Baffling anaerobic reactor and sewage treatment unit applying the same

A sewage treatment device, baffled anaerobic technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Problems such as increased mud concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Some embodiments of the present invention will be further introduced below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

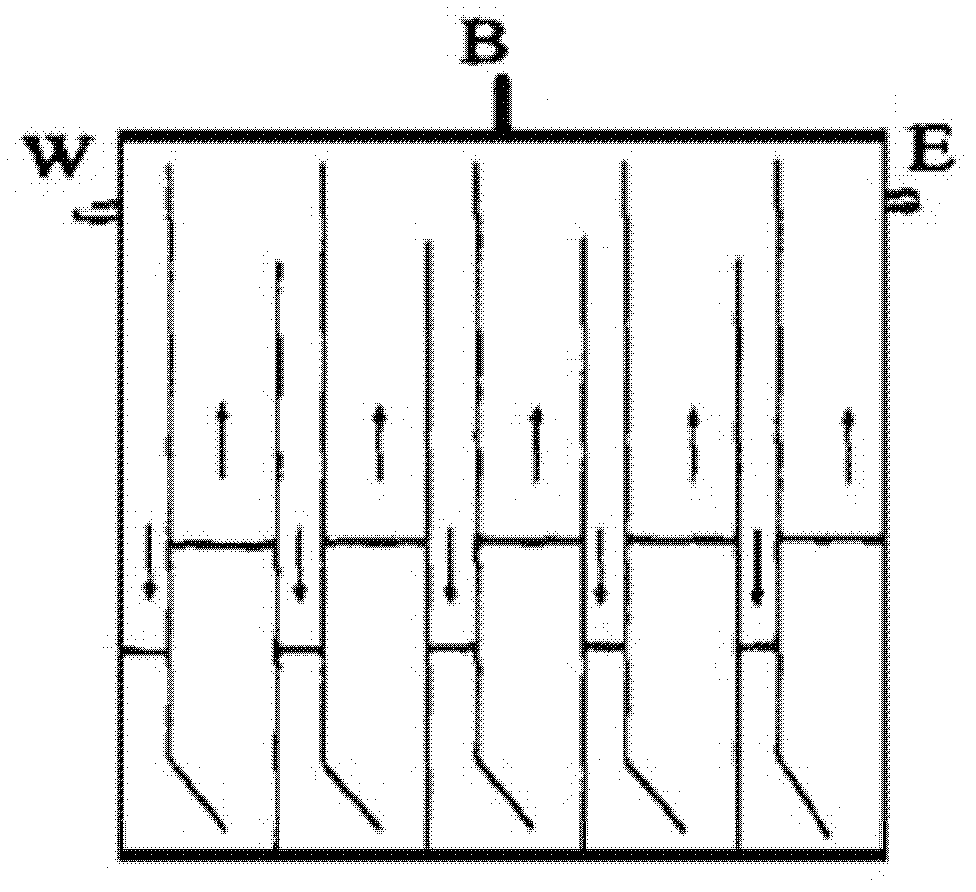

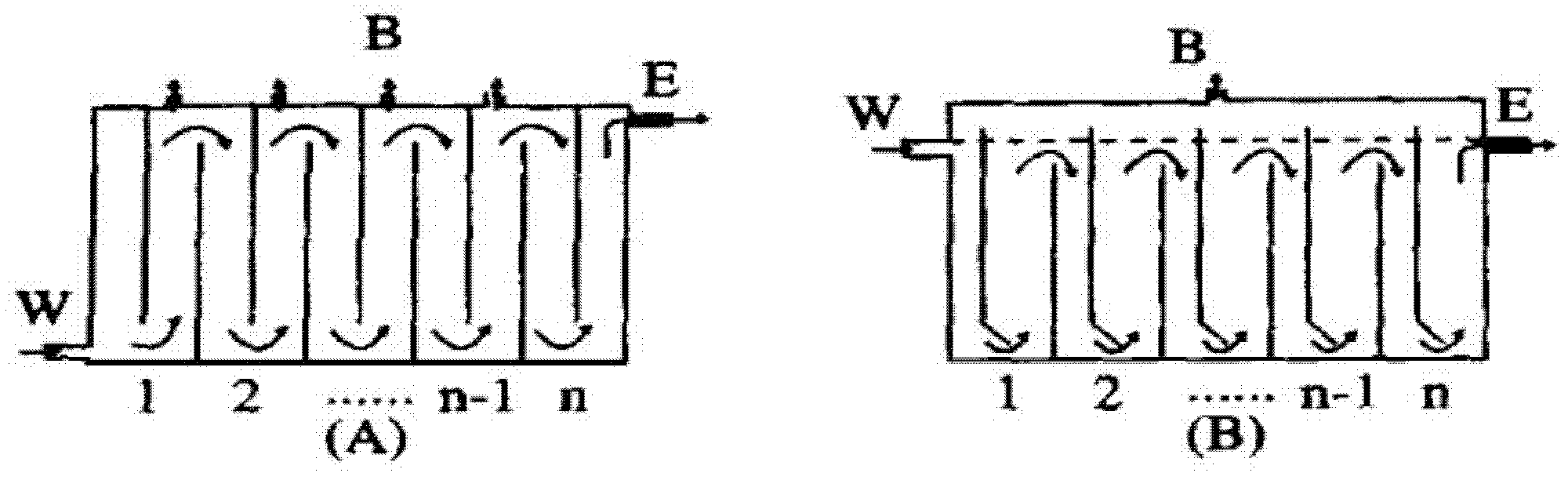

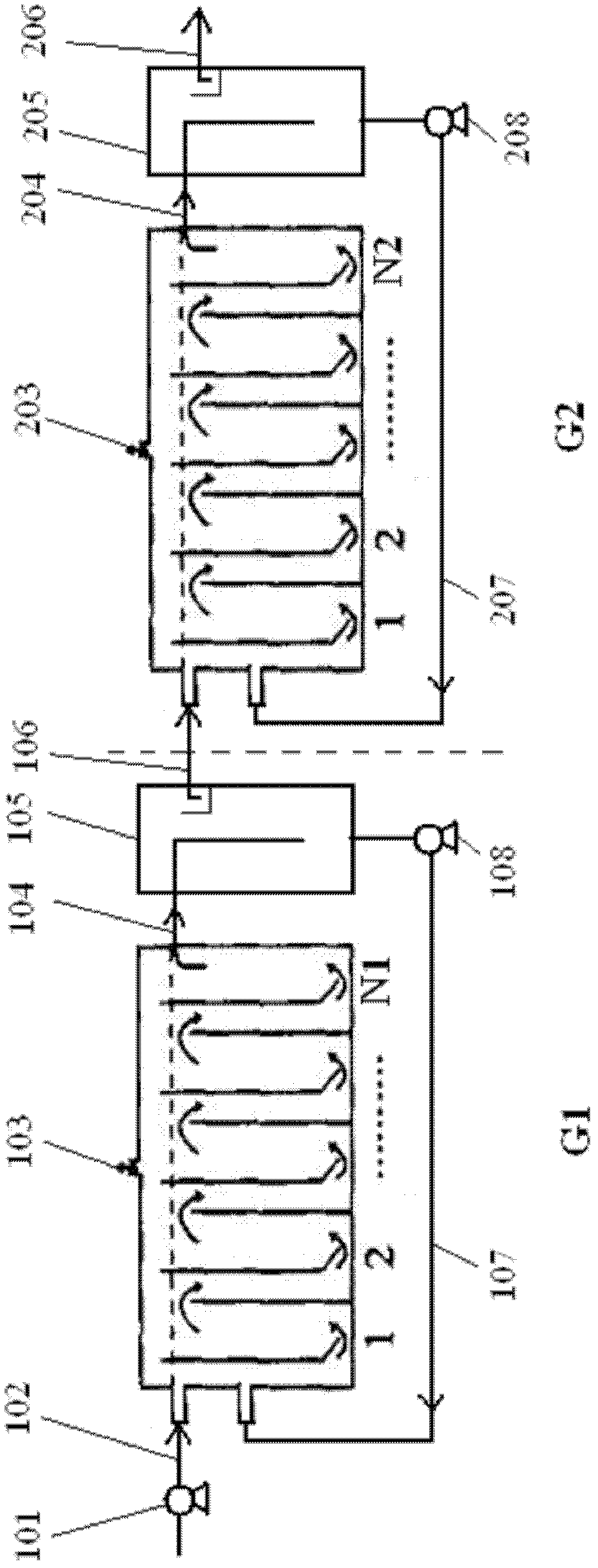

[0045] attached image 3 It is a structural schematic diagram of an embodiment of the baffled anaerobic reactor according to the present invention, wherein the baffled anaerobic reactor includes two sets of multi-stage baffled anaerobic reaction tanks (G1 and G2). The first group of multi-stage baffle anaerobic reaction tanks (G1) has a total of N1 levels (such as 10, 15 or 20) baffle anaerobic reaction tanks, and the second group of multi-stage baffle anaerobic reaction tanks (G2) It has a total of N2 grades (such as 30 grades, 50 grades, 70 grades or 90 grades) baffled anaerobic reaction tanks.

[0046] The sewage feed (102) enters the first stage of the first group of multi-stage baffled anaerobic reaction tanks (G1) for anaerobic treatment after the flow is controlled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com