the filter cloth filtering region after passing through a grating plate, effluent enters the disinfecting region from meshes in the bottom through a wastewater collecting tank after being filtered, and discharged through a wastewater outlet pipe through a third water passing hole after being disinfected, and a sludge part reflows to the flocculating region through a sludge reflowing pipe, and is partially discharged through the sludge discharging pipe. The process provided by the invention is reasonable in procedures; the device is compact in integrated design, saving in occupation area, less in head loss and less in chemical adding amount.

Owner:中清生态环境(宁波)有限公司

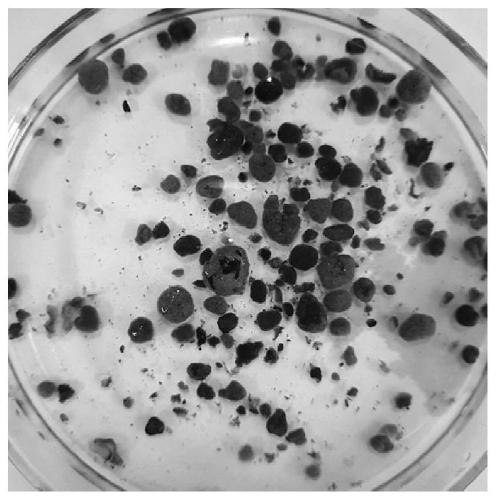

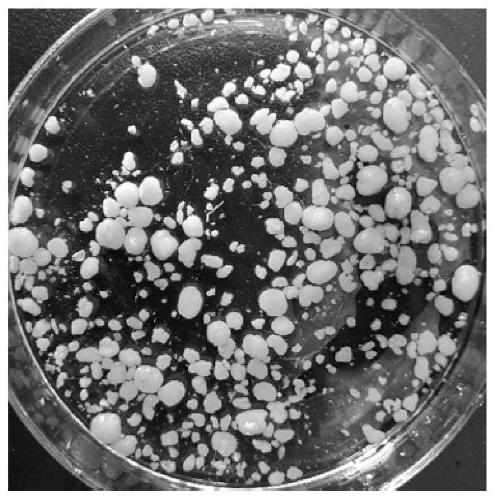

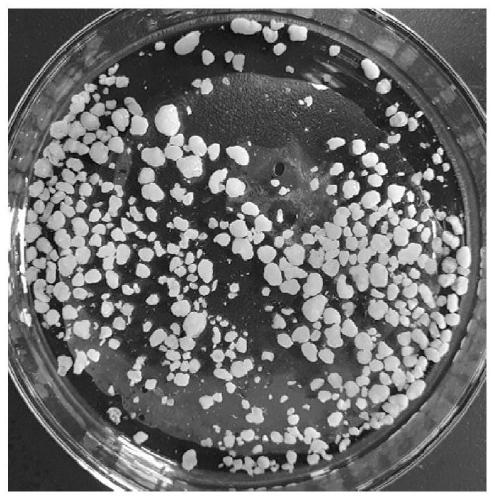

Method for using signal molecules for accelerating repair of disintegrated aerobic granular sludge

PendingCN109987698AImprove hydrophobicityAccelerated structural repairWater treatment parameter controlSustainable biological treatmentSignalling moleculesSludge

The invention relates to a method for using signal molecules for accelerating repair of disintegrated aerobic granular sludge. According to the method for using the signal molecules for accelerating repair of the disintegrated aerobic granular sludge, by adding the exogenous AHLs signal molecules to repair the disintegrated the aerobic granular sludge, in a process of repairing structures of the disintegrated aerobic granular sludge, regranulation of the crushed granular sludge is accelerated, after 20-30 days, the disintegrated aerobic granular sludge is basically and completely repaired, therepaired aerobic granular sludge is smooth in particle surface, regular in shape and compact in structure, and has good settling performance, after adding of the exogenous AHLs is stopped, the granular sludge structures are still intact, and the settling performance and the granule density remain at high levels. According to the method for using the signal molecules for accelerating repair of thedisintegrated aerobic granular sludge, by adding the exogenous AHLs temporarily, an excellent repairing effect on the disintegrated aerobic granular sludge is achieved, the repaired granular sludge is intact in structure and good in settling performance, moreover, operation is simple, and practical application is easy.

