Concentrated upflow integrated reactor and reaction control system thereof

An intensive, reactor technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the interference of anaerobic zone, aerobic zone treatment procedures, sewage flow distance Short, large sewage flow inertia and other problems, to achieve the effect of increasing sedimentation performance and sludge concentration, increasing procedures and processes, and increasing the number of sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

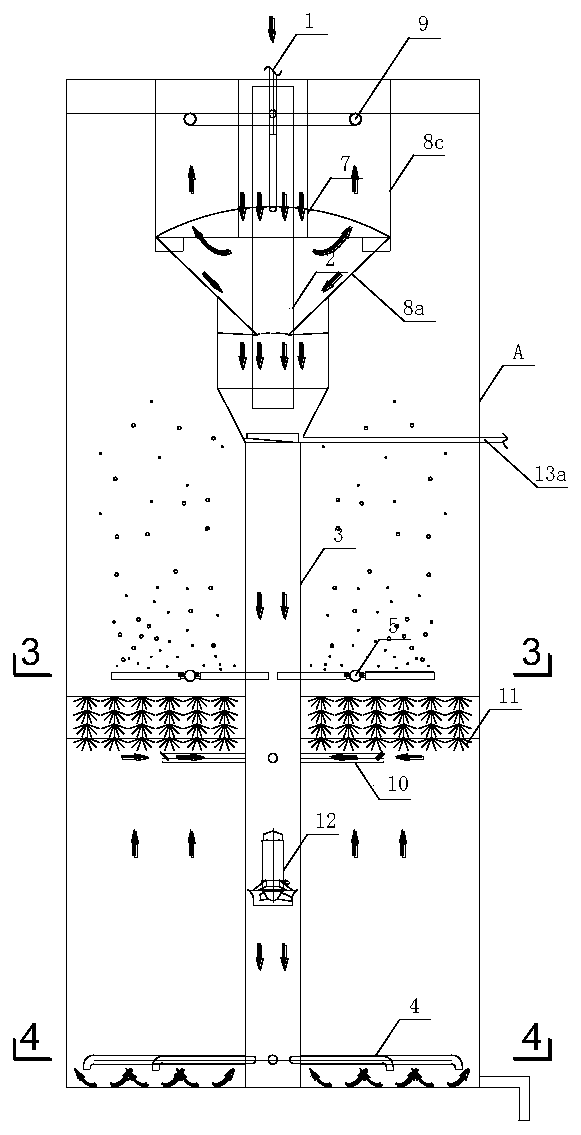

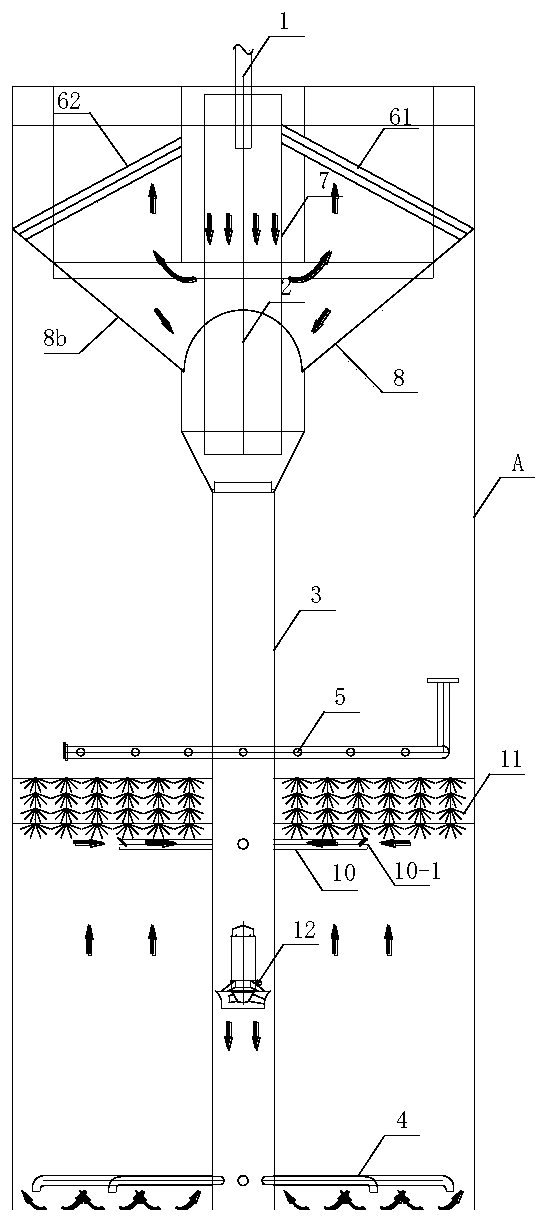

[0053] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

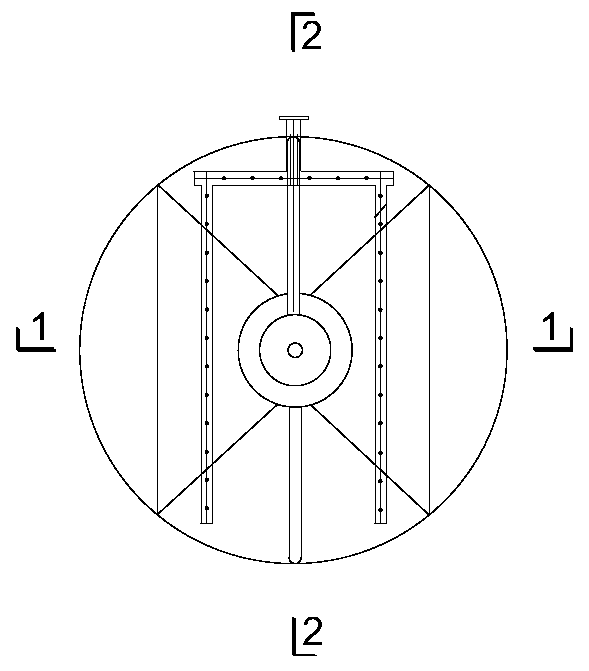

[0054] From Figure 1-3 It can be seen that an intensive upflow integrated reactor includes a sewage treatment tank A for vertical installation, the top of the sewage treatment tank A is provided with a water inlet pipe 1 communicating with the outside world, and a water inlet mixed liquid diversion Pipe 2, sedimentation tank water inlet distribution pipe 7, the water inlet pipe 1 extends through the top of the sewage treatment tank A into the sewage water inlet end side of the water inlet mixed solution diversion pipe 2, and the water inlet mixed solution The sewage outlet end of the diversion pipe 2 passes through the water inlet pipe 7 of the sedimentation tank and then extends to the outlet of the mixed solution of the sedimentation tank 8. An anaerobic tank inlet pipe 3 is connected to the outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com