Chemical-electrochemical-biological three-section combined wastewater treatment device and application thereof

A wastewater treatment and electrochemical technology, applied in the field of environmental protection and sewage treatment, can solve the problems of high organic matter, high phosphorus in passivation liquid wastewater, poor biodegradability, etc., to reduce the generation of iron sludge, high sludge age, The effect of short reaction times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

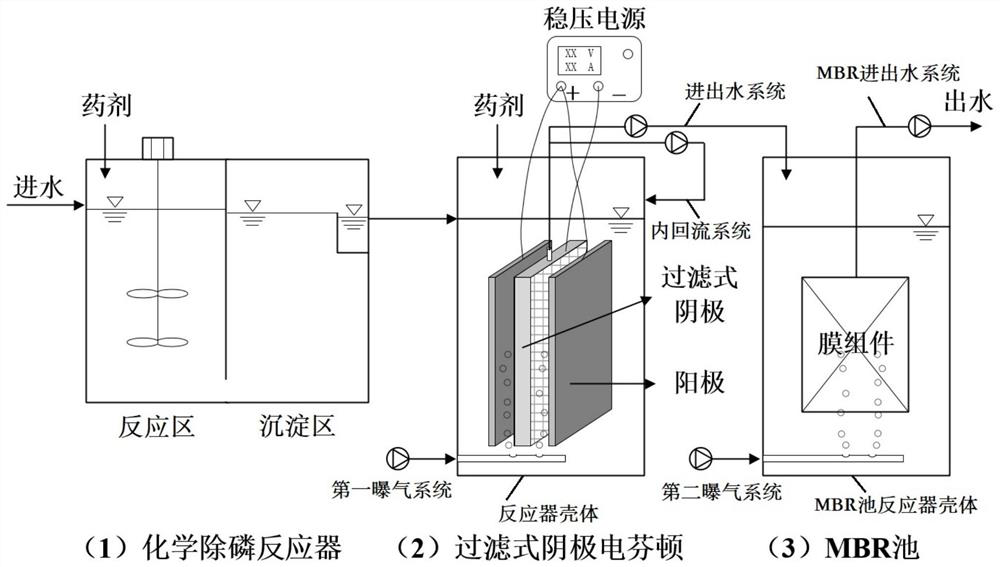

[0031] Such as figure 1As shown, a chemical-electrochemical-biological three-stage combined wastewater treatment device provided for this implementation includes a chemical phosphorus removal reactor 1, a filter type cathode electro-Fenton reactor 2 and an MBR pool 3, and is characterized in that, The chemical phosphorus removal reactor 1 is composed of two parts: the chemical phosphorus removal reaction zone and the chemical phosphorus removal precipitation zone, wherein the chemical phosphorus removal reaction zone is equipped with a stirring mixing device and a chemical dosing device; the filter cathode electro-Fenton reactor 2 includes Reactor shell, filter cathode, anode, DC stabilized power supply, water inlet and outlet system, first aeration system and chemical dosing system, in which the filter cathode is composed of a membrane frame and mesh electrodes on both sides, and the membrane frame The upper part is provided with a suction port communicating with the filtered...