Owner:SHANDONG UNIV

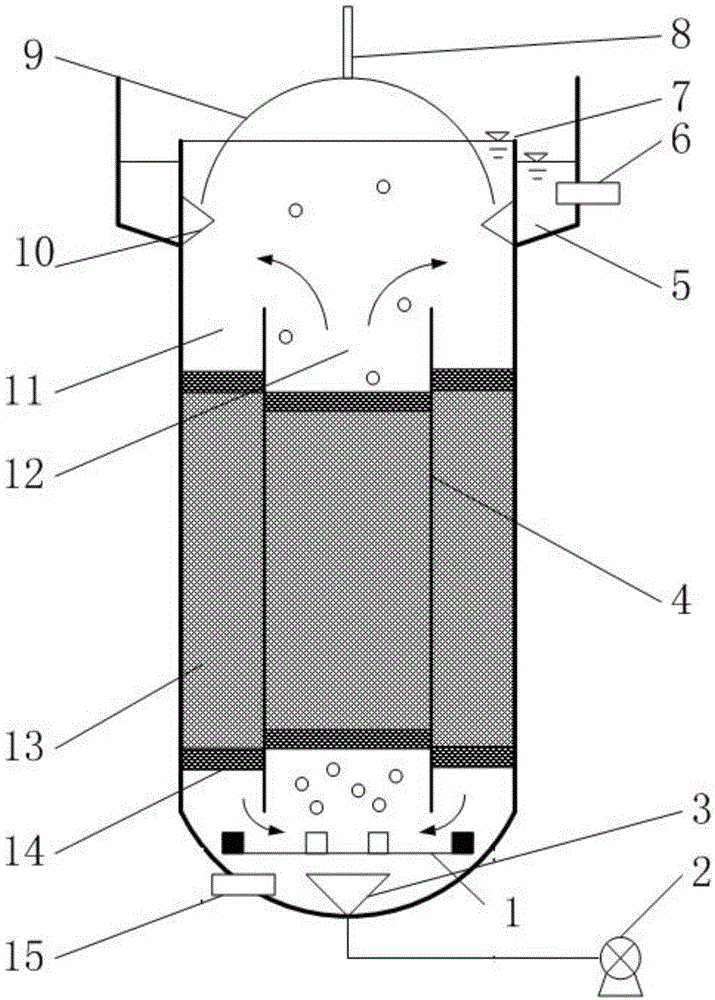

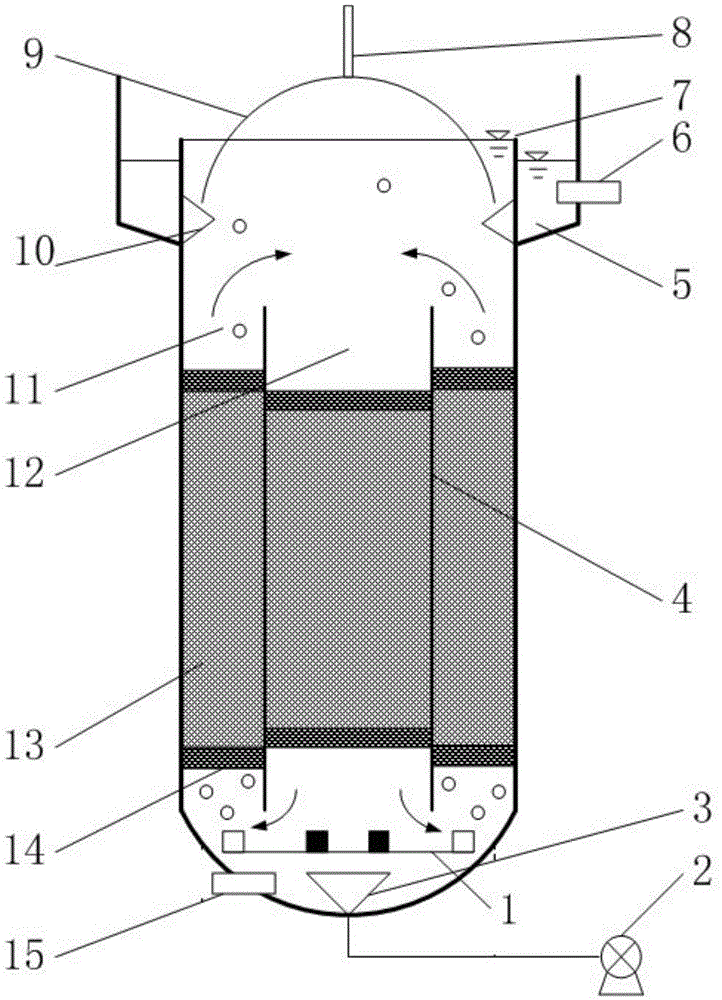

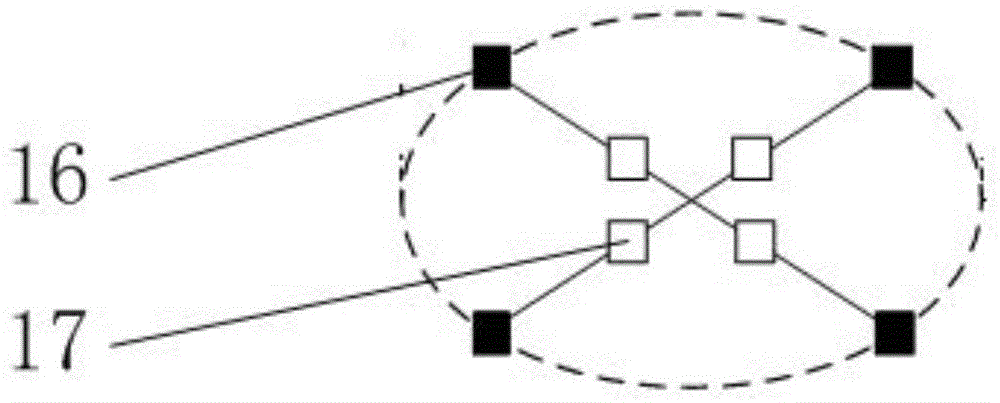

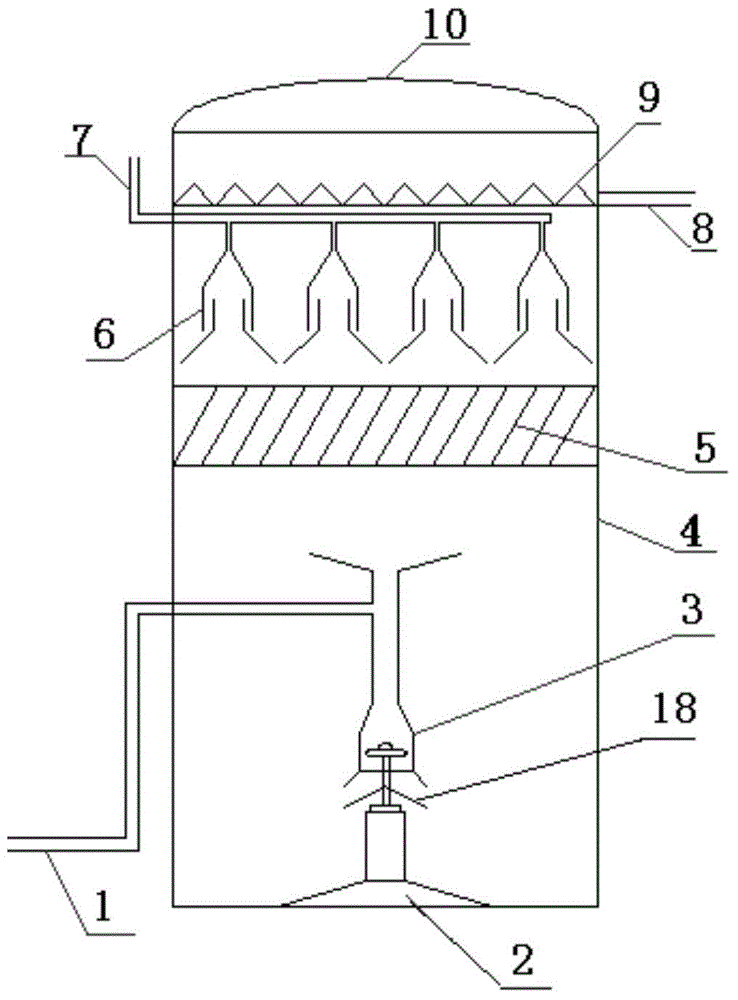

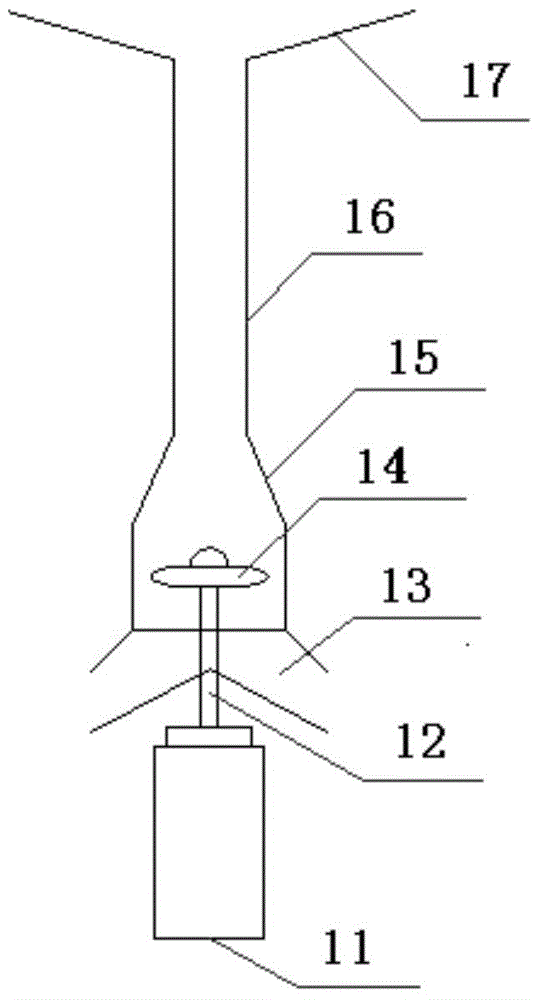

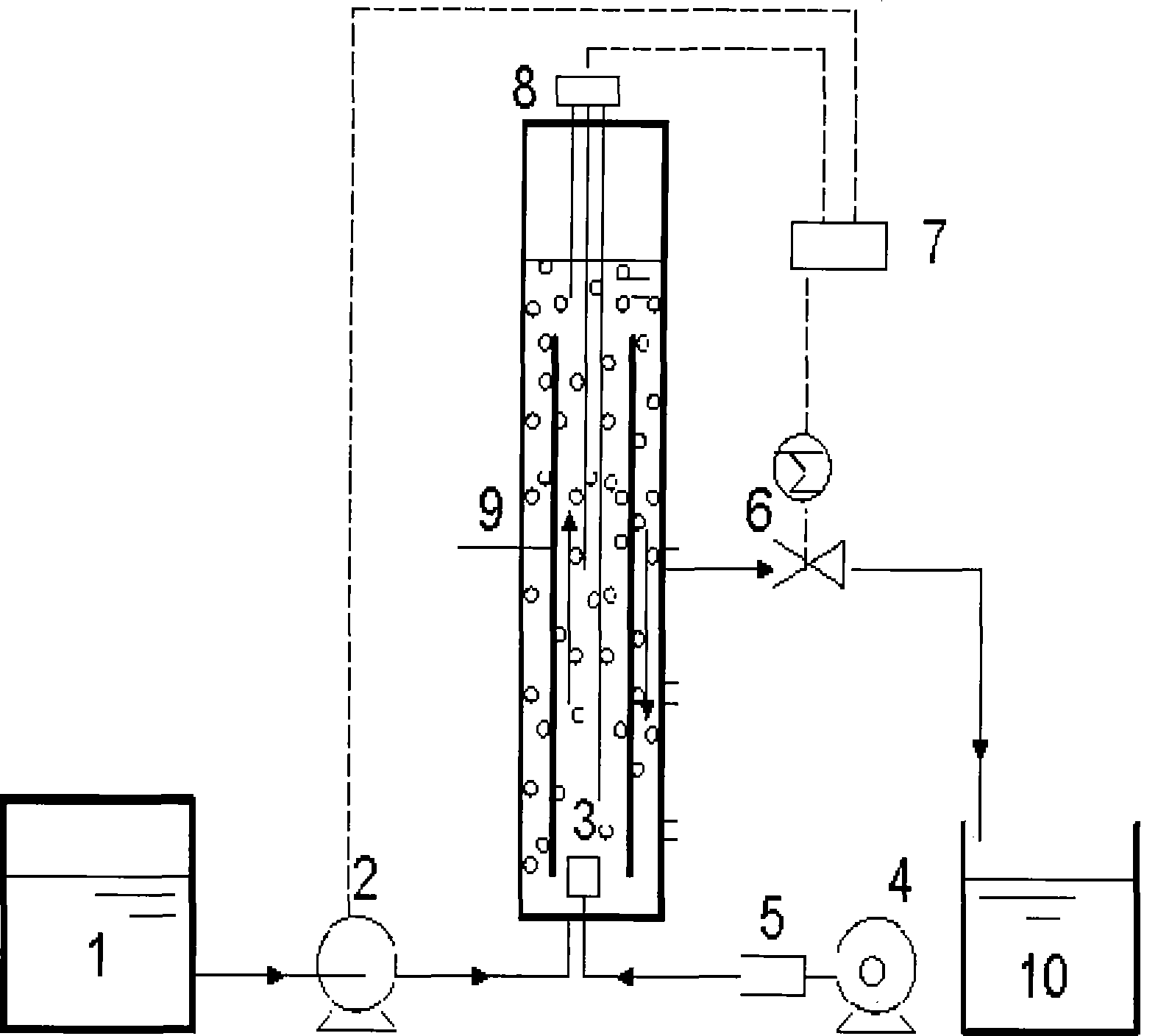

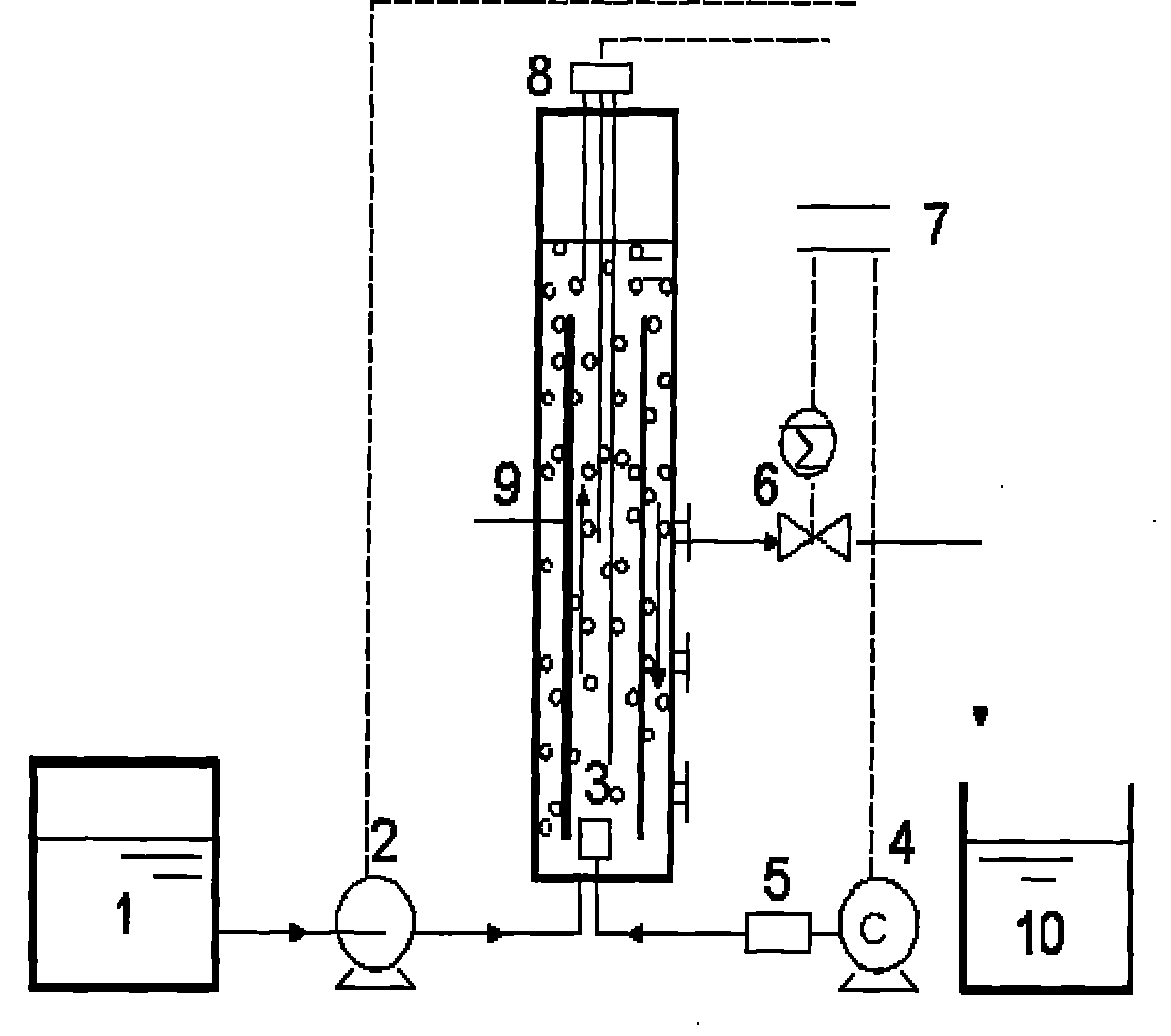

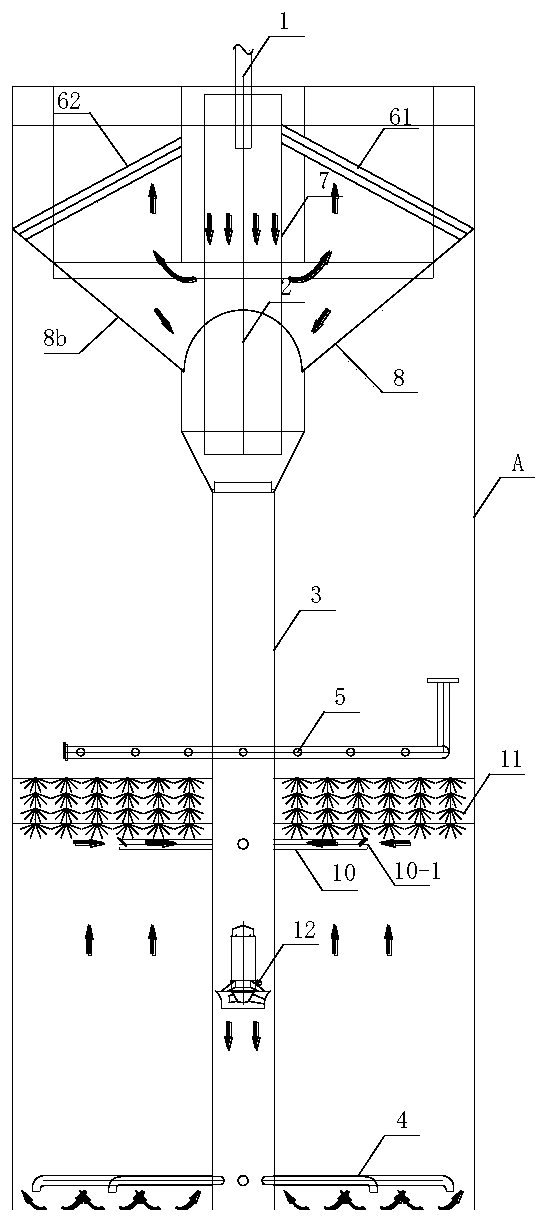

Two-stage double-flow autotrophic denitrification biofilter

InactiveCN104817173AIncrease sludge concentrationAvoid inhibitionTreatment with aerobic and anaerobic processesThree-phaseBiological membrane

The invention discloses a two-stage double-flow autotrophic denitrification biofilter. The biofilter comprises a reactor body, and a sleeve and a filler arranged in the reactor, wherein the reactor body is provided with, from bottom to top, a backflow water-distribution unit, a mud discharge unit, an autotrophic denitrification unit, a three-phase separation unit, and water outlet and air-exhausting units; the backflow water-distribution unit is provided with a conical water distributor and an aeration tray; the mud discharge unit is provided with a mud outlet at the left side of the bottom end of the reactor body; the autotrophic denitrification unit is divided by the sleeve into an outer filter and an inner filter which are upward-and-downward communicated, and the interiors of the filters are filled with the filler; the three-phase separation unit is provided with a conical guide plate, a hemispherical air-collecting hood, an air outlet and an overflow weir; and the water outlet unit comprises a water outlet groove and a water outlet. The invention has the following beneficial effects: a novel pneumatic design is adopted, and the two filters can be independently switched between micro-aerobic and anaerobic environments and between flow rising and flow falling modes, so falling-off and renewal of biological membranes are accelerated and the problem of blockage of the filler is effectively overcome; and a two-stage internal-circulation system is arranged, so strong shock load resistibility and good denitrification effect are obtained.

Owner:HANGZHOU NORMAL UNIVERSITY

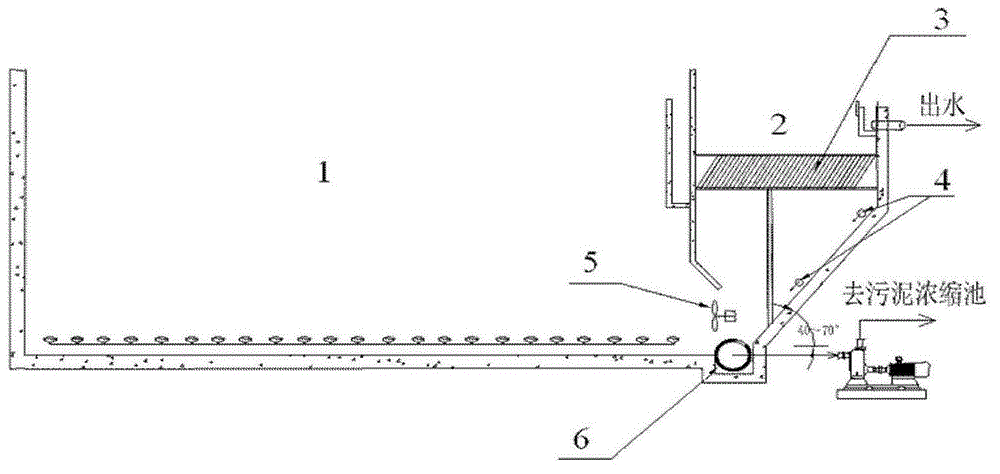

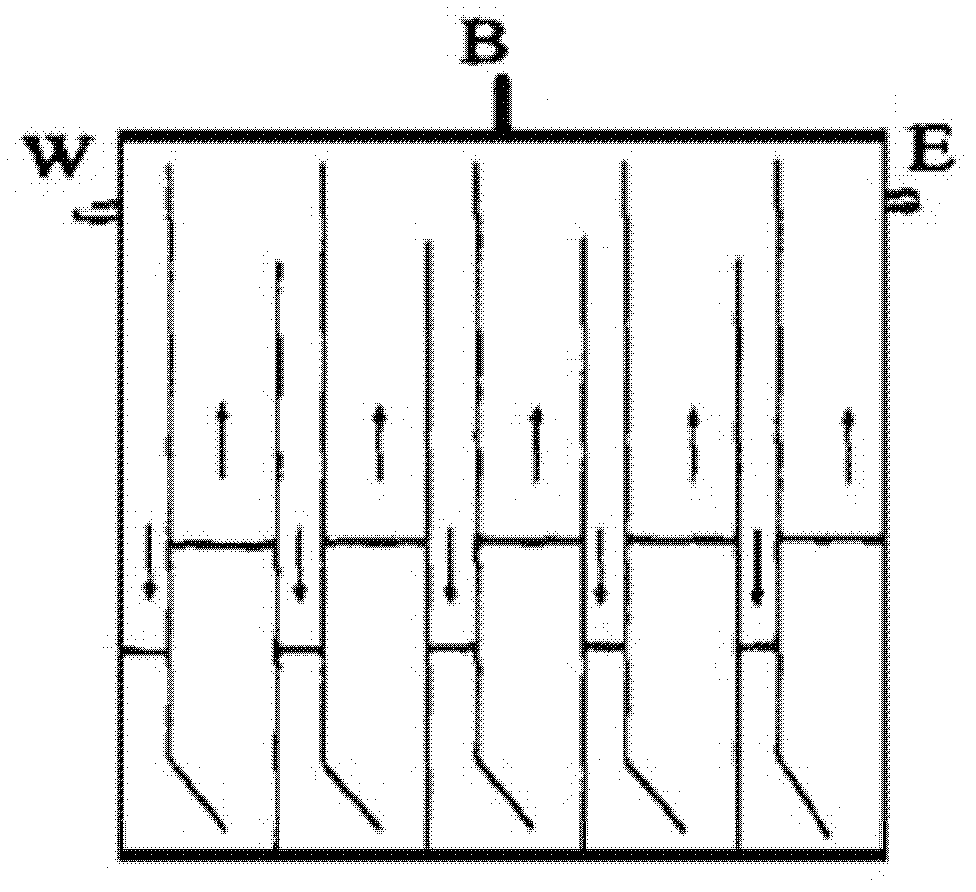

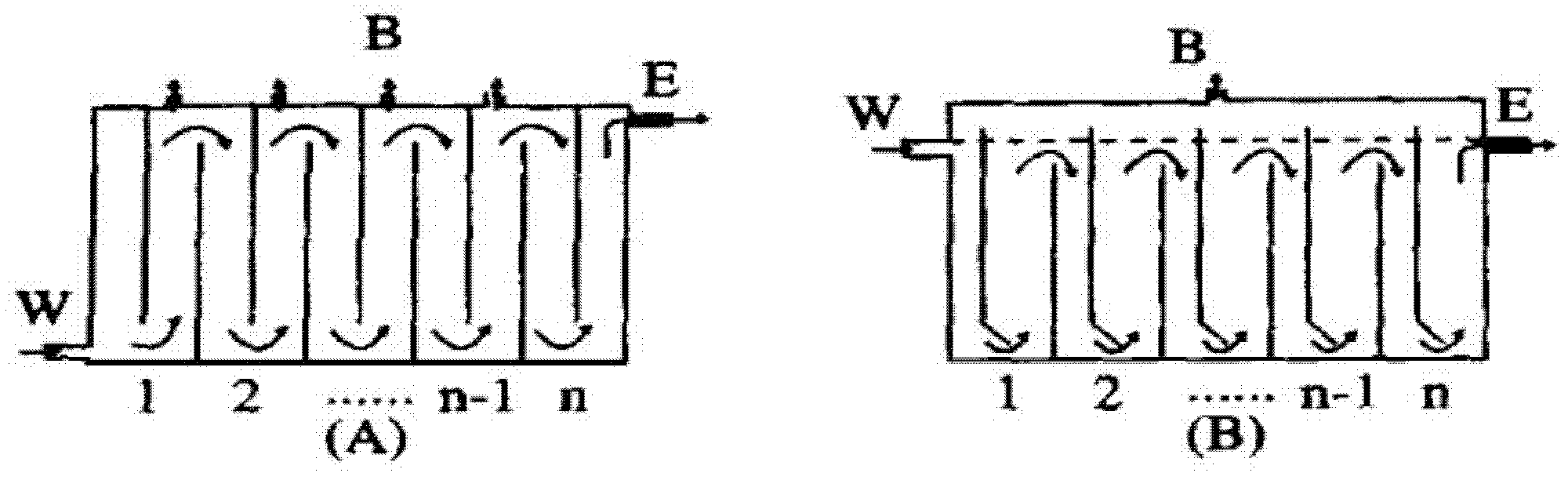

Baffling anaerobic reactor and sewage treatment unit applying the same

ActiveCN102874971AIncrease sludge concentrationImprove reaction efficiencyMultistage water/sewage treatmentAnaerobic reactionWater treatment

The invention relates to a baffling anaerobic reactor, comprising two or more sets of multistage baffling anaerobic reaction tanks, wherein each set of the multistage baffling anaerobic reaction tanks further comprises a sedimentation tank and a sludge return pipe to allow a mixed solution coming from the last stage of the set to enter into the sedimentation tank to separate a supernatant and a concentrated mixed solution, allow the supernatant to enter into the first stage of the next set, and allow the concentrated mixed solution to enter into the first stage of the set through the sludge return pipe. The invention further relates to a sewage treatment unit containing the baffling anaerobic reactor and a sewage treatment method using the baffling anaerobic reactor.

Owner:金锣水务有限公司

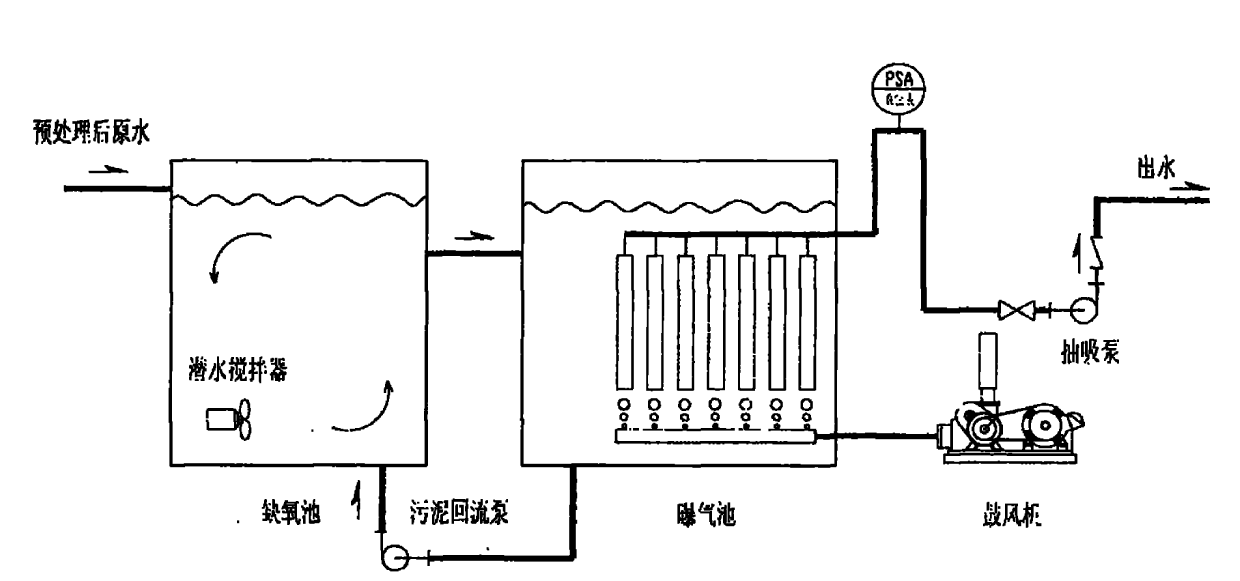

Aerobic membrane bioreactor and process

InactiveCN102260016AIncrease sludge concentrationSimple process designMultistage water/sewage treatmentBiochemical engineeringNitration

The invention discloses an aerobic membrane bioreactor and a technology thereof. The aerobic membrane bioreactor comprises an anoxic tank, an aerobic tank and a membrane tank. The anoxic tank is provided with an upper opening and a first upper overflow port. Liquid level of the anoxic tank is higher than that of the aerobic tank. An outlet is arranged on the bottom of the aerobic tank. The outletis respectively connected to the bottom of the anoxic tank and the bottom of the membrane tank. The membrane tank is provided with a second upper overflow port. Liquid level of the membrane tank is higher than that of the aerobic tank. A membrane component is arranged in the membrane tank. The membrane tank is connected to a clean water tank. According to the invention, the membrane tank is separated from the aerobic reaction tank. The aerobic membrane bioreactor is suitable for large-batch sewage processing, and is convenient to maintain. Liquid levels of the anoxic tank and the membrane tank are higher than that of the aerobic tank, and communications between the tanks are realized through overflowing. Sludge concentration in the membrane tank can be controlled effectively. According tothe invention, high accumulating density of the components can be maintained, quality of produced water is good, area occupied by the equipment is small, amount of discharged sludge is small, nitration capacity of the bioreactor is good, and the structure of the bioreactor is simple.

Owner:上海膜达克环保工程有限公司

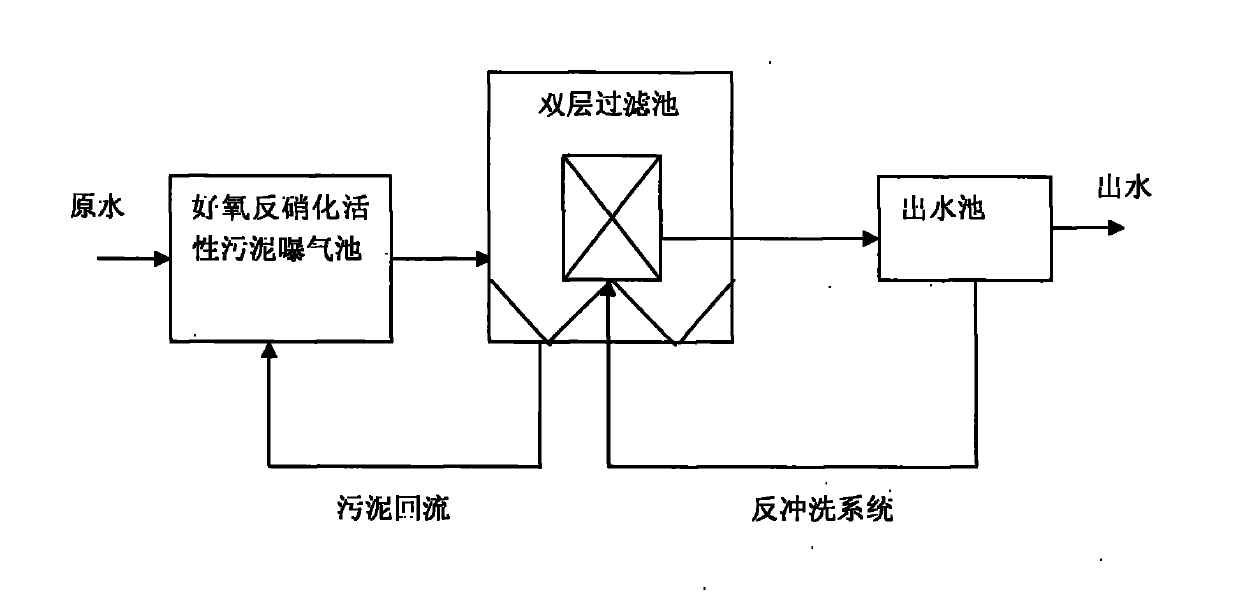

Method for treating municipal sewage by adopting millipore FBR (Filter Bio-reactor)

ActiveCN102070279AMeet the requirements of emission standardsLess investmentMultistage water/sewage treatmentEmission standardMunicipal sewage

The invention discloses a method for treating municipal sewage by adopting a millipore FBR (Filter Bio-reactor), belonging to the technical field of resources and environments. The municipal sewage can be treated by adopting a mode of combining aerobic denitrification with a dual-layer millipore filter tank in the method, thus pollutants, such as NH3-N, TN (Total N), COD, SS, TP (Total Phosphorus) and the like, in the municipal sewage can be greatly effectively reduced, the treated discharge water can reach the national earth surface IV class water standard, wherein CODCr is not more than 30mg / l, NH3-N is not more than 1.5mg / l, the total N (lake, reservoir, in the terms of N) is not more than 1.5mg / l, the total phosphorus (in the terms of P) is not more than 0.3mg / l, and the potassium permanganate index is not more than 10. The discharge water can be directly discharged in an earth surface riverway so as to reduce the environment pollution and meet the requirement on the increasingly improved municipal sewage emission standard. The invention can be applied to building municipal sewage treatment plants and modifying and reconstructing the traditional sewage treatment plants.

Owner:JIANGSU XIANTONG ENVIRONMENT TECH

Device and method for producing biogas by distillers' grain fermentation

ActiveCN106115911AEasy to separateIncrease sludge concentrationBioreactor/fermenter combinationsBiological substance pretreatmentsHigh concentrationSludge

The invention discloses a device and a method for producing biogas by distillers' grain fermentation. The device comprises a mixing tank, a circulating pump, a reaction tank and a return pipe, wherein the mixing tank, the circulating pump and the reaction tank are sequentially connected through a pipeline, and the reaction tank is connected with the mixing tank through the return pipe. The reaction tank is provided with a water distributor, a first reaction chamber, a primary three-phase separator, a second reaction chamber, a secondary three-phase separator, a flow guide pipe, a drain port and an exhaust port, and the mixing tank is provided with a heating device, an emptying port, a stirrer and a feed port. The method for producing the biogas by distillers' grain fermentation includes the steps: 1) preliminarily fermenting distillers' grain wastewater in the mixing tank; 2) performing two-stage anaerobic fermentation treatment for the distillers' grain wastewater in the reaction tank. The device is stable in running, easy to control, less in discharged sludge quantity and capable of generating the biogas with the methane content of 60% or more. The device and the method are applicable to treating high-concentration distillers' grain wastewater, less in sludge loss, good in organic matter removing effect and low in running cost.