Embodiment 2

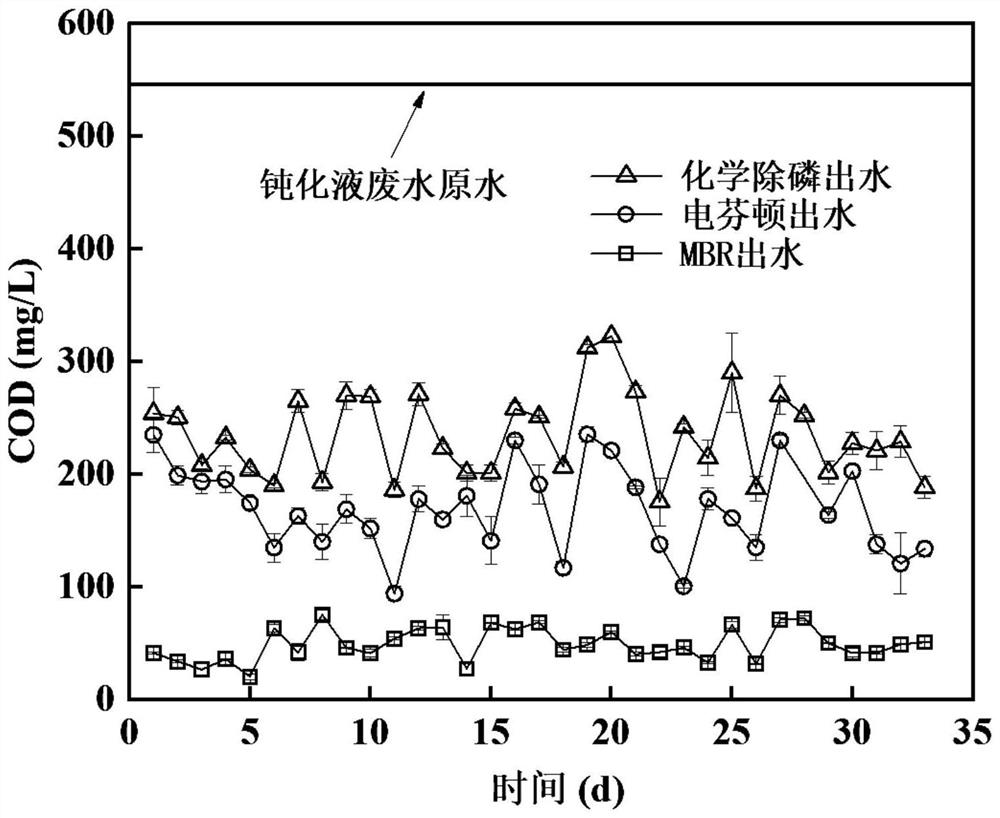

[0037] This embodiment provides a treatment method for applying the chemical-electrochemical-biological three-stage combined wastewater treatment device provided in Example 1 to steel passivation liquid wastewater, including the following steps:

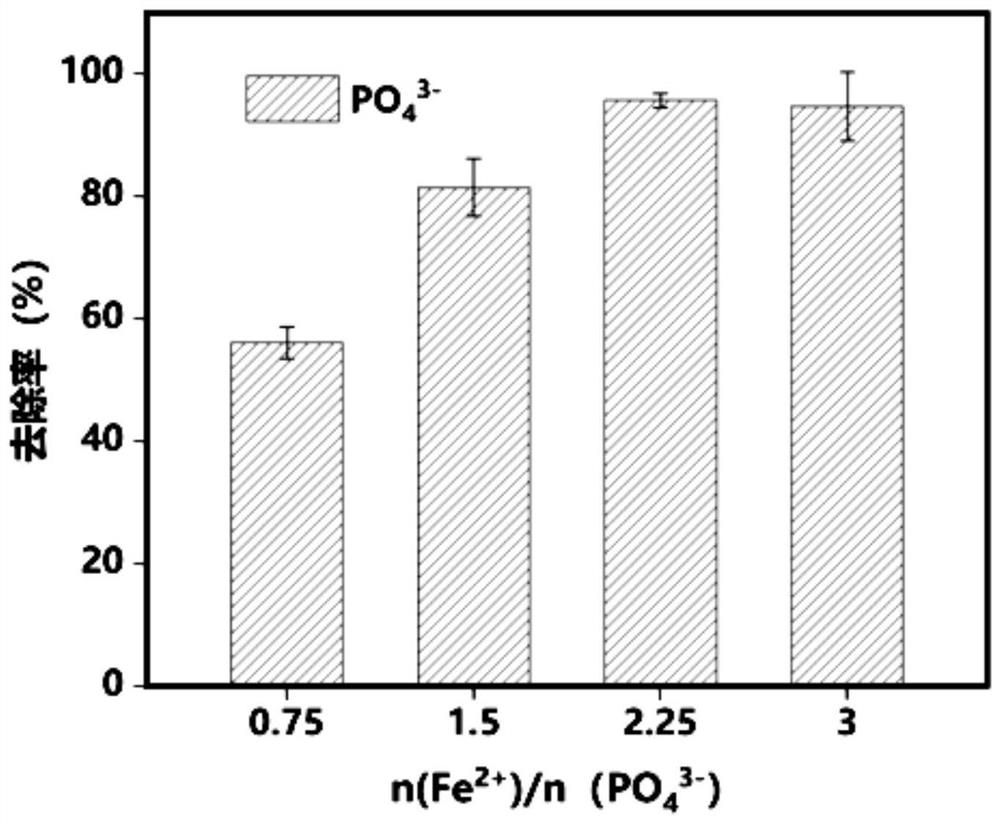

[0038] 1) Chemical phosphorus removal stage: add phosphorus removal agent to the chemical phosphorus removal reaction area, the high concentration of phosphate in the steel passivation liquid wastewater reacts with the phosphorus removal agent, and the phosphate formed by the reaction precipitates in the chemical phosphorus removal precipitation area through solid-liquid Separation and removal; due to the coagulation and precipitation of chemical phosphorus removal agents, the chemical phosphorus removal process is accompanied by the removal of part of suspended solids and organic matter;

[0039] 2) Filtration-type cathodic electro-Fenton stage: through step 1) the liquid after solid-liquid separation enters the filtration-type catho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com