Owner:广州市金龙峰环保设备工程股份有限公司

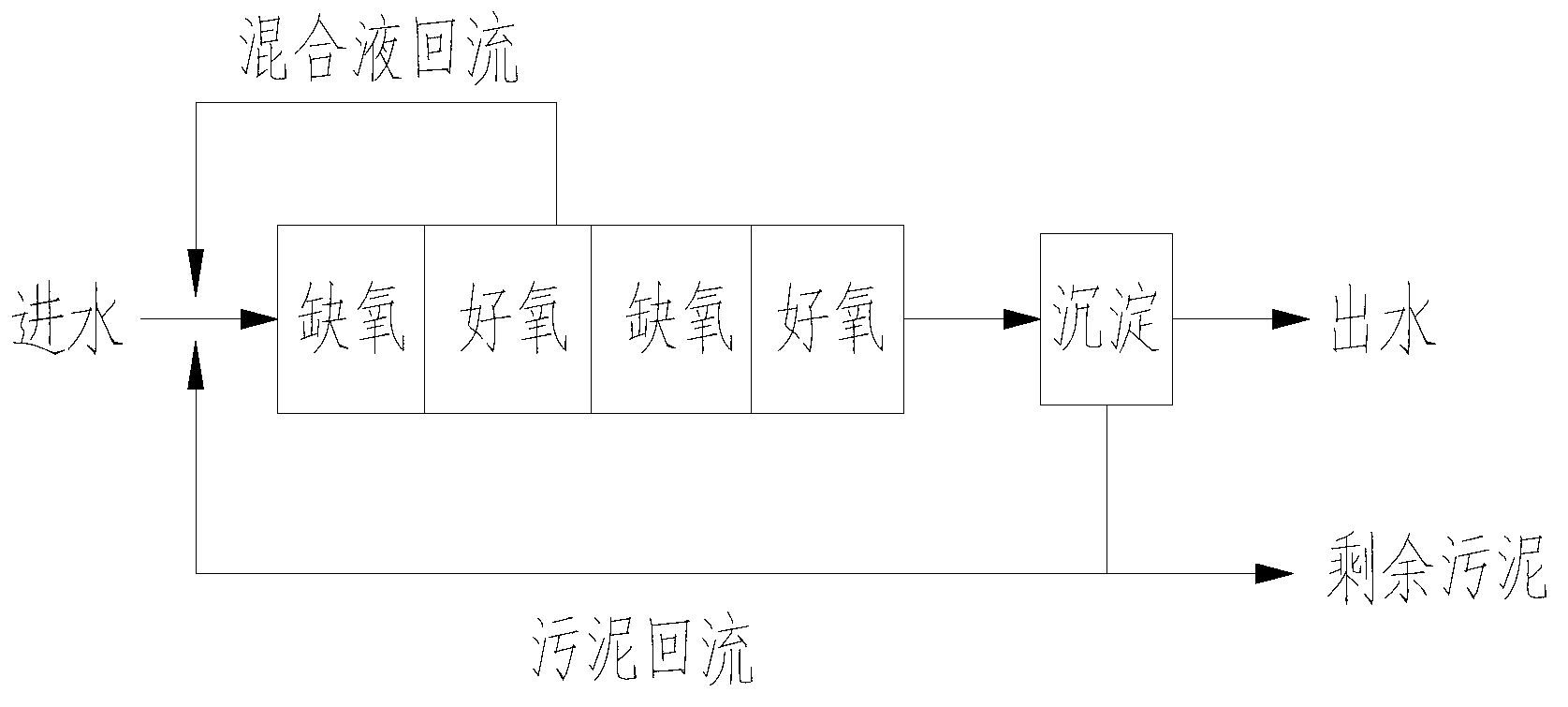

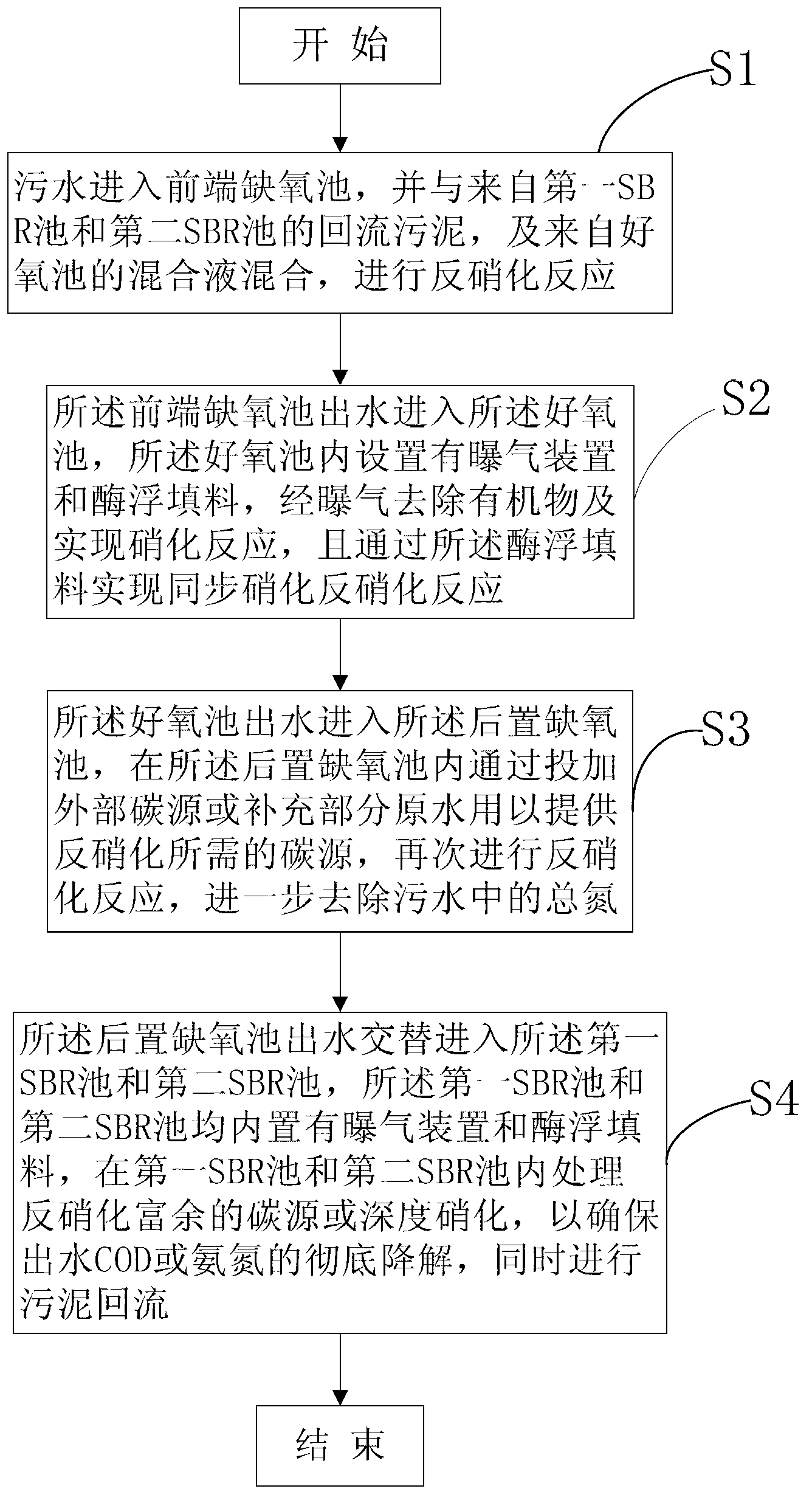

Coupling type biological denitrification method and system thereof

ActiveCN103183454AImprove denitrification effectGood effectMultistage water/sewage treatmentSequencing batch reactorChemical oxygen demand

The invention discloses a coupling type biological denitrification method which comprises the following steps: enabling sewage to enter a front-end anoxic pool, mixing with returned sludge and mixed liquid and carrying out denitrification reaction; entering an aerobic pool, removing an organic matter through aeration, realizing the nitration reaction and synchronizing the nitration reaction and the denitrification reaction; entering a rear anoxic pool and carrying out denitrification reaction again; and alternately entering a first SBR (Sequencing Batch Reactor) pool and a second SBR pool, treating a surplus carbon source generated in the denitrification or deeply nitrating and simultaneously carrying out sludge return. The invention also provides a coupling type biological denitrification system. The coupling type biological denitrification method and the coupling type biological denitrification system have the beneficial effects that pre-denitrification plus aerobic denitrification and CODcr degrading plus post-denitrification plus sequencing batch aerobic reaction are adopted to overcome the influence of an excessive denitrification carbon source on outlet water, the nitrogen removal efficiency is greatly improved, the nitrogen removal effect is remarkable, and the coupling type biological denitrification system is suitable for degrading high ammonia nitrogen and high COD (Chemical Oxygen Demand) wastewater and particularly has an remarkable effect on coal chemical industry wastewater treatment.

Owner:SHANGHAI HONESS ENVIRONMENTAL TECH CORP

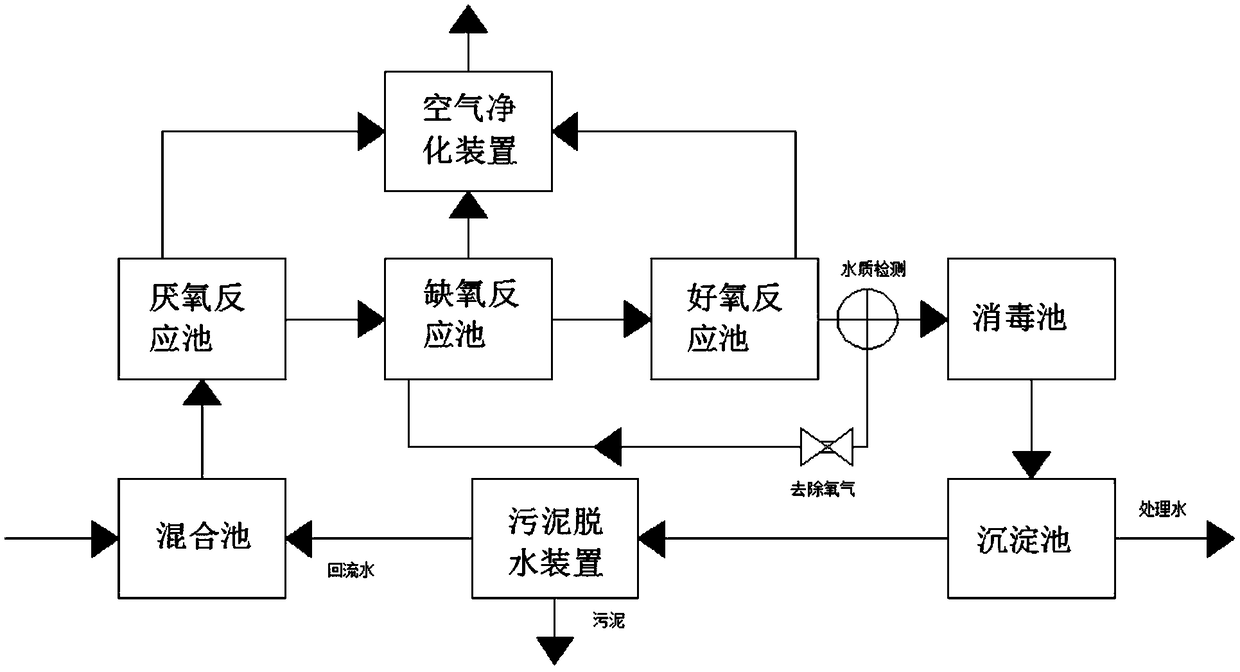

Denitrification and dephosphorization treatment technology for municipal sewage

InactiveCN108862828AHigh porosityLarge specific surface areaCombination devicesWater contaminantsOxygenPollution

The invention discloses a denitrification and dephosphorization treatment technology for municipal sewage. The technology comprises the following steps: firstly mixing and stirring after filtering domestic sewage, treating the sewage through an anaerobic reaction pool, an anoxic reaction pool and an aerobic reaction pool successively, entering a disinfecting pool for disinfecting and deodorizing after the sewage is treated to reach a standard, reflowing to the anoxic reaction pool for treating while the sewage does not reach the standard, discharging waste gases generated by the sewage treatment in the anaerobic reaction pool, the anoxic reaction pool and the aerobic reaction pool to the air after treated by an air purifying device, reducing air pollution, discharging the disinfected sewage after precipitating in a precipitating pool, performing dehydration treatment on sludge and feeding water to a mixing pool, and discharging the dehydrated sludge. The technology is low in cost, goodin water treatment effect, rapid in degradation speed, especially high in nitrogen and phosphorus element and organic matter removal rate in the sewage, safe and stable, and extensive in applicationrange, beneficial to promotion and popularization and capable of performing waste gas treatment, reducing secondary pollution and guaranteeing the effect of the sewage treatment.

Owner:即墨市污水处理有限公司

MBBR (Moving Bed Biofilm Reactor) high-standard sewage treatment system and treatment process

ActiveCN108585384ADoes not affect anaerobic phosphorus release and energy storageGood biological phosphorus removal effectWater treatment parameter controlSpecific water treatment objectivesSludgeFilling rate

The invention discloses an MBBR (Moving Bed Biofilm Reactor) high-standard sewage treatment system and a treatment process and belongs to the technical field of sewage treatment. The problems in the prior art that a treatment process of the traditional sewage treatment plant is high in effluent TN concentration, low in integration level, low in load, high in carbon source requirement and common ineffect of removing nitrogen, phosphorus and SS are solved. The sewage treatment system comprises an anaerobic zone, an anoxic zone I, an anoxic zone II, a flocculation zone, a settling zone, a biofilm zone, a buffer zone, a denitrification filter zone, an effluent zone and pipelines for connecting the zones. According to operations of adjusting reflux, controlling the sludge concentration, setting parameters of the suspended carrier filling rate in the biofilm zone and DO, setting the carbon source addition amount and backwash frequency in the denitrification filter zone and the like, by utilizing the characteristic of denitrifying phosphate-accumulating organisms, the settling zone is arranged on a middle section of biochemical treatment, the biofilm process is coupled to the denitrification filter process, and the sewage treatment system disclosed by the invention has the advantages that the integration level is high, nitrogen and phosphorus can be synchronously removed, the carbonsource is saved, the concentrations of the nitrogen, phosphorus and SS in the effluent are low, the load is high, and the operation is simple.

Owner:QINGDAO SPRING WATER TREATMENT

Mechanical internal circulation jet-flow anaerobic reactor and wastewater treatment method thereof

ActiveCN104445605AChange cloth waterChange the way of beingTreatment with anaerobic digestion processesHigh concentrationFluidized bed

The invention discloses a mechanical internal circulation jet-flow anaerobic reactor and a wastewater treatment method thereof, and belongs to the technical field of biological sewage treatment. The mechanical internal circulation jet-flow anaerobic reactor comprises a reactor tank body, a multi-phase separator, a water outlet weir and an internal circulation jet-flow device, wherein the internal circulation jet-flow device comprises an upper part and a lower part; the upper part comprises a jet-flow hole, a diffusion hole, a flow guide pipe and a flow stabilization hole; the lower part comprises a motor, a rotary shaft and high-speed blades. The wastewater treatment method comprises the following steps: forming a fluidized bed layer, forming a suspended bed layer, separating a separation region and discharging water from the water outlet weir. Due to the use of the internal circulation jet-flow device, the difficult problems of low treatment load, instable effect and relatively narrow application range in the treatment process of an existing conventional anaerobic reactor are solved; the mechanical internal circulation jet-flow anaerobic reactor has the advantages of high treatment load, good water impact resistance, high concentration of biological toxicity resistance matters, quick starting and the like.

Owner:NANJING UNIV

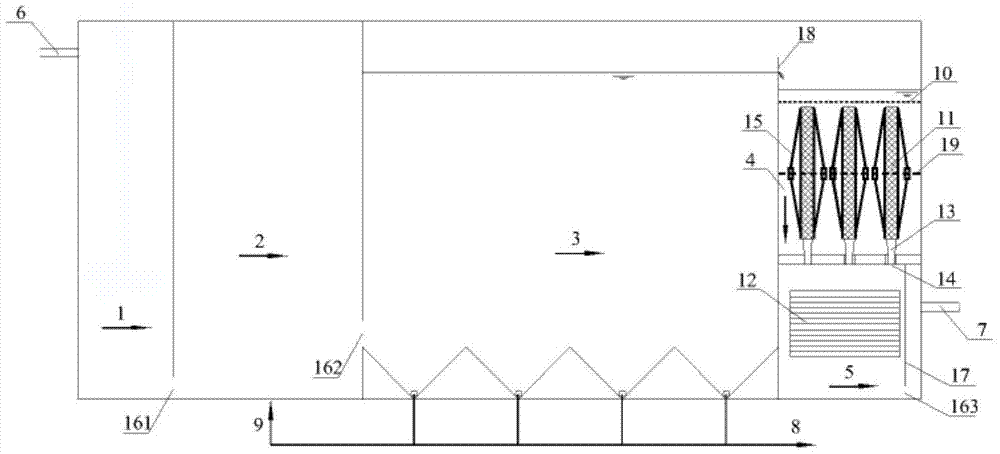

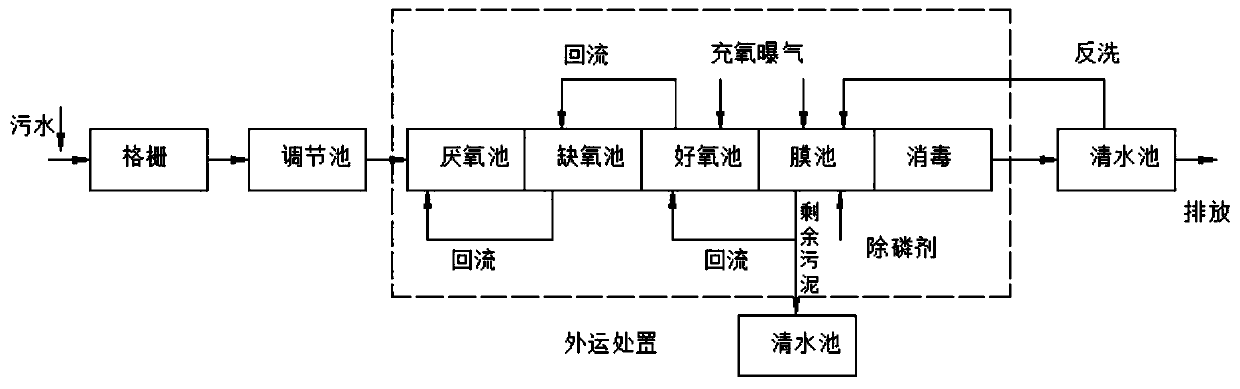

Enhanced type efficient nitrogen and phosphorus-removing sewage treatment system and treatment technology

PendingCN110040906AAvoid enteringLarge doseWater treatment parameter controlTreatment using aerobic processesWater treatment systemReaction rate

The invention relates to an enhanced type efficient nitrogen and phosphorus-removing sewage treatment system. A structure thereof comprises the following units: 1) a biochemical treatment unit, 2) a membrane treatment unit, 3) a backflow unit, 4) filling units and 5) a control unit, wherein the membrane treatment unit is connected with a water outlet end of the biochemical treatment unit; backflowsludge of the membrane treatment unit is connected with a water inlet end of an aerobiotic tank of the biochemical treatment unit, and the backflow rate is 300%-400%; the water outlet end of the aerobiotic tank flows back to the water inlet end of an anoxic tank through a backflow pipeline and a backflow device, the water outlet end of the aerobiotic tank and the water outlet end of an anaerobictank are jointly connected with the anoxic tank, and the backflow rate is 100%-200%; the water outlet end of the anoxic tank flows back to the water inlet end of the anaerobic tank through the backflow pipeline and the backflow device, the water outlet end of the anoxic tank and a pretreated water outlet end are jointly connected with the anaerobic tank, and the backflow rate is 100%-200%; the filling units are arranged in the anoxic tank and the aerobiotic tank. In the invention, a filler is added in a traditional A / A / O technical reactor, the backflow position and the backflow rate are adjusted, the carbon source is efficiently utilized, the nitrogen and phosphorus removal effect is enhanced, the reaction rate is effectively increased and the effluent index can be guaranteed.

Owner:新权诚工程建设项目咨询管理有限公司

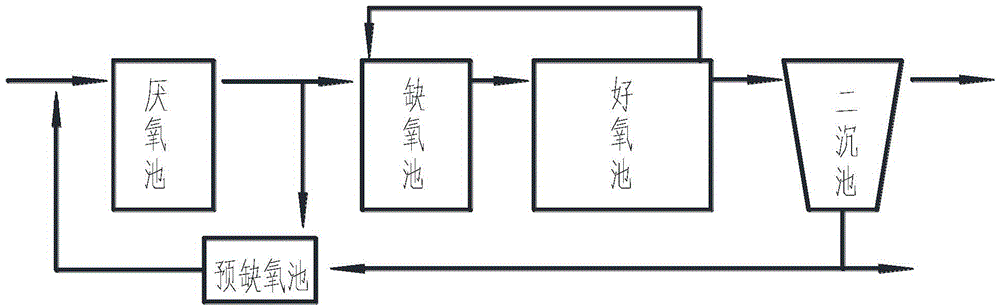

Anaerobic-anoxic/aerobic-parallel reinforced dephosphorization and denitrification technique

InactiveCN104478081AReduce power consumptionIncrease sludge concentrationWater contaminantsTreatment with aerobic and anaerobic processesNitrate nitrogenSewage

The invention relates to an anaerobic-anoxic / aerobic-parallel reinforced dephosphorization and denitrification technique which comprises the following steps: raw water is introduced into an anaerobic tank and treated by the anaerobic tank, enters an anoxic tank, is treated by the anoxic tank, and enters an aerobic tank; part of water flow treated by the aerobic tank flows back to the anoxic tank, and the rest enters a secondary precipitation tank to precipitate; the supernate in the secondary precipitation tank is discharged; and the precipitated sludge is partially discharged and partially flows back to the anoxic tank to enter the anaerobic tank together with the raw water. The technique is characterized in that part of the water flow treated by the anaerobic tank is introduced into the pre-anoxic tank and mixed with return sludge of the secondary precipitation tank to remove nitrate nitrogen in the sludge, and flows back to enter the anaerobic tank together with the raw water. The technique is suitable for any sewage in need of denitrification and dephosphorization treatment. The technique effectively solves the problem of lower dephosphorization efficiency since nitrate nitrogen carried by the return sludge destroys the anaerobic environment, and provides sufficient organic matters for anaerobic phosphorus release. The technique reduces the volume of the anoxic tank and anaerobic tank, lowers the power consumption and enhances the dephosphorization efficiency.

Owner:CHINA UNIV OF MINING & TECH

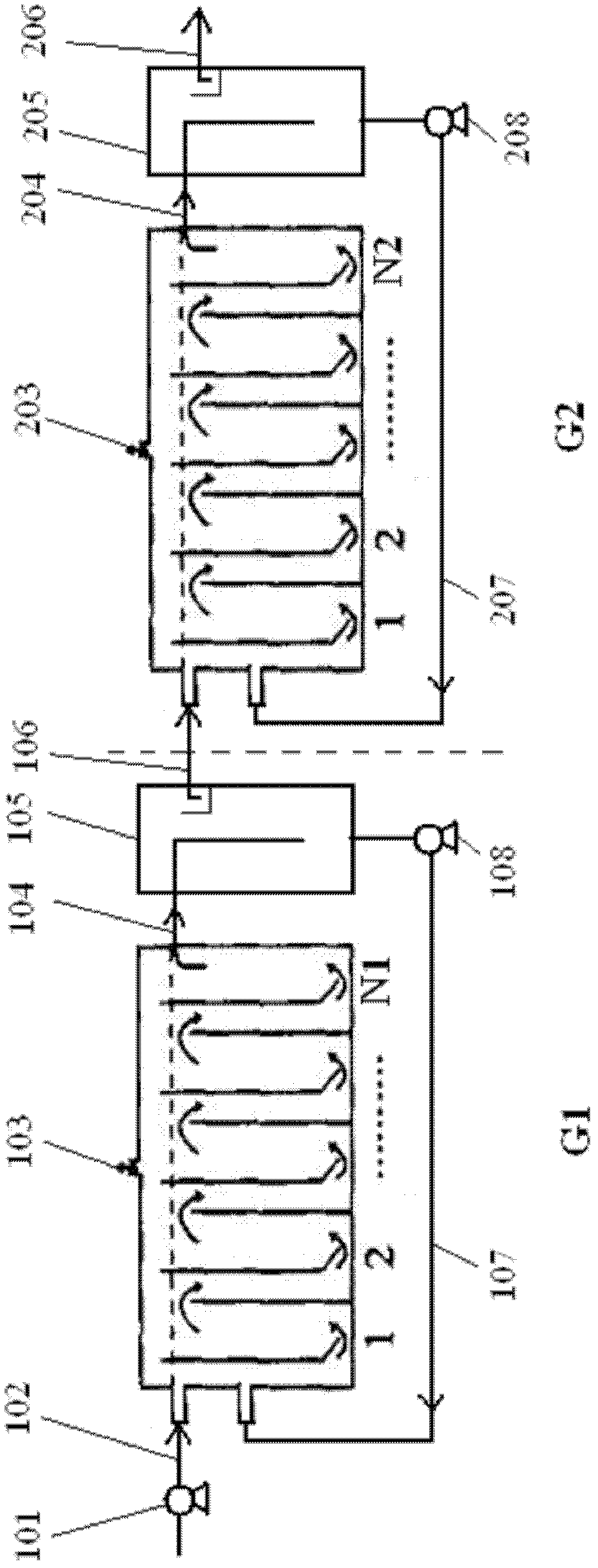

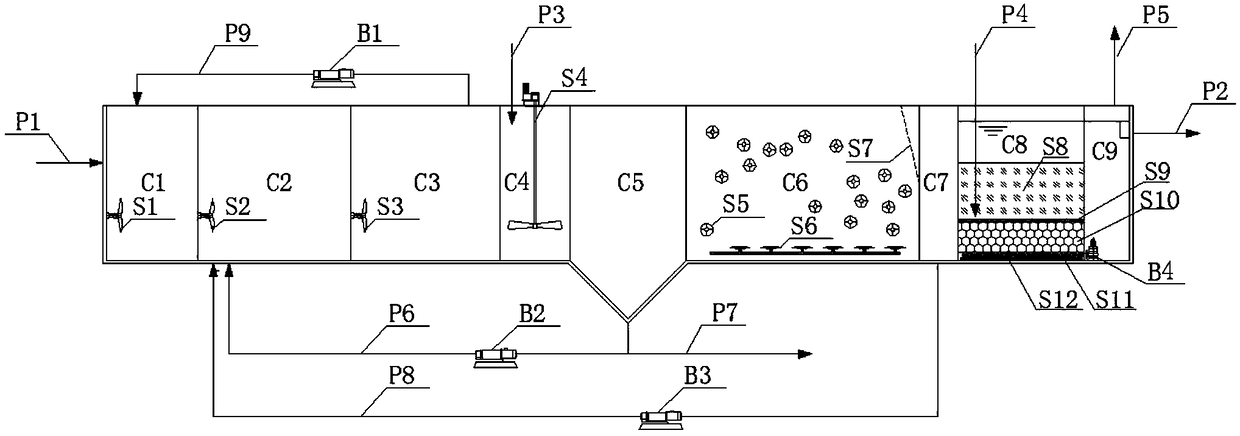

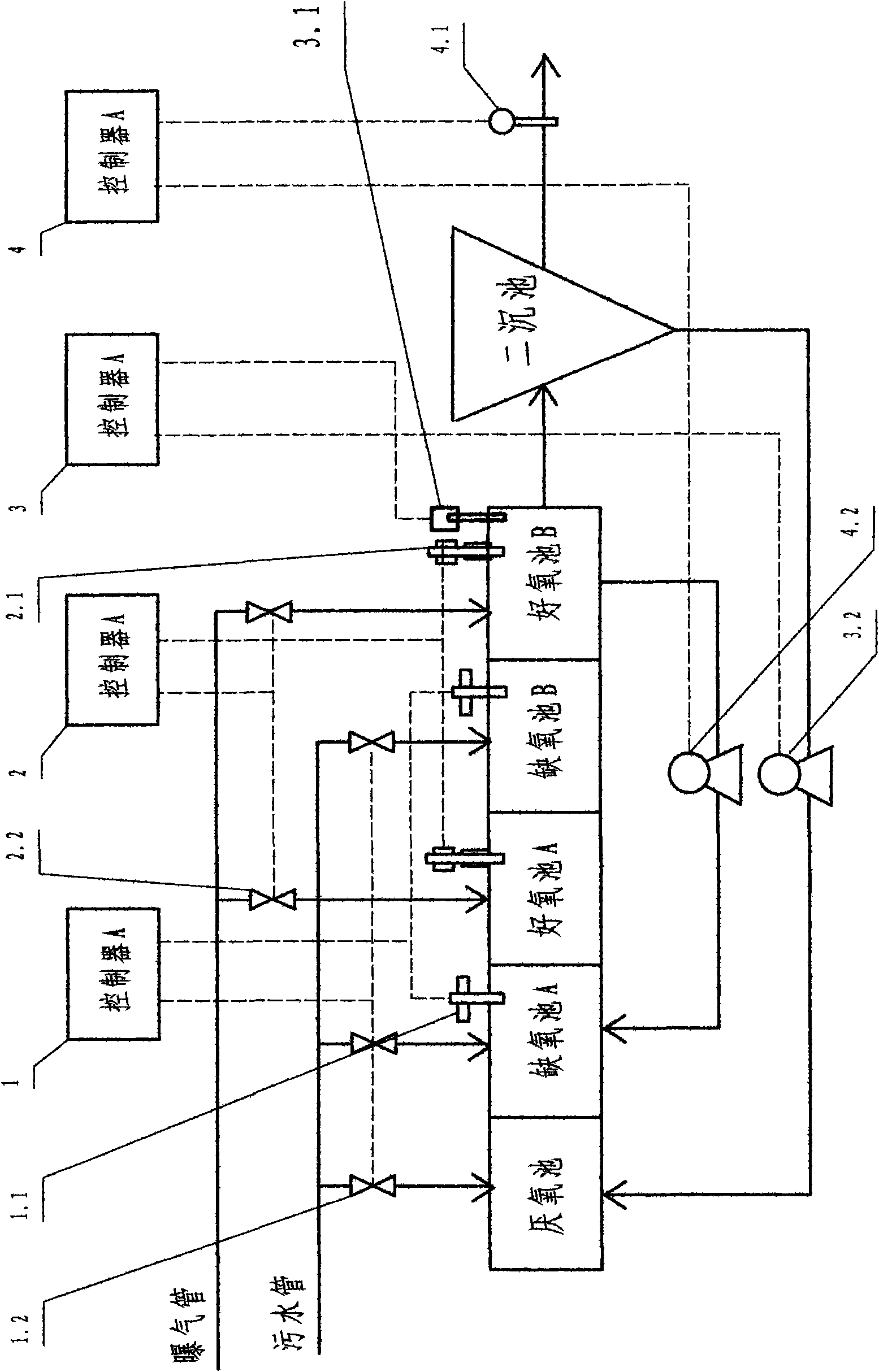

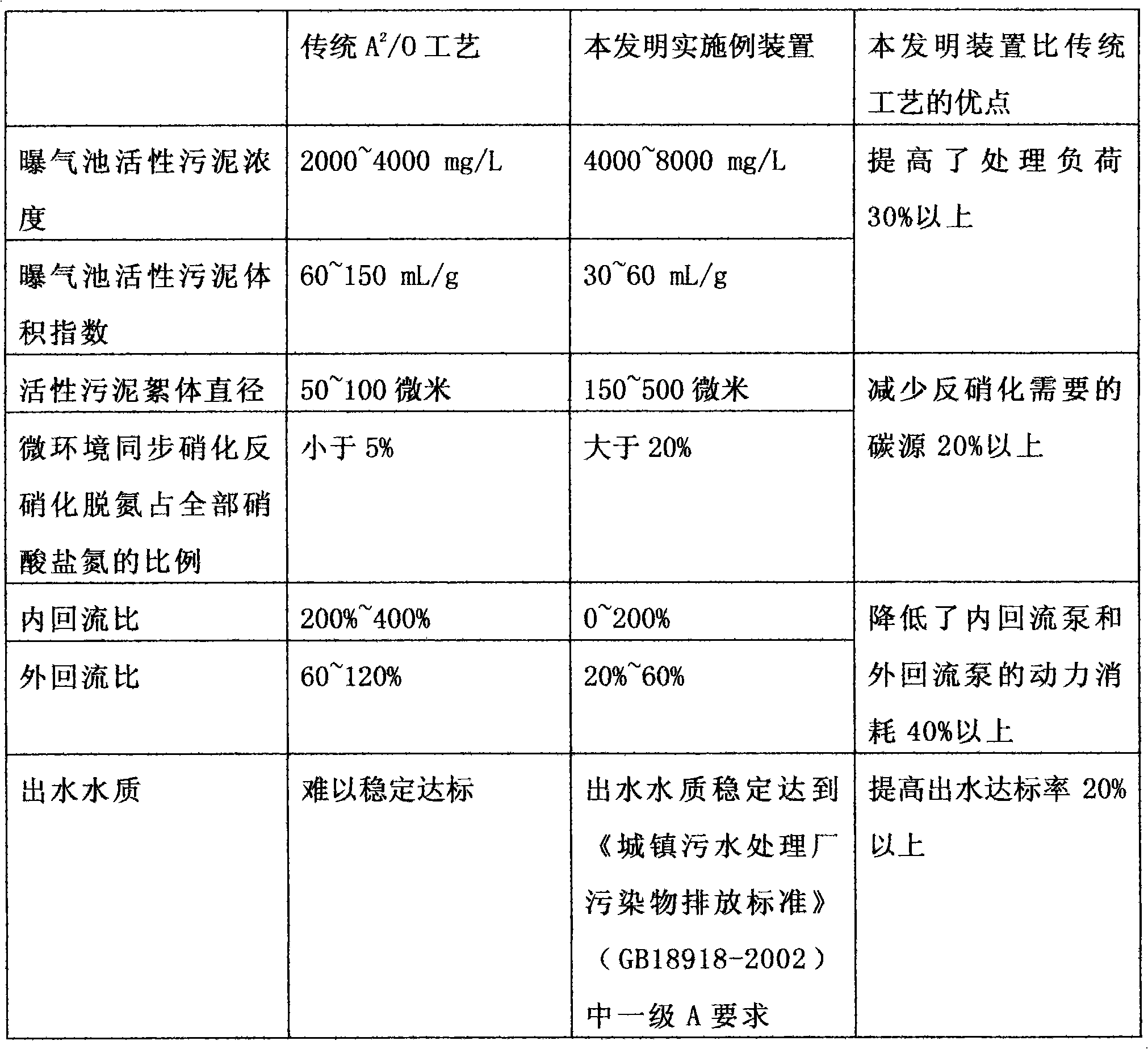

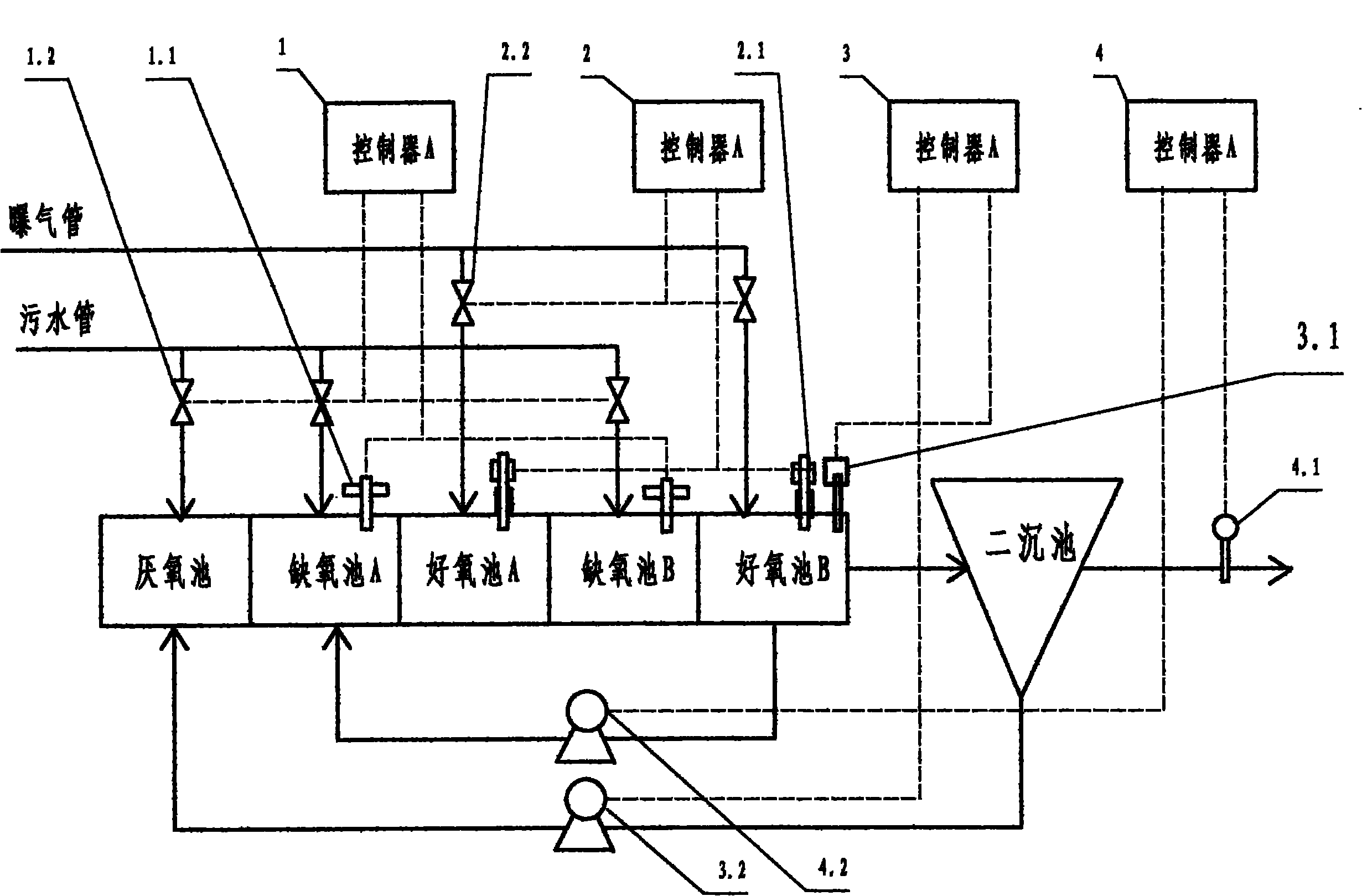

Waste water treatment device and process for synchronously removing nitrogen and phosphorus of sludge concentration microenvironment

ActiveCN101898831AAccelerated settlementHigh shear forceTreatment with aerobic and anaerobic processesOxygen controllerNitrate nitrogen

The invention relates to a waste water treatment device for synchronously removing nitrogen and phosphorus of sludge concentration microenvironment, comprising an anaerobic pond, two anoxic ponds, two oxidation ponds, two sedimentation ponds, an internal reflux pump, an external reflux pump, pipelines, a dissolved oxygen control device, an inlet water carbon source distribution device, an internal reflux positive displacement pump and an external reflux positive displacement pump; the dissolved oxygen control device is provided with a dissolved oxygen controller B and a dissolved oxygen concentration meter; the inlet water carbon source control device is provided with a nitrate nitrogen-concentration controller A and a nitrate nitrogen concentration meter; and the waste water treatment device is further provided with an internal reflux control device and an external reflux control device. The process utilizing the waste water treatment device comprises the following steps of setting control data of a controller C of the internal reflux pump A; setting control data of a controller D of the external reflux pump B; setting control data of the dissolved oxygen controller B and the nitrate nitrogen concentration controller A; and opening an inlet water gate and all machines and electric control parts for running. The invention is suitable for waste water treatment, and has simple process, energy saving, low cost and high water outlet efficiency and good quality.

Owner:BEIJING DRAINAGE GRP CO LTD

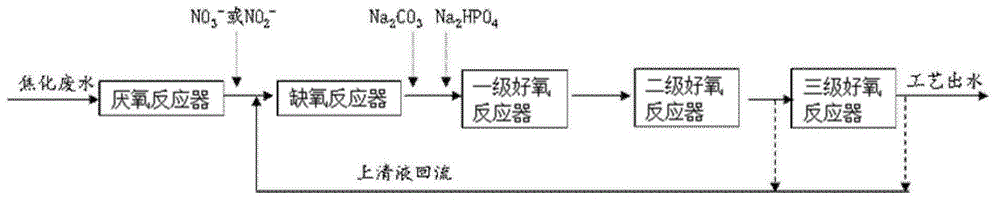

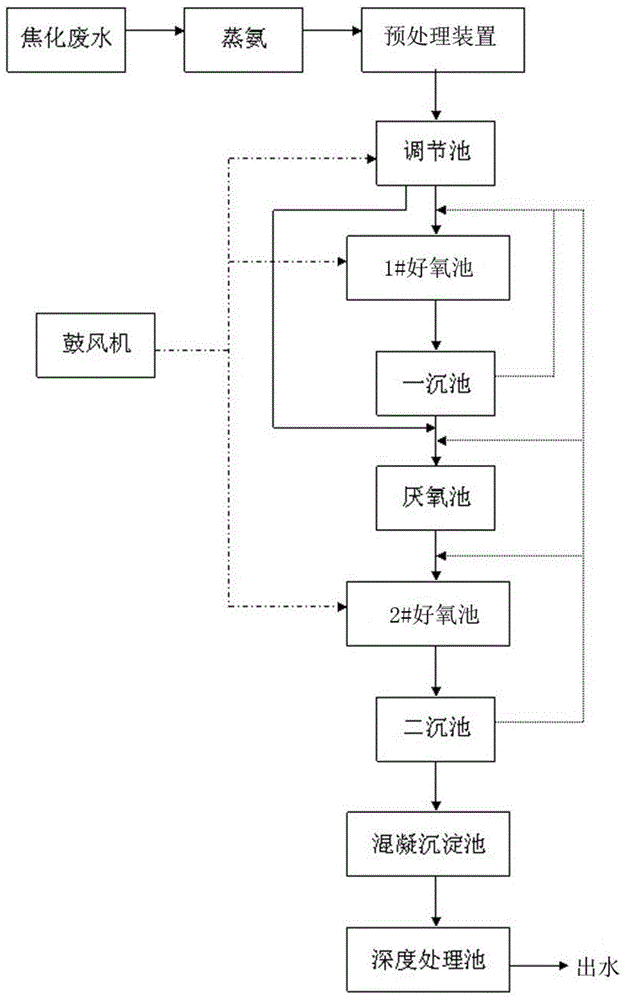

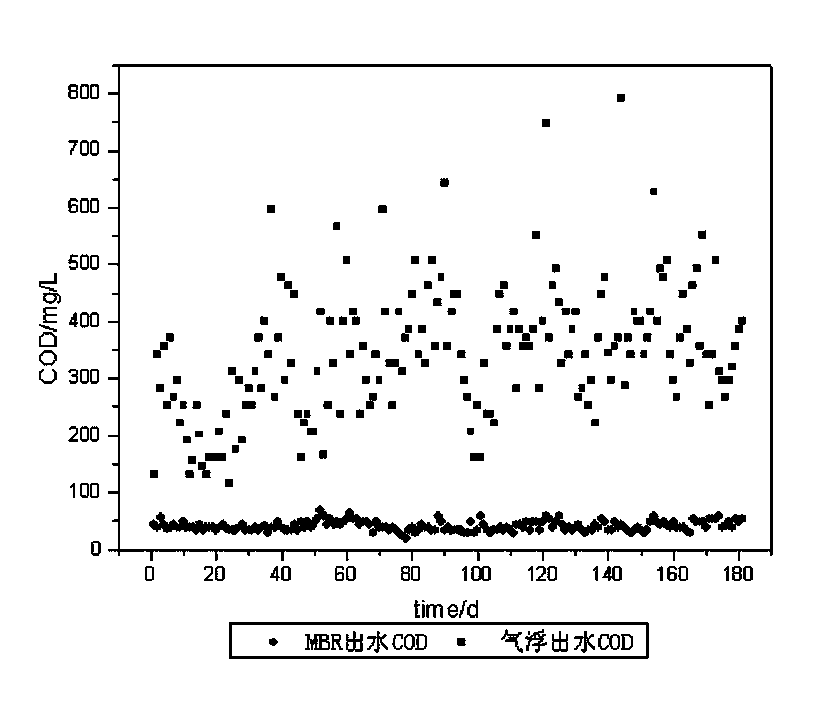

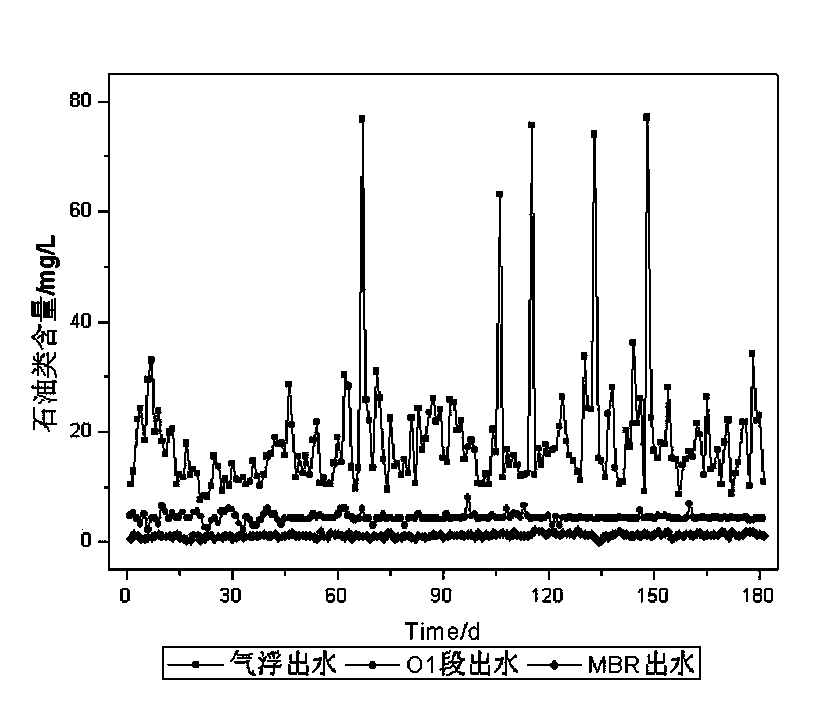

Coking wastewater optimizing treatment process and device

ActiveCN104944703AReduce shock loadPromote growthMultistage water/sewage treatmentVolatile phenolsSocial benefits

The invention relates to a coking wastewater optimizing treatment process and device. The process is as follows: light oil and heavy oil contained in the coking wastewater are firstly removed in an oil separator; then air flotation treatment is carried out to reduce ammonia nitrogen; water distribution is carried out in a regulating tank; after water distribution, 70% of the coking wastewater is introduced into an aerobic tank 1, and 30% of the coking wastewater is introduced into an anaerobic tank; after the coking wastewater is subjected to treatments in the aerobic tank 1, a sedimentation tank I, the anaerobic tank, an aerobic tank 2, a sedimentation tank II, a coagulative precipitation tank and a deep treatment tank in sequence, the quality of the final effluent is as follows: COD is lower than 80 mg / L, ammonia nitrogen is lower than 10 mg / L, volatile phenol is lower than 0.3 mg / L, cyanogen is lower than 0.2 mg / L, oil and suspended solids are basically removed, and water quality indicators meet the discharge standards. According to the invention, the process route is short, the equipment investment cost is low, the processing efficiency is high, the effect is stable, energy conservation and cost reduction are achieved, and economic and social benefits are remarkable.

Owner:辽宁中冠环境工程股份有限公司

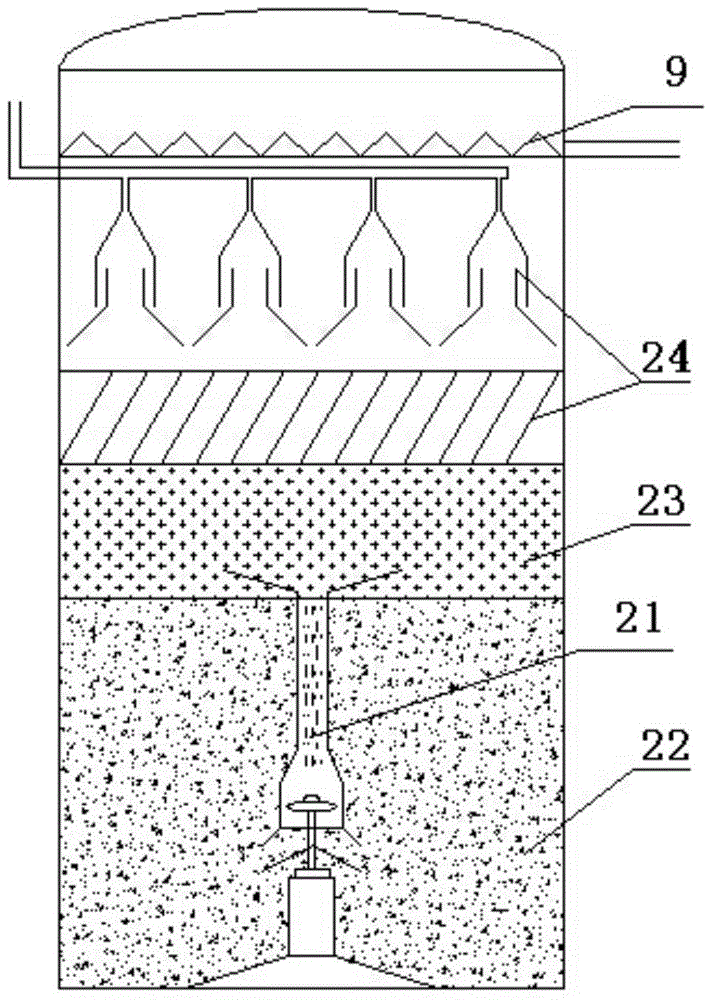

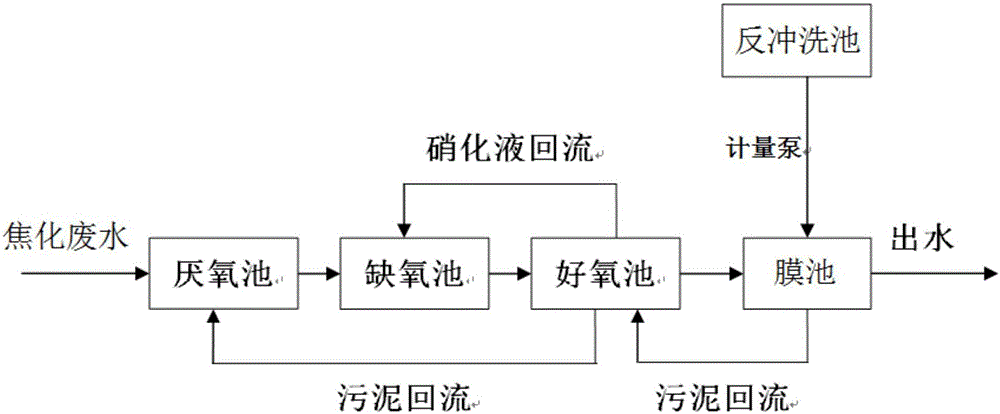

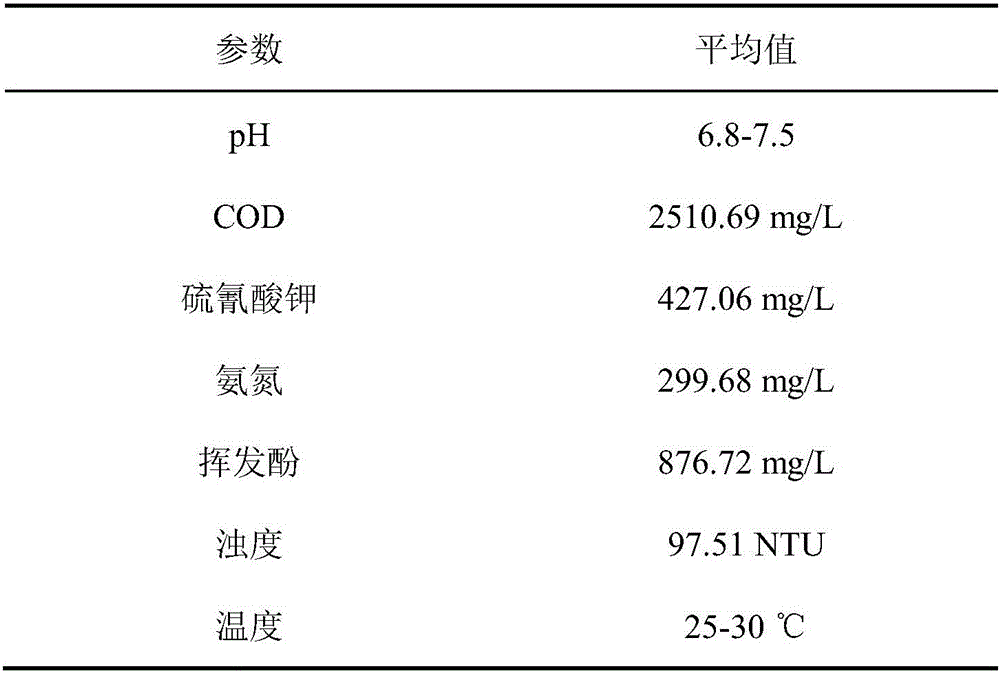

Composite technology for coking wastewater treatment

InactiveCN105731726AImprove biodegradabilityImprove processing efficiencyTreatment using aerobic processesWater contaminantsTherapeutic effectNitrogen gas

The invention discloses a coking wastewater treatment composite process, which comprises an anaerobic pool, anoxic pool, an aerobic pool, a membrane pool, and a backwashing pool; specifically, it is composed of the following steps: the coking wastewater enters the anaerobic pool, and in the anaerobic pool The phosphorus accumulating bacteria release phosphorus and absorb easily degradable organic matter such as low-level fatty acids, and then enter the anoxic pool for biological denitrification through overflow, convert it into nitrogen and release it into the air, and then enter the aerobic pool for biological nitrification It is converted into nitrate, and then enters the membrane tank to suck the water out to the backwash tank and backwash the hollow fiber membrane module regularly through the metering pump. The invention adopts a composite process to treat coking wastewater, and through the organic combination of biological treatment and membrane treatment, the nitrification capacity of the treatment system is improved, and a good treatment effect is achieved for coking wastewater with a COD concentration of 2500ppm and an ammonia nitrogen concentration of 300ppm.

Owner:INNER MONGOLIA UNIVERSITY

Preparation and remediation method of aerobic nitrifying granular activated sludge

InactiveCN101386448BImprove denitrification effectHigh activitySustainable biological treatmentBiological water/sewage treatmentActivated sludgePtru catalyst

The invention relates to a preparation and repair method of aerobic nitrification granular sludge, and pertains to the technical field of water treatment. The method is characterized in that a mode of improving the concentration of a substrate NH4<+>-N gradually is adopted to prepare the aerobic nitrification granular sludge and a way of adding activated sludge is adopted to repair disintegrated aerobic nitrification granular sludge. The method has the advantages of: (1) being capable of avoiding the free ammonia inhibition problem during cultivation under the condition of high NH4<+>-N so that the heterotrophic bacteria and nitrifying bacteria of the aerobic nitrification granular sludge to be formed have high activity, large particle size and relatively high denitrification capability; (2) being capable of recovering the disintegrated granular sludge to excellent performance and completer structure and shortening the start-up time of an aerobic granular sludge reactor. The aerobic nitrification granular sludge prepared by the method is suitable for treating low COD and high NH4<+>-N waste water such as catalyst wastewater and the method is a biological wastewater treatment technique with wide market application prospect.

Owner:DALIAN UNIV OF TECH

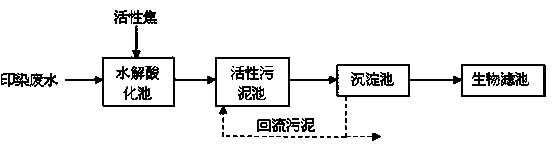

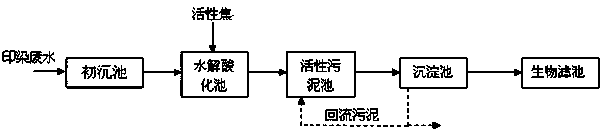

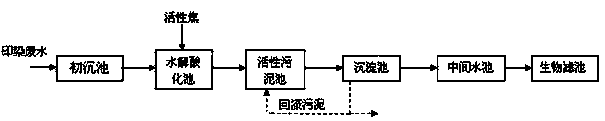

System for treating printing and dyeing wastewater with activated coke adopted and process thereof

ActiveCN103058455BExtended stayImprove removal efficiencyMultistage water/sewage treatmentActivated sludgeBiological filter

The invention provides a system for treating printing and dyeing wastewater with activated coke adopted. The system comprises a hydrolytic acidification device, an activated sludge pool, a settling pool and a biological filter pool, wherein the hydrolytic acidification device, the activated sludge pool, the settling pool and the biological filter pool are arranged in a sequentially connected mode, activated coke is added into the hydrolytic acidification device, and discharging water with the activated coke and from the hydrolytic acidification device enters the activated sludge pool again. According to the system, the activated coke is added into the hydrolytic acidification device, the activated coke is fully mixed with the wastewater in the hydrolytic acidification device, so that standing time of recalcitrant molecules in the wastewater on the hydrolytic acidification device is improved, and efficiency of hydrolytic acidification is improved. The wastewater with the activated coke and from the hydrolytic acidification device enters the activated sludge pool again, the activated coke continues to have the function of absorption and degradation, and removal efficiency on sludge concentration and organic matter in the activated sludge pool is improved.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

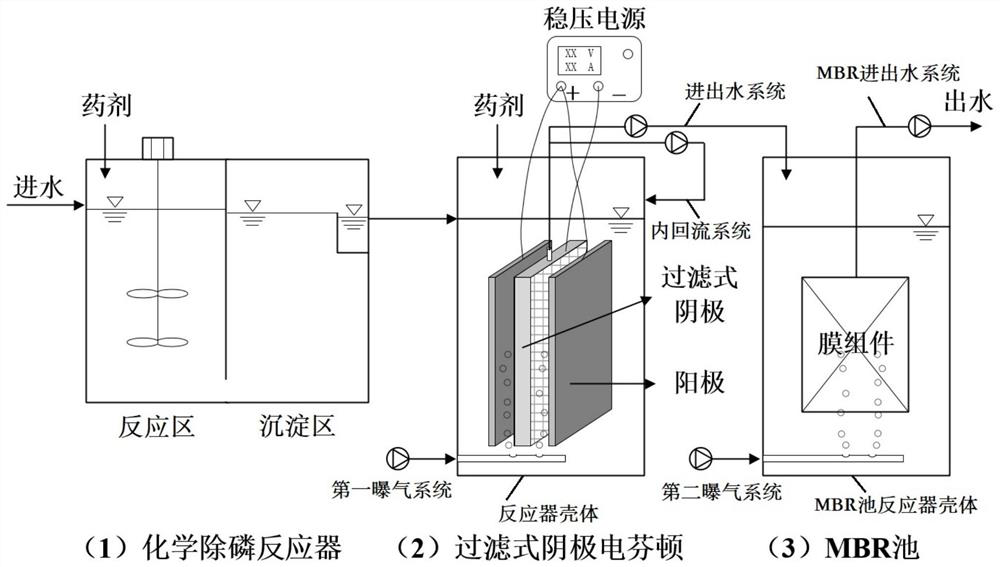

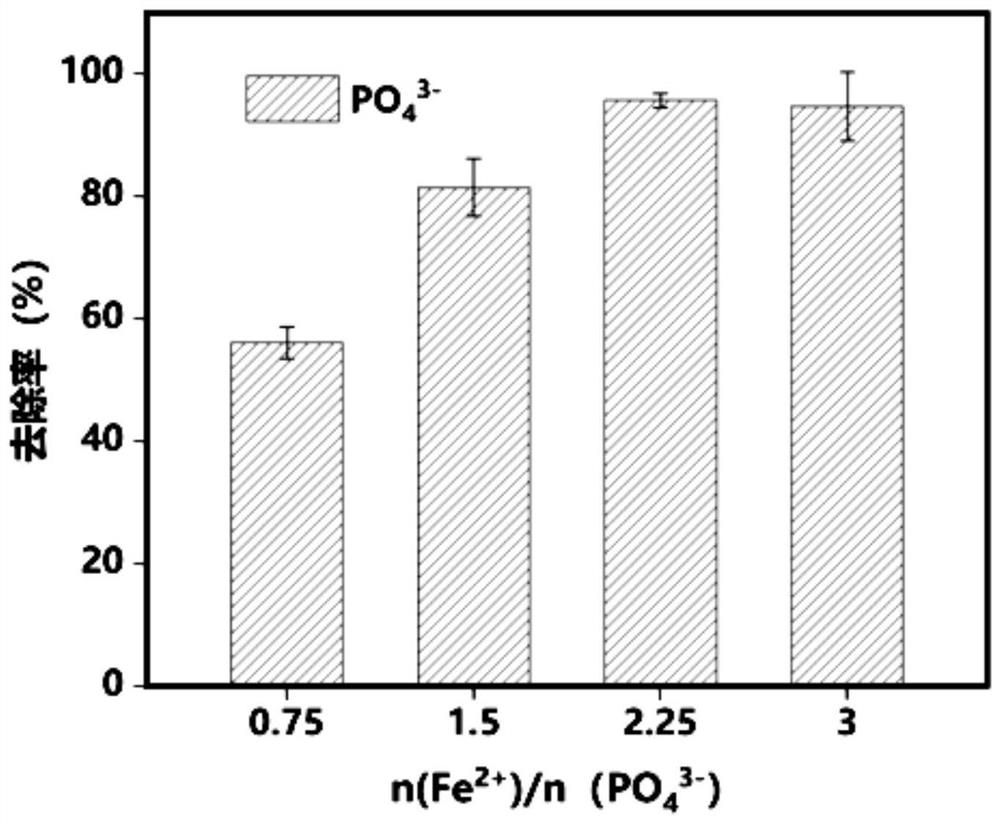

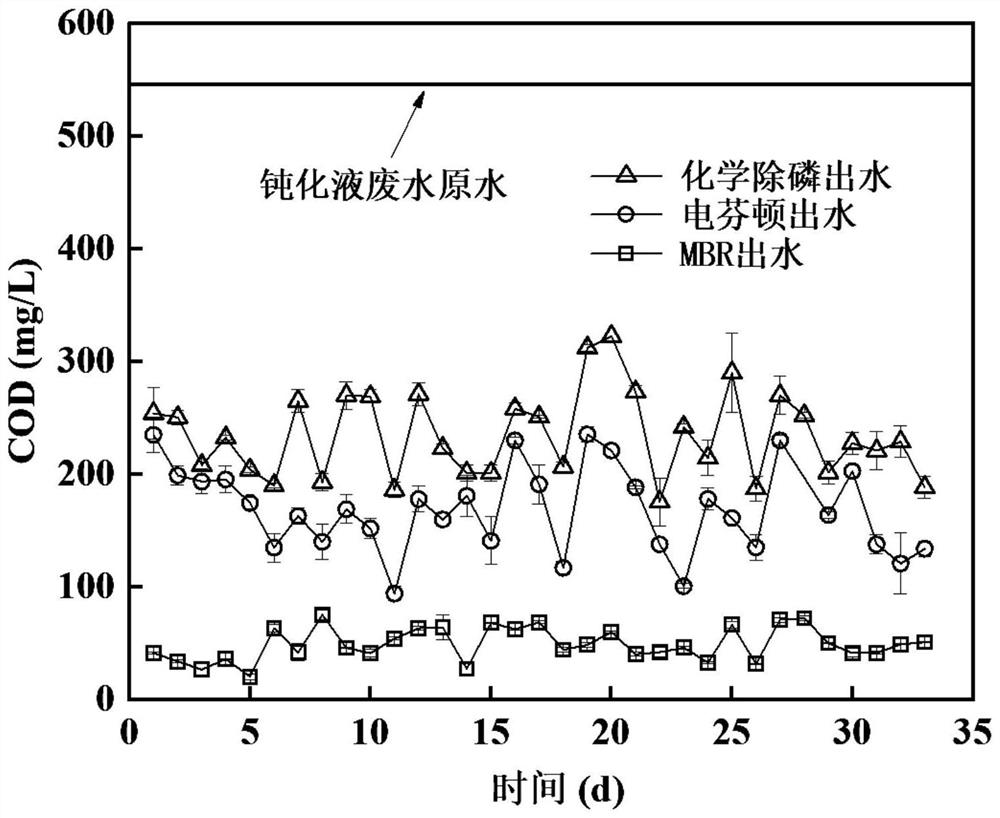

Chemical-electrochemical-biological three-section combined wastewater treatment device and application thereof

PendingCN113860638AOrganic load reductionReduce dosageWater treatment compoundsWater contaminantsAeration systemPhosphate

The invention discloses a chemical-electrochemical-biological three-section combined wastewater treatment device and a treatment method for steel passivation solution wastewater by adopting the chemical-electrochemical-biological three-section combined wastewater treatment device, the device comprises a chemical phosphorus removal reactor, a filter type cathode electro-Fenton reactor and an MBR tank, the chemical phosphorus removal reactor consists of a reaction zone and a precipitation zone, the filtering type cathode electro-Fenton reactor comprises a filtering type cathode, an anode, a first aeration system and the like, and the MBR tank comprises a membrane component, a second aeration system and the like. The filtering type cathode electro-Fenton reactor can effectively utilize residual Fe<2+> in a chemical phosphorus removal section, the filtering type cathode can achieve the purpose of solid-liquid separation, and meanwhile, iron substances intercepted on the surface of an electrode can still continue to be subjected to an interface Fenton reaction; through organic combination of chemical phosphorus removal, filtering type cathode electro-Fenton and MBR technologies, high-efficiency removal of refractory organics and phosphates in passivation solution wastewater can be realized, and the method has the advantages of small dosage of chemicals, low operation cost, short reaction time, high treatment efficiency and the like.

Owner:TONGJI UNIV

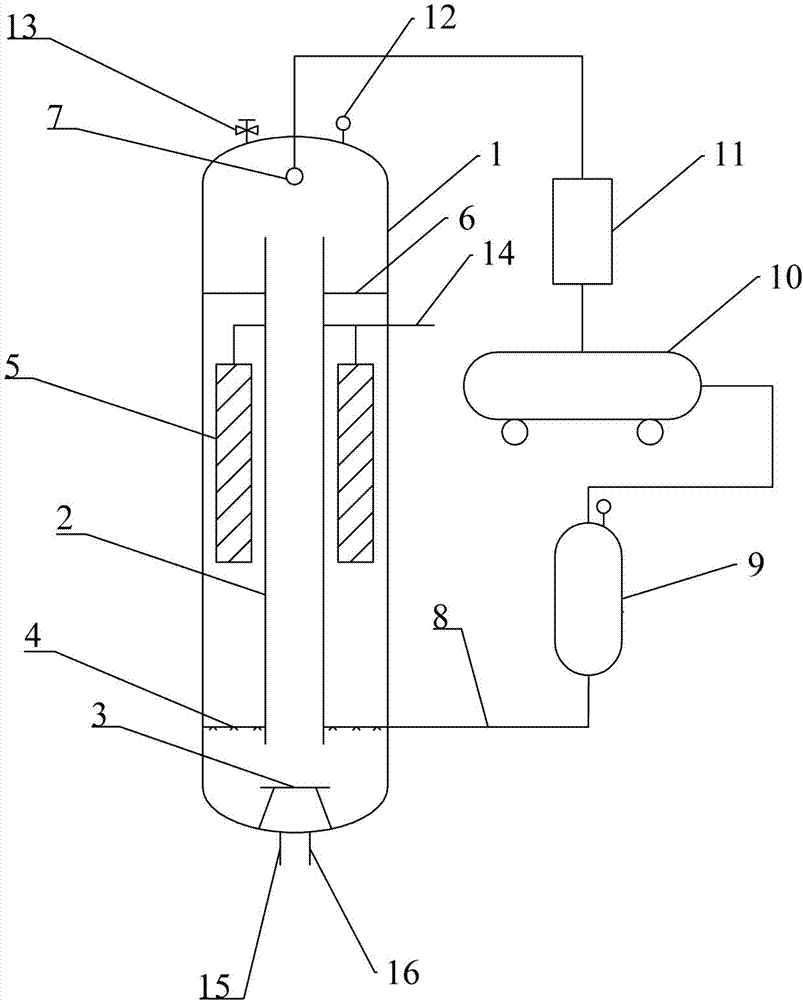

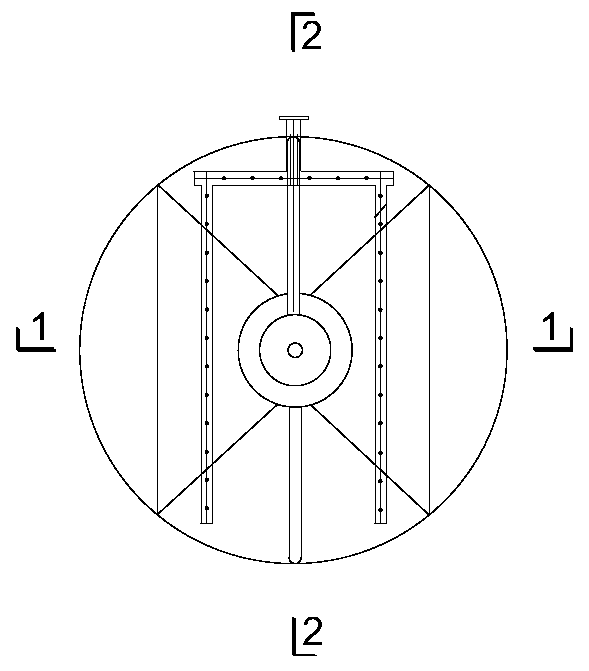

Pressurizing and aerating MBR (Membrane Bioreactor) water treatment equipment and method

ActiveCN102765806AIncrease sludge concentrationLarge volume load of the deviceSustainable biological treatmentBiological water/sewage treatmentPollutantProcess engineering

The invention discloses a pressurizing and aerating MBR (Membrane Bioreactor) water treatment device. The device comprises a tower body, wherein a guide plate, a gas diffusion system, an MBR membrane system, a support rid and a pressure sensor are arranged in the tower body from bottom to top. The tower body is further internally provided with a drainage straight cylinder. The gas diffusion system is connected with a gas storage tank, an air compressor and a pressure adjusting work station out of the towel body sequentially through a gas inlet tube. The pressure adjusting work station is further communicated with the pressure sensor. With the adoption of the device provided by the invention, advantages of two processes of pressurizing and aerating and MBR membrane treatment can be coordinately and perfectly exerted, and the treatment efficiency and the removal rate of pollutants are remarkably superior to those of common aerobic biological treatment.

Owner:GUANGZHOU EP ENVIROMENTAL ENG

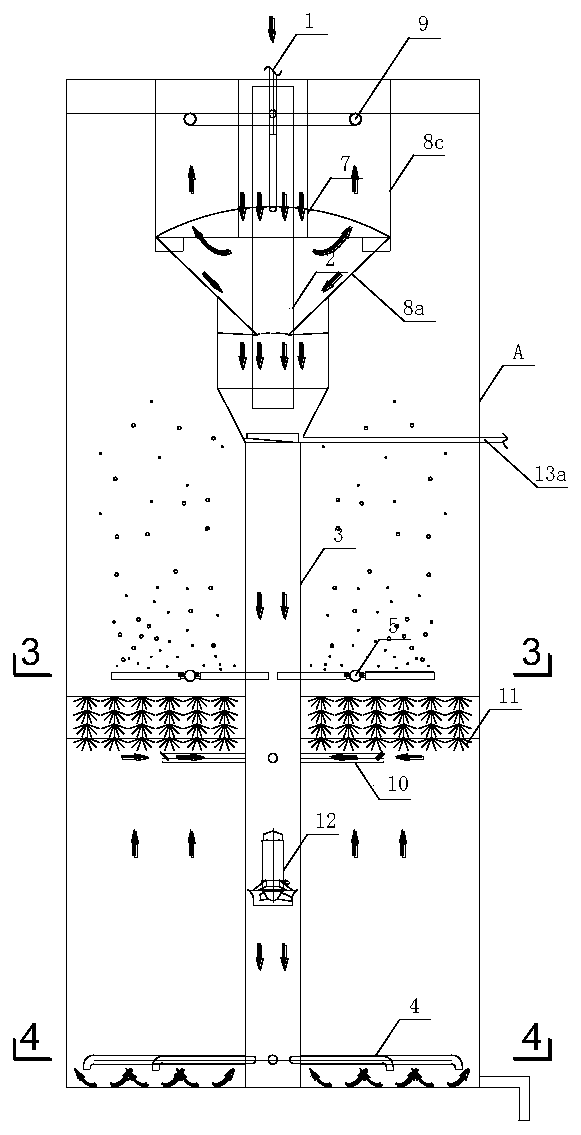

Concentrated upflow integrated reactor and reaction control system thereof

PendingCN111498993AEasy to handleAdvanced technologyTreatment with aerobic and anaerobic processesPower equipmentWater disinfection

The invention discloses a concentrated upflow integrated reactor and a reaction control system thereof. The reactor comprises a sewage treatment tank used for vertical installation, and an aerobic reaction zone, a biochemical mixing zone, an anaerobic reaction zone, a disturbance control zone, a precipitation separation zone, a reflux water distribution system, an aeration system, an effluent disinfection system and a power equipment control system are arranged on the basis of the sewage treatment tank. In the invention, the whole sewage treatment tank structure is optimized, equipment materials and plant station space are reduced; and meanwhile, the performance of a biochemical combination process is reserved and improved; both the anaerobic system and the aerobic system utilize an up-flow fluidization operation mode to promote granular sludge to be gradually formed, so that the sludge precipitation performance and the sludge concentration in the system are improved, and the sewage treatment efficiency is improved; the whole system only needs one set of fan to meet the functions of oxygen supply, backflow, stirring and the like, so that the purposes of saving energy and reducing consumption are achieved.

Owner:何敏

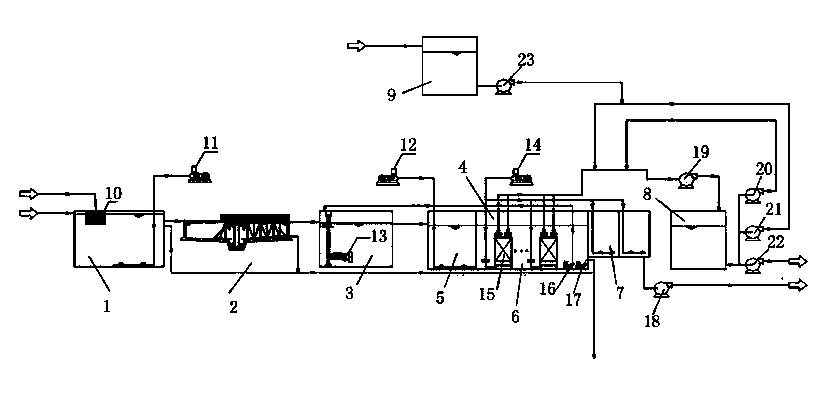

MBR (membrane bioreactor)-based system and method for oil refining wastewater biochemical treatment and membrane component cleaning method

ActiveCN102718359BImprove adsorption capacitySlow the rate of pollutionSemi-permeable membranesMultistage water/sewage treatmentHigh concentrationMembrane bioreactor

The invention discloses an MBR (membrane bioreactor)-based system and method for oil refining wastewater biochemical treatment and a membrane component cleaning method. A biochemical treatment system comprises an aerobic aeration tank, a middle sedimentation tank, an anoxic tank and a membrane bioreactor. The aerobic aeration tank allows pretreated oil refining wastewater to enter, and the middle sedimentation tank connected with the aerobic aeration tank is used for separation mud and water in the aerobic aeration tank to enable part of sludge to be discharged and part of precipitated sludge to flow back into the aerobic aeration tank. The anoxic tank is connected with the middle sedimentation tank, supernatant in the middle sedimentation tank enters the anoxic tank for denitrification, and the membrane bioreactor which forms an organic pollutant main removing unit is connected with the anoxic tank. The MBR system membrane component cleaning method includes: air scrubbing, online backwashing, online chemical cleaning and offline cleaning, especially online cleaning adopts high-concentration NaClO solution and low-concentration NaClO solution alternately, and offline cleaning adopts sodium dodecyl sulfate and sodium carbonate solution for cleaning or NaClO solution for cleaning.

Owner:ZHEJIANG SHUANGYI ENVIRONMENTAL PROTECTION TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